Академический Документы

Профессиональный Документы

Культура Документы

A9110 Installation Manual PDF

Загружено:

phantd_hcmИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A9110 Installation Manual PDF

Загружено:

phantd_hcmАвторское право:

Доступные форматы

Alcatel GSM

A9110 BTS Installation Manual

BTS Document

Installation & Dismantling Manual

3BK 20460 0001 RJZZA Ed.15

BLANK PAGE BREAK

Status RELEASED

Short title A9110 INS

All rights reserved. Passing on and copying of this document, use

and communication of its contents not permitted without written

authorization from Alcatel.

2 / 52 3BK 20460 0001 RJZZA Ed.15

Contents

Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.1 Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.2 Cases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.3 Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.4 Initial State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.5 Final State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.6 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.7 Grouped Task Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.1 Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.2 Site-Specific Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.3 Scheduling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.4 Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.4.2 Forms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.4.3 Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.4.4 Applicable Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2 Install A9110 BTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.1 Before Going On Site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2 Before You Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.1 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.2 Required Knowledge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3 Install Cable Equipment and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.1 Install Cable Tray (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.3.2 Install Cable Protection (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3.3 Install Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.4 Install BTS Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.4.1 Types of Fixation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.4.2 Case 1: Fix MOCO on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4.3 Case 2: Fix Back Cover and MOCO on a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.4.4 Case 3: Fix Back Cover and MOCO on a Mast . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.5 Connect the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5.1 Prepare Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5.2 Connect Earth Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

2.5.3 Connect Power Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.5.4 Connect Abis Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

2.5.5 Connect External Alarm Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

2.5.6 Connect IEB Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2.6 Install the Fan Hat (Option) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.6.1 Fix Fan Hat to Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.6.2 Connect the Cables at COBO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

2.6.3 Install Front Cover and Connect Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2.7 Close the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.8 Before You Leave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3BK 20460 0001 RJZZA Ed.15 3 / 52

Contents

4 / 52 3BK 20460 0001 RJZZA Ed.15

Preface

Preface

Purpose This document describes the installation procedure for the Alcatel 9110 BTS

in release B9 of the Alcatel BSS.

What’s New In Edition 15

Description improvement in Connect Abis Cable (Section 2.5.4).

In Edition 14

Update for document type, category and mnemonic, as well as a global rewrite

and restructure to ensure quality and conformity to the standard Methods

presentation.

In Edition 13

DDF label reference change in Installation Kits (Section 1.4.1.2).

In Edition 12

Update for new version of Fan Hat (MFCC) in Installation Kits (Section 1.4.1.2).

In Edition 11

Updating for naming rules

In Edition 10

Update for new ABISCO

Audience This document is intended for:

Site administrators

Project managers

Field service technicians

Supervisors

Occasional users (e.g. subcontractors).

3BK 20460 0001 RJZZA Ed.15 5 / 52

Preface

Assumed Knowledge You must have a basic understanding of the following:

Alcatel Base Station Subsystem equipment

Electrical mounting and cabling.

6 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

1 Overview

This Overview gives information needed by project managers and foremen, for

presentation to the customer and for site planning.

3BK 20460 0001 RJZZA Ed.15 7 / 52

1 Overview

1.1 Presentation

1.1.1 Hardware Description

1.1.1.1 BTS Configuration

The A9110 BTS comprises up to three units of two TRX, linked by an

interconnection bus. The master unit handles the Abis lines. The other units

are slaves.

Each unit can have:

One antenna output (2 W power)

Single Antenna Single Antenna Single Antenna

Network Network Network

TRX 1 TRX 2 TRX 3 TRX 4 TRX 5 TRX 6

Slave 1 Slave 2

Master

Two antenna outputs (4.5 W power).

Low−Loss Low−Loss Low−Loss

Antenna Antenna Antenna

Network Network Network

(Diversity) (Diversity) (Diversity)

TRX 1 TRX 2 TRX 3 TRX 4 TRX 5 TRX 6

Slave 1 Slave 2

Master

8 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

The A9110 BTS physical unit comprises:

A micro BTS

The mounting frame and connection box (MOCO)

Covers.

BTS installation consists of mounting and cabling the MOCO and the covers.

The micro BTS is inserted during commissioning.

1.1.1.2 Weight and Dimensions

The following table provides the weight and dimensions of the A9110 BTS.

