Академический Документы

Профессиональный Документы

Культура Документы

ADOS D110E Navodila Za Uporabo in Kalibracijo

Загружено:

Matjaz LОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ADOS D110E Navodila Za Uporabo in Kalibracijo

Загружено:

Matjaz LАвторское право:

Доступные форматы

INSTRUCTION

MANUAL

D110E

5

4 Update SW rv. 3.06 22/03/10 Paulitti G. Laserra C.

3 Update MODBUS RTU 22/01/08 Paulitti G. Laserra C.

2 Update to SW rv. 3.03 19-02-01 Golinelli G: Paulitti G.

1 Printer handling 19-07-99 Golinelli G: Paulitti G.

0 First issue 29-03-99 Paulitti G. Laserra C.

621_4.docx Subject of revision Date Prepared Checked Approved

621-MTU30105 Rev. 4 Pag. 1 di 43

ADOS S.R.L. Buccinasco (MI)

CONTENTS

1 INTRODUCTION ....................................................................................................................... 4

1.1.1 General information ......................................................................................................................... 4

1.2 Versions/options .................................................................................................................... 4

1.3 Documentation ...................................................................................................................... 4

2 FUNCTIONAL SPECIFICATIONS.......................................................................................... 5

2.1 Technical features ................................................................................................................. 5

3 USING THE INSTRUMENT ..................................................................................................... 7

3.1 Turning on the instrument ................................................................................................... 7

3.2 Display indications ................................................................................................................ 7

3.3 LED status signals ................................................................................................................ 7

3.4 Key functions......................................................................................................................... 8

3.5 Auto shut-off ......................................................................................................................... 9

3.6 Tare weight management ..................................................................................................... 9

3.7 Manually setting weight to zero........................................................................................... 9

3.8 Automatically setting weight to zero when instrument is turned on ............................... 9

3.9 Totalizing ............................................................................................................................. 10

3.9.1 Displaying totals ............................................................................................................................. 10

3.9.2 Printing of totals ............................................................................................................................. 10

3.9.3 Setting totalizers to zero ................................................................................................................. 10

3.10 Load cell response filtering ................................................................................................ 11

3.11 Printer handling .................................................................................................................. 12

3.12 Printout ................................................................................................................................ 12

3.12.1 Normal weighing printout........................................................................................................... 13

3.12.2 Totalization printout ................................................................................................................... 14

3.12.3 Totalized value printout .............................................................................................................. 14

3.13 Date and time setting .......................................................................................................... 15

3.14 Battery life ........................................................................................................................... 16

3.15 Recharging the battery ....................................................................................................... 16

3.16 Switch ................................................................................................................................... 17

3.17 Self-testing ........................................................................................................................... 17

3.17.1 EEPROM integrity control ......................................................................................................... 17

3.17.2 Controlling integrity of configuration parameters ...................................................................... 18

3.18 Serial line management ...................................................................................................... 19

3.18.1 Main line ..................................................................................................................................... 19

3.18.2 Auxiliary line .............................................................................................................................. 19

3.18.3 Continuous or demand mode ...................................................................................................... 19

3.18.4 Duplex mode with MODBUS protocol ...................................................................................... 20

Functions supported by D110E ....................................................................................................... 20

4 INSTALLATION ....................................................................................................................... 25

4.1 Receiving materials............................................................................................................. 25

4.2 General instructions for use ............................................................................................... 26

4.3 Connections ......................................................................................................................... 27

4.4 Connecting serial ports ...................................................................................................... 27

5 INSTRUMENT MAINTENANCE .......................................................................................... 28

5.1 Preventive maintenance ..................................................................................................... 28

5.2 Corrective maintenance ..................................................................................................... 28

6 OPERATING THE INSTRUMENT........................................................................................ 29

6.1 Introduction......................................................................................................................... 29

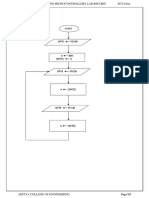

6.2 Selection of management functions ................................................................................... 29

6.2.1 Accessing configuration functions ................................................................................................. 30

621 -MTU30105 Rev. 4 Page 2 of 43

ADOS S.R.L. Buccinasco (MI)

6.2.2 Keypad Timeout ............................................................................................................................. 30

6.3 Configuration of operating parameters ............................................................................ 31

6.3.1 Selection of operating parameters .................................................................................................. 31

6.3.2 Modification of operating parameter values................................................................................... 32

6.3.3 Graduation ...................................................................................................................................... 33

6.3.4 Resolution....................................................................................................................................... 33

6.3.5 Local gravity coefficient ................................................................................................................ 33

6.3.6 Decimal point ................................................................................................................................. 33

6.3.7 Averages ......................................................................................................................................... 34

6.3.8 Language selection ......................................................................................................................... 34

6.3.9 Auto Zero when turned on.............................................................................................................. 34

6.3.10 AZM limit ................................................................................................................................... 34

6.3.11 Motion band ................................................................................................................................ 34

6.3.12 Time before automatically turning off ........................................................................................ 35

6.3.13 Display brightness ...................................................................................................................... 35

6.3.14 Enable total ................................................................................................................................. 35

6.3.15 Minimum weight ........................................................................................................................ 35

6.3.16 Main serial port ........................................................................................................................... 36

6.3.17 Baud rate ..................................................................................................................................... 36

6.3.18 RS485 address ............................................................................................................................ 36

6.3.19 Enable configuration access........................................................................................................ 36

6.3.20 Printer ON time........................................................................................................................... 36

6.4 Calibration .......................................................................................................................... 37

6.4.1 Zero calibration .............................................................................................................................. 38

6.4.2 Full-scale calibration ...................................................................................................................... 39

6.5 Initialization ........................................................................................................................ 40

6.6 Test ....................................................................................................................................... 41

7 INSTRUMENT CONFIGURATION TABLE ........................................................................ 42

621 -MTU30105 Rev. 4 Page 3 of 43

ADOS S.R.L. Buccinasco (MI)

1 INTRODUCTION

1.1.1 General information

D110E is a microprocessor-controlled electronic hanging scale powered by a rechargeable 6 V 10

Ah lead battery.

The instrument is equipped with an internal battery charger. The microprocessor controls battery

condition and runs the battery charger as necessary.

The instrument is supplied with an infrared remote control that works within a range of

approximately 15 m.

All operations involved in programming, configuration and calibration of the instrument may be

performed using either the keypad or the remote control.

Access to calibration and programming processes is password-protected.

The main features of the application are:

Gross/net selection

Self-calibration when turned on (configurable)

Totalizer management (configurable)

1.2 Versions/options

D 1 1 0 E - 1 0

Hanging scale capacity:

1 1000 kg

2.5 2500 kg

5 5000 kg

10 10000 kg

25 25000 kg

30 30000 kg

50 50000 kg

1.3 Documentation

This manual is written specifically for the hanging scale.

621 -MTU30105 Rev. 4 Page 4 of 43

ADOS S.R.L. Buccinasco (MI)

2 FUNCTIONAL SPECIFICATIONS

2.1 Technical features

Power supply 6 V DC battery

Consumption 8 W Max

Fuse F2A

Operating temperature from - 10 C to + 40 C

Storage temperature from - 40 C to + 70 C

Relative humidity 95% non-condensing

Load cell power supply 5 V DC (short-circuit proof)

Analogue signal 1 2 mV/V

Sensitivity 1 V/div

Number of divisions 1000-2000-3000-4000-5000

Reading sensitivity 1-2-5-10

Out of range (UL/OL) 5% of full scale load

Display five (5) digit LED

Polarity - sign

Decimal point may be selected from: 0,0.0,0.00,0.000,0.0000

Keypad six (6) keys

Indicator lights four (4) indicator LED’s

Self-zeroing range (AZM range) Configurable (OFF - 1.9% - 100% of F.S.)

