Академический Документы

Профессиональный Документы

Культура Документы

GEKO-EUS-1 en 2011 PDF

Загружено:

Adi PeterfiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GEKO-EUS-1 en 2011 PDF

Загружено:

Adi PeterfiАвторское право:

Доступные форматы

Control Device EUS-1

According to the VOC Directive 94/63/E.C. and

related European standard EN 13922 on Overfill

Prevention Systems for bottom-loading tank trucks

As stationary part of the Euro Overfill Prevention System for

liquid fuels the control device type EUS-1 complies with the

harmonised requirements on overfill prevention systems for

bottom-loading tank trucks according to Annex IV of the

VOC-Directive (directive 94/63/EC). In this directive it was

determined that since 01.01.2005 all bottom-loading gan-

tries for A1 products had to be equipped with an Europe-

wide harmonised overfill prevention controller.

The Control Device type EUS-1 performs in combination

The explosion-proof Control Device type EUS-1 has been with the level sensors on the tank truck the European Over-

developed in full compliance with correlated EN standard fill Prevention System for bottom loading tank trucks in

EN 13922 on “Overfill Prevention Systems for liquid fuels”. accordance with the VOC directive and CENELEC standard

As a result the full compatibility to corresponding truck EN 13922. Up to 8 appropriate two-wire sensors or 12 five-

equipment and level sensors of other manufacturers can be wire sensors can be connected to the control device.

ensured.

Euro Overfill Prevention

Control Device type EUS-

Level sensors on the

As an electrical equipment of the category II (1) 2 G the con- tank truck

1 Steuer- und Messtechnik

Befüllung

trol device type EUS-1 is intended for use in potentially ex-

Stop

Freigabe

Erdung

plosive atmospheres of the zone 1 and supplies the intrinsi-

Status Niveausensoren

1 2 3 4 5 6 7 8

cally energy for the level sensors on the tank truck (zone 0).

Euro-Überfüllsicherung

Steuergerät Typ EUS-1

It has been proofed by an EC type-examination according to

the directive 94/9/E.C. (ATEX 95). The type of protection is

Ex e ib q [ia] IIA T4.

Truck connector shut-off of the product

with coiled cable flow for all compart-

ments

Principle of Operating

During loading the level sensors on the tank truck side (one When being connected to a tank truck, the control

sensor per tank compartment) are connected to the control device automatically recognises the type of level

device at the filling gantry via a standard 10-pole plug and sensors (five-wire / two-wire sensors) and acti-

socket connector. The level sensors are positioned in such a vates the required operating mode.

way that they trigger the shut-off of the product flow for

all compartments via the stationary gantry controller right The vapour recovery hose connection is monitored

in time to prevent an overfilling. Level sensors, cable and on the tank truck side by means of a switching con-

connectors are also specified by the EN standard EN 13 tact looped into the circuit of the level sensors. In

922. addition the control device permanently observes

the correct grounding of the truck, which is carried

out as well by the 10-pole connection cable. As a

result it is ensured that filling is only possible, if the

vapour recovery system and the grounding line are

connected properly.

H. Timm Elektronik GmbH

Humboldtstraße 29 21509 Glinde bei Hamburg

Tel.: +49 40 248 35 63-0 Fax: +49 40 248 35 63-39

www.timm-elektronik.de info@timm-elektronik.de

Special Features Operating data

Type of protection: Ex e ib q [ia] IIA T4

The control device type EUS-1 is equipped with four control

outputs (two potential-free contact outputs and two poten- Device category acc. to ATEX 95: II (1) 2 G

tial-free signal outputs), each optionally switchable to differ- Supply circuit: Type of protection „Increased

ent operating modes. Referring to the control signals the safety“ Ex e, 230 V a.c. ± 6%, 50 – 60 Hz,

control device meets the requirements of the standard for approx. 25 VA

overfill prevention systems and furthermore provides addi-

Protection of enclosure acc. to EN 60529: IP65

tional control signals (e.g. „Earthing O.K.“ or „Truck Connec-

tor in Parking Position“) as well as the possibility of data Ambient temperature range: -25°C to +50°C

communication for an optimum control and signalling during

the filling process via the product managing system.

