Академический Документы

Профессиональный Документы

Культура Документы

BOYDEL Case Study BlueTech Forum 2020 Innovation Showcase - Olga FINAL

Загружено:

Sivakumar Selvaraj0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаОригинальное название

3.-BOYDEL-Case-Study-BlueTech-Forum-2020-Innovation-Showcase_Olga-FINAL

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

30 просмотров1 страницаBOYDEL Case Study BlueTech Forum 2020 Innovation Showcase - Olga FINAL

Загружено:

Sivakumar SelvarajАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

BOYDEL WASTEWATER TECHNOLOGIES Inc.

British Columbia,

Canada

SludgeMiner™ www.boydel.ca

USA Meat Processing Plant High Removals: FOG>95%,

SludgeMiner™ TSS>90%, BOD>80%

Dual zone Electro-coagulation / electro-oxidation

An example BOYDEL project in the

Reactor technology

USA meat processing industry

Flow 20,000 US gallons/d (75 m3/d)

• Very high contaminant loading

INFLUENT mg/L Treated Effluent mg/L • Strict discharge regulations:

BOD5 5,000-10,000 <500 ( >250 mg/L FOG = plant closure)

TSS 20,000-40,000 <500

• 3 stage plant start-up: 20,000 US

FOG 15,000-20,000 <250

gallons/d increasing by 20,000 US

gallons/d every six months

• Required to manage inconsistent

Why SludeMiner™ provides a start-up flows and contaminant

variability

Compelling Value Proposition • Limited space available for treatment

solution

Conventional treatment options

Bio-chemical and DAF processes

• Larger tankage footprints

• Typically 40% higher OPEX and 30-40% SludgeMiner™

Lower CAPEX

• Lower and unstable removal capabilities and meat processing

TECHNOLOGY DEVELOPMENT With success of the first commercial

SludgeMiner™; non-biological, dynamic installation of SludgeMiner™ at a US

process with <15 min. total residence time. The SludgeMiner™ was configured on this meat processing facility imminent,

1. Instant on/off process to deal with bumpy wastewater stream with stable and predictable Boydel will demonstrate an

start-up or production flows. OPEX as follows: alternative solution to temperamental

DAF, biology or bio-chemical

2. Very high and predictable removals confirmed. • Fe dosing: 100 mg/L of influent processes for the thousands of

3. Equipment for each phase is scalable and

modular – buy what you need, when you need it. • Polymer dosing: 0.01 mg/L of influent similar facilities across North

4. Modules added every 6-8 months as client • Power consumption : 3 0.0114 kW / US gallon America.

ramps production @ 480v 3ph (3 kW / m ) SludgeMiner™ is a low cost, fully

5. ReactorLink™; Automated, guaranteed Dewatering can be done using simple static tank controllable, stable, low sludge and

cost consumables supply and technical low odor treatment option for this and

support program.

decanting followed by sludge bag final dewatering other high solids wastewater

6. Clean equipment purchase or BOYDEL and disposal by client. industries.

Fee-For-Service (F4S) model offered.

Вам также может понравиться

- All Plumbing CalculationДокумент46 страницAll Plumbing Calculationhtranggono100% (2)

- Bectel ASME Process Cal R2Документ21 страницаBectel ASME Process Cal R2Sivakumar SelvarajОценок пока нет

- Sajjan India Corporate - PresentationДокумент33 страницыSajjan India Corporate - PresentationPalkeshОценок пока нет

- Chapter 2 Part 1Документ11 страницChapter 2 Part 1virajain100% (3)

- URS - Tanauan Factory WWTP Upgrade PDFДокумент23 страницыURS - Tanauan Factory WWTP Upgrade PDFVer AmorosoОценок пока нет

- Paradip Etp O&m Sop-FinalДокумент39 страницParadip Etp O&m Sop-FinalDhal Engineering Company SalesОценок пока нет

- 13-Caterpillar Lean Certification-Rene Jeanfreau, CaterpillarДокумент10 страниц13-Caterpillar Lean Certification-Rene Jeanfreau, CaterpillarVignesh WaranОценок пока нет

- Resident Marine Mammals of The Protected Seascape Tanon Strait Vs ReyesДокумент2 страницыResident Marine Mammals of The Protected Seascape Tanon Strait Vs ReyesPiaОценок пока нет

- (S. Curwell) Sustainable Urban Development Volume (BookFi)Документ238 страниц(S. Curwell) Sustainable Urban Development Volume (BookFi)Rimbun LandscapeОценок пока нет