Motion band Configurable (OFF - 0.5 - 1 - 2 - 5- 10- 20 div)

Serial outputs Main output may be selected from RS232 or

RS485 Half-duplex, aux. output RS232 simplex

621 -MTU30105 Rev. 4 Page 5 of 43

ADOS S.R.L. Buccinasco (MI)

621 -MTU30105 Rev. 4 Page 6 of 43

ADOS S.R.L. Buccinasco (MI)

3 USING THE INSTRUMENT

3.1 Turning on the instrument

When the instrument is turned on, the following messages will appear on the display about two

seconds apart:

D 1 1 0 E

V 3. - - (Revision of the installed software)

3.2 Display indications

Under regular operating conditions the display indicates weight expressed according to the

following criteria:

Zeros do not appear at the beginning of a number unless they have significance

The “minus” sign (for negative weights) appears in the first position on the left

In the case of a negative weight with six digits (such as -132400), the first digit on the left will

alternately flash the “minus” sign and the first digit in the weight.

The limits on weights that may be indicated are:

lower limit: - 5% of full-scale

upper limit: 105% of full-scale

Weights under the lower limit will result in the following display:

U L

Weights over the upper limit (or cell signals exceeding 20 mV) will result in the following display:

O L

The display guides the operator through configuration and calibration of the instrument.

3.3 LED status signals

The LED signals on the front of the instrument are used to convey the following messages:

0

The LED comes on when weight is stable at 0 and remains stable within ¼ division.

This signal is given when the instrument is set to display either gross or net weight.

When the instrument is set for automatic shut off, the LED pulses to indicate that the

instrument is in stand-by.

Net

621 -MTU30105 Rev. 4 Page 7 of 43

ADOS S.R.L. Buccinasco (MI)

The LED comes on when the instrument is displaying net weight (gross weight minus tare).

S1

This LED comes on when value of totalizer 1 is displayed .

S2

This LED flashes when battery voltage falls below the alarm threshold.

The LED comes on when value of totalizer 2 is displayed.

When the instrument goes off because its battery is flat, the LED flashes on and off (in place

of the zero LED) to indicate that the instrument is on stand-by and battery is fully discharged.

3.4 Key functions

Key functions depend on the instrument’s current status.

The functions of the keys when in “Operating” mode are listed below. During the configuration

procedure the keys perform different functions, which are described in the section entitled

“Configuration”.

If the instrument is unable to perform a function which has been requested while in “operating”

mode (for instance, the instrument cannot fulfil a request for TARE when it is set to GROSS), the

display will flash rapidly for 2 seconds to indicate that it has acknowledged the request but is unable

to fulfil it.

G/N

Press this key to switch between Gross and Net.

ZERO

Press this key (with the instrument set to Gross and weight is stable) to clear the weight displayed to

zero; this is possible within the range specified by the “0 limit” parameter.

T

Press this key (with the instrument set to Net and with a stable weight) to copy the current gross

weight as the tare value, setting net weight to zero as a result.

FUNC

Has no function in operating mode

TOT

Press this key to request display of the totalizer values (if the totalizer function has been enabled).

PRINT

Press this key to request a printout of the current weight or of the totalizer appearing on the display

(if the totalizer function is enabled).

621 -MTU30105 Rev. 4 Page 8 of 43

ADOS S.R.L. Buccinasco (MI)

3.5 Auto shut-off

The instrument may be set to turn itself off (in order to preserve battery life) when weight remains

stable and no keys are pressed for a certain amount of time, which may be configured.

The instrument will come on again as soon as any key is pressed.

3.6 Tare weight management

Press T when the instrument is set to NET and weight is stable, and the current weight will be

stored as the tare weight.

3.7 Manually setting weight to zero

Gross weight may be reset to zero manually by pressing >0< when the instrument is set to GROSS,

the weight is stable and the total value of the weight to be reset to zero falls within the limits

specified by the “0 LIMIT” parameter.

The ZERO command has the effect of translating the instrument’s response curve without altering

its gradient: if 2000 Kg is set to zero in a system in which full-scale is 5000Kg, full-scale will

become 3000 Kg.

3.8 Automatically setting weight to zero when instrument is turned on

Gross weight may be set to zero automatically when the instrument is turned on if this function is

enabled and the total value of the weight to be set to zero falls within the limits set by the “0

LIMIT” parameter.

621 -MTU30105 Rev. 4 Page 9 of 43

ADOS S.R.L. Buccinasco (MI)

3.9 Totalizing

The instrument may be configured to deal with one, two or no totalizers.

When the totalizers are enabled, printing functions are automatically enabled.

Weight is acquired with the instrument set to NET by pressing M+ on the remote control.

The net weight is added to both the totalizers, and the weighing counters associated with each of

them are increased by one.

The totalizers may each be set to zero independently.

3.9.1 Displaying totals

Press MR on the remote control (with totalizers enabled) and the following data will be displayed

in order:

the number of cycles of totalizer 1

the value of totalizer 1

the number of cycles of totalizer 2

the value of totalizer 2

3.9.2 Printing of totals

Press PRINT to print out the current weight.

Press PRINT when totals are being displayed to print out total weight and number of cycles.

3.9.3 Setting totalizers to zero

Each totalizer may be set to zero independently. To do this:

display the value of the totalizer to be set to zero.

press >0<

the instrument will display a request for confirmation: 0 TOT

press E/PRINT

621 -MTU30105 Rev. 4 Page 10 of 43

ADOS S.R.L. Buccinasco (MI)

3.10 Load cell response filtering

Staring with SW rev 3.03 a new method of filtering the signal provided by the load cell have been

introduced (FIR filters). This method is based on a Digital Signal Processing (DSP) approach.

As example the below graphic shows the response to a step variation of the load cell signal as

function of the selected filter.

The graphic shows hat FIR filter 1 as a response time of about 0.2 seconds and FIR filter 5 has a

response time of about 2.5 seconds

3500000

3000000

2500000

2000000

1500000

1000000

500000

0

-1,00 -0,50 0,00 0,50 1,00 1,50 2,00 2,50 3,00

Cella FIR 1-12 FIR 2-24 FIR 3-42 FIR 4-62 FIR 5-80

621 -MTU30105 Rev. 4 Page 11 of 43

ADOS S.R.L. Buccinasco (MI)

3.11 Printer handling

The scale can be equipped with a 40 column printer mounted at floor with wireless connection.

3.12 Printout

As function of scale configuration (see table) normal weighing printout and totalization printout are

possible.

Total configuration Printout SERIAL LINE PORT

The value of load showed on

Disabled (Off) Primary

display is printed

Acquired load value and/or totals

Enabled (1 or 2) Auxiliary

can be printout

621 -MTU30105 Rev. 4 Page 12 of 43

ADOS S.R.L. Buccinasco (MI)

3.12.1 Normal weighing printout

Pressing the PRINT key the actual load value on scale is printed with the following format:

1249 Kg Gross

11:01 04-11-13

85 Kg Net

11:01 04-11-13

Print on demand is directed on primary serial line.

