Академический Документы

Профессиональный Документы

Культура Документы

Understanding Boat Design 99 PDF

Загружено:

Łukasz ZygielОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Understanding Boat Design 99 PDF

Загружено:

Łukasz ZygielАвторское право:

Доступные форматы

boat, It makes good sense to use the higher-grade

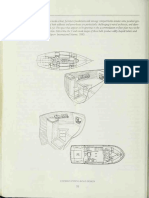

The aluminum sailmg yacht Troubador shows ojjher mte-

material for the hull.

riorjramm^, looking aft. Notice the closely spaced lon^tudi-

nal frames and the buill-m tank.

Metal Boats

Metal hulls, both aluminum and steel, are becom-

ing more popular every year due to their strength,

durability, low cost (steel), and light weight (alu-

minum). Chine hulls have always been fairly com-

mon in metal, but round-bilge hulls were rarely seen

in North America (although they have been popular

in Europe since the 1920s) because they require skills

and equipment possessed by only a few of the better

boatyards.

This changed in the mid 1970s when Brewer

Yacht Designs pioneered the radius-bilge hull. This on our latest designs the longitudinals are set proud

is essentially a single-chine hull that uses very large of the transverse frames, and the plating is not

radius sections between the flat topsides and bot- welded to the latter at all. This produces a very fair

tom. This radius can taper gradually from 2 feet aft hull, with none of the starved-dog look of the

to 4 feet or more forward. The resulting yachts are athwartship-framed vessel, because the longitudinal

difficult to tell from a pure round-bilge vessel. Other stnngers eliminate the tendency of the plating to sag

designers have used a radius bilge, but some use the between the frames.

same radius from bow to stern, and this does not Fastening today in both steel and aluminum is

produce as handsome a hull in my opinion. Radius- done almost completely by welding. The exceptions

bilge hulls are not all that difficult to build and are are thinly plated aluminum outboard boats, which

quite suitable to a small metal-fabricating yard. are often riveted. The advantage of the all-welded

Even amateurs have completed 45-footers and hull is that it is a one-piece, seamless structure with

larger craft of our design in both steel and alu- great strength and complete watertight integnty

minum. Electrolysis is a problem in metal craft. Since both

steel and aluminum react strongly with copper-based

metals, bronze fittings must be avoided wherever

Basic Construction

possible. Stainless steel shafts and propellers are

Metal hulls are framed with either bent frames of available with nonmetallic stem bearings, and fiber-

angular or T-shape sections, or sawn, flat-bar frames glass-reinforced nylon seacocks can substitute for

set athwartship. Older craft used all athwartship bronze. A bronze fitting must be insulated from the

frames, closely spaced. Modem construction favors hull metal with a Micarta block and fastened v\nth

widely spaced transverse frames with closely spaced stainless steel bolts. Similarly, bronze deck hardware

longitudinal stringers to support the plating. Indeed, should be replaced by aluminum or stainless where

CONSTRUCTION

87

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Chapelle Howard Boatbuilding A Complete Handbook of Wooden B PDFДокумент632 страницыChapelle Howard Boatbuilding A Complete Handbook of Wooden B PDFreda reda100% (8)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- List of Crusing BoatsДокумент61 страницаList of Crusing BoatsJim Kiesling100% (2)

- Time Domain Analysis Shock Response Pipeline Ship PDFДокумент6 страницTime Domain Analysis Shock Response Pipeline Ship PDFFernando Raúl LADINOОценок пока нет

- Not A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalДокумент1 страницаNot A Deck (From Boat Repair Manual, by Marine, 1988) : Areas of or Are Cored. Fiberglass Allan InternationalŁukasz ZygielОценок пока нет

- Understanding Boat Design 102 PDFДокумент1 страницаUnderstanding Boat Design 102 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 95 PDFДокумент1 страницаUnderstanding Boat Design 95 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 92 PDFДокумент1 страницаUnderstanding Boat Design 92 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 96 PDFДокумент1 страницаUnderstanding Boat Design 96 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 100 PDFДокумент1 страницаUnderstanding Boat Design 100 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 97 PDFДокумент1 страницаUnderstanding Boat Design 97 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 103 PDFДокумент1 страницаUnderstanding Boat Design 103 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 94 PDFДокумент1 страницаUnderstanding Boat Design 94 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 91 PDFДокумент1 страницаUnderstanding Boat Design 91 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 101 PDFДокумент1 страницаUnderstanding Boat Design 101 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 98 PDFДокумент1 страницаUnderstanding Boat Design 98 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 90 PDFДокумент1 страницаUnderstanding Boat Design 90 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 106 PDFДокумент1 страницаUnderstanding Boat Design 106 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 89 PDFДокумент1 страницаUnderstanding Boat Design 89 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 87 PDFДокумент1 страницаUnderstanding Boat Design 87 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 75 PDFДокумент1 страницаUnderstanding Boat Design 75 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 93 PDFДокумент1 страницаUnderstanding Boat Design 93 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 104 PDFДокумент1 страницаUnderstanding Boat Design 104 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 88 PDFДокумент1 страницаUnderstanding Boat Design 88 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 78 PDFДокумент1 страницаUnderstanding Boat Design 78 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 80 PDFДокумент1 страницаUnderstanding Boat Design 80 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 77 PDFДокумент1 страницаUnderstanding Boat Design 77 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 79 PDFДокумент1 страницаUnderstanding Boat Design 79 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 85 PDFДокумент1 страницаUnderstanding Boat Design 85 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 82 PDFДокумент1 страницаUnderstanding Boat Design 82 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 81 PDFДокумент1 страницаUnderstanding Boat Design 81 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 84 PDFДокумент1 страницаUnderstanding Boat Design 84 PDFŁukasz ZygielОценок пока нет

