Академический Документы

Профессиональный Документы

Культура Документы

SpinChem ApplicationNote 1029

Загружено:

Harsh Kabra0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров2 страницыОригинальное название

SpinChem-ApplicationNote-1029

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

21 просмотров2 страницыSpinChem ApplicationNote 1029

Загружено:

Harsh KabraАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

SpinChem® Application Note No.

1029

Effects of channelling on flow

rates through rotating bed

reactors and fixed bed reactors

The performance and robustness of the rotating bed reactor (RBR) technology was examined

and compared to a fixed bed reactor (FBR) using fluid dynamics simulations in ANSYS

Fluent. By means of flow simulations through loosely packed beds, the RBR was found to be

extremely robust with respect to the density of the packed solid phase bed within. Adverse

effects of channelling that can occur in non-optimally packed fixed beds had very little impact

on the performance of the RBR. The FBR was found to be affected negatively by channelling,

with very poor performance for non-optimally solid phase packing. This explains why the

SpinChem® RBR can be used with great results even when not fully packed, something that

generally entails major problems for an FBR set-up.

Keywords: Simulation, Technology, Easy handling

A common issue faced with when utilizing fixed bed reactors a) b)

(FBR) for heterogeneous reactions is a phenomenon known

as channelling. This is caused by uneven packing of the

solid phase material in the column. In parts of the column

where the solid material is loosely packed, the liquid being

pumped through will experience less resistance, leading to

a higher flow rate. This means that the liquid parcels will c)

favour this route over one containing more densely packed

material. The liquid will thus pass through void regions in

the bed rather than in the proximity of the packed material,

greatly reducing the performance of the set-up.

Fig 1. a) SpinChem® rotating bed reactor, model S2, open at top.

The rotating bed reactor (RBR) technology is an innovative

b) RBR S2, open at top, top view. c) One compartment of the RBR

alternative to conventional methods, such as FBRs, for divided into two parts, used as the geometry for the packed bed in

heterogeneous reactions. The RBR consists of a hollow the flow simulations. One half was simulated as optimally packed,

and one half was simulated with varying degrees of packing.

cylinder into which the solid phase is packed and contained.

As the RBR is rotated in solution, the centrifugal forces

pumped through the FBR for all degrees of packing. This

created by the rotary movement will drive the flow of liquid

represents a typical FBR operation at fixed flow rate. The

through the filters of the RBR and the packed bed within

simulated bed was in both cases split into two halves so

repeatedly at high flow rates.

that a loosely packed region could be modelled alongside

In this application note, simulations were carried out in an optimally packed region. By simulating alternations

ANSYS Fluent to determine the impact that channelling in the packing density in the loosely packed half, and

in a section of the RBR had on flow performance of the observing the flow rate in the optimally packed half, the

reactor set-up, relative to that of an FBR. For an equitable effect of channelling could be monitored for the different

comparison, the same geometry and flow rate were used reactor types. Different packing densities were simulated

for simulations of a spinning RBR and a stationary FBR. The by changing the relative permeability coefficient of the

flow rate determined for the RBR at optimal packing was loosely packed half of the bed.

SpinChem® Application Note No. 1029; ”Effects of channelling on flow…” Printed 2018-06-12

It was found that the volumetric flow rate through the

optimally packed half of the solid phase bed in the RBR

decreased by <0.1% when the specific permeability

coefficient of the loosely packed half of the bed was

increased to 133% of the reference value. This was done

to simulate the effect of moderate channelling, and the

corresponding value for the FBR was a 15% decrease

in flow rate. The specific permeability coefficient in the

region with channelling was also increased to 200% with

respect to the reference value, corresponding to severe

channelling. In this case the volumetric flow rate in the

optimally packed region of the RBR was <0.5% lower than

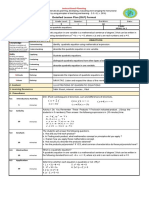

Level of Relative Relative Relative

in the reference case, while the corresponding flow rate for channelling specific volumetric volumetric

the FBR dropped by 33% compared to the reference value. permeability flow rate flow rate

RBR FBR

None 100% 100 100

Moderate 133% >99 85

Severe 200% >99 67

Fig 3. Diagram and table showing the effect of channelling on

the flow rate through a packed bed inside an RBR and FBR,

respectively. Homogeneous packing was simulated by assigning

the region a specific permeability coefficient corresponding to

that of an ion exchange resin of uniform particle size. This value

served as a reference value for the simulations, and corresponds

to a pressure drop of 0.054 bar/m for water at 20°C with a

linear velocity of 1 mm/s. Moderate and severe channelling was

assigned specific permeability values corresponding to 133%

Fig 2. Schematic representation of flow rates in the two halves and 200% of that of the reference, respectively.

of the simulated bed for an RBR and an FBR at different levels

of packing. One half was simulated as optimally packed (top half

in figure), while one half was simulated with varying degrees of of the optimally packed bed will stay unchanged even as

packing (bottom half). the flow rate through the loosely packed half increases.