621 -MTU30105 Rev. 4 Page 13 of 43

ADOS S.R.L. Buccinasco (MI)

3.12.2 Totalization printout

When a load value is acquired and totalized pressing the M+ key, a printout having the following

format is generated:

Net: 2258Kg

11:01 04-11-13

3.12.3 Totalized value printout

Pressing the PRINT key while totals are displayed, a printout having the following format is

generated:

Oper . No.: 2

Total 2: 2402 Kg

621 -MTU30105 Rev. 4 Page 14 of 43

ADOS S.R.L. Buccinasco (MI)

3.13 Date and time setting

The real time clock is mounted on the printer. See the printer manual instruction for date & time

setting operations.

621 -MTU30105 Rev. 4 Page 15 of 43

ADOS S.R.L. Buccinasco (MI)

3.14 Battery life

Battery life (number of hours of continuous operation) depends on how the instrument is used.

If weight is displayed in “High intensity” mode, rated battery life is approximately 80 hours.

If weight is displayed “Low intensity” mode, rated battery life is approximately 120 hours.

Battery life also depends on how old the battery is, and on the number of digits shown on the

display.

Battery life on stand-by is about 600 hours.

3.15 Recharging the battery

The internal microprocessor commands battery recharging.

It takes about 10 hours to fully recharge a flat battery.

To recharge the battery, proceed as follows:

Turn off the hanging scale using the switch on the back of the instrument.

Plug the battery charger into the socket on the back of the hanging scale.

Plug the battery charger into a 230 V AC power outlet.

Turn on the hanging scale.

The instrument will automatically stop charging the battery when full voltage has been restored.

The battery charger may be left permanently connected to the hanging scale with no ill effect on the

battery.

When the scale is recharging the battery, this is indicated by flashing letter “B” when the battery test

function is performed.

When the battery is almost flat, indicator S2 flashes intermittently. There are about 10 hours of

battery life remaining when indicator S2 comes on.

When the battery reaches minimum operating voltage, the following message will appear:

B A T T (flashing)

This message is displayed for about 5 seconds, after which the hanging scale is switched to stand-by

status.

The same indication will appear if an attempt is made to turn the instrument on.

621 -MTU30105 Rev. 4 Page 16 of 43

ADOS S.R.L. Buccinasco (MI)

3.16 Switch

The instrument has an internal set of switches with the following functions:

Position Function Normal status

SW1-1 Not in use OFF

SW1-2 Initialisation of configuration data OFF

Can be used as an alternative to the guided initialisation

process using the keypad and display, in which case it will set

all configuration data to default values.

For instructions on how to use, refer to the section entitled

“Initialisation”

3.17 Self-testing

The D110E instrument is programmed with a series of self-testing functions which increase its

overall level of operating security.

Normally, when a fault is detected the instrument is put in safe condition and the function related

with the faulty parameters are inhibited.

A series of instructions are provided to help identify the cause of faults.

3.17.1 EEPROM integrity control

This control is performed when the instrument is turned on. If any problems are detected, the

instrument will interrupt the sequence of operations involved in turning itself on and it will not be

possible to use it; as a result the relays are kept de-energized, the analogue output remains zero and

the serial line is disabled.

The instrument forces initialization of the parameters and the display indicates:

I N I T Flashing

The instrument will remain in this condition until a key is pressed.

It will then be necessary to reconfigure the instrument.

621 -MTU30105 Rev. 4 Page 17 of 43

ADOS S.R.L. Buccinasco (MI)

3.17.2 Controlling integrity of configuration parameters

The integrity of configuration parameters is controlled every operating cycle.

If errors are found in the configuration memories, the indication “ER XX” (XX being the code

identifying the erroneous parameter) flashes for half a second every two seconds, in alternation with

the weight detected.

CODE Cause Effect Remedy

ER 01 Error in Relays are deactivated. Recalibrate the instrument

CALIBRATION The error code is sent

parameters over the line.

ER 02 Error in Relays are deactivated. Reset tare

TARE The error code is sent

parameters over the line.

ER 03 Error in Relays are deactivated. Reconfigure parameters

DIVIS and SENSIT The error code is sent

parameters over the line.

ER 04 Error in No effect. The error code Reconfigure parameters

FILTER and DEC POINT is sent over the line.

parameters

ER 05 Error in Relays are deactivated. Reconfigure parameters

LIM AZM - MOTION - ZERO The error code is sent on

TRACKING the line.

parameters

ER 06 Serial line parameters No effect – Reconfigure parameters

SER P - SER A-BAUD - DLY Communications remain

SND - DLY RCV – AD485 active and the error code

is sent over the line.

ER 09 Totalizers No effect – Set totals to zero or update

Communications remain them

active and the error code

is sent over the line

621 -MTU30105 Rev. 4 Page 18 of 43

ADOS S.R.L. Buccinasco (MI)

3.18 Serial line management

The instrument is equipped with two serial lines: a main line for transmission and reception and an

auxiliary line for transmission only.

3.18.1 Main line

The main line is available in RS232 mode.

The main line may be configured in any of the following operating modes:

Continuous transmission

Transmission upon request from push button

Modbus

The transmission parameters for the main and auxiliary lines are:

8 bit – No parity - 1 Stop

The speed of the main line may be configured at:

9600

4800

2400

1200

3.18.2 Auxiliary line

The auxiliary line is used to print out weights or totalizers.

3.18.3 Continuous or demand mode

The instrument will send (continuously or upon request) a string in the following format:

<STX><POL><PESO><K/L><L/N><STATO><CR><LF>

where:

<STX> “Start Of Test” (Hex 02) character

<POL> “Blank” (Hex 20) or “-” (Hex 2D) character to indicate data polarity

<PESO> string of 7 digits (Hex 30 .. 39) identifying weight shown on display

with “.” if required (Hex 2E)

<K/L> “K” (Hex 4B) or “L” (Hex 4C) character to indicate unit of measurement

<G/N> “G” (Hex 47) or “N” (Hex 4E) character to indicate Gross/Net status

<STATO> one of the following characters:

“Blank” (Hex 20) System under normal operating conditions

“I” (Hex 43) Instrument requires calibration (invalid data)

“S” (Hex 43) Instrument is being configured

“O” (Hex 4F) Instrument is out of range

“M” (Hex 4D) Weight is in motion

<CR> “Carriage Return” (Hex 0D) character

<LF> “Line Feed” (Hex 0A) character

621 -MTU30105 Rev. 4 Page 19 of 43

ADOS S.R.L. Buccinasco (MI)

3.18.4 Duplex mode with MODBUS protocol

The RTU version of the MODBUS protocol is employed.

Structure of strings transmitted and received

The general structure of the strings is as follows:

ADDRESS FUNCTION DATA CHECK

8 bits 8 bits N x 8 bits 2 x 8 bits

ADDRESS 8 bits with value between 1 and 32.

FUNCTION 8 bits identifying the function to be carried out by the slave

The following functions may be specified:

Code 03 Read Holding Registers

Code 05 Force Single Coil

Code 06 Preset Single Register

Code 16 Preset Multiple Registers

DATA All data associated with the requested function

CHECK CRC-16 (Cyclic Redundancy Check) for validation of string content

Response to illegal requests

When the transmitter receives an illegal request, it sends back a response consisting of address,

function code, error code and checksum.

In order to indicate that the response is notification of an error, the most significant bit in the

function code is forced to “1”.

Error codes are as follows:

01 Illegal function

02 Illegal data address

03 Illegal data value

Functions supported by D110E

For a complete description of MODBUS commands please refer to specific MODBUS

documentation.

Below is a brief descriptions of the functions supported by D110E.

Function 03 - Read Holding Registers

Permits transfer of weight, status and configuration data from transmitting device to host.

