Академический Документы

Профессиональный Документы

Культура Документы

Oil List - Compressor HSC - 20142

Загружено:

ironiteОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oil List - Compressor HSC - 20142

Загружено:

ironiteАвторское право:

Доступные форматы

Lubricating instructions for screw

compressors, Type HSC 177469

1. General

Moving parts require the correct lubricant. Good quality lubrication oils increase the service life of

the compressor.

Please note: only the lubrication oil manufacturer knows his products thoroughly. Therefore, it is

advisable to contact him when making your choice.

Ask only the lubricant manufacturer for his recommendation! He is the expert.

2. Lubrication Oil Quality

Above all, compressor oils must have good lubrication properties for which their viscosity is highly

important. HATLAPA recommends lubrication oils within the following range:

ambient temperature 0 .. +25 °C constantly over 25 °C

(engine room of sea going ships)

viscosity class ISO VG 68

. ISO VG 46

viscosity at 40°C 41 .. 51 mm2/s 61 .. 75 mm2/s

flash point > 200 °C > 200 °C

pourpoint at least 5 °C under the lowest

ambient temperature

The screw compressor oils should have low tendency to ageing and foaming.

3. Guarantee

If lubrication oils are used which do not meet the requirements, damage to the compressor may

occur. This damage is not covered by HATLAPA's guarantee obligations.

4. Lubricant Examples

The following oils are examples which comply with the above specification:

BP ENERSYN RC-S 68

CASTROL AIRCOL SR-68

CHEVRON TEXACO (FAMM) CETUS PAO 68

TOTAL (LUBMARINE) BARELF SM-68 / DACNIS-68

ESSO (ExxonMobil Marine) RARUS SHC-1026

MOBIL (ExxonMobil Marine)

SHELL CORENA AS-68

However, the oil properties are subject to change without notice by the

oil manufacturer. Also, the oil characteristics may vary depending on the

regional market. Therefore this list does not release the operator of the

compressor from verifying that the selected oil complies with the above

specification.

Rev. 2014-09-04 1/1

Вам также может понравиться

- Ose 5-91 2066-9001-200-Im PDFДокумент210 страницOse 5-91 2066-9001-200-Im PDFironite100% (1)

- Ushio ReinetsuДокумент1 страницаUshio Reinetsuironite100% (2)

- Chapter 02 PDFДокумент12 страницChapter 02 PDFshahin gholamiОценок пока нет

- Lube Oil SystemДокумент3 страницыLube Oil SystemCharan Kumar100% (1)

- 6 Cyl and Packing LubricationДокумент10 страниц6 Cyl and Packing LubricationMohamed Nagim Cheikh AhmedОценок пока нет

- LUB OILS NOHAB W25 W25SG W25DF 9193911800eДокумент2 страницыLUB OILS NOHAB W25 W25SG W25DF 9193911800eLIVIA100% (2)

- Oil - Program Vilter PDFДокумент92 страницыOil - Program Vilter PDFRicardoОценок пока нет

- Automatic Lubrication Manual Sandvik PrimaryДокумент10 страницAutomatic Lubrication Manual Sandvik PrimaryBalaji Kakade100% (1)

- Technical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air CompressorsДокумент2 страницыTechnical Topic Procedure For Flushing Oil-Flooded Rotary Screw Air Compressorsdhavit wijayantoОценок пока нет

- LTB-26 Lubricant Storage, Stability and Shelf Life 120120Документ3 страницыLTB-26 Lubricant Storage, Stability and Shelf Life 120120Jorge Flores BarzolaОценок пока нет

- AEROSHELL 33 - DatasheetДокумент2 страницыAEROSHELL 33 - DatasheetJohn DochertyОценок пока нет

- AeroShell Grease 33 PDFДокумент2 страницыAeroShell Grease 33 PDFAnonymous oAbjbl4HОценок пока нет

- Oil Recommendation For TMC CompressorsДокумент1 страницаOil Recommendation For TMC CompressorsFilipposОценок пока нет

- Lubricating Oils: 3-1. Oil RefiningДокумент7 страницLubricating Oils: 3-1. Oil RefiningJerome Christopher Gacusan IdioОценок пока нет

- Lub-Oil en 1602Документ19 страницLub-Oil en 1602Raúl Oscar LedesmaОценок пока нет

- Lubrication Systems: A. Principies of Engine LubricationДокумент36 страницLubrication Systems: A. Principies of Engine LubricationMiguelОценок пока нет

- AeroShell Grease 33 (en-GB) TDSДокумент2 страницыAeroShell Grease 33 (en-GB) TDSduy tanОценок пока нет

- Transmisión Reintjes LAF 1173 - Manual de LubricantesДокумент2 страницыTransmisión Reintjes LAF 1173 - Manual de LubricantesJorge Arrieta TorresОценок пока нет