- 2ND Quarter Exam UCSPДокумент2 страницы2ND Quarter Exam UCSPRuth AcopiadoОценок пока нет

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisОт EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisРейтинг: 5 из 5 звезд5/5 (1)

- 120 MLD Sewage Treatment Plant: NCL/TMX/STP-VIKARABAD/BP-2244/R0/Tec OfferДокумент39 страниц120 MLD Sewage Treatment Plant: NCL/TMX/STP-VIKARABAD/BP-2244/R0/Tec OfferVķ MãħëšħОценок пока нет

- Next Generation of MBBR TechnologyДокумент48 страницNext Generation of MBBR TechnologyLouay Mansour100% (1)

- Edible Oil and Biodiesel Refining - Biodiesel Expansion - Biodiesel ReactorsДокумент11 страницEdible Oil and Biodiesel Refining - Biodiesel Expansion - Biodiesel ReactorsJohn Maguire100% (1)

- Avant-Garde Mr. K Mohan KumarДокумент46 страницAvant-Garde Mr. K Mohan KumarSivakumar SelvarajОценок пока нет

- BIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeДокумент26 страницBIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeK SASIKUMAR100% (1)

- 1) STP 500 LTR (Lal Pathlabs)Документ16 страниц1) STP 500 LTR (Lal Pathlabs)raj enterprise100% (1)

- Diligent Etp 1000m3Документ18 страницDiligent Etp 1000m3Prabhakar DhamaleОценок пока нет

- CMAP G11 Earth and Life ScienceДокумент20 страницCMAP G11 Earth and Life ScienceRhieza Perez Umandal100% (2)

- Next Generation of MBBR Technology PDFДокумент48 страницNext Generation of MBBR Technology PDFAbhisek BhattacharyaОценок пока нет

- Biomod: Packaged Moving Bed Biofilm ReactorДокумент4 страницыBiomod: Packaged Moving Bed Biofilm ReactorAlvaro Huete100% (1)

- 07 Apr 2019 1431276907G6O3U69Annexure-ETPproposalДокумент8 страниц07 Apr 2019 1431276907G6O3U69Annexure-ETPproposalSUN AQUATECHОценок пока нет

- Wartsila OEM Engine Manufacturer ApprovalsДокумент8 страницWartsila OEM Engine Manufacturer ApprovalsSivakumar SelvarajОценок пока нет

- Supply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Документ24 страницыSupply, Installation & Commissioning of Effluent Treatment Plant (ETP) For Bang Jin Bangladesh-1Saif Ahmed Nabil100% (1)

- 40 KLD MBR QuoteДокумент15 страниц40 KLD MBR QuoteV Narasimha RajuОценок пока нет

- Water Soluble Polymers PDFДокумент57 страницWater Soluble Polymers PDFarchanaОценок пока нет

- 100 KLD STP New-1Документ13 страниц100 KLD STP New-1Anjita KumariОценок пока нет

- How To Increase Crude Throughput in Desalter ApplicationsДокумент28 страницHow To Increase Crude Throughput in Desalter ApplicationsAnonymous bHh1L1Оценок пока нет

- Chlorine Dioxide Generator Systems: Capacity OverviewДокумент2 страницыChlorine Dioxide Generator Systems: Capacity OverviewOchoa Para La BandaОценок пока нет

- Element Brochure 9 3Документ6 страницElement Brochure 9 301DOGG01Оценок пока нет

- BioMOD MBR BrochureДокумент4 страницыBioMOD MBR BrochureDouglas CostaОценок пока нет

- Sadesa Paraguay Proposal 11800247 Rev03Документ20 страницSadesa Paraguay Proposal 11800247 Rev03Natii LopezОценок пока нет

- Generox™ CSR: A Total Control Program Providing Safe and Economical DisinfectionДокумент4 страницыGenerox™ CSR: A Total Control Program Providing Safe and Economical Disinfectionjuan pablo suarezОценок пока нет

- BioMOD MBBR BrochureДокумент4 страницыBioMOD MBBR BrochureDouglas CostaОценок пока нет

- Ionpro LXДокумент2 страницыIonpro LXAlon CarlosОценок пока нет

- Adi Anmbr BrochureДокумент2 страницыAdi Anmbr BrochureprannoyОценок пока нет

- Leading-Edge Biological Treatment - MBBR Moving Bed Biofilm ReactorДокумент6 страницLeading-Edge Biological Treatment - MBBR Moving Bed Biofilm ReactorManuel AlejandroОценок пока нет