Multiple registers may be transferred at the same time in a single request.

621 -MTU30105 Rev. 4 Page 20 of 43

ADOS S.R.L. Buccinasco (MI)

A string for requesting peripheral device 01 to transfer 3 registers starting with register 0 would be

as follows:

ADDR FUNC START START # OF # OF CHECK

REG REG REG REG

HI LOW HI LOW

01 03 00 00 00 03 05 CB

The response would be as follows:

ADDR FUNC BYTE REG REG REG REG REG REG CHECK

COUNT 0 0 1 1 2 2

HI LOW HI LOW HI LOW

01 03 06 00 0F 00 00 01 C0 74 B4

The content of register 0 is 15, the content of register 1 is 0 and the content of register 2 is 448.

Function 05 - Force Single Coil

Allows the host to control relays on the peripheral device. In the D110E it is used for the ZERO,

G/N, and TARE commands and for resetting the POF from the host.

The ZERO command is only accepted if the function is enabled and the weight to be set to zero

falls within the programmed limits.

The command string is as follows:

ADDR FUNC COIL COIL DATA DATA CHECK

# # VALUE VALUE

HI LOW HI LOW

01 05 00 00 FF 00 8C 3A

If the data is accepted, the peripheral device will return the same message:

ADDR FUNC COIL COIL DATA DATA CHECK

# # VALUE VALUE

HI LOW HI LOW

01 05 00 00 FF 00 8C 3A

Function 06 - Preset Single Register

Allows the host to modify the content of a D110E register.

The string for forcing peripheral device 01 with value 54 in register 12 is as follows:

ADDR FUNC REG REG DATA DATA CHECK

621 -MTU30105 Rev. 4 Page 21 of 43

ADOS S.R.L. Buccinasco (MI)

# # VALUE VALUE

HI LOW HI LOW

01 16 00 0C 00 36 C9 DF

If the data is accepted, the peripheral device returns the same message:

ADDR FUNC REG REG DATA DATA CHECK

# # VALUE VALUE

HI LOW HI LOW

01 06 00 0C 00 36 C9 DF

NOTE The command is not accepted if the register is Read Only or double length

Function 16 - Preset Multiple Registers

Permits the hose to modify the content of multiple registers in the D110E.

The string for forcing peripheral device 01 with values 5, 0, 342 in registers 22,23,24 is as follows:

ADDR FUNC STRT STRT # OF # OF BYTE DATA DATA DATA DATA DATA DATA CHECK

REG REG REG REG CNT VAL. VAL. VAL. VAL. VAL. VAL.

HI LOW HI LOW HI LOW HI LOW HI LOW

01 16 00 16 00 03 06 00 05 00 00 01 56 4A A4

If the data is accepted, the peripheral device returns a message containing the number of the first

register and the number of registers loaded:

ADDR FUNC STRT STRT # OF # OF CHECK

REG REG REG REG

HI LOW HI LOW

01 16 00 16 00 03 61 CC

NOTE The command will not be accepted if it is addressed to Read Only registers or if the

first register is the low register of a variable with double length.

621 -MTU30105 Rev. 4 Page 22 of 43

ADOS S.R.L. Buccinasco (MI)

List of D110E registers

Register 0 is bit coded.

All weight data (gross weight, weight set to zero, thresholds and dead bands) is coded on two

consecutive registers complementing 2.

For coding of configuration parameters, refer to the section entitled “Configuration”.

Type “R” registers are read-only, while “R/W” registers allow reading and writing.

Register Function Type

Number

0 Status word R

1-2 Gross weight R

3-4 Tare weight R

5 Number of operation included in totalizer 1 R/W

6-7 Totalizer 1 R/W

8 Number of operation included in totalizer 2 R/W

9-10 Totalizer 2 R/W

11 Instrument divisions R

12 Sensitivity R

13-14 Local gravity coefficient

15 Position of decimal point R/W

16 Averages R/W

17 Zero on Power On R/W

18 Limit for setting to zero R/W

19 Motion R/W

20 Shut Off R/W

21 Brightness control R/W

22 Totals function R/W

23-24 Minimum load R/W

25 Serial port mode R/W

26 Baud rate R/W

27 Device address R/W

28 Configuration enable R/W

29 Language R/W

30 Printer ON time

621 -MTU30105 Rev. 4 Page 23 of 43

ADOS S.R.L. Buccinasco (MI)

List of Coils managed by D110E

Coil Function

Number

0 Power On Flag reset command

1 Set GROSS (Data = $FF00)

2 ZERO command

3 TARE command

4 Reset Totalizer1 command

5 Reset Totalizer 2 command

6 Reset totalization completed flag command

7 Set NET (Data = $FF00)

Status word codes

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

POF M S Self-testing code G/N 0 0 0 0 0 0 0

POF Power On Flag. Instrument’s power supply has come back on.

D110E forces the flag to 1; the host may reset it by forcing Coil 1

M Totalization completed flag.

D110E forces the flag to 1; the host may reset it by forcing Coil 6

S if = 1 indicates that instrument is being configured or tested

Self-testing code reports error code in configuration parameters

G/N if = 1 indicates that instrument is set to NET

621 -MTU30105 Rev. 4 Page 24 of 43

ADOS S.R.L. Buccinasco (MI)

4 INSTALLATION

4.1 Receiving materials

Remove the instrument from its packaging and check it for damage suffered during transport.

If any damage is detected, notify the supplier and the carrier who delivered the instrument

immediately in writing.

The instrument is supplied with:

1 remote control

1 battery charger

1 copy of the instrument manual

2 copies of the instrument’s test certificate (check that the serial number shown on the back of

the instrument is the same as the number shown on the test certificate)

621 -MTU30105 Rev. 4 Page 25 of 43

ADOS S.R.L. Buccinasco (MI)

4.2 General instructions for use

Check cables used with the hanging scale constantly to ensure that they are in good condition;

inspect them visually by lowering the hook to the ground and slowly raising the cables to

prevent breakage of wires.

Do not raise any load which is poorly balanced, slung with improper equipment or with any

equipment other than that provided; take great care when raising and transporting loose

materials.

It is extremely dangerous and absolutely FORBIDDEN to:

swing the load and hit things with it

swing the load in order to put it down in a position that is not directly under the hook,

pull to one side,

pull at a load which is fixed in position in order to remove it.

When moving the hanging scale with no load, raise the hook and cables or chains high enough

to go over a man’s head or any other obstacle which may be present on the route.

When finished operating the hanging scale, raise the hook high enough above the ground that it

will not present a danger to people or equipment in movement.

Before beginning to raise the hanging scale, make sure that personnel who have slung the load

and any other workers in the area move away from it.

Operators of cranes and hoists controlled from the ground must keep far away from the moving

load.

Ensure that the weight of the load to be raised falls within the capacity of the hanging scale,

which appears on the hook and on the instrument’s case.

Use of slings and hooks other than those provided is FORBIDDEN.

Making modifications or using improvised systems for hooking and slinging loads is

FORBIDDEN.

Keep the hook closure in good condition to make sure that cables and chains used to sling the

load cannot be released.

Use of the end of the hook to raise a load is FORBIDDEN.

Maneuvers which cause abnormal stress that will compromise the functioning of the hook and

of the instrument are FORBIDDEN.

Before moving the load, check that it has been balanced properly and that it cannot shift its

position while it is being moved.

Position the device perpendicular to the load while raising the load.

The manufacturer shall not accept liability for injury or damage

attributable to improper use of the instrument.

