Академический Документы

Профессиональный Документы

Культура Документы

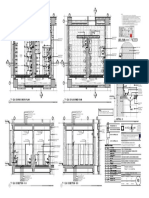

Provision of Special Confining Reinforcement in Footing

Загружено:

SS INFRAZONEОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Provision of Special Confining Reinforcement in Footing

Загружено:

SS INFRAZONEАвторское право:

Доступные форматы

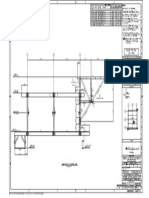

NOTE:

)

m

1. ALL DIMENSIONS ARE IN mm. UNLESS SPECIFIED OTHERWISE.

m

75

2. FOR GENERAL NOTES, SPECIAL NOTES AND TYPICAL STRUCTURAL DETAILS

>

d(

PLEASE REFER THIS PROJECT R.C.C. DRAWING NO.- SSI/STR/GER/01

10

Ld+10db SPECIAL CONFINING 3. THE FOOTINGS ARE DESIGNED FOR SAFE BEARING CAPACITY OF T / SQ M.

AT A DEPTH OF 2 M.

REINFORCEMENT IN

L0

4. THE BUILDING IS DESIGN TO WITHSTAND THE EARTHQUAKE EFFECT OF

DEPTH OF FOOTING

2000MM FORM NGL

SEISMIC ZONE-III.

db 'L0' LENGTH

OR UPTO GOOD

YELLOW SOIL

d

100 SPECIAL CONFINING

SPECIAL CONFINING

D

REINFORCEMENT > 300mm. >150mm C/C STIRRUPS SPACING

BEAM REINF. AS REQUIRED

BEAM WEB REINFORCEMENT IN 'L0' LENGTH

>300

L0

A SPECIAL CONFINING

d

100

REINFORCEMENT IN

> hc4

WHICHEVER IS MORE

)

P.C.C

10 TIMES OF DIA

m

75mm. MIN OR

100

'L0' LENGTH

m

OF BAR(Ø)

Ld = DEVELOPMENT LENGTH

75

P.C.C.

>

(1:3:6)

d(

IN TENSION OPEN

10

COLUMN d TIE

db = BAR DIAMETER

TRANVERSE REINF.

AS PER COL. SCH.

Ø

IN L1 LENGTH

TRANSVERSE

SPLICE

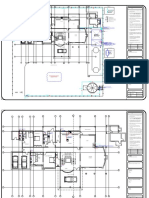

PROVISION OF SPECIAL CONFINING REINFORCEMENT

hc

ANCHOR OF BEAM BARS DETAIL AT : 'A' FOR SPACING < 150

REINFORCEMENT IN FOOTING IN AN EXTERNAL JOINT HOOK IN OPEN TIES

DISRIBUTION BARS AT TOP( MINIMUM 2 BARS.)

10

d(

>

0.3 L1 0.3 L2 0.3 L2 0.3 L3

75

0.5As1

m

m

> hc4

)

SLAB SLAB

SPECIAL CONFINING

P/2 P db d

L0

As1 0.5As1 REINFORCEMENT IN

0.15 L1 0.25 L1 0.25 L2 0.25 L2 0.25 L3

BEAM BEAM BEAM 'L0' LENGTH

L1 L2 L3

d = DIA OF BARS

>150mm C/C STIRRUPS SPACING

< Ld TRANSVERSE REINFORCEMENT

TYPICAL REINFORCEMENT DETAILING FOR SLABS IN COLUMN

Ld = DEVELOPMENT LENGTH SPECIAL CONFINING CONFINED JOINT WITH

FLOOR FINISH LEVEL IN TENSION REINFORCEMENT IN

L0

BEAMS FRAMING INTO

db = BAR DIAMETER 'L0' LENGTH ALL FOUR SIDES

MIN As per Arch

150MM Drawing

D as per shedule

Plinth-Beam

Typical PLINTH BEAM

details of

Ground Level LAP SPLICE IN BEAM

200 THK. WALL 75

Outer

COLUMN AND JOINT DETAILING

100

Plinth 400 THK. WALL

300

Beam 75 75

P.C.C [1:4:8]

P.C.C. (1:4:8)

TYPICAL DRAWING FOR INTERNAL PLINTH BEAM

GENERAL INSTRUCTION

1. All Dimension are in mm unless otherwise specified. 14. All HYSD bars used shall confirm to IS :1786 -2008 ( grade Fy =500 MPa ) Specifications & similarly for TMT bars 0 Denotes TOR/TMT, Ø

2. These general instructions shall be applicable to all our drawings throughout the project. denotes mild steel.

3. All structural drawings shall be read in conjuction with architectural drawings & any discrepancy shall be brought to our notice before 15. Reinforcement shall be bent and fixed in accordance with the procedure specified in IS: 2502-1963. rings in all beams and columns shall be

execution. provided as follows. d he links an.