- Midiro ™: Reverse Osmosis SystemsДокумент2 страницыMidiro ™: Reverse Osmosis SystemsEta TrutaОценок пока нет

- 4723 BetterДокумент3 страницы4723 BetterMuharrem KorkmazОценок пока нет

- Hematology Eco Reagent GLB Brochure PDFДокумент2 страницыHematology Eco Reagent GLB Brochure PDFYasushi KoezukaОценок пока нет

- Template Assisted Crystallization TAC Guide Antunes 1050086Документ2 страницыTemplate Assisted Crystallization TAC Guide Antunes 1050086HauptmanОценок пока нет

- 2mld Insitu Cbpur 1march 2024Документ31 страница2mld Insitu Cbpur 1march 2024Jeevan RoyОценок пока нет

- Ag HR Seri S: High Rejection Brackish Water RO ElementsДокумент2 страницыAg HR Seri S: High Rejection Brackish Water RO ElementsPraveen KumarОценок пока нет

- SPVCQ632210071156 - Rev6 - 50CMD STP - 29oct2022Документ17 страницSPVCQ632210071156 - Rev6 - 50CMD STP - 29oct2022Arvie Batisla-ongОценок пока нет

- Wtu DatasheetДокумент2 страницыWtu DatasheetHassan SleemОценок пока нет

- Cs Phar Indww en 1106 Na Ge LogoДокумент2 страницыCs Phar Indww en 1106 Na Ge Logoanandhra2010Оценок пока нет

- HyCa Technologies BrochureДокумент7 страницHyCa Technologies BrochureHuzefa CalcuttawalaОценок пока нет

- 3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetДокумент2 страницы3M Water Filtration Products - High Flow Series - HF40 and HF40 - S Performance Data SheetSergioОценок пока нет

- Lopressurero System (L.P.R.O.) : Culligan Commercial Reverse Osmosis Water SystemsДокумент5 страницLopressurero System (L.P.R.O.) : Culligan Commercial Reverse Osmosis Water SystemsIyad AlemОценок пока нет

- FS1622ENДокумент2 страницыFS1622ENquimica 2117Оценок пока нет

- Federico M - Berruti Feb 13, 2013Документ50 страницFederico M - Berruti Feb 13, 2013Apoli ApatoroОценок пока нет

- Contoh Commercial ProposalДокумент8 страницContoh Commercial ProposalkhristprasatyaОценок пока нет

- Publication UASB+TechnologyДокумент6 страницPublication UASB+TechnologyecotechconsultantsОценок пока нет

- Aguas de LastreДокумент12 страницAguas de LastreElias Dalens CastroОценок пока нет

- 2 Imech - Energy Dome Company PresentationДокумент16 страниц2 Imech - Energy Dome Company PresentationRoque Alfredo Da Rosa AvilaОценок пока нет

- CECEP Environmental Protection Equipment Co., LTD.: Going Green, Investing GreenДокумент39 страницCECEP Environmental Protection Equipment Co., LTD.: Going Green, Investing GreenBUKITMAS INDONESIAОценок пока нет

- Aplicacoes Do Biogas Na Europa Stephen EtheridgeДокумент113 страницAplicacoes Do Biogas Na Europa Stephen EtheridgeBelay AyalewОценок пока нет

- Punjab GWMДокумент33 страницыPunjab GWMrajinder_hpiphОценок пока нет

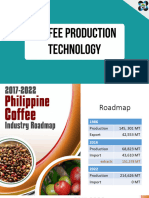

- Coffee Production TechnologyДокумент25 страницCoffee Production TechnologyjeffreyОценок пока нет

- ACTI-Mag Brochure 2016Документ4 страницыACTI-Mag Brochure 2016Atharva UlangwarОценок пока нет

- VITEC 55™ Antiscalant/Dispersant - Liquid Product DatasheetДокумент1 страницаVITEC 55™ Antiscalant/Dispersant - Liquid Product DatasheetaftabОценок пока нет

- CECHLO-MS 200 Marketing BrochureДокумент4 страницыCECHLO-MS 200 Marketing BrochureDorina CotoarăОценок пока нет

- Contract Manufacturer's Journey To Higher ContainmentДокумент24 страницыContract Manufacturer's Journey To Higher ContainmentBulent InanОценок пока нет

- 2 Micro Safa EN - IP66Документ3 страницы2 Micro Safa EN - IP66j8164322Оценок пока нет