- (SAUER Compressor) Oil RecommendationДокумент19 страниц(SAUER Compressor) Oil RecommendationEvandro LaureanoОценок пока нет

- Cotta Transfer Case Lube PlanДокумент3 страницыCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichОценок пока нет

- Oilrecommendations For Two Stage CompressorsДокумент1 страницаOilrecommendations For Two Stage CompressorsogmОценок пока нет

- Hydraulic OilsДокумент5 страницHydraulic OilsBenjamín GerpeОценок пока нет

- Flender Gearbox Lubricant 7300 (En)Документ28 страницFlender Gearbox Lubricant 7300 (En)samer salamehОценок пока нет

- Sauer-Compressors: Oil RecommendationДокумент19 страницSauer-Compressors: Oil Recommendationigor.kokorsciyОценок пока нет

- #1 OilДокумент41 страница#1 Oilcoordinadortecnicotravel1Оценок пока нет

- Lubrication Oils and AdditivesДокумент12 страницLubrication Oils and AdditivesavciayОценок пока нет

- Aeropress XR 46Документ1 страницаAeropress XR 46NESОценок пока нет

- Ga Aeon Fam 1st 1 14Документ8 страницGa Aeon Fam 1st 1 14Vfuentes14Оценок пока нет

- Section 3Документ18 страницSection 3Yurvis VasquezОценок пока нет

- Falk Series C, E, F, G, J, P, Q, S, Y Gear Drives - Service ManualДокумент4 страницыFalk Series C, E, F, G, J, P, Q, S, Y Gear Drives - Service ManualJorge Iván Carbajal100% (1)

- Compressor Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Min. Description / ApplicationДокумент2 страницыCompressor Oils: Product Kin. Viscosity CST at 40 Vi Min. Flash Point Coc, Min. Description / ApplicationmdkhandaveОценок пока нет

- 2915 8275 00 - Fluids and Lubricants - 2017Документ20 страниц2915 8275 00 - Fluids and Lubricants - 2017GuptaОценок пока нет

- EN 2 1 Spec Withoutrail Rev16 2018 12 18Документ10 страницEN 2 1 Spec Withoutrail Rev16 2018 12 18deni jakaОценок пока нет

- Epiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Документ12 страницEpiroc: Fluids and Lubricating Greases Drilling Solutions (Nanjing)Bontor TuaОценок пока нет

- Di̇zel MotorlarДокумент8 страницDi̇zel MotorlarhuseynseymenОценок пока нет

- 08 A Lubrication - Coollant - en - RДокумент6 страниц08 A Lubrication - Coollant - en - Rp_jankoОценок пока нет

- Cylinder and Packing LubeДокумент6 страницCylinder and Packing LubemadhancairnОценок пока нет

- Oil Compressor Brochure-1-3Документ3 страницыOil Compressor Brochure-1-3fauzan datasheetОценок пока нет

- Transformer Oil Used in LocoДокумент17 страницTransformer Oil Used in LocoArun DharmikОценок пока нет

- Turbine LubricationДокумент3 страницыTurbine Lubricationpeach5Оценок пока нет

- InfoДокумент2 страницыInfoFlota PacualesОценок пока нет

- 2.5 Lubrication System - NotesДокумент6 страниц2.5 Lubrication System - NotesAustin ChechecheОценок пока нет

- Servosystem HLPДокумент1 страницаServosystem HLPAdari SagarОценок пока нет

- Section 5 - LubricationДокумент7 страницSection 5 - LubricationJulio Chapilliquen SandovalОценок пока нет

- Lubrication and Maintenance: LubricantsДокумент12 страницLubrication and Maintenance: LubricantsmnCenasОценок пока нет

- Chevron Base OilДокумент3 страницыChevron Base OilNeha AntimonyОценок пока нет

- AeroShell Grease 33Документ2 страницыAeroShell Grease 33Anonymous oAbjbl4HОценок пока нет

- Elsvare Gas Turbine Lube OilДокумент36 страницElsvare Gas Turbine Lube OilshaonaaОценок пока нет

- Lubricación Por Modelo PDFДокумент3 страницыLubricación Por Modelo PDFMatias Alfredo Contreras KöbrichОценок пока нет

- Kluebersynth GEM 4 460N-EnДокумент4 страницыKluebersynth GEM 4 460N-Ensobhan61Оценок пока нет

- Petrovietnam University: Viet Nam Oil and Gas GroupДокумент21 страницаPetrovietnam University: Viet Nam Oil and Gas GroupHoang BuiОценок пока нет

- 3330703Документ2 страницы3330703Syed Aaqib Farhan AhmedОценок пока нет

- SKF Coupling MaintananceДокумент4 страницыSKF Coupling MaintananceDavinder MakhijaОценок пока нет