4. No dimensions shall be scaled from structural drawings, but only written dimensions be followed. Any missing dimensions / details be brought 16. The links and rings in all beams and columns shall be provided as follows.

to our notice before execution.

5. All back filling of foundation trenches & earth filling for plinth shall be done by cohesive non swelling soil (CNS Soil) properly watered b b

& compacted in layers of a thickness not more than 250 mm depth.

6. The shuttering shall be removed as follows: Links

Column & beam sides-----------------------02 Days.

Slab bottom-----------------------------------07 Days.

Beam bottom for span <= 6.0 m---------------14 Days BENT LENGTH B=10 TIMES D OR 75 MM (WHICHEVER IS LARGER)

Beam bottom for span > 6.0 m & all cantilevers-----21 Days. WHERE D= BAR DIA OF LINKS/ RINGS

7. Concrete grade used for slabs,beams,footings and column shall be M25 unless otherwise mentioned. Proper mix design shall be done to

achieve proper concrete grade.

8. Concrete sample cubes shall be taken for all parts / buildings components & strengths verified. 17. NO LAP IN COLUMN MAIN STEEL SHALL BE PROVIDED AT TOP ONE FOURTH HEIGHT AND BOTTOM ONE FOURTH HEIGHT OF THE

9. Lap length for various bars shall be 50 times the bar diameter for all members. COLUMN FULL STOP LAP TO BE PROVIDED ONLY IN MIDDLE ONE HALF HEIGHT OF COLUMN IN SUCH A WAY THAT MAXIMUM HALF OF

10. The clear covers for different members shall be as follows: THE MAIN STEEL BARS ARE LAPPED AT A PARTICULAR LEVEL.

Footing ----------------50mm 18. SAND USED FOR CONSTRUCTION SHALL BE WELL GRADED (COARSE TYPE) AND WITHOUT SILT CONTENT. KAPACHI USED TYPICAL GENERAL NOTES

Column ----------------45mm SHALL BE WITH SHARP EDGES, WELL GRADED, BLACK IN COLOUR AND MAXIMUM SIZE 20 MM.

stair -------------------30mm 19. CURING OF CONCRETE SHALL BE DONE UP TO 14 DAYS AFTER CASTING. USE PONDING METHOD FOR SLAB AND WRAP JUTE STRUCTURAL

Beam ------------------45mm BAGS AROUND COLUMNS, WETTING COMMANDER

Slab --------------------30mm WORKS ENGINEERS (AF)

20. Spacer bar/pin shall be of 25dia @600c/c to keep clear distance of 25mm Between two horizontal layers of reinforcement. CHILODA

11. No change in size or reinforcement shall be made without written approval or revised drawings from structural engineer. 21. All the partition walls shall be reinforced with 2 nos. of ^8mm bars at every 6th. layer of masonry.

12. Under no circumstances concreting be done unless reinforcement is checked,approved & certified by structural engineer. 22. All footings should be at one level.

13. The beam depths mentioned in our drawing include slab thickness wherever applicable. 23. This structure is not designed for any impact or blasting.

24. The structure design is safe upto the limits prescribed in relevant I.S codes. 00 01

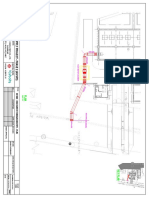

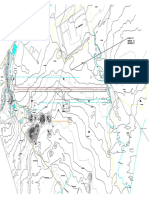

NOTES : THIS DRAWING IS PREPARED BY M/S SSPACIA DESIGN AND NUMBER ALLOTTED BY CHIEF ENGINEER

AIRFORCE GANDHINAGAR

Вам также может понравиться

- Design of Footing For Corner ColumnДокумент4 страницыDesign of Footing For Corner Columnilachezhiyan82% (11)