- Brochur de Analizador de Fibra Modelo A2000Документ2 страницыBrochur de Analizador de Fibra Modelo A2000BETZABETH ROSA CANTORIN BENITESОценок пока нет

- VWT - NA - Oxidation - Ditch - Letter - LR - PDF - 0Документ6 страницVWT - NA - Oxidation - Ditch - Letter - LR - PDF - 0Roberto CarvalhoОценок пока нет

- H 07 Specsheet v3.1 2015 01 07Документ2 страницыH 07 Specsheet v3.1 2015 01 07murtada gubaОценок пока нет

- JohkasouДокумент20 страницJohkasoumoodpihuОценок пока нет

- Se-dcf-En-05 11 Crossflow Filter PrayefsДокумент4 страницыSe-dcf-En-05 11 Crossflow Filter Prayefslimim56582Оценок пока нет

- Adapting Industry Practice For Rapid Large Scale Manufacture of Pharmaceutical ProteinsДокумент34 страницыAdapting Industry Practice For Rapid Large Scale Manufacture of Pharmaceutical ProteinsRajavelu PerumalОценок пока нет

- Indian Dairy Dairy Products Industry - June 2020Документ13 страницIndian Dairy Dairy Products Industry - June 2020Sivakumar SelvarajОценок пока нет

- COD & TOC AnalyserДокумент24 страницыCOD & TOC AnalyserSivakumar SelvarajОценок пока нет

- Boiler Treatment Capabilities: SUEZ Water Technologies and SolutionsДокумент25 страницBoiler Treatment Capabilities: SUEZ Water Technologies and SolutionsSivakumar SelvarajОценок пока нет

- Indian Dairy Dairy Products Industry - June 2020Документ13 страницIndian Dairy Dairy Products Industry - June 2020Sivakumar SelvarajОценок пока нет

- Ammonia FDA 173.184Документ2 страницыAmmonia FDA 173.184Sivakumar SelvarajОценок пока нет

- BromineChlorine by DPDДокумент3 страницыBromineChlorine by DPDSivakumar SelvarajОценок пока нет

- Boc Case Studies Cooling Towers 2019 Aquatech IndustrialДокумент16 страницBoc Case Studies Cooling Towers 2019 Aquatech IndustrialSivakumar SelvarajОценок пока нет

- Boiler Trouble Shooting Guide - K.K.ParthibanДокумент287 страницBoiler Trouble Shooting Guide - K.K.ParthibanSivakumar SelvarajОценок пока нет

- Radico Khaitan MR K P SinghДокумент67 страницRadico Khaitan MR K P SinghSivakumar Selvaraj100% (1)

- W Watert T Alk: Amine RegulationsДокумент4 страницыW Watert T Alk: Amine RegulationsSivakumar SelvarajОценок пока нет

- The Future of Wastewater Treatment Is Here.: Taron RDD FilterДокумент1 страницаThe Future of Wastewater Treatment Is Here.: Taron RDD FilterSivakumar Selvaraj100% (1)

- Daily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDДокумент2 страницыDaily Manufacturing Report: Shreenath Mhaskoba Sakhar Karkhana LTDSivakumar SelvarajОценок пока нет

- Lee R. Madsen II, Research Associate /doctoral StudentДокумент19 страницLee R. Madsen II, Research Associate /doctoral StudentSivakumar SelvarajОценок пока нет

- Distillery Sector1Документ32 страницыDistillery Sector1Sivakumar SelvarajОценок пока нет

- Distillery SectorДокумент36 страницDistillery SectorSivakumar SelvarajОценок пока нет

- Drimax 1234 MSDSДокумент8 страницDrimax 1234 MSDSSivakumar SelvarajОценок пока нет

- M/S. Ponni Sugars (Erode) Limtied (Distillery Plant)Документ21 страницаM/S. Ponni Sugars (Erode) Limtied (Distillery Plant)Sivakumar SelvarajОценок пока нет

- ACUMER™ 2000 Phosphate and Zinc Stabilizer: DescriptionДокумент14 страницACUMER™ 2000 Phosphate and Zinc Stabilizer: DescriptionSivakumar Selvaraj100% (1)

- Ugar Sugar DR Pattan ShettyДокумент23 страницыUgar Sugar DR Pattan ShettySivakumar SelvarajОценок пока нет