Characteristics Without cover and With cover and With cover and top fan

top fan without top fan

Width (mm) 384 450 450

Height (mm) 750 (w/ o PG) 818 (w/ o PG) 940 with fan (w/ o PG)

Depth (mm) 137 190 190

A9110 BTS unit weight (kg) 21.5 21.5 21.5

Cover weight (kg) 0 5.5 5.5

Top fan weight (kg) 0 0 2.5

MOCO weight (kg) 5.5 5.5 5.5

Maximum weight (kg) 27 32.5 35

3BK 20460 0001 RJZZA Ed.15 9 / 52

1 Overview

1.1.1.3 Common BTS Data

The following table lists essential information about the BTS.

A9110 micro BTS

Installation On the wall without cover (indoor)

On the wall with cover (indoor / outdoor)

On the mast with cover (indoor / outdoor)

Position Installation at minimum 2.5 m height in public places

Installation at minimum 1.0 m height in places not open to the public

Distance between two BTS (master / slave):

maximum 1 m with basic option for the Inter Entity Bus (IEB) cable (2 m)

Output for antennae Bottom side of micro BTS housing

In / Out for external cables Bottom side of micro BTS housing

Clearance Left, right: 0.1 m

Top: 0.4 m above top fixation points of basic unit to the MOFRA

Bottom: 0.25 m

Front: 0.8 m

1.1.2 Cases

The following cases apply:

Case 1: Fix MOCO on a Wall (Section 2.4.2)

Case 2: Fix Back Cover and MOCO on a Wall (Section 2.4.3)

Case 3: Fix Back Cover and MOCO on a Mast (Section 2.4.4).

None.

1.1.3 Options

The following options apply:

Install Cable Tray (Option) (Section 2.3.1)

Install Cable Protection (Option) (Section 2.3.2)

Install the Fan Hat (Option) (Section 2.6)

1.1.4 Initial State

The installation kits are packed and delivered on site.

10 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

1.1.5 Final State

At the end of the installation, the equipment is ready for commissioning, as

shown in the following figures:

Example of an A9110 BTS in an indoor environment (without a cover)

Alarms points

for Customer

Two Mbit/s

cables

per BTS

Decoupling

TX Unit

DDF 220BOX

DC V

AC

48V/60V

Wire braid

RX 1.0

1.5 mm

Ground

Plate

Example of an A9110 BTS in an indoor environment (with a cover)

Alarm points

for Customer

SLAVE 2 MASTER SLAVE 1

Two Mbit/s

cables

per BTS

Decoupling

TX Unit

DDF DC

220 BOX

VAC

Wire braid 48V/60V

RX 1.0 m

Ground

Plate

3BK 20460 0001 RJZZA Ed.15 11 / 52

1 Overview

Example of an A0110 BTS in an outdoor environment (wall installation)

Example of an A0110 BTS in an outdoor environment (mast installation)

ANTENNA

ANTENNA

FEEDER

ANTENNA

SLAVE 2

SLAVE 1

ANTENNA

FEEDER

MASTER MASTER

ANTENNA JUMPER ANTENNA JUMPER

METALLIC SHEATING METALLIC SHEATING

PCM

PCM 220 V & 220 V

& ALARM

ALARM

2.5 m

2.5 m

1.1.6 Restrictions

None.

12 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

1.1.7 Grouped Task Sequence

The following figure shows the task sequence used to install an A9110 BTS.

Before Going On Site

Before You Start

Install Cable Equipment and Cables

Install BTS Equipment

Connect the Cables

Install the Fan Hat (Option)

Close the Covers

Before You Leave

3BK 20460 0001 RJZZA Ed.15 13 / 52

1 Overview

1.2 Preparation

1.2.1 Prerequisites

The following prerequisites must be fulfilled:

The site must comply with the safety rules given in the General Wiring

Handbook

The site is ready to receive the BTS, according to the SPP 36 - Specification

for site preparation A9110 Micro BTS

The equipment is delivered on site (packed) with the associated kits (the

BTS unit will be put into position during commissioning).

Note: The cable tray is not required during installation.

1.2.2 Site-Specific Information

The following site-specific information is needed before starting the installation:

Site

Positions of BTS units on site

Position of BTS power breakers on the power panel

Position of PCM cables (Abis, Abis2) at the Digital Distribution Frame

(DDF)

Position of external alarm cables at the DDF

Presence of the cable tray.

Hardware Configuration

BTS configuration

Presence of cover

Presence of fan hat.

14 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

1.3 Scheduling

Time based on technical constraints

The following table does not take into account individual customer or safety

requirements.

More time may be required, depending on the options to be installed.