- Government of Telangana Irrigation & Cad Department: Longitudinal SectionДокумент1 страницаGovernment of Telangana Irrigation & Cad Department: Longitudinal Sectionrvkumar361Оценок пока нет

- 2011 Exam GeotechnicalДокумент9 страниц2011 Exam GeotechnicalAhmed AwadallaОценок пока нет

- 011 012 MergedДокумент12 страниц011 012 MergedAli HusseinОценок пока нет

- Leyenda: Av. COSTANERA: Jr. Tumbes - Jr. LibertadДокумент1 страницаLeyenda: Av. COSTANERA: Jr. Tumbes - Jr. LibertadMel RiszeОценок пока нет

- Camana: Leyenda de Agua PotableДокумент1 страницаCamana: Leyenda de Agua PotableJohann Nick Flores AparicioОценок пока нет

- Redes de Agua Potable - Accesorios - A0Документ1 страницаRedes de Agua Potable - Accesorios - A0Jesud ZarmientoОценок пока нет

- D E F G H: Grating SpecificationsДокумент1 страницаD E F G H: Grating SpecificationssivagnanamОценок пока нет

- Tiger Bike Share Heat MapДокумент1 страницаTiger Bike Share Heat MapCaseyAndersonОценок пока нет

- RCC Cladding Wall Detail-D CH-100+460-100+520: LWL Bed LevelДокумент1 страницаRCC Cladding Wall Detail-D CH-100+460-100+520: LWL Bed Levelrao shoaibОценок пока нет

- Drawing No.: IssueДокумент2 страницыDrawing No.: IssuevvkОценок пока нет

- KEC RWSS GAN KHA SLU GA 014 Layout1Документ1 страницаKEC RWSS GAN KHA SLU GA 014 Layout1IkramОценок пока нет

- MAPA URBANO - Av - Matheus RaphaelДокумент1 страницаMAPA URBANO - Av - Matheus RaphaelGuilhermeFregoneziОценок пока нет

- LSC 12 To 16 GADДокумент5 страницLSC 12 To 16 GADGerard Vallespí CatalàОценок пока нет

- MATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesДокумент1 страницаMATCHLINE E 4039.000 SEE DWG. 5220-65K-001: NotesJonathanSaucedoОценок пока нет

- TH 003 WD - TH BP 003Документ1 страницаTH 003 WD - TH BP 003Robert SmartОценок пока нет

- Cogito: General NotesДокумент1 страницаCogito: General NotesHarsh BhavsarОценок пока нет

- 100 - PlumbingДокумент5 страниц100 - PlumbingfebousОценок пока нет

- Attachment-1: Selection Chart-Primary Supports (4 Sheets)Документ172 страницыAttachment-1: Selection Chart-Primary Supports (4 Sheets)syed muhammad wasimОценок пока нет

- Instrument Hookup 9Документ1 страницаInstrument Hookup 9Wael ZakariaОценок пока нет

- P4283 350 DRG ME 013 - B - ReviewedДокумент1 страницаP4283 350 DRG ME 013 - B - ReviewedalimfakihsalehОценок пока нет

- Faith Chogo Two BedroomДокумент1 страницаFaith Chogo Two BedroomBrian KibetОценок пока нет

- Faith Chogo Two BedroomДокумент1 страницаFaith Chogo Two BedroomBrian KibetОценок пока нет

- Detail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student VersionДокумент1 страницаDetail-D RCC Cladding Wall CH-100+460-100+520: Produced by An Autodesk Student Versionrao shoaibОценок пока нет

- PACS020001PDДокумент1 страницаPACS020001PDdpk000000Оценок пока нет

- Tank 100KL 12M A3 - 5 Layout2Документ1 страницаTank 100KL 12M A3 - 5 Layout2Tarun SinghalОценок пока нет

- 2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Документ1 страница2a Domestic Water Meter Installation in Meter Room For Buildings Drawing PEWSTD AMI 003 Rev3Hassan KhanОценок пока нет

- SHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFДокумент1 страницаSHD Cscec 18 F01 ST SC 01 Ex 05 0007 0000 01 PDFMohamed SherifОценок пока нет