- Biological Drain Maintenance Systems: ChemsearchДокумент4 страницыBiological Drain Maintenance Systems: ChemsearchSivakumar SelvarajОценок пока нет

- EBPR ProcessДокумент11 страницEBPR ProcessSivakumar SelvarajОценок пока нет

- 5.2 WorkbookДокумент9 страниц5.2 WorkbookKerui BanОценок пока нет

- Interview From Dupty Director Thermal Projects Wapda House Lahor1Документ3 страницыInterview From Dupty Director Thermal Projects Wapda House Lahor1Iqrẵ Šẵjîd KhẵnОценок пока нет

- PMNP 1Документ33 страницыPMNP 1Yang ObreroОценок пока нет

- Class X Subject: Social Science Economics CH 1 Development NotesДокумент10 страницClass X Subject: Social Science Economics CH 1 Development NotesTajinderpal SinghОценок пока нет

- No Penggolongan Tumbuhan Air Nama Ilmiah Tumbuhan Air Nama Lokal Tumbuhan AirДокумент2 страницыNo Penggolongan Tumbuhan Air Nama Ilmiah Tumbuhan Air Nama Lokal Tumbuhan AirAdindaОценок пока нет

- Onboard Water Test Solutions MA-K28450-KWДокумент5 страницOnboard Water Test Solutions MA-K28450-KWPhan Cao An TruongОценок пока нет

- Team 10 Problem Statement Final DraftДокумент9 страницTeam 10 Problem Statement Final Draftapi-732172867Оценок пока нет

- Concrete: The GCCA 2050 Cement and Concrete Industry Roadmap For Net Zero ConcreteДокумент48 страницConcrete: The GCCA 2050 Cement and Concrete Industry Roadmap For Net Zero ConcreteLeicel John BelmesОценок пока нет

- An Evolutionary Conception of Nature ConservationДокумент2 страницыAn Evolutionary Conception of Nature ConservationYannick Ovolo EngongaОценок пока нет

- Call Applications 2022 Unn FДокумент2 страницыCall Applications 2022 Unn FChristiam Hernández PérezОценок пока нет

- The Swedish Sustainable Energy Market Opportunitis and Barriers For New Actors - Samer Al Mimar PDFДокумент102 страницыThe Swedish Sustainable Energy Market Opportunitis and Barriers For New Actors - Samer Al Mimar PDFSamer Al-MimarОценок пока нет

- Nepal College of Information Technology: Hydropower Project - PUWA KHOLA 1, IlamДокумент18 страницNepal College of Information Technology: Hydropower Project - PUWA KHOLA 1, IlamAnurag JoshiОценок пока нет

- Site Visit ReportДокумент10 страницSite Visit ReportKushal ThakkarОценок пока нет

- Summary of The Basic Plan For Food, Agriculture and Rural AreasДокумент40 страницSummary of The Basic Plan For Food, Agriculture and Rural AreasElegant AspireОценок пока нет

- AB 1385 Support Letter From Supervisor V. Manuel PerezДокумент2 страницыAB 1385 Support Letter From Supervisor V. Manuel PerezThe Press-Enterprise / pressenterprise.comОценок пока нет

- Updated Malawis Strategy On Climate Change Learning 2021Документ84 страницыUpdated Malawis Strategy On Climate Change Learning 2021Colin KaduyaОценок пока нет

- RS3853 - Grade - 9 Water Supply and Sanitary EngineeringДокумент166 страницRS3853 - Grade - 9 Water Supply and Sanitary EngineeringVam PiresОценок пока нет

- Red TideДокумент9 страницRed TideKhang KhangОценок пока нет

- CHAPTER 2-Water PollutionДокумент18 страницCHAPTER 2-Water PollutionkhairulhakamОценок пока нет

- Activity Sheet 4 BitangaДокумент1 страницаActivity Sheet 4 BitangaVann AlfredОценок пока нет

- IN Assignment 3Документ2 страницыIN Assignment 3Ritika PrasadОценок пока нет

- T14 05 Visnjic - Minic - GNP2020Документ10 страницT14 05 Visnjic - Minic - GNP2020Kenan KajosevicОценок пока нет

- 7737 (2500 Words)Документ21 страница7737 (2500 Words)haseeb ahmedОценок пока нет

- De Thi Thu Tot Nghiep 2022 Mon Anh Tran Quoc Tuan Lan 3Документ6 страницDe Thi Thu Tot Nghiep 2022 Mon Anh Tran Quoc Tuan Lan 3Ngo Ba ThangОценок пока нет