Grouped Task Time/Task: Total

Com1 Time/Task

Before Going On Site 10 10

Before You Start 10 10

Install Cable Equipment and Cables 5h 5h

Install BTS Equipment 1h50 1h50

Connect the Cables 1h 1h

Install the Fan Hat (Option) 15 15

Close the Covers 5 5

Before You Leave 5 5

Total 8h35 8h35

3BK 20460 0001 RJZZA Ed.15 15 / 52

1 Overview

1.4 Resources

1.4.1 Tools

The following tables describe the necessary hardware tools and installation kits.

1.4.1.1 Hardware Tools

The following table lists the necessary hardware tools.

Refer to the Tools Catalogue for Field Activity for more information.

Kit name Reference Calibration

Basic installation kit OUT 001 No

Testing tool kit for PCM cables OUT 002 No

1.4.1.2 Installation Kits

The following table lists the mandatory or optional delivery item kits.

The symbols used are:

• mandatory kit

∇ technical choice kit

◊ customer option kit.

Kits Mnemonic Code Quantity

Basic Installation Kits

• Standard installation kit for BTS MOCO 3BK 08639 AA 1/unit

• Basic kit for BTS MMKT 3BK 07653 AB 1/unit

• Label kit MLBL 3BK 08651 AA 1/BTS

Optional Kits for BTS Configuration

◊ Antenna jumper cable (l: 1m, Nm-Nm) MACC 3BK 07928 AB

∇ for 1 antenna output 1/ unit

∇ for 2 antenna outputs 2/ unit

◊ Antenna jumper cable Nm-7/16

∇1m BLF1N7 3BK 07928 AC 1/ ant

∇2m BLF2N7 3BK 07928 AD 1/ ant

∇3m BLF3N7 3BK 07928 AE 1/ ant

∇5m BLF5N7 3BK 07928 AF 1/ ant

16 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

Kits Mnemonic Code Quantity

◊ Bus cable between two BTS master/slave (l: MSCO 3BK 08278 AC 1/unit

2m) + 10 fixation screws with tie wrap for wall

+ 1 PG11 cap

◊ Standard cover MSTC 3BK 08640 AA 1/unit

◊ Fan Hat (fan integrated in top of cover) MFCC 3BK 08681 AB 1/unit

◊ Cable gland PG11 CG-PG11 3BK 26853 AA 1/unit

◊ Scotch tape PVCADHE 1AC 01556 0001 1

◊ Mast adaptation, 80 mm< mast< 160 mm MMFI 3BK 07637 AB 1/unit

◊ Service kit for micro BTS MSKT 3BK 08635 AA 1

1/ team for commissioning and installation

◊ Insertion tool for PCM and alarm jack strip TJS10 1AD 01604 0001 1

1/team for JS10

Optional Kits for Site Preparation

Kits Mnemonic Code Quantity

◊ Basic conduit kit, outdoor site (metallic pipe 3m, BCDK 3BK 04731 AA 1/unit

D19.19 mm for PG 16)

◊ Extension conduit kit, outdoor site (extension ECDK 3BK 04731 AB 1/unit

metallic pipe 3m, D19.19 mm for PG 16)

◊ Wire mesh cable trays 6m x 0.1m, indoor site MCTW 3BK 04753 AB 1/unit

◊ Wire mesh cable trays 6m x 0.05m, indoor site MCTN 3BK 04753 AA 1/unit

◊ Cable duct kit, indoor site (plastic pipe, PCAD 3BK 07371 AA 1/unit

60x110x2000)

◊ PCM cable, cable 4 pairs 120 ohm, L907 indoor L907/4 1AC 01328 0004 1/BTS

(up to 100 m)

◊ PCM cable, 4 coax 75 ohm, FLEX3 indoor (up FLEX3/4 1AC 00110 0011 1/ BTS

to 100 m)

◊ Ground cable 10 mm2 for AC power (up to 165 GRD 1AC 00730 0003 1/unit

m)

◊ Power cable 1.5 mm2 , 3 wires without shield AC POW 1AC 01402 0001 1/unit

230 V with breaker 6A (up to 165 m)

◊ 4 pairs cable, L907 for 4 alarms (in case of 8 L907 1AC 01328 0004 1/unit

alarms use a second cable)

3BK 20460 0001 RJZZA Ed.15 17 / 52

1 Overview

Optional Kits for Site Preparation

Kits Mnemonic Code Quantity

◊ Lug 8 mm for ground cable 1AB 03205 0153 2/unit

◊ Shrink yellow/green for ground cable 1AC 00057 0060 —

◊ PCM/alarm CAD terminal block (120/75 ohm) for JS10 1AD 06634 0011 1

L907 / L904 / FLEX3 cable

◊ Label for 24 terminal block LAB 1AD 02853 0001 1

◊ Mechanical part for 24 terminal block MP24 1AD 02844 0001 1

◊ Fixation kit for wall (for terminal block) FKW 1AD 02844 0001 1

1.4.2 Forms

You must have the following forms:

BSS Site Premises Inspection Form (post handover)

8BL 00704 0016 DRBRA

Site Premises Inspection Form (CEL)

8BL 00704 0015 DRBRA

1.4.3 Supplies

The following table lists the necessary items that are not included in the

Alcatel kit.