- Stairs 1Документ1 страницаStairs 1anandit sharmaОценок пока нет

- Colour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Документ1 страницаColour Tv Schematic Diagram: Pdf 文件使用 "Pdffactory Pro" 试用版本创建gansolОценок пока нет

- To Kaptai DN 630 MM Dia Water Pi PeДокумент1 страницаTo Kaptai DN 630 MM Dia Water Pi PegawtomОценок пока нет

- Ilovepdf MergedДокумент5 страницIlovepdf MergedAlejo VelozОценок пока нет

- 1 Plan Situatie GAI-03 PDFДокумент1 страница1 Plan Situatie GAI-03 PDFwww.criticarad.roОценок пока нет

- A102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor PlanДокумент1 страницаA102-R7 Ground Floor Plan-A102-r7 Revised Ground Floor Planzubair khanОценок пока нет

- Pile Cap of Abutment A1 & A2 (Takarma) - 1Документ1 страницаPile Cap of Abutment A1 & A2 (Takarma) - 1Nilay GandhiОценок пока нет

- Tarma Tumbes Limatambo: Ortofoto - Satellite - EcwДокумент1 страницаTarma Tumbes Limatambo: Ortofoto - Satellite - EcwJulio Cesar Sanchez MezaОценок пока нет

- Generic Oil & Gas Production Process Notes:: Choke ValveДокумент1 страницаGeneric Oil & Gas Production Process Notes:: Choke ValveBuonQuaBuonQuaОценок пока нет

- Redes de Agua Potable - Modelamiento Hidraulico - A0Документ1 страницаRedes de Agua Potable - Modelamiento Hidraulico - A0Jesud ZarmientoОценок пока нет

- Redes de Agua Potable - Plano Clave - A0Документ1 страницаRedes de Agua Potable - Plano Clave - A0Jesud ZarmientoОценок пока нет

- Concession Map 21 Sep 2021Документ1 страницаConcession Map 21 Sep 2021Mehrez AssidyОценок пока нет

- Reston Dulles Special Study 2009E4 ParksДокумент1 страницаReston Dulles Special Study 2009E4 ParksTerry MaynardОценок пока нет

- FL3B-474-P-2636 As BuiltДокумент1 страницаFL3B-474-P-2636 As BuiltAlbet MulyonoОценок пока нет

- PACS017001PDДокумент1 страницаPACS017001PDdpk000000Оценок пока нет

- 6-2 Plan Situatie VLAICU BERD-43 PDFДокумент1 страница6-2 Plan Situatie VLAICU BERD-43 PDFwww.criticarad.roОценок пока нет

- Camana: Plano ClaveДокумент1 страницаCamana: Plano ClaveJohann Nick Flores AparicioОценок пока нет

- K06 16223006 Azzahra Raihana PR3Документ3 страницыK06 16223006 Azzahra Raihana PR3Azzahra RaihanaОценок пока нет

- Fadil 2013 Fix-A3 (Plot)Документ1 страницаFadil 2013 Fix-A3 (Plot)Dimas WiryaОценок пока нет

- Instrument Hookup 10Документ1 страницаInstrument Hookup 10Wael ZakariaОценок пока нет

- IQ347-000-V1A-MEA0-00001 - Code 2Документ1 страницаIQ347-000-V1A-MEA0-00001 - Code 2arasОценок пока нет

- Road Crossing DuctsДокумент1 страницаRoad Crossing Ductsmohan890Оценок пока нет

- Sectiune 1-1: SCARA 1:50Документ1 страницаSectiune 1-1: SCARA 1:50George EnacheОценок пока нет

- 02 - Ro PTSДокумент1 страница02 - Ro PTSabdulhalimbinamrinОценок пока нет

- Situasi Kontur TowerДокумент1 страницаSituasi Kontur TowerIlhamОценок пока нет

- Escalera Tipo: Fachada FrontalДокумент1 страницаEscalera Tipo: Fachada FrontalNancy Paco GuachallaОценок пока нет

- Pages From IT GDR Rev0 Vol 1Документ1 страницаPages From IT GDR Rev0 Vol 1JohnnyОценок пока нет

- Stairs 2Документ1 страницаStairs 2anandit sharmaОценок пока нет

- Gaita Serrana: Transcrição: Alex ReimannДокумент3 страницыGaita Serrana: Transcrição: Alex ReimannGustavo161524Оценок пока нет