Output circuits

The analysis of the different control signals enables the Contact circuits (K1, K2): in type of protection

higher product management system to recognise whether a „Increased safety“ Ex e, Maximum values:

filling process is only interrupted due to a removable fault 250 V a.c., 5 A, 100 VA or 250 V a.c., 3 A, cos

(e.g. missing vapour recovery hose connection) or finally 0,7

completed because of an actual overfilling. „Filling Release“ (K1): 1 potential-free closing

contact

According to the standard, the control device type EUS-1

exhibits fail-safe behaviour. A filling release is only possible if „Filling Process“ (K2): 1 potential-free change-

the periodic self-test operates properly. Interruptions or short over contact, configurable by internal switches

circuits in the cabling or in associated components prevent for signalling of „Truck connector in Parking

position“ / „Earthing“

the periodic self-test and thus the filling release.

Contactless control outputs (E1, E2):

The filling status “Permissive” or “Non-Permissive” is indi- in type of protection „Intrinsic Safety“ Ex ib

cated by two large LED-indicators, to be visible in a wide only for connection to certified intrinsically

range. Additional 9 two-colour LED indicators signal the safe circuits with the following maximum val-

”Compartment Status” and the “Earthing Status“. ues: Uo = 20 V, Ik = 163 mA, Po = 815 mW

„Filling Release“ (E1): 1 potential-free output,

oscillating (fail-safe), NAMUR-compatible

„Filling Process“ (E2): 1 potential-free output,

Steuer- und Messtechnik

optionally switchable static or dynamic,

Befüllung

NAMUR-compatible

Stop

Sensor and earthing circuits: in type of protec-

Freigabe tion „Intrinsic Safety“ Ex ia IIA, only for connec-

Erdung

tion to appropriate level sensors maximum 8

Status Niveausensoren two-wire-sensors or maximum 12 five-wire-

1 2 3 4 5 6 7 8

sensors respectively

Serial data interface: in type of protection

Euro-Überfüllsicherung

„Increased Safety“ Ex e, reversible: TTY [pas-

Steuergerät Typ EUS-1

sive] / RS422 / RS 485; As communication pro-

tocol are selectable: DUST 3964R or AMCC-

Protocol

Weight and dimensions

Dimensions: 230 x 475 x 135 mm (L x H x D)

Weight: approx. 12 kg

H. Timm Elektronik GmbH

Humboldtstraße 29 21509 Glinde bei Hamburg

Tel.: +49 40 248 35 63-0 Fax: +49 40 248 35 63-39

www.timm-elektronik.de info@timm-elektronik.de

Truck Coiled Cable type EUS-1-SSK3 with

Accessories for the EUS-1 device disconnector plug

The following types of connecting leads with standard

truck connector and intrinsically safe disconnector sockets

are available:

Truck Coiled Cable type EUS-1-SK7:

Truck connector with PUR coiled cable (blue), overall cable

length approx. 2.6 m, expandable to approx. 7 m;

for direct connection to the control device.

Ex-i-Disconnector Socket type EUS-1-ST:

Disconnector socket (to be installed at the filling station) to

connect a plug-in coiled cable type EUS-1-SSK3 or EUS-1-SSK7.

Socket complete with normal 1 m tail cable for connection to

the control device.

Ex-i-Disconnector Socket type EUS-1-STP:

As previous, but with additional truck socket for recognition

of the „Truck Connector in Parking Position“ status by inte-

grated socket code generator.

Truck Coiled Cable type EUS-1-SSK7:

As type EUS-1-SK7, but with additional disconnector plug for

connection to socket EUS-1-ST or EUS-1-STP respectively.

Truck Coiled Cable type EUS-1-SSK3:

As type EUS-1-SSK7, but with short coiled cable. Normal

cable length approx. 1.5 m, expandable to approx. 3.5 m; Ex-i-Disconnector Socket type EUS-1-STP

preferably in combination with disconnector socket type with additional truck socket for recognition of the

EUS-1-STG... on loading arm. „Truck Connector in Parking Position“ status

Ex-i-Disconnector Socket type EUS-1-STG11:

Disconnector socket on loading arm (close to coupling)

to connect the plug-in coiled cable type EUS-1-SSK3.

With normal 11 m tail cable for installation on the vapour

recovery arm and to the control device.

Ex-i-Disconnector Socket type EUS-1-STG11P:

As previous, but with additional truck socket for recognition

of the „Truck Connector in Parking Position“ status by inte-

grated socket code generator.