621 -MTU30105 Rev. 4 Page 26 of 43

ADOS S.R.L. Buccinasco (MI)

4.3 Connections

All connections are made on the back of the instrument.

WARNING

Make sure that the battery charger is plugged in to a 230 V AC 10% power supply.

ANY IMPROPER CONNECTION WILL RESULT IN INVALIDATION OF THE

GUARANTEE

Shielded cables are preferable for use as serial line cables.

MODEL D110E-

SERIAL No

ON

OFF

FUSE 230V/F2A

CARICA BATT.

BATTERY CHAR.

USCITA SERIALE

4.4 Connecting serial ports

SERIAL LINE FUNCTIONS

PIN 1 Battery positive

PIN 2 RX232 - RTX485 B

PIN 3 TX232 - RTX485 A

PIN 4 TX AUX

PIN 5 SGROUND

PIN 6 Battery Negative

PIN 7 Battery Positive to printer

PIN 8 NC

PIN 9 NC

621 -MTU30105 Rev. 4 Page 27 of 43

ADOS S.R.L. Buccinasco (MI)

5 INSTRUMENT MAINTENANCE

5.1 Preventive maintenance

The instrument requires no particular preventive maintenance.

Periodic inspection of the condition of the battery charger power cable is recommended to ensure

safety.

5.2 Corrective maintenance

All maintenance work required as a result of faults in the instrument must be performed in ADOS

workshops or by ADOS personnel.

TAMPERING WITH THE INSTRUMENT WILL RESULT IN INVALIDATION OF THE

GUARANTEE.

621 -MTU30105 Rev. 4 Page 28 of 43

ADOS S.R.L. Buccinasco (MI)

6 OPERATING THE INSTRUMENT

6.1 Introduction

The D110E indicator is a programmable instrument which performs a series of functions that may

be adapted and/or customized by the user to suit a variety of applications.

These functions may be modified by changing configuration parameters.

The instrument should be configured to suit the primary application for which it will be used.

All configuration parameters are stored in permanent memory.

Parameter memory status is checked when the instrument is turned on; if a problem should be

detected, the instrument will automatically be reinitialized to the standard configuration, and it will

have to be reconfigured and recalibrated.

6.2 Selection of management functions

The D110E features the following management functions:

Configuration of general parameters

Weight calibration

Initialization

All operations are guided by messages appearing in light text on the display, which is used to

display and set the value of parameters to be modified.

After entering configuration mode, the instrument prepares to configure parameters and displays the

following message:

C O N F

press F to switch to management level, and the following messages will appear:

C O N F

C A L I B

I N I T

press E to confirm the selection.

Press C to cancel the request and return to regular operating mode.

621 -MTU30105 Rev. 4 Page 29 of 43

ADOS S.R.L. Buccinasco (MI)

6.2.1 Accessing configuration functions

Instrument configuration functions may be accessed at any time when the instrument is not

calibrated (during initialization); if the instrument has been calibrated, to gain access to calibration

functions hold down the FUNC and E keys at the same time while the instrument is being turned

on.

Access to configuration, calibration and initialization functions is password protected and requires

the user to type in the following password:

C E N/G T >O<

The password remains the same and cannot be changed during operation.

The password is intended to prevent accidental modification of configuration or calibration

parameter values, rather than to prevent fraudulent use of the instrument.

When the operator selects one of these functions, the password is requested:

P A S S W

The letters in the message are replaced with “-” as the password is entered.

If the password is entered correctly, the menu of functions of the type requested will appear; if the

password is incorrect, the instrument will return to the function selection menu.

6.2.2 Keypad Timeout

If no keys are pressed for 60 seconds the instrument automatically generates a “C” key code, which

means that if the operator leaves the instrument during configuration or calibration it will

automatically return to the menu at the next highest level and therefore to operating mode.

621 -MTU30105 Rev. 4 Page 30 of 43

ADOS S.R.L. Buccinasco (MI)

6.3 Configuration of operating parameters

6.3.1 Selection of operating parameters

When entering configuration mode from the configuration level selection menu, the instrument

prepares to configure the first parameter, displaying the message:

G R A D

Press FUNC to select all the configurable parameters in order (when the last parameter is

reached, it will automatically go back to the first).

Press number keys to go directly to the parameter to be configured.

Press T to go to the parameter prior to the selected parameter (when the first parameter is reached,

it will automatically go back to the last)

Press C to cancel the configuration request and return to the configuration level selection menu.

Press E to confirm the selection made, and the instrument will prepare to configure the selected

parameter; the parameter value or parameter code will appear on the display, while the auxiliary

display will flash to show that the instrument is ready to accept the modified parameter value.

621 -MTU30105 Rev. 4 Page 31 of 43

ADOS S.R.L. Buccinasco (MI)

6.3.2 Modification of operating parameter values

When configuration mode is entered from the parameter selection menu, the instrument will show

the parameter value or code on the main display, while the auxiliary display will flash to show that

the instrument is ready to accept the modified parameter value.

Press FUNC to increase the value of the selected parameter (when the maximum value is reached

it will automatically return to 0).

If the data displayed is a weight (such as a relay threshold) it will be increased in steps according to

the sensitivity for which it is configured.

If the FUNC key is held down, the step by which it is increased will be increased up to a

maximum of 128 times the basic step value.

Press T to decrease the value of the selected parameter (when zero is reached, it will automatically

return to the maximum value).

If the data displayed is a weight (such as a relay threshold), it will be decreased in steps according

to the sensitivity for which it is configured.

Hold down the T key to increase the step by which the weight value is decreased up to a maximum

of 128 times the basic value.

Press number keys to enter the parameter number to be configured directly.

Press >0< to set the value of the selected parameter to zero.

Press C to cancel the configuration request and return to the selection menu for the next parameter.

Press E to confirm the modification.

The instrument will check that the form of the value that has been entered is acceptable and then

display the following message for 2 seconds:

D O N E

before returning automatically to the selection menu for the next parameter.

621 -MTU30105 Rev. 4 Page 32 of 43

ADOS S.R.L. Buccinasco (MI)

6.3.3 Graduation

G R A D

May be set to the following values:

1000

2000

3000

4000

5000 (initialization configuration)

6.3.4 Resolution

R E S O l

May be set to the following values:

1 (initialization configuration)

2

5

10

6.3.5 Local gravity coefficient

G R A V

Can be used to set the decimal fraction value of the local gravity factor. May be set to between

(9.)79000 and (9.)81000

6.3.6 Decimal point

D E C P T

May be set to:

0 (initialization configuration)

0.0

0.00

0.000

0.0000

621 -MTU30105 Rev. 4 Page 33 of 43

ADOS S.R.L. Buccinasco (MI)

6.3.7 Averages

A V E R G

May be set to:

1 12

2 24

3 42 (initialization configuration)

4 62

5 80

6.3.8 Language selection

L A N G

To define the language for menu presentation and printout

Available values are:

ITAL Italian (initialization configuration)

ENG English

FRANC French

DEUTC Dutch

6.3.9 Auto Zero when turned on

A U T 0

Enables or disables the Auto Zero function when the instrument is turned on.

May be set to:

OFF (initialization configuration)

ON

6.3.10 AZM limit

0 L I M

The maximum value at which the instrument may be set to zero from the key on its front.

May be set to:

OFF (initialization configuration)

1.9%

100%

6.3.11 Motion band

M O T I O

May be set to:

OFF (initialization configuration)

0.5 divisions/sec

621 -MTU30105 Rev. 4 Page 34 of 43

ADOS S.R.L. Buccinasco (MI)

1.0 divisions/sec

2.0 divisions/sec

5.0 divisions/sec

10.0 divisions/sec

20.0 divisions/sec

6.3.12 Time before automatically turning off

S H U T F

May be used to set the amount of time after which the instrument will turn itself off if there is no

change in weight and no keys are pressed.