- 1 Lubrication Chart: Marine Gearboxes With Built-In Disc ClutchДокумент2 страницы1 Lubrication Chart: Marine Gearboxes With Built-In Disc ClutchFlota PacualesОценок пока нет

- Section 3 Section 3: Routine MaintenanceДокумент2 страницыSection 3 Section 3: Routine MaintenanceСергій БоженкоОценок пока нет

- Top Drive LubricationДокумент14 страницTop Drive LubricationWahyu TICKETОценок пока нет

- Fuel Safety FilterДокумент15 страницFuel Safety FilterArun SОценок пока нет

- Eja 0Документ10 страницEja 0Myasaga AdrianОценок пока нет

- Lubrication and Maintenance: LubricantsДокумент12 страницLubrication and Maintenance: Lubricantsblackjeep44Оценок пока нет

- Vlsfo Fuel Guide: How Aderco 2055G Improves The Five Key Fuel Oil IssuesДокумент3 страницыVlsfo Fuel Guide: How Aderco 2055G Improves The Five Key Fuel Oil IssuesRudyОценок пока нет

- Case Study - Fuel OilДокумент34 страницыCase Study - Fuel OilironiteОценок пока нет

- REC 036 Stern Tube LO ContaminationДокумент2 страницыREC 036 Stern Tube LO Contamination003086Оценок пока нет

- WinGD Guide For Judging Condition of Relevant Piston Running Components V4 June 2020 PDFДокумент36 страницWinGD Guide For Judging Condition of Relevant Piston Running Components V4 June 2020 PDFStancu PetricăОценок пока нет

- Condition Monitoring of Stern Tube LubricationДокумент10 страницCondition Monitoring of Stern Tube LubricationironiteОценок пока нет

- Vanadium in FuelДокумент18 страницVanadium in FuelAlfiansyah DarmawanОценок пока нет

- Shell Gadinia s3 40 PDFДокумент2 страницыShell Gadinia s3 40 PDFNatália ValeriaОценок пока нет

- Alfa Laval Cat-Fine BookletДокумент40 страницAlfa Laval Cat-Fine BookleticeburnerОценок пока нет

- MAN Diesel & Turbo: Surveyor's Day Gard/Norwegian Hull ClubДокумент29 страницMAN Diesel & Turbo: Surveyor's Day Gard/Norwegian Hull ClubironiteОценок пока нет

- 2020 Switchover GuideДокумент6 страниц2020 Switchover GuideviОценок пока нет

- Vlsfo Fuel Guide: How Aderco 2055G Improves The Five Key Fuel Oil IssuesДокумент3 страницыVlsfo Fuel Guide: How Aderco 2055G Improves The Five Key Fuel Oil IssuesRudyОценок пока нет

- Visga-15 TDS v171023Документ1 страницаVisga-15 TDS v171023Prince DhakaОценок пока нет

- Parker Kittiwake Announces The Easy-To-Use Cat Fines Test KitДокумент6 страницParker Kittiwake Announces The Easy-To-Use Cat Fines Test KitironiteОценок пока нет

- Final Draft Recommendation 31 2017-06-23 CIMAC WG8-SG4 2-Stroke LubricationДокумент86 страницFinal Draft Recommendation 31 2017-06-23 CIMAC WG8-SG4 2-Stroke Lubricationpavlo_790317697Оценок пока нет

- TU BrochureДокумент2 страницыTU BrochureironiteОценок пока нет

- URS R404aДокумент1 страницаURS R404aironiteОценок пока нет

- Disola MДокумент4 страницыDisola MironiteОценок пока нет

- Condensate Treatment 9-150 25 LTRДокумент18 страницCondensate Treatment 9-150 25 LTRironiteОценок пока нет

- Marine Fuel Stability and Compatibility TestingДокумент4 страницыMarine Fuel Stability and Compatibility TestingRebekah SchmidtОценок пока нет

- Shell Tellus s2 VX 68Документ3 страницыShell Tellus s2 VX 68ironiteОценок пока нет

- Tellus S4 VXДокумент2 страницыTellus S4 VXironiteОценок пока нет

- PowerPlant BrochureДокумент4 страницыPowerPlant BrochureironiteОценок пока нет

- Tellus S3 VДокумент2 страницыTellus S3 VironiteОценок пока нет

- Azolla Zs 68 PDFДокумент1 страницаAzolla Zs 68 PDFironiteОценок пока нет

- Equivis Zs 68Документ1 страницаEquivis Zs 68ironiteОценок пока нет

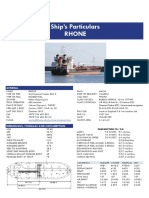

- Rhone 9327164 Oil Chemical - Tanker 71386Документ2 страницыRhone 9327164 Oil Chemical - Tanker 71386ironiteОценок пока нет

- BulkCarrier (13) KellettIslandДокумент1 страницаBulkCarrier (13) KellettIslandironiteОценок пока нет