Consumable supplies Quantity

Indelible markers 1/ rack

Rubber sleeves for cables 1/ rack

Tie wraps 1/ rack

Lugs 1/ rack

Adhesive tape 1/ rack

Blank labels for cables 1/ rack

18 / 52 3BK 20460 0001 RJZZA Ed.15

1 Overview

1.4.4 Applicable Documents

The following documents are needed to complete the installation.

Document Title Reference

Catalogue of Technical and Logistic Information (ITL-PRO) 3DF 00462 0004 AAAGA

Catalogue of Instruction Operation (IO) 3DF 00300 0004 UAZZA

BSS Methods Handbook — release B9 3BK 17422 0002 PCZZA

CI-08 Site Equipment Inventory 3BK 17257 0001 RJZZA

Tools Catalogue for Field Activity 3BK 20458 0001 RJZZA

BSS Site Premises Inspection Form (post handover) 8BL 00704 0016 DRBRA

Site Premises Inspection Form (CEL) 8BL 00704 0015 DRBRA

Installation Manual Generic Completion Check List (CCL) 3BK 17200 0002 QZZZA

SPP 36 - Specification for Site Preparation A9110 Micro BTS 8BL 00704 0052 DRAGA

3BK 20460 0001 RJZZA Ed.15 19 / 52

1 Overview

20 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2 Install A9110 BTS

Install A9110 BTS presents all the checks needed before starting the

installation, and all detailed tasks to be performed on site.

3BK 20460 0001 RJZZA Ed.15 21 / 52

2 Install A9110 BTS

2.1 Before Going On Site

Before going on site, you must check that the following information and supplies

are available:

The customer has been informed of the:

Date

Time

Site name

Site address

Purpose of the operation.

All Prerequisites (Section 1.2.1) are fulfilled

Personnel are available and ready for operation

(see Scheduling (Section 1.3))

Site-Specific Information (Section 1.2.2) is available and ready for operation

All Tools (Section 1.4.1) and Supplies (Section 1.4.3) are available and

ready for operation

Applicable Documents (Section 1.4.4) are available.

2.2 Before You Start

2.2.1 Checks

On arrival at site, before you start, perform the following operations:

Check that all Prerequisites (Section 1.2.1) are fulfilled

Check applicable notifications and operating instructions (refer to the

Catalogue of Technical and Logistic Information (ITL-PRO) and Catalogue

of Instruction Operation (IO))

Check that all Tools (Section 1.4.1) and Supplies (Section 1.4.3) are

available and ready for operation

Check that safety precautions have been taken in accordance with the

safety instructions described in the General Wiring Handbook

Check if any Cases (Section 1.1.2) and Options (Section 1.1.3) apply

Complete the header field of the CCL

Complete the Site Premises Inspection Form (CEL)

Check that the resistance of the antistatic wrist strap is greater than 1M .

Connect the anti-static wrist strap to the rack earth.

22 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.2.2 Required Knowledge

You must be familiar with the following:

The safety rules and precautions given in the General Wiring Handbook

How to document faults and anomalies, as described in the BSS Methods

Handbook — release B9

How to complete the Site Premises Inspection Form (CEL)

Grouped Task Sequence (Section 1.1.7).

2.3 Install Cable Equipment and Cables

This section tells you how to run cables towards the BTS and how to connect

the cables.

2.3.1 Install Cable Tray (Option)

Use the wire mesh cable trays in the installation kit for indoor sites.

For more information about the position of the cable trays in relation to the

micro BTS, power box and DDF, see Site-Specific Information (Section 1.2.2).

The cable ways must be isolated or several cable ways must be installed in

order to separate the various electrical supply systems. Alternatively, a space

of 30 cm must be left between two signal types (for example, the 220 V must

not be adjacent to the transmission lines).

The following conditions must be fulfilled:

The cable trays must reach:

The middle-bottom part of micro BTS housing

The power supply box

The DDF for Abis and external alarms

The antenna feeders

The room earthing plate.