Testing Equipment type EUS-1-TST2:

The testing equipment serves to check the functions of

the control device. It is provided with a truck socket to be

connected to the truck connector cable as well as with ap- Testing Equipment type EUS-1-TST2

propriate testing switches to simulate the criteria Earthing,

Vapour Recovery Hose Connection and Sensor Status.

H. Timm Elektronik GmbH

Humboldtstraße 29 21509 Glinde bei Hamburg

Tel.: +49 40 248 35 63-0 Fax: +49 40 248 35 63-39

www.timm-elektronik.de info@timm-elektronik.de

Certificates of the control device EUS-1

Safety Certificate in accordance with national

EC Type Examination Certificate according to regulations relating to the preservation of

directive ATEX 95: water against pollution with fuels:

H. Timm Elektronik GmbH

Humboldtstraße 29 21509 Glinde bei Hamburg

Tel.: +49 40 248 35 63-0 Fax: +49 40 248 35 63-39

www.timm-elektronik.de info@timm-elektronik.de

Вам также может понравиться

- Tohatsu 2 Stroke Service Manual 1992 2000Документ329 страницTohatsu 2 Stroke Service Manual 1992 2000Adi Peterfi97% (38)

- T1N Body Electrical Diagnostic Training Manual PDFДокумент94 страницыT1N Body Electrical Diagnostic Training Manual PDFAdi Peterfi100% (1)

- ASSIGNMENT 3 - Security Alarm SystemДокумент9 страницASSIGNMENT 3 - Security Alarm SystemTalha Yazdani100% (1)

- Diy VP44 Repair PDFДокумент1 страницаDiy VP44 Repair PDFOvidio Rios67% (3)

- Diy VP44 Repair PDFДокумент1 страницаDiy VP44 Repair PDFOvidio Rios67% (3)

- 117 Mitsubishi Triton KA4 KB4 KB8 Factory Service ManualДокумент558 страниц117 Mitsubishi Triton KA4 KB4 KB8 Factory Service Manualโจ้ สแปร์แร็ค91% (44)

- EPC bid document electrical equipment price summaryДокумент64 страницыEPC bid document electrical equipment price summaryVimal Singh0% (1)

- Control Device Ensures Safe Fuel LoadingДокумент4 страницыControl Device Ensures Safe Fuel Loadingechi_maniezz8719Оценок пока нет

- Autopulse Z-20 Data Sheet T-2016171Документ14 страницAutopulse Z-20 Data Sheet T-2016171Javier ToscanoОценок пока нет

- V450-650 PFC UNIT Instructions Manual (May-04)Документ4 страницыV450-650 PFC UNIT Instructions Manual (May-04)EddyОценок пока нет

- LPG Installation Manual for AC STAG Diesel ControllerДокумент41 страницаLPG Installation Manual for AC STAG Diesel ControllerAdi PeterfiОценок пока нет

- Komatsu Pc200en Pc200el-6Документ671 страницаKomatsu Pc200en Pc200el-6Adi Peterfi92% (37)

- BMP en fst2xt 201610Документ11 страницBMP en fst2xt 201610Kemal DemОценок пока нет

- Overfill Prevention Sensor ProductflyerДокумент2 страницыOverfill Prevention Sensor Productflyermajdmanhal11Оценок пока нет

- Controlled Grounding Device Ensures Safe Filling ProcessesДокумент10 страницControlled Grounding Device Ensures Safe Filling Processesel misОценок пока нет

- MAIN/BUS control switch procedureДокумент1 страницаMAIN/BUS control switch procedureenambimanbdОценок пока нет

- Level Measurement For Safeguarding ApplicationДокумент1 страницаLevel Measurement For Safeguarding ApplicationrenvОценок пока нет

- Tanker Overfill Systems, Bisens PDFДокумент2 страницыTanker Overfill Systems, Bisens PDFant29539432Оценок пока нет

- Safety System, Total Crane Control - TCC, 10-13Документ34 страницыSafety System, Total Crane Control - TCC, 10-13Krum KashavarovОценок пока нет

- FIRE ALARM SYSTEM 16721Документ10 страницFIRE ALARM SYSTEM 16721m.abdelsalam772570Оценок пока нет

- Labcontrol enДокумент19 страницLabcontrol enIvanОценок пока нет

- LQR 1Документ4 страницыLQR 1ananОценок пока нет

- K-Gauge Hla 600: Independent High Level and Overfill Alarm SystemДокумент4 страницыK-Gauge Hla 600: Independent High Level and Overfill Alarm SystemPavel ViktorОценок пока нет