May be set to:

OFF (initialization configuration)

1

2

4

8

12

16

6.3.13 Display brightness

B R G H T

May be used to adjust display brightness.

May be set to:

HIGH (initialization configuration)

LOW

REGUL

6.3.14 Enable total

T O T A L

May be used to disable or enable one or both of the weight totalizers.

May be set to:

OFF (initialization configuration)

1

2

6.3.15 Minimum weight

M I N L

Used to set the value of the minimum weight which enables weight totalization and printout.

May be set from 0 to full-scale (given by produced sensitivity divisions).

621 -MTU30105 Rev. 4 Page 35 of 43

ADOS S.R.L. Buccinasco (MI)

6.3.16 Main serial port

S E R P

May be set to:

Continuous transmission

Deferred transmission

MODBUS (initialization configuration)

6.3.17 Baud rate

B A U D

May be set to:

9600 (initialization configuration)

4800

2400

1200

6.3.18 RS485 address

A 4 8 5

May be set to a value between 0 (default configuration) and 32.

6.3.19 Enable configuration access

E N B F

(ABLE F)

Used to enable or disable access to configuration functions from the keypad or remote control.

May be set to:

OFF (initialization configuration)

ON

6.3.20 Printer ON time

T P R T

To define the power ON time of the printer while printing.

Possible values ranges from 0 (default value) up to 100 sec.

621 -MTU30105 Rev. 4 Page 36 of 43

ADOS S.R.L. Buccinasco (MI)

6.4 Calibration

The instrument must be calibrated following initialization before it can perform any weighing

operations.

There are two steps to calibration:

calibration of zero value

calibration of full-scale

Both steps must be carried out at least once, or the instrument will continue to indicate FAULT.

Later on, it will be possible to calibrate either one of the two values on its own.

To enter calibration mode, first enter instrument management mode, then press F to select:

C A L I B

and press E.

The instrument will prepare to calibrate zero value and display the following message:

C A L. 0

Press F to switch to calibration of full-scale; the following message will be displayed:

C A L. F S

where 12345 is the weight currently on the scale.

Press E to request that the selected calibration sequence be started.

Press C to cancel the request for calibration and return to the instrument management menu.

621 -MTU30105 Rev. 4 Page 37 of 43

ADOS S.R.L. Buccinasco (MI)

6.4.1 Zero calibration

The weighing system must be prepared with weight ZERO.

First select the mode:

C A L. 0

and then press E.

The instrument will prepare to receive confirmation, flashing the message on the auxiliary display.

Press E again, and the instrument will begin the zero calibration procedure; the following message

will appear:

W A I T (flashing)

During this time period the instrument will integrate the input signal.

Once the time has expired the instrument will calibrate zero and display the following message for

two seconds:

D O N E

before automatically returning to the calibration menu.

621 -MTU30105 Rev. 4 Page 38 of 43

ADOS S.R.L. Buccinasco (MI)

6.4.2 Full-scale calibration

The weighing system must be prepared with a KNOWN weight which exceeds 12.5% of full-scale.

The closer the known weight is to full-scale, the more accurate calibration of full-scale will be.

The system prepares for calibration with a known weight corresponding to the weight currently on

the scale.

The operator may change this by either directly entering the known weight (using the numerical

keypad) or pressing F or T to increase or decrease the displayed value by steps equal to one

division; press F or G/N to increase the step up to a maximum of 128 divisions.

Press E and the instrument will prepare to receive confirmation, flashing the following message on

the display:

C A L. F S

Press E and the instrument will begin the full-scale calibration process; the following message will

be displayed:

W A I T (flashing)

During this time period the instrument will integrate the input signal.

When the time has expired, the instrument will perform calibration and then display the following

message for two seconds:

D O N E

before returning automatically to the calibration menu.

If the value of the known weight that has been entered is incorrect, the instrument will display the

following message for two seconds:

E R R O R

before returning automatically to the calibration menu.

621 -MTU30105 Rev. 4 Page 39 of 43

ADOS S.R.L. Buccinasco (MI)

6.5 Initialization

The instrument may be returned to the default configuration by commanding initialization from the

keypad.

To enter initialization mode, first enter instrument management mode and then press F to enter the

following mode:

I N I T

and press E.

The instrument will display the message:

I N I T -

Press C to cancel the request for initialization and return to the instrument management menu.

Press E to start up the sequence, and the instrument will prepare to receive confirmation:

O K I N (flashing)

The operator may confirm the request for initialization by pressing E or cancel it by pressing C.

Press E t confirm the selection, and the instrument will initialize parameters and restart

automatically.

Press C to cancel the request for initialization and return to the instrument management menu.

621 -MTU30105 Rev. 4 Page 40 of 43

ADOS S.R.L. Buccinasco (MI)

6.6 Test

The user may test battery charge and read internal temperature using this function.

This function is called up from the remote control only.

To enter test mode, press TEST ; battery voltage will be displayed:

B 6. 0 4

Press TEST again to check temperature, and the instrument will display its internal temperature:

T 2 2. 5

Press TEST once more and the instrument will display the number of hours remaining in battery

life calculated on the basis of the battery voltage it has detected.

H 4 8

Press C to return to operating mode.

621 -MTU30105 Rev. 4 Page 41 of 43

ADOS S.R.L. Buccinasco (MI)

7 INSTRUMENT CONFIGURATION TABLE

Weighing parameters

Parameter

Divisions 1000 2000 3000 4000 5000

Sensitivity 1 2 5 10

Gravity .80516

Dec. pnt. 0 0.0 0.00 0.000 0.0000

N. averages 1-12 2-24 3-42 4-62 5-80

Auto 0 OFF ON

Limit 0 OFF 1.9 100

Motion OFF 0.5 1.0 2.0 5.0 10.0 20.0

Auto off OFF 1 2 4 8 12 16

Brightness HIGH LOW REGUL

Totals OFF 1 2

Minimum weight 0

Main serial CONT DE MODBU

Baud rate 9600 4800 2400 1200

485 address 0

F. enabled OFF ON

Printer ON time 0

621 -MTU30105 Rev. 4 Page 42 of 43

ADOS S.R.L. Buccinasco (MI)

IMPORTANT

Keep this instruction manual for consultation by all personnel authorised to operate the

instrument for as long as the instrument remains in service.

Additional copies may be ordered from ADOS service centres.

If additional technical information or clarification is required, contact an ADOS service

centre.