The distance between the cable tray and micro BTS housing must be no

greater than 15 cm

The following cable ways groups must be isolated:

Power and ground cables

Abis and alarm cables.

3BK 20460 0001 RJZZA Ed.15 23 / 52

2 Install A9110 BTS

2.3.2 Install Cable Protection (Option)

The cable ways must be isolated or several cable ways must be installed in

order to separate the various electrical supply systems. Alternatively, a space

of 30 cm must be left between two signal types (for example, the 220 V must

not be adjacent to the transmission lines).

For an outdoor installation (wall or mast), the conduit kit for outdoor sites

must be used.

For more information about the position of the cable trays in relation to the

micro BTS, the power box and the DDF, see Install Cables (Section 2.3.3).

2.3.2.1 Wall Installation

The following conditions must be fulfilled for a wall installation:

When the distance between the micro BTS, the power box and the DDF is

less than 70 cm, only flexible metallic pipe must be used for wall installation

On the micro BTS, the conduit must reach the middle bottom end of the

micro BTS cover, and stop at 40 cm below the cover

On the power box and DDF boxes, the conduit must stop 25 cm above

the equipment

At each end of the conduit, flexible metallic pipe must be used to guide the

cables inside the covers (micro BTS, power box, and DDF)

Two different conduits must be used:

One for power and ground cables

One for Abis and alarms cables.

2.3.2.2 Mast Installation

The following conditions must be fulfilled for a mast installation:

Only flexible metal pipe must be used

On the micro BTS, the flexible metal pipe must reach the middle bottom end

of the micro BTS cover, and run into the cover

On the power box and DDF boxes, the flexible metallic pipe must reach

the top of both covers and run into both covers

Two different flexible metal pipes must be used:

One for power and ground cables

One for Abis and alarms cables.

24 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.3.3 Install Cables

Note: On the micro BTS, all the cables enter the cover from underneath.

2.3.3.1 Run Earth Cable to Equipment

Run the earth cable to 1. Use an earth cable and lugs, as described in Supplies (Section 1.4.3).

the equipment: 2. Clearly identify both the earthing connection to a trolley and the earthing

plate.

Note: Only the master is directly connected to the site earthing system. The slaves’

earth cables are connected to the master in the same place (right-bottom

part of the COBO).

3. Run the cable through the cable tray.

4. Cut the cable to the required length. On the micro BTS, the cable must

reach the top right side of the COBO.

Leave a reserve of 10 cm for connection purposes.

5. On the earth terminal, strip 10 mm of cable insulation and crimp one lug on

the end.

6. Choose the required terminal to connect the cable to the trolley or to the

earthing plate:

Trolley: Place a "T" terminal on the trolley

Earthing plate: Screw a straight terminal to the earthing plate.

7. Connect the cable to the trolley or to the earthing plate.

The earth cable is connected to the equipment.

2.3.3.2 Run and Connect Power Supply Cable to Site Power Terminal

Note: The following procedure applies to the master and to slave that are initially

installed together with the master.

Do not work under power. Open the circuit breakers to ensure that the power

supply is disconnected.

Run and connect the 1. Select a 3 wire cable for power connection.

power supply cable to 2. Run the cable through the cable tray:

the site power terminal:

For the master, the power cable runs from the site power terminal

For the slaves, the power cables run from the master.

3. Cut the cable to the required length. On the micro BTS, the cable must

reach the bottom of the COBO.

Leave a reserve of 40 cm at one end for connection to the master, and at

both ends for connection to the slaves.

3BK 20460 0001 RJZZA Ed.15 25 / 52

2 Install A9110 BTS

4. On the site power terminal, strip the power cable and terminate each wire

with a ferrule or a cable lug.

Note: Slaves installed later must be powered from the site power terminal and not

from the master. In this case, the power connection for the slaves is the

same as for the master.

5. Connect the power cable to the corresponding circuit breaker within the

power terminal (line L, neutral N and protective earth PE).

6. Label the power cable on the DDF, as shown in Apply Labels to COBO

(Section 2.5.1.1).

7. If there is more than one BTS on the site, check that the power supply

circuit breakers are labeled.

The power supply cable is run and connected to the site power terminal.

2.3.3.3 Run and Connect Abis Cables to DDF

Run and connect the 1. Use one of the following cables:

Abis cables to the DDF: 4 pair L907 cable (120 ohm) for lengths less then 100 m

L904 cable (120 ohm) for lengths between 100 m and 300 m

4 coax FLEX3 cable (75 ohm)

2. Run the Abis cable through to the site DDF.

3. Cut the cable to the required length. On the micro BTS, the cable must

reach the bottom left of the COBO.