- Vapor Liquid SequenceДокумент11 страницVapor Liquid SequencecemsavantОценок пока нет

- Brochure Ex-P Pressurized Enclosure System Zone1 f850sДокумент6 страницBrochure Ex-P Pressurized Enclosure System Zone1 f850ssaman749Оценок пока нет

- LEC1Документ17 страницLEC1christophermrequintoОценок пока нет

- Sil AtexДокумент6 страницSil AtexEfari BahcevanОценок пока нет

- 7ML19981GC61 1Документ59 страниц7ML19981GC61 1Andres ColladoОценок пока нет

- ECOM Installation & Operators Manual V1.1Документ23 страницыECOM Installation & Operators Manual V1.1Phong TrầnОценок пока нет

- SIMOCODE-DP Motor Protection and Control DevicesДокумент16 страницSIMOCODE-DP Motor Protection and Control DeviceschochoroyОценок пока нет

- 9.8 Inverter Transformer Station (ITS) : 9.8.1 EnclosureДокумент7 страниц9.8 Inverter Transformer Station (ITS) : 9.8.1 Enclosurekser82Оценок пока нет

- Altronic EPC100E Brochure PDFДокумент4 страницыAltronic EPC100E Brochure PDFpspsuparingОценок пока нет

- 16-Remote Control and Electrical Equipment-02Документ14 страниц16-Remote Control and Electrical Equipment-02Grisha Mari KosoyanОценок пока нет

- AemaestroДокумент22 страницыAemaestroCharefОценок пока нет

- Gd-Boiler Rooms PDFДокумент6 страницGd-Boiler Rooms PDFpasckyОценок пока нет

- Siemens LFE1 Data SheetДокумент14 страницSiemens LFE1 Data SheetJosé Fabio Lou0% (1)

- SECTION 16721 Fire Alarm SystemДокумент8 страницSECTION 16721 Fire Alarm Systemahmed fouadОценок пока нет

- Pac ExДокумент8 страницPac Exs.kurpishОценок пока нет

- Valve Actuation at The World's Largest Flow Metering: Calibration FacilityДокумент5 страницValve Actuation at The World's Largest Flow Metering: Calibration FacilityFelipe Gamboa GálvezОценок пока нет

- BRAHMA Control de Llama MPIДокумент5 страницBRAHMA Control de Llama MPIAriel SantambrosioОценок пока нет

- ACTech Ltd Cargo Hold Water Ingress Detection and Monitoring SystemДокумент3 страницыACTech Ltd Cargo Hold Water Ingress Detection and Monitoring SystemhoangductuanОценок пока нет

- 02 Exhibit I ServicesДокумент27 страниц02 Exhibit I ServicestungluongОценок пока нет

- Data Sheet for High-Level Alarm Level Switch NRS 1-51Документ2 страницыData Sheet for High-Level Alarm Level Switch NRS 1-51roni kurniawanОценок пока нет

- Extinguishing Panel 8010: Integrated Solution For More EfficiencyДокумент4 страницыExtinguishing Panel 8010: Integrated Solution For More EfficiencymotaОценок пока нет

- ElemecPlusOffshoreGOM 1545370402 PDFДокумент5 страницElemecPlusOffshoreGOM 1545370402 PDFPoy NainggolanОценок пока нет

- N6873e EpacДокумент10 страницN6873e EpacEdyson91Оценок пока нет

- Emergency Locator Transmitter: Aircraft Distress Signal Device (ELTДокумент33 страницыEmergency Locator Transmitter: Aircraft Distress Signal Device (ELTH R VALAОценок пока нет

- TC 6Документ180 страницTC 6Pankaj kumarОценок пока нет

- Technical Specification For Tender No - NFC/HRPU/PT/MIA/1315Документ4 страницыTechnical Specification For Tender No - NFC/HRPU/PT/MIA/1315tetrixОценок пока нет

- EL6010 Gas Analyzers: The Specialists For Hazardous AreasДокумент4 страницыEL6010 Gas Analyzers: The Specialists For Hazardous AreaswhitelmzОценок пока нет

- LFL Gas Burner ControlДокумент26 страницLFL Gas Burner ControlRoyalty GouldОценок пока нет