- Gambar Pondasi AA Tower TelkomselДокумент6 страницGambar Pondasi AA Tower TelkomselAlioОценок пока нет

- Rewards Catalogue PDFДокумент12 страницRewards Catalogue PDFtejaiipm9809Оценок пока нет

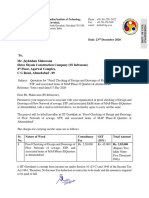

- To, Mr. Jaykishan Makavana Shree Shyam Construction Company (SS Infrazone) 4 Floor, Agarwal Complex, C G Road, Ahmedabad - 09Документ4 страницыTo, Mr. Jaykishan Makavana Shree Shyam Construction Company (SS Infrazone) 4 Floor, Agarwal Complex, C G Road, Ahmedabad - 09SS INFRAZONEОценок пока нет

- Steps To Design A CulvertДокумент18 страницSteps To Design A CulvertOliver Brown67% (9)

- STR-01 (A3)Документ1 страницаSTR-01 (A3)SS INFRAZONEОценок пока нет

- STR-01 (A3)Документ1 страницаSTR-01 (A3)SS INFRAZONEОценок пока нет

- STR-01 (A3)Документ1 страницаSTR-01 (A3)SS INFRAZONEОценок пока нет

- STR-01 (A3)Документ1 страницаSTR-01 (A3)SS INFRAZONEОценок пока нет

- Ground Floor Plan: Garage Garage GarageДокумент1 страницаGround Floor Plan: Garage Garage GarageSS INFRAZONEОценок пока нет

- SP-34-1987 Handbook On Reinforcement and DetailingДокумент286 страницSP-34-1987 Handbook On Reinforcement and DetailingEr Prabhakara B88% (69)

- Front Elevation Back Elevation: Right Elevation Left ElevationДокумент1 страницаFront Elevation Back Elevation: Right Elevation Left ElevationSS INFRAZONEОценок пока нет

- Finalreport 170308170043Документ177 страницFinalreport 170308170043Chandan VatsОценок пока нет

- Footing ScheduleДокумент1 страницаFooting ScheduleSS INFRAZONEОценок пока нет

- Technical Paper - SanjibДокумент5 страницTechnical Paper - SanjibalenriderОценок пока нет

- Arc-01 (A3)Документ1 страницаArc-01 (A3)SS INFRAZONEОценок пока нет

- 200 Soil Report PDFДокумент42 страницы200 Soil Report PDFSS INFRAZONEОценок пока нет

- LinksДокумент1 страницаLinksSS INFRAZONEОценок пока нет

- TABLE: Modal Periods and Frequencies Case Mode Period Frequency Circular Frequency EigenvalueДокумент1 страницаTABLE: Modal Periods and Frequencies Case Mode Period Frequency Circular Frequency EigenvalueSS INFRAZONEОценок пока нет

- cvl861 Rosf PDFДокумент22 страницыcvl861 Rosf PDFellenОценок пока нет

- To-Do List - To Do PDFДокумент2 страницыTo-Do List - To Do PDFSS INFRAZONEОценок пока нет

- TABLE: Response Spectrum Modal Information Response Spectrum Case Modal Case Mode Period Damping Ratio U1 AccelerationДокумент4 страницыTABLE: Response Spectrum Modal Information Response Spectrum Case Modal Case Mode Period Damping Ratio U1 AccelerationSS INFRAZONEОценок пока нет

- Isolated Footing - 02Документ22 страницыIsolated Footing - 02SS INFRAZONEОценок пока нет

- Quotation PDFДокумент1 страницаQuotation PDFSS INFRAZONEОценок пока нет

- To-Do List - To Do PDFДокумент2 страницыTo-Do List - To Do PDFSS INFRAZONEОценок пока нет

- AC Plant Room Bhuj LetterДокумент6 страницAC Plant Room Bhuj LetterSS INFRAZONEОценок пока нет

- To-Do List - To Do PDFДокумент2 страницыTo-Do List - To Do PDFSS INFRAZONEОценок пока нет

- To-Do List - To Do PDFДокумент2 страницыTo-Do List - To Do PDFSS INFRAZONEОценок пока нет

- Quotation PDFДокумент1 страницаQuotation PDFSS INFRAZONEОценок пока нет

- Accounting Voucher BhujДокумент1 страницаAccounting Voucher BhujSS INFRAZONEОценок пока нет