621 -MTU30105 Rev. 4 Page 43 of 43

Вам также может понравиться

- SW Release 1.53c: Instruction ManualДокумент76 страницSW Release 1.53c: Instruction ManualDmitriyОценок пока нет

- SW Release 1.53: Instruction ManualДокумент76 страницSW Release 1.53: Instruction ManualMilan GašićОценок пока нет

- Abacus 5 JuniorДокумент74 страницыAbacus 5 JuniorEnfant Perdu100% (1)

- Mie12166-Cba1000 Introductory GuideДокумент113 страницMie12166-Cba1000 Introductory GuideEmir KamberovićОценок пока нет

- I-2 - CUC User Guide For Leak Detector, Gas 06 (Cir) ET2 (K2 - 1022395 - 1 - R03)Документ48 страницI-2 - CUC User Guide For Leak Detector, Gas 06 (Cir) ET2 (K2 - 1022395 - 1 - R03)shanmugaraj m100% (3)

- DMG - 93010242.EN - Q - MUSA-reference-manual - 161004 - v3.6Документ128 страницDMG - 93010242.EN - Q - MUSA-reference-manual - 161004 - v3.6bdgnsОценок пока нет

- Operating Manual Adsorption Dryer DPS 120-630: Version: 11/2010/DEДокумент64 страницыOperating Manual Adsorption Dryer DPS 120-630: Version: 11/2010/DEMendoud SofianeОценок пока нет

- Mse10015 - TDMS - 0713Документ129 страницMse10015 - TDMS - 0713xanderkeiОценок пока нет

- NSR NSV-1000B BnwasДокумент56 страницNSR NSV-1000B BnwasJahid IslamОценок пока нет

- Fuel Burner's ManualДокумент48 страницFuel Burner's ManualLyndon TinongaОценок пока нет

- FD-13 - FD-15 User ManualДокумент45 страницFD-13 - FD-15 User ManualRokОценок пока нет

- Villa Vision User ManualДокумент102 страницыVilla Vision User ManualLuis Fernando Garcia SОценок пока нет

- UM MSI-MD-FB en 50132704Документ67 страницUM MSI-MD-FB en 50132704Lucas VieiraОценок пока нет

- iDOC027 53 00791 MRZ07Документ130 страницiDOC027 53 00791 MRZ07saras unggulОценок пока нет

- 090768.232 3.00 018 A e - AДокумент111 страниц090768.232 3.00 018 A e - ANoman Abu-FarhaОценок пока нет

- BP Angola FPSO PAS Hardware SpecificationДокумент68 страницBP Angola FPSO PAS Hardware SpecificationArnel Moreno100% (1)

- RV-3029 Application Manual GuideДокумент67 страницRV-3029 Application Manual GuideBENTABET AKILAОценок пока нет

- Position Detection System PDS Using DGPS S 57632ZAДокумент53 страницыPosition Detection System PDS Using DGPS S 57632ZAjJasper-jasОценок пока нет

- BuellTuningGuide en V2.0Документ148 страницBuellTuningGuide en V2.0William Bernard JrОценок пока нет

- MSE10166 - CBAProДокумент92 страницыMSE10166 - CBAProSlobodan SavicОценок пока нет

- Oki Data Printer Maintenance ManualДокумент242 страницыOki Data Printer Maintenance ManualReneeОценок пока нет

- HQD Portable Meter User Manual: May 2009, Edition 1Документ50 страницHQD Portable Meter User Manual: May 2009, Edition 1Dragoslav NikolicОценок пока нет

- Sonoscape S9 Service ManualДокумент105 страницSonoscape S9 Service ManualRadovan JakovljevicОценок пока нет

- User Manual Boot Manager Boot-US: November/16/2021Документ160 страницUser Manual Boot Manager Boot-US: November/16/2021winkywinnypapuchoОценок пока нет

- BA Profiler2 en 2014-06-27 06Документ138 страницBA Profiler2 en 2014-06-27 06Tiago da Silva PereiraОценок пока нет

- DCD 2Документ48 страницDCD 2Jorge SánchezОценок пока нет

- MU 78 15E BEAT TR12.r4Документ51 страницаMU 78 15E BEAT TR12.r4razvan.pintilieОценок пока нет

- DOC022.53.80116Документ56 страницDOC022.53.80116aboali8686Оценок пока нет

- Verify ManualДокумент125 страницVerify ManualMohamed MohamedОценок пока нет

- DOC0245293001 410 19edДокумент102 страницыDOC0245293001 410 19edA SofyanОценок пока нет

- Tunable Diode Laser Spectrometer: Tdls Gpro 500Документ36 страницTunable Diode Laser Spectrometer: Tdls Gpro 500Flávia OliveiraОценок пока нет

- Man VL-66203 Rev1.5 EngДокумент18 страницMan VL-66203 Rev1.5 EngBeneDict Ben DОценок пока нет

- Imageuploadinstruction Manual and SoftwareInstruction Manualstesto 350 Instruction Manual 5771.PDF# 3Документ106 страницImageuploadinstruction Manual and SoftwareInstruction Manualstesto 350 Instruction Manual 5771.PDF# 3Randa AmarОценок пока нет

- 2010 - 2020 Microplate Absorbance Reader 2020 Sw-Version 2.0 Up Operating Manual Ver 03 - 10Документ70 страниц2010 - 2020 Microplate Absorbance Reader 2020 Sw-Version 2.0 Up Operating Manual Ver 03 - 10luroguita-1Оценок пока нет

- DAS-3224 - 3248 - User Manual-V1 0 - 2014-05-29Документ54 страницыDAS-3224 - 3248 - User Manual-V1 0 - 2014-05-29Daniel IliescuОценок пока нет

- GD Pilot MK Electronics For Stationary Screw Air CompressorsДокумент36 страницGD Pilot MK Electronics For Stationary Screw Air Compressorsandy habibiОценок пока нет

- ROLLER 15-30 Manual Tecnico (Ingles)Документ47 страницROLLER 15-30 Manual Tecnico (Ingles)fabiosan0567% (3)

- Gpredict User Manual 1.2Документ64 страницыGpredict User Manual 1.2Will JacksonОценок пока нет

- C5400/C5200/C5150/ C3100 Color LED Page Printer: Maintenance ManualДокумент141 страницаC5400/C5200/C5150/ C3100 Color LED Page Printer: Maintenance ManualTomislav BelosevicОценок пока нет

- Operator's Guide and Instruction Manual: Digital Bypass Solid State StarterДокумент48 страницOperator's Guide and Instruction Manual: Digital Bypass Solid State StarterMatthew Keegan100% (1)

- Salwico GS5000 - System Description & Application Examples - M - EN - 2015 - DДокумент58 страницSalwico GS5000 - System Description & Application Examples - M - EN - 2015 - DAdegbola AdedipeОценок пока нет

- ChemWell R6Документ234 страницыChemWell R6Tran Trong Nghia100% (1)

- CPM For DLT-5500: Communication PlatformДокумент54 страницыCPM For DLT-5500: Communication PlatformMauricio Contreras R.Оценок пока нет

- 7 - 7005 - 10 - USE Sigma Control BasicДокумент36 страниц7 - 7005 - 10 - USE Sigma Control BasicWilliam BeadenkopfОценок пока нет

- SMT 06 R&SДокумент462 страницыSMT 06 R&Spaquirri999Оценок пока нет

- Mse20080 - Distance 21 PDFДокумент147 страницMse20080 - Distance 21 PDFSaiful Karim ShantoОценок пока нет

- Dissolved Oxygen (D.O.) Meter: Operating ManualДокумент62 страницыDissolved Oxygen (D.O.) Meter: Operating ManualTin Cậy Kỹ ThuậtОценок пока нет

- Service Manual: Wired Remote Controller BRC1H61W / BRC1H61KДокумент140 страницService Manual: Wired Remote Controller BRC1H61W / BRC1H61KAbdulSattarОценок пока нет

- Menami Inspector Oxygen 01Документ78 страницMenami Inspector Oxygen 01李奇Оценок пока нет

- MB2 HardwareManual 2Документ43 страницыMB2 HardwareManual 2NamiJen LobatoОценок пока нет