- (Echo Sounder) Laz5100elac-E Feb 03Документ79 страниц(Echo Sounder) Laz5100elac-E Feb 03Howo4DieОценок пока нет

- Ritzbrochure - PQ Sensors To Be Used With PQ AnalysersДокумент4 страницыRitzbrochure - PQ Sensors To Be Used With PQ AnalysersKelly chatОценок пока нет

- Strulik Fire Prevention Part VДокумент22 страницыStrulik Fire Prevention Part VNenad MutavdzicОценок пока нет

- EMG ManualДокумент2 страницыEMG ManualOmar Manzano CaceresОценок пока нет

- Instruction Manual FLA3.1-product-line Expert Menu Rev2e PDFДокумент2 страницыInstruction Manual FLA3.1-product-line Expert Menu Rev2e PDFOmar Manzano CaceresОценок пока нет

- Error Detector and Controller OverviewДокумент11 страницError Detector and Controller OverviewRaymond FuentesОценок пока нет

- SOW N-1 Fire System UpgradeДокумент5 страницSOW N-1 Fire System UpgradeHashemAliHashemОценок пока нет

- Al Sadd Complex Fire Strategy Report Rev 1Документ16 страницAl Sadd Complex Fire Strategy Report Rev 1sameh100% (2)

- Easylab: Controller TCU3Документ20 страницEasylab: Controller TCU3mdalt9180Оценок пока нет

- Auto Helm 6000 Stern DriveДокумент38 страницAuto Helm 6000 Stern DriveLin LinОценок пока нет

- Techrite Siemens Siemens Lme Series Burner Controls 013060320901Документ28 страницTechrite Siemens Siemens Lme Series Burner Controls 013060320901Kang KamalОценок пока нет

- Oil Burner Manual Provides Safety and Installation InstructionsДокумент6 страницOil Burner Manual Provides Safety and Installation InstructionsBerhanu GebreyohannesОценок пока нет

- ICF - Control Panel - Manual (1999)Документ27 страницICF - Control Panel - Manual (1999)sangramjitОценок пока нет

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageОт EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Operating Instructions Heater Test Bench ENGДокумент32 страницыOperating Instructions Heater Test Bench ENGAdi PeterfiОценок пока нет

- Regulators r5 Ice SeriesДокумент2 страницыRegulators r5 Ice SeriesAdi PeterfiОценок пока нет

- Blending Systems European MarketДокумент4 страницыBlending Systems European MarketCarlos TorresОценок пока нет

- Regulators r5 Ice SeriesДокумент2 страницыRegulators r5 Ice SeriesAdi PeterfiОценок пока нет

- Control Overfill Prevention SystemsДокумент4 страницыControl Overfill Prevention SystemsAdi Peterfi100% (1)

- Portable Toilet ManualДокумент124 страницыPortable Toilet ManualAdi PeterfiОценок пока нет

- Group Tab Locator: Service Manual Comment Forms (Rear of Manual)Документ1 232 страницыGroup Tab Locator: Service Manual Comment Forms (Rear of Manual)Adi PeterfiОценок пока нет

- Dive Xtras X-Scooter Owner's ManualДокумент23 страницыDive Xtras X-Scooter Owner's ManualAdi PeterfiОценок пока нет

- Workshop Manual Table of Contents and FiguresДокумент114 страницWorkshop Manual Table of Contents and FiguresAUDRANОценок пока нет

- Measuring GuideДокумент2 страницыMeasuring GuideAdi PeterfiОценок пока нет

- Measuring GuideДокумент2 страницыMeasuring GuideAdi PeterfiОценок пока нет

- OUTLET 11.5.2020 - Diving 700Документ6 страницOUTLET 11.5.2020 - Diving 700Adi PeterfiОценок пока нет

- Sprinter Switch TableДокумент2 страницыSprinter Switch TableAdi PeterfiОценок пока нет

- Accuload III Installation Manual PDFДокумент94 страницыAccuload III Installation Manual PDFJim HerwigОценок пока нет

- flashing-BV6000 v4 PDFДокумент1 страницаflashing-BV6000 v4 PDFAdi PeterfiОценок пока нет

- ENA Assessed Switchgear July 2016Документ9 страницENA Assessed Switchgear July 2016AleksandraОценок пока нет

- Group - 6-Experiment 7Документ14 страницGroup - 6-Experiment 7Jerome NuevoОценок пока нет