- Understanding Boat Design 86 PDFДокумент1 страницаUnderstanding Boat Design 86 PDFŁukasz ZygielОценок пока нет

- Gunboat 55 Brochure Sept14Документ4 страницыGunboat 55 Brochure Sept14valentinorocoОценок пока нет

- Raking Stresses On Ro-Ro ShipДокумент46 страницRaking Stresses On Ro-Ro ShipChristopher JebarajОценок пока нет

- Prospects For Hard Chine, Monohull VesselsДокумент17 страницProspects For Hard Chine, Monohull VesselsGiulia Bunn vellosoОценок пока нет

- RINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINALДокумент16 страницRINA 2009 Bulk Carriers - Allowable Hold Mass Curves - Bureau Veritas - FINALKonstantis_chОценок пока нет

- U-Boat Archive - Type VII C ManualДокумент173 страницыU-Boat Archive - Type VII C ManualHortodoxocs100% (2)

- Calypso Operation and Installation ManualДокумент64 страницыCalypso Operation and Installation Manualmilen65Оценок пока нет

- 2011 Stanley CatalogueДокумент20 страниц2011 Stanley CatalogueRoger AugeОценок пока нет

- Ship ConДокумент7 страницShip ConThusitha DalpathaduОценок пока нет

- Function: Controlling The Operation of The Ship & Care For Persons On Board at Operational LevelДокумент3 страницыFunction: Controlling The Operation of The Ship & Care For Persons On Board at Operational LevelAnshu BhushanОценок пока нет

- Own A Steel BoatДокумент294 страницыOwn A Steel BoatMaxi SieОценок пока нет

- Effects of Nonlinear FK (Froude-Krylov) and Hydrostatic Restoring Forces On Arctic-Spar Motions in WavesДокумент17 страницEffects of Nonlinear FK (Froude-Krylov) and Hydrostatic Restoring Forces On Arctic-Spar Motions in WavesAlex MtzОценок пока нет

- PDF PDFДокумент12 страницPDF PDFÖmer Faruk KorkmazОценок пока нет

- Releasing From Surface CompartmentДокумент21 страницаReleasing From Surface Compartmentsennimalai100% (1)

- Naval - October - 2022Документ3 страницыNaval - October - 2022shaan51019888Оценок пока нет

- Hydrodynamic Analysis of The Performance of Stern Flaps in A Semi-Displacement HullДокумент1 страницаHydrodynamic Analysis of The Performance of Stern Flaps in A Semi-Displacement HulljvexoskeletalОценок пока нет

- Unit 5 - Stress & StrainsДокумент14 страницUnit 5 - Stress & StrainsMidhul MineeshОценок пока нет

- A Preliminary Design Tool For Resistance and Powering Prediction of Catamaran VesselsДокумент144 страницыA Preliminary Design Tool For Resistance and Powering Prediction of Catamaran VesselsAthul DileepОценок пока нет

- Ayrs074.All A5Документ292 страницыAyrs074.All A5FradjОценок пока нет

- Anchor LossДокумент49 страницAnchor LossÇağlar KazmanoğluОценок пока нет

- Design of YachtДокумент77 страницDesign of YachtMelissa Rios100% (1)

- Lebv4830 08 Final CD VerДокумент760 страницLebv4830 08 Final CD Verhyromec100% (1)

- Manual 12 mc0 PDFДокумент81 страницаManual 12 mc0 PDFNa'iim ZakriОценок пока нет

- Is Code 2008Документ97 страницIs Code 2008Jerrym AbañoОценок пока нет

- Pivot PointДокумент26 страницPivot PointJet RocetОценок пока нет

- LS-DYNA Applications in ShipbuildingДокумент17 страницLS-DYNA Applications in ShipbuildingAdnan NajemОценок пока нет

- Guldhammer1962 FORM DATA IIДокумент34 страницыGuldhammer1962 FORM DATA IIrawhul setyokoОценок пока нет