- AC O& M City Mall Version 1.0Документ12 страницAC O& M City Mall Version 1.0yewminyun6098Оценок пока нет

- Display Unit TechnologyДокумент51 страницаDisplay Unit TechnologyNavin GillmanОценок пока нет

- Emma Warlinge - Sterilization of Sterile TanksДокумент6 страницEmma Warlinge - Sterilization of Sterile Tanksaaro_oraalОценок пока нет

- Class Xi Physics Annual Exam 2017 18Документ3 страницыClass Xi Physics Annual Exam 2017 18Anupam TiwariОценок пока нет

- Polymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesДокумент10 страницPolymers: Fabrication and Characterization of Aluminum Nanoparticle-Reinforced CompositesTRNADEWОценок пока нет

- Self Inductance of A CoilДокумент7 страницSelf Inductance of A CoilIANDU PCОценок пока нет

- Earth and Life Science Copy (Repaired)Документ39 страницEarth and Life Science Copy (Repaired)Aaron Manuel MunarОценок пока нет

- Shore ScleroscopeДокумент6 страницShore ScleroscopeAaliyahОценок пока нет

- C-05 April - May-2012Документ30 страницC-05 April - May-2012John SandaОценок пока нет

- GTP For TowersДокумент7 страницGTP For Towersabhi_akОценок пока нет

- Segui 6e ISM Ch08Документ105 страницSegui 6e ISM Ch08miraj patelОценок пока нет

- Geotechnical Variation of London Clay Across Central LondonДокумент12 страницGeotechnical Variation of London Clay Across Central LondonChiaraОценок пока нет

- 2.basic Electrical Engineering PDFДокумент152 страницы2.basic Electrical Engineering PDFkandavel71Оценок пока нет

- GMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsДокумент46 страницGMAT QUANT TOPIC 3 (Inequalities + Absolute Value) SolutionsBhagath GottipatiОценок пока нет

- Question and Ans.3Документ153 страницыQuestion and Ans.3gangoorsgОценок пока нет

- Pipesim 2006.1 Fundamentals GasliftДокумент13 страницPipesim 2006.1 Fundamentals GasliftamulyanaОценок пока нет

- Annual Plans 7th GradeДокумент5 страницAnnual Plans 7th GradeDiego Antonio RodriguezОценок пока нет

- Task 3 Ronald GarzonДокумент23 страницыTask 3 Ronald GarzonRonal Enrique Garzon SanchezОценок пока нет

- MSC MathmaticsДокумент24 страницыMSC Mathmaticsyadavgup61Оценок пока нет

- A New Fatigue Damage Accumulation Rating Life Model of Ball Bearings Under Vibration LoadДокумент11 страницA New Fatigue Damage Accumulation Rating Life Model of Ball Bearings Under Vibration LoadAlbertoОценок пока нет

- Atp ProductionДокумент20 страницAtp ProductionMirriam AgpanganОценок пока нет

- First-Order Linear Fuzzy Differential Equations On The Space of Linearly Correlated Fuzzy NumbersДокумент33 страницыFirst-Order Linear Fuzzy Differential Equations On The Space of Linearly Correlated Fuzzy NumbersHo Nhat NamОценок пока нет

- Priyanka Patel Resume r6Документ2 страницыPriyanka Patel Resume r6api-288092186Оценок пока нет

- Fuzzy: When We Say About Certainty of A ThingДокумент15 страницFuzzy: When We Say About Certainty of A ThingRajesh kumarОценок пока нет

- Performance Evaluation On Low-Crest Breakwater at North Coast of Java IslandДокумент12 страницPerformance Evaluation On Low-Crest Breakwater at North Coast of Java IslandSobariMuchlisОценок пока нет

- ML12142A123Документ58 страницML12142A123Mohammed RiyaazОценок пока нет

- Interface and Density Profiling PresentationДокумент50 страницInterface and Density Profiling PresentationheriОценок пока нет

- Quality On Yarn 1Документ39 страницQuality On Yarn 1Ashiq Khan100% (1)

- XII - Physics - Chapter 3 - Current Electricity - Saju - Hsslive PDFДокумент15 страницXII - Physics - Chapter 3 - Current Electricity - Saju - Hsslive PDFArpit TyagiОценок пока нет