Leave a reserve of 10 cm at one end for connection purposes.

4. Strip the cable and affect the pair numbers, as shown in the following tables:

Quad 1 Abis 1 White

TX Grey

Abis 2 Blue

TX Purple

Quad 2 Abis 1 Yellow

RX Grey

Abis 2 Brown

RX Purple

Table 1: Pair Number Allocation to Abis for L907 Cable

Coax number Abis

1 Abis IN RX

2 Abis OUT RX

26 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

3 Abis IN TX

4 Abis OUT TX

Table 2: Coax Number Allocation to Abis for FLEX3 Cable

5. To connect the cables on the DDF, proceed according to the type of

DDF already installed or to be installed on the site (refer to the site

documentation).

6. Label the Abis cable on the DDF, as shown in Apply Labels to COBO

(Section 2.5.1.1).

The Abis cable is run to the DDF.

2.3.3.4 Run External Alarm Cables

Note: Only the external alarms cables for master BTS are installed by default.

Alarm cables for slaves must only be installed if necessary.

Up to three alarms cables can be connected per BTS.

Run the external alarm 1. Use a 4 pair L907 cable, as described in Tools (Section 1.4.1).

cables: 2. Run the external alarms cable from the COBO to the DDF or the sensors.

3. Cut the cables to the required length. On the micro BTS, the cable must

reach the bottom of the COBO.

Leave a reserve of 20 cm at one end for connection purposes.

4. Connect the cables to their sensors or to the DDF (refer to the site

documentation).

5. Label the external alarm cable on the DDF, as shown in Apply Labels to

COBO (Section 2.5.1.1).

Alarm position in COBO Color

Quad 1 1/5 White

(first / second cable L907) Grey

2/6 Blue

(first / second cable L907) Purple

Quad 2 3/7 Yellow

(first / second cable L907) Grey

4/8 Brown

(first / second cable L907) Purple

The external alarm cables are run.

3BK 20460 0001 RJZZA Ed.15 27 / 52

2 Install A9110 BTS

2.3.3.5 Run and Connect Antenna Jumpers to Feeders

Note: Antenna jumpers are connected to the antenna outputs of the micro BTS

during the commissioning.

The corresponding ends of antenna jumpers are protected by a protection cap.

The antenna connectors must be dry before connection.

On the micro BTS, the antenna jumpers must reach the bottom part of the micro

BTS housing and there must be at least 30 cm of cable available for connection.

Connect the antenna jumpers to the antenna feeders:

For indoor sites, as shown in the following figure.

1 2

1234

1234

1234

1234

1 : Antenna feeder

2 : Antenna jumper cable

For outdoor sites, as shown in the following figure.

1 2 3 4

1234

1234

1234

1234

1 : Antenna feeder

2 : Tape

3 : Tape auto-vulcanisant

4 : Antenna jumper cable

The antenna jumpers are connected to the feeders.

28 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.4 Install BTS Equipment

This section tells you how to position and fix the BTS equipment.

2.4.1 Types of Fixation

The following figures show the fixation for:

The MOFRA

400.6

200

12

The MOCO to the back cover

Back cover

4 Screws M5

3BK 20460 0001 RJZZA Ed.15 29 / 52

2 Install A9110 BTS

The half clamps to the MOCO and to the back cover (for mast installation)

Half clamps

4 SCREWS M6

On different types of walls.

HOLLOW WALL SOLID WALL METAL PARTITION

plastic plug

washer washer

washer

screw

supplied screw

screw

with plug

FLANGE FLANGE

FLANGE

metal plug insert

30 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.4.2 Case 1: Fix MOCO on a Wall

Fix the equipment on 1. Identify the position where the equipment is to be installed (see Site-Specific

a wall, for an indoor Information (Section 1.2.2)).

installation, without 2. Mark the position of the four fixation holes, using the dimensions shown in

using the cover: Types of Fixation (Section 2.4.1), a spirit level, and the installation drawing.

3. Punch, drill and plug the hole (use the fixation method appropriate to the

type of wall, as shown inTypes of Fixation (Section 2.4.1).

4. Mount the MOCO on the wall, using the flanges, screws and washers,

without tightening them, as shown in the following figure.

4 Dowels S12

MOFRA

COPO

4 Screws M10 x 80

4 Washers

COBO

5. Level the MOCO using the spirit level.

6. Tighten the screws.

The equipment is fixed on the wall.