- DC Electric Machine Drives ChapterДокумент59 страницDC Electric Machine Drives ChapterAnonymous AFFiZnОценок пока нет

- Ib33 790 1 PDFДокумент96 страницIb33 790 1 PDF322399mk7086Оценок пока нет

- Power Electronics SolutionsДокумент19 страницPower Electronics SolutionsRhiza Navallasca0% (2)

- Machine Lab 1Документ7 страницMachine Lab 1Taha Al-sprieОценок пока нет

- Pub 4269Документ525 страницPub 4269Luis TavisОценок пока нет

- Anton A 06Документ82 страницыAnton A 06Daniel Rey ReyОценок пока нет

- Cat - Dcs.sis - Controller (12H - 8MN)Документ2 страницыCat - Dcs.sis - Controller (12H - 8MN)Warley Moraes Oliveira100% (1)

- Payback Analysis For MR ROLANDO GARCIA: Annual Electricity Production 8700Документ1 страницаPayback Analysis For MR ROLANDO GARCIA: Annual Electricity Production 8700Peter VukovicОценок пока нет

- Standard Operating Procedure For Captive Power Plants Utilizing Coal Allotted Under SHAKTI B (Ii)Документ11 страницStandard Operating Procedure For Captive Power Plants Utilizing Coal Allotted Under SHAKTI B (Ii)soumitrabanОценок пока нет

- Three Ways To Control A Single-Phase Induction Motor PDFДокумент5 страницThree Ways To Control A Single-Phase Induction Motor PDFBook4All100% (2)

- ECP 11-0008 LV Cable Testing ProcedureДокумент9 страницECP 11-0008 LV Cable Testing Procedurerobertovm2002Оценок пока нет

- SG20KTL Data SheetДокумент2 страницыSG20KTL Data SheetPaulo Cesar M CostaОценок пока нет

- 08a App751 Synchcheckprotection r9 PDFДокумент16 страниц08a App751 Synchcheckprotection r9 PDFabdelmouen larfiОценок пока нет

- Estimation of Motor ParametersДокумент6 страницEstimation of Motor ParametersAlvinMaghirangОценок пока нет

- FramesДокумент120 страницFramesqbit42Оценок пока нет

- Precommissioning Check of H.V., Indoor Board L.V. Power Control CentreДокумент3 страницыPrecommissioning Check of H.V., Indoor Board L.V. Power Control CentreShameer BasheerОценок пока нет

- Electrical Service Manual Original Manual Issue Date: 4/2010Документ51 страницаElectrical Service Manual Original Manual Issue Date: 4/2010Marcyo LimaОценок пока нет

- Annunciator SДокумент4 страницыAnnunciator Sali_107Оценок пока нет

- ELEC3203 M1 OverviewOfElectricPowerSystemsДокумент28 страницELEC3203 M1 OverviewOfElectricPowerSystemsNameОценок пока нет

- Testing & Commissioning ManualДокумент37 страницTesting & Commissioning ManualVenkata Raja Suresh J100% (2)

- 1000kw Industrial Generator Set Weichai Baudouin)Документ2 страницы1000kw Industrial Generator Set Weichai Baudouin)Vyrax FalconОценок пока нет

- 2010-08-20 001234 M11Code434TroubleshootingДокумент13 страниц2010-08-20 001234 M11Code434TroubleshootingVictor Hugo Benitez Paez100% (1)

- Supreme Stitch Ltd. 264 kW Roof-Top Solar Project LayoutДокумент1 страницаSupreme Stitch Ltd. 264 kW Roof-Top Solar Project LayoutParesh Chandra DebnathОценок пока нет

- Zelio Relay - RXM2LB2BDДокумент7 страницZelio Relay - RXM2LB2BDTrần Anh LuậtОценок пока нет

- Advance PP3 Twin DC SupplyДокумент13 страницAdvance PP3 Twin DC SupplyJohn DosherОценок пока нет

- CT PTCalculationsДокумент79 страницCT PTCalculationsRK KОценок пока нет

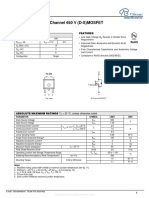

- N-Channel 0 V (D-S) Mosfet: Features Product SummaryДокумент9 страницN-Channel 0 V (D-S) Mosfet: Features Product SummaryJakson Kley SantosОценок пока нет