- PKDT PKDM ImoДокумент28 страницPKDT PKDM ImoedgardОценок пока нет

- Manual MI 2893, MI 2892, MI 2885 - PowerMaster XT, Power Master, Master Q4 ANG Ver 1.2.2 20753179Документ242 страницыManual MI 2893, MI 2892, MI 2885 - PowerMaster XT, Power Master, Master Q4 ANG Ver 1.2.2 20753179Nhật Tân Nguyễn VănОценок пока нет

- FC 5706Документ47 страницFC 5706AliОценок пока нет

- Testo 350 Instruction ManualДокумент104 страницыTesto 350 Instruction ManualSherab GyeltshenОценок пока нет

- 8dg33995aaaatqzza - V1 - 1359 Corba NbiДокумент33 страницы8dg33995aaaatqzza - V1 - 1359 Corba NbiRaja solaimalaiОценок пока нет

- Konicaminolta Bizhub c220 c280 c360 Service Manual FreeДокумент47 страницKonicaminolta Bizhub c220 c280 c360 Service Manual FreeАлексей ПросвирнинОценок пока нет

- User Manual 04/2013 Edition 3A: © Hach-Lange GMBH, 2011, 2013. All Rights Reserved. Printed in GermanyДокумент150 страницUser Manual 04/2013 Edition 3A: © Hach-Lange GMBH, 2011, 2013. All Rights Reserved. Printed in GermanyJaya SriwiОценок пока нет

- Troubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersОт EverandTroubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersРейтинг: 5 из 5 звезд5/5 (2)

- Prediction of Burnout: An Artificial Neural Network ApproachОт EverandPrediction of Burnout: An Artificial Neural Network ApproachОценок пока нет

- Integrated and Participatory Water Resources Management - PracticeОт EverandIntegrated and Participatory Water Resources Management - PracticeОценок пока нет

- User's Manual: Counting ScalesДокумент20 страницUser's Manual: Counting ScalesMatjaz LОценок пока нет

- Cardinal 204 Operation ManualДокумент36 страницCardinal 204 Operation ManualMatjaz LОценок пока нет

- CAS DBII Uk-Cert-2847Документ9 страницCAS DBII Uk-Cert-2847Matjaz LОценок пока нет

- Weight Indicating Instrument ManualДокумент56 страницWeight Indicating Instrument ManualMatjaz LОценок пока нет

- KERN EG-EW-BA-e-1829 Navodila Za UporaboДокумент59 страницKERN EG-EW-BA-e-1829 Navodila Za UporaboMatjaz LОценок пока нет

- BOSCHE - AWI-ASP-user - Manual - en PDFДокумент26 страницBOSCHE - AWI-ASP-user - Manual - en PDFMatjaž LekšanОценок пока нет

- D400 Manuale enДокумент72 страницыD400 Manuale eninstengg100% (1)

- (New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffДокумент1 страница(New) Adjustable Voltage Power Supply 55 V - 20A High Power and Current - Automatic Fan On - OffSek PyroОценок пока нет

- Infinity Box UserManualДокумент10 страницInfinity Box UserManualRomel DiazОценок пока нет

- 01-07 VPLS ConfigurationДокумент237 страниц01-07 VPLS ConfigurationAhmed Ould MouhammedОценок пока нет

- 8051 InterfacingДокумент8 страниц8051 InterfacingDr.R.RAMANОценок пока нет

- Main characteristics of database approachДокумент17 страницMain characteristics of database approachSaladAss GamingОценок пока нет

- 02 - Buffer Cache TuningДокумент11 страниц02 - Buffer Cache TuningAMEYОценок пока нет

- Project Synopsis CseДокумент8 страницProject Synopsis CseSagar SharmaОценок пока нет

- Personal Digital Assistant Audit Checklist June 2009: Page 1 of 7Документ7 страницPersonal Digital Assistant Audit Checklist June 2009: Page 1 of 7T&J HR OFFICIALОценок пока нет

- Description Features: Ltc6900 Low Power, 1Khz To 20Mhz Resistor Set Sot-23 OscillatorДокумент12 страницDescription Features: Ltc6900 Low Power, 1Khz To 20Mhz Resistor Set Sot-23 OscillatorcartobonОценок пока нет

- Dip Lab Short Code-1Документ7 страницDip Lab Short Code-1SANIYYA AAFREENОценок пока нет

- CONTROL-M Job Parameter and Variable Reference Guide 20091008Документ542 страницыCONTROL-M Job Parameter and Variable Reference Guide 20091008Rajni ChaudharyОценок пока нет

- RS232 To DALI User Guide V8Документ16 страницRS232 To DALI User Guide V8Arun DasariОценок пока нет

- TC 20KL03Документ26 страницTC 20KL03davidОценок пока нет

- Liang Chapter 4Документ42 страницыLiang Chapter 4THEO DOMINIC REQUERME SILVOSAОценок пока нет

- ISDP for Student Grade Evaluation SystemДокумент25 страницISDP for Student Grade Evaluation SystemJunskhie Yap0% (1)

- 6,75$,1 7udlqlqjiru, Qgxvwu/: Course DR-G12-PM Course DR-G12-PMДокумент304 страницы6,75$,1 7udlqlqjiru, Qgxvwu/: Course DR-G12-PM Course DR-G12-PMFercho OeОценок пока нет

- CURS 6 Protocoale FireДокумент38 страницCURS 6 Protocoale FireCosmina DulhanОценок пока нет

- Scanner For Drive Tests and I/Q Streaming: R&S®TSMW Universal Radio Network AnalyzerДокумент24 страницыScanner For Drive Tests and I/Q Streaming: R&S®TSMW Universal Radio Network AnalyzersaagОценок пока нет

- 4:1 HDMI/DVI Switch With Equalization, DDC/CEC Buffers and EDID ReplicationДокумент28 страниц4:1 HDMI/DVI Switch With Equalization, DDC/CEC Buffers and EDID Replicationlucas silvaОценок пока нет

- HP BIOS Configuration Utility: Technical White PaperДокумент12 страницHP BIOS Configuration Utility: Technical White Paperdaniel de los riosОценок пока нет

- MAX77511/MAX77711 10V Input, Quad-Phase Configurable, 3A/Phase, High-Efficiency Buck ConverterДокумент3 страницыMAX77511/MAX77711 10V Input, Quad-Phase Configurable, 3A/Phase, High-Efficiency Buck ConvertermstrkoskiОценок пока нет

- Hytera pd702 pd705 pd706 pd708 pd782 pd785 pd786 pd788 hd705 hd785g SMДокумент299 страницHytera pd702 pd705 pd706 pd708 pd782 pd785 pd786 pd788 hd705 hd785g SMPT7CJDОценок пока нет

- Lesson 1 Introduction To NetworkingДокумент14 страницLesson 1 Introduction To NetworkingKevin SambuОценок пока нет

- COMP1829: Week 3Документ22 страницыCOMP1829: Week 3SujiKrishnanОценок пока нет

- Ashish - GC Format CVДокумент4 страницыAshish - GC Format CVdivakarzОценок пока нет

- New Text DocumentДокумент21 страницаNew Text DocumentBasit AliОценок пока нет

- Potentiometer and LVDTДокумент4 страницыPotentiometer and LVDTAbhishek Kumar JaiswalОценок пока нет

- The Intel Microprocessors Chapter 1Документ195 страницThe Intel Microprocessors Chapter 1Ajay Singhania100% (1)

- Types of Control Systems - Linear and Non Linear Control SystemДокумент8 страницTypes of Control Systems - Linear and Non Linear Control SystemLalita KumariОценок пока нет

- Standard Variable Output LDO RegulatorsДокумент12 страницStandard Variable Output LDO RegulatorsDaniela GarciaОценок пока нет