3BK 20460 0001 RJZZA Ed.15 31 / 52

2 Install A9110 BTS

2.4.3 Case 2: Fix Back Cover and MOCO on a Wall

Fix the equipment on 1. Identify the position where the equipment is to be installed (see Site-Specific

a wall, for an indoor Information (Section 1.2.2)).

installation, using the 2. Mark the position of the four fixation holes, using the dimensions shown in

cover: Types of Fixation (Section 2.4.1) , a spirit level, and the installation drawing.

3. Punch, drill and plug the hole (use the fixation method appropriate to the

type of wall, as shown in Types of Fixation (Section 2.4.1).

4. Fix the back cover to the MOCO (as described in Types of Fixation (Section

2.4.1)).

5. Mount the MOCO on the wall, using the flanges, screws and washers,

without tightening them, as shown in the following figure.

Back cover

4 Dowels S12

4 Screws M10 x 80

4 Washers

6. Level the MOCO using the spirit level.

7. Tighten the screws.

The equipment is fixed on the wall.

32 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.4.4 Case 3: Fix Back Cover and MOCO on a Mast

Fix the equipment on a 1. Identify the position where the equipment is to be installed (see Site-Specific

mast, for an outdoor Information (Section 1.2.2)).

installation, using the 2. Mark the position of the four fixation holes, using the dimensions shown in

cover: Types of Fixation (Section 2.4.1) , a spirit level, and the installation drawing.

3. Fix the back cover to the MOCO (as described in Types of Fixation (Section

2.4.1)).

4. Fix the two half clamps onto the back cover and the MOCO, using the four

M6 screws provided, as shown in Types of Fixation (Section 2.4.1).

5. Assemble the cover and the MOCO on the mast, using the other two half

clamps and the four M10 screws (140 mm long or 200 mm long, depending

on the diameter of the mast), as shown in the following figure. The screws

are supplied with the kit.

4 Screws

M10 x 140 (200)

+

4 Washers

6. Adjust to the required height and orientation.

7. Level the MOCO using the spirit level.

8. Tighten the screws.

The equipment is fixed on the mast.

3BK 20460 0001 RJZZA Ed.15 33 / 52

2 Install A9110 BTS

2.5 Connect the Cables

This section tells you how to connect the cables to the COBO.

Before making any electrical connections, ensure that the safety instructions

are followed.

It is essential that:

The electrical power supply is disconnected. Make sure that all breakers are

switched off.

The antistatic wrist strap is used when working in contact with ABISCO

board.

2.5.1 Prepare Connection

Before you begin the connection procedures, you must:

Be familiar with the connections

Apply the labels to the COBO

Know how to run the cables through the PG glands.

The cables can be connected as follows:

For Master (for Master - Slave Configuration with 2 alarm cables)

POWER MASTER

Abis

M

Ground

POWER Abis IEB IEB

S2 POWER POWER

MASTER S1

S2 S1

EXT S2 S1

M Ground cables

ALARMS

Ground cable (going to slaves)

(comming from site earthling system)

34 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

For Slave 1 (with one alarm cable)

POWER

POWER IEB EXT

SLAVE 1 S1 ALARM

Ground cable

(goes to Master)

For Slave 2 (with one alarm cable)

POWER

IEB EXT

POWER Ground cable

S2 ALARMS

MASTER (goes to Master)

3BK 20460 0001 RJZZA Ed.15 35 / 52

2 Install A9110 BTS

2.5.1.1 Apply Labels to COBO

The labels must be applied after each end cable connection.

They must be visible inside the COBO, the power box or on the DDF.

Before beginning, you 1. Open the COBO

must apply the labels 2. Label the COBO cover:

to the COBO: MASTER, SLAVE 1, SLAVE 2.

This is shown in the following figure (example for master).

Labels applied in factory

MASTER

COBO door

MASTER

The labels are applied.

36 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.5.1.2 Apply Labels to Cables

Apply the labels to the cables as follows:

For the power cables, as shown in the following figure.

Power box side Master side

Master Master Main

220 V− AC 220 V− AC 220 V− AC

Master side Slave BTS side

Slave 1 Slave 1

220 V− AC 220 V− AC

Master side Slave BTS side

Slave 2 Slave 2

220 V− AC 220 V− AC

For the Abis cables, as shown in the following figure.

Note: In normal situations, only one Abis cable (4 pairs) is used to connect to the

master. A second cable is used when only necessary.

Master BTS side (COBO) DDF side

Master Master

ABIS1 ABIS1

Master BTS side (COBO) DDF side

Master Master

ABIS2 ABIS2

For the alarm cables, as shown in the following figure (example for master).

