Академический Документы

Профессиональный Документы

Культура Документы

A3 Sheet - Reduce COPQ

Загружено:

RizkiawanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A3 Sheet - Reduce COPQ

Загружено:

RizkiawanАвторское право:

Доступные форматы

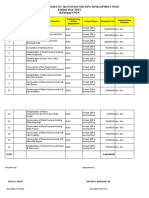

Title: Reduce COPQ by 30% in 6 months Leader: Adi Permana (Black Belt)

A3 Location: UTC Aerospace Bandung Team member: Iman D, Yana W, Wahyu, Lucky, Fian, Satrio, Budi

REPORT Date: Feb 18th, 2016 Mentor: Steve Schady (Master Black Belt)

Background: Future state & Countermesaure

COPQ cost for the line 5 is very high, the cost was around 150,000 USD per year in 2015, this situation is 1). Improvement in MSA

trigerred by many reject/defect product as well as some claim from end of customer. Product delay is 2). TPM implemented in the line

another issue resulted from this situation 3). Operators were trained in TPM, 5S & MSA

4). Regular meeting in shopfloor lead by supervisor

Current condition: 5). Quality audit in place

1). COPQ cost was 150,000 USD per year (2015)

2). Cpk is only 0.72 (<1.0) Impact

1). Reject is reduced significantly

Objective: 2). MSA is improved

1). COPQ cost is < 72,000 USD per year in 2016 3). Cpk achive 1.67

2). Cpk is > 1.3 4). Est COPQ is around 60,000 USD

Root cause analysis:

Follow up

1). Continue to measure MSA regularly (every month)

2). Measure Cpk regularly (every month)

3). Perform 5S & TPM Audit in weekly basis

4). COPQ review in daily and monthly basis

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- User's Manual: FRAX 99/101/150Документ54 страницыUser's Manual: FRAX 99/101/150RizkiawanОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- FRAX Demo Guide: Sweep Frequency Response AnalysisДокумент34 страницыFRAX Demo Guide: Sweep Frequency Response AnalysisveeakumarОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- MRCT User Manual R8 EnglishДокумент141 страницаMRCT User Manual R8 EnglishRizkiawanОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- MRCT User Manual R8 EnglishДокумент141 страницаMRCT User Manual R8 EnglishRizkiawanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Structure Latihan 1,2,3,4Документ47 страницStructure Latihan 1,2,3,4mei-257402Оценок пока нет

- Barber Shop Business Plan ExampleДокумент34 страницыBarber Shop Business Plan ExampleJoseph Quill100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- CPM & Pert-1Документ13 страницCPM & Pert-19923288772Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- 01Документ24 страницы01deepakkumar20002Оценок пока нет

- HIS ModulesДокумент28 страницHIS Modulespriya sainiОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- CVJ 26054757 20190924210440Документ4 страницыCVJ 26054757 20190924210440Ayman RiyadhОценок пока нет

- Chapter 5 - Small BusinessesДокумент13 страницChapter 5 - Small BusinessesKin FallarcunaОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Grant GalanДокумент2 страницыGrant GalanDave Laryll SantosОценок пока нет

- 2011 Administrative Report-FinalДокумент73 страницы2011 Administrative Report-FinalDonna BrodberОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Definition:: Dba 102: Principles of Management Session 1: Intoroduction To ManagementДокумент4 страницыDefinition:: Dba 102: Principles of Management Session 1: Intoroduction To ManagementNilufar RustamОценок пока нет

- 1.2 Project Management FundamentsДокумент43 страницы1.2 Project Management FundamentsVishwas JОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Strategic Management CHAPTER-fiveДокумент27 страницStrategic Management CHAPTER-fivewubeОценок пока нет

- Apqp Pro 8.3 Process Development PlanningДокумент7 страницApqp Pro 8.3 Process Development PlanningMattОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Points - 4 v5Документ119 страницPoints - 4 v5m.awaisuohОценок пока нет

- Aip202320% Development FundДокумент2 страницыAip202320% Development FundRolly SinoyОценок пока нет

- PB13MAT - 13 Project Stakeholder ManagementДокумент30 страницPB13MAT - 13 Project Stakeholder ManagementYudhi ChristianОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Inventory MGT TechniquesДокумент21 страницаInventory MGT TechniquesTambe Chalomine AgborОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Module 6 - Elevator Pitch and SubmissionДокумент13 страницModule 6 - Elevator Pitch and SubmissionIbrahim HabibОценок пока нет

- Segmented Reporting, Investment Center Evaluation, and Transfer PricingДокумент80 страницSegmented Reporting, Investment Center Evaluation, and Transfer PricingHanabusa Kawaii Idou0% (1)

- Chapter 10 - Operations ManagementДокумент9 страницChapter 10 - Operations ManagementAnagha PranjapeОценок пока нет

- Course Outline: General Information About The ExamДокумент2 страницыCourse Outline: General Information About The ExamWajidSyedОценок пока нет

- American Express - Management TraineeДокумент2 страницыAmerican Express - Management TraineeHarshОценок пока нет

- Process and Capacity Analysis: Author: B. Mahadevan Operations Management: Theory and Practice, 3eДокумент47 страницProcess and Capacity Analysis: Author: B. Mahadevan Operations Management: Theory and Practice, 3esunit dasОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Arindam Basu: ResumeДокумент1 страницаArindam Basu: ResumeBhusan PradhanОценок пока нет

- Contact No: 00 91 85477 69130: Arjun KannambathДокумент10 страницContact No: 00 91 85477 69130: Arjun KannambathShankker KumarОценок пока нет

- Continual Service ImprovementДокумент4 страницыContinual Service ImprovementJosh AlmasiОценок пока нет

- Activpack Company ProfileДокумент36 страницActivpack Company ProfileRenzОценок пока нет

- Social Media Marketing A Practitioner GuДокумент1 страницаSocial Media Marketing A Practitioner GuEmrah GulmezОценок пока нет

- Commercial Programming Lecture Notes 2020Документ68 страницCommercial Programming Lecture Notes 2020Kelvin Karis100% (1)

- Brandscape TataSaltДокумент1 страницаBrandscape TataSaltPratik GoenkaОценок пока нет

- AICPA AUD UpdatedДокумент82 страницыAICPA AUD Updatedsagar deep0% (1)