For the FBR, the overall volume flowing through the bed

The optimally packed half of the simulated bed for the RBR is constant, and will thus be redistributed over all the

was not affected by the higher flow rate through the loosely points of the bed as channelling occurs. A higher specific

packed half. For the FBR, the flow rate through the optimally permeability in one part of the bed due to channelling

packed half of the bed decreased as the flow rate through will lead to lower flow rate in parts with a lower specific

the other half increases due to looser packing of material. permeability.

The differences observed for the RBR and FBR implies

Conclusion:

that the performance of the RBR will not be significantly

affected by the level of flow channelling, while the FBR is • The performance of an RBR is very robust and will

greatly affected. This can be explained by the fact that the not be significantly affected by channelling due to a

overall flow through an RBR will increase as channelling loosely packed bed, while the performance of an FBR

occurs, meaning that the flow through a specific point set-up is significantly diminished by channelling.

The SpinChem® rotating bed reactor (RBR) technology is revolutionizing mass transfer in heterogeneous

reactions where solid phases are used for catalysis, enzymatic reactions, adsorption, scavenging and other

processes. The convenience of a protected bed within an RBR significantly reduce the need for post-reaction

work-up. The SpinChem® RBR concept is fully scalable from laboratory to production, thus providing both

more efficient reaction development and improved production economy.

SpinChem AB, Tvistevägen 48, SE-907 36 Umeå, Sweden

+46 (0)90 19 25 01 | info@spinchem.com | www.spinchem.com

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Music: Teachers ManualДокумент208 страницMusic: Teachers Manualmydrina100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- IQan Trouble Shooting-RockДокумент20 страницIQan Trouble Shooting-RockВячеслав РубцовОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- PlaxisДокумент6 страницPlaxisRehan HakroОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Astm c1060Документ6 страницAstm c1060jorgeОценок пока нет

- Calin o An Informal Introduction To Stochastic Calculus WithДокумент331 страницаCalin o An Informal Introduction To Stochastic Calculus Withjldelafuente100% (5)

- Solutions Manual 4th EditionДокумент57 страницSolutions Manual 4th Editionabdul5721100% (6)

- Artificial Intelligence - EdurekaДокумент37 страницArtificial Intelligence - EdurekaTechnical NoviceОценок пока нет

- 6-Heat Transfer in Multi Phase Materials PDFДокумент460 страниц6-Heat Transfer in Multi Phase Materials PDFJoselinaSosaZavalaОценок пока нет

- iPLON ProfileДокумент11 страницiPLON Profilesudhirm16Оценок пока нет

- Madanapalle Institute of Technology & ScienceДокумент40 страницMadanapalle Institute of Technology & ScienceRavikanth NssОценок пока нет

- Chan SHP Final-NolinksДокумент3 страницыChan SHP Final-NolinksaliОценок пока нет

- Second Periodical ExamДокумент19 страницSecond Periodical ExamMaynard Lee Estrada GomintongОценок пока нет

- FMS 304 Research Methodology - 0 PDFДокумент188 страницFMS 304 Research Methodology - 0 PDFvicky100% (2)

- Book 1Документ6 страницBook 1Team UnitedОценок пока нет

- Man Act GB Vec211r4Документ218 страницMan Act GB Vec211r4Román AndrésОценок пока нет

- As Level Biology Summary Notes (2022-2024 Syllabus)Документ5 страницAs Level Biology Summary Notes (2022-2024 Syllabus)ElisaОценок пока нет

- G. Measurement of Angles and DirectionsДокумент3 страницыG. Measurement of Angles and DirectionsJasleneDimarananОценок пока нет

- Tutorial Module 3Документ24 страницыTutorial Module 3erieshaОценок пока нет

- Elogic Learning Use Case Scenarios TemplateДокумент206 страницElogic Learning Use Case Scenarios TemplatepuuziОценок пока нет

- Tutorial 4Документ3 страницыTutorial 4chinnu rokzОценок пока нет

- Predictive Data Mining and Discovering Hidden Values of Data WarehouseДокумент5 страницPredictive Data Mining and Discovering Hidden Values of Data WarehouseLangit Merah Di SelatanОценок пока нет

- Lecture 3 - Enzyme and Enzyme Kinetics PDFДокумент8 страницLecture 3 - Enzyme and Enzyme Kinetics PDFJulius BersabeОценок пока нет

- DRV8353Документ92 страницыDRV8353Lu HoaОценок пока нет

- Long-Range DependenceДокумент3 страницыLong-Range Dependencewoodword99Оценок пока нет

- 634904411345780000Документ24 страницы634904411345780000chintan kapadiaОценок пока нет

- Mid-Semester Paper 09Документ2 страницыMid-Semester Paper 09Harsh ThakurОценок пока нет

- NTPC Nabinagar BiharДокумент3 страницыNTPC Nabinagar BiharTECH FoReVerОценок пока нет

- Detailed Lesson Plan (DLP) Format: Nowledge ObjectivesДокумент2 страницыDetailed Lesson Plan (DLP) Format: Nowledge ObjectivesErwin B. NavarroОценок пока нет

- ACC20 Engine Safety UnitДокумент2 страницыACC20 Engine Safety UnitVictor EugenОценок пока нет