Note: A maximum of 3 alarm cables per BTS can be connected, depending on the

number of sensors and their source.

Master BTS side (COBO) DDF/sensors side

Master Master

ALARM 1 ALARM 1

Master BTS side (COBO) DDF/sensors side

Master Master

ALARM 2 ALARM 2

Master BTS side (COBO) DDF/sensors side

Master Master

ALARM 3 ALARM 3

For the IEB cables, as shown in the following figure.

MASTER SIDE SLAVE 1 SIDE

MASTER−SIDE SLAVE−SIDE

CON. TO MSCO MSCO

SLAVE 1

MASTER SIDE Labels applied in factory SLAVE 2 SIDE

CON. TO MSCO MSCO

SLAVE 2

MASTER−SIDE SLAVE−SIDE

3BK 20460 0001 RJZZA Ed.15 37 / 52

2 Install A9110 BTS

2.5.1.3 Run Cables Through PG Glands

Mount the PG gland on the cables, as follows:

For Abis and alarm cables, as shown in the following figure.

For the power cable, as shown in the following figure.

38 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.5.2 Connect Earth Cable

Note: This procedure applies for master and slaves.

The earth cable for the master is connected to the top right part of the COBO.

The earth cables coming from slaves are connected to master in the same

place (bottom right part of the COBO).

Connect the earth cable 1. Prepare the earth cables. Cut the earth cables to the necessary length,

to all the micro BTS: as shown in the following figure.

Connection of earth cable for

master (master side)

Principle of ground connection

COBO COBO COBO

S1 M S2

Connection of earth cables for

slaves (master and slaves sides)

2. Strip 10 mm of cable insulation from each end.

3. Crimp lugs on the ends (on one end only for the master, and at both ends

for the slaves).

4. For the master: On the micro BTS, fix the end of cable, using a screw and

washers, on the top right hole of the COBO.

For the slaves: On each slave side, fix the end of cable, using a screw and

washers, on the bottom right hole of the COBO. On the master, connect

the earth cables coming from slaves to the same place in the bottom right

part of the master COBO.

The earth cable is connected to the micro BTS.

3BK 20460 0001 RJZZA Ed.15 39 / 52

2 Install A9110 BTS

2.5.3 Connect Power Cable

Do not work under power. Open the circuit breakers to ensure that the power

supply is disconnected.

2.5.3.1 Connect Power Cable Directly to Power Box

Connect the power cable 1. Run the power cable inside the COBO through the PG16 gland on the top

from one micro BTS right part, as shown in Run Cables Through PG Glands (Section 2.5.1.3).

(master or slave) to the 2. Cut the cable to the required length.

power panel: 3. Strip 40 mm of external insulation from the cable.

4. Strip 5 mm of insulation from each wire within the cable (there are 3 wires

per cable).

5. Insert the stripped wires into the clamp strips labeled MAIN, as shown in

the following figure.

BROWN BLUE

Y/G

Ferrule

Wire

L PE N

40 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

6. Label the power cable on the COBO side, as shown in Apply Labels to

COBO (Section 2.5.1.1).

The power cable is connected from one micro BTS (master or slave) to the

power panel.

2.5.3.2 Connect Power Cable Between Master and Slaves

Note: Use this connection for slaves which are powered by the master BTS.

Connect the power cable between the slaves and the master:

On the slaves 1. Remove the unused, top left PG13.5 gland and replace with a PEG13.5

protection (to close the hole), taken from the master.

2. Strip 40 mm of external insulation from the cable.

3. Strip 5 mm of insulation from each wire within the cable.

4. Run the end of power cable through the top right PG16 gland (leave

sufficient length for connection purposes).

5. Insert the stripped wires into the clamp strips on the ACCO, within the slave

COBO, as shown in the following figure.

SLAVE 2 MASTER SLAVE 1

PG 13.5 gland

taken from Slave 1

PG 13.5 gland

taken from Slave 2

BROWN BLUE

Y/G

Ferrule

Wire

L PE N

PG 13.5 PG 13.5

Slave 2 Master Slave 1

PEG 13.5

PEG 13.5

6. Label the cable, as shown in Apply Labels to COBO (Section 2.5.1.1).

3BK 20460 0001 RJZZA Ed.15 41 / 52

2 Install A9110 BTS

The power cable between the slaves and the master is connected from the

slave end.

On the master 1. Insert the PG 13.5 gland taken from the slave into the corresponding hole on

the master COBO (see 1).

2. Cut the cable to the required length.

3. Strip 40 mm of external insulation from the cable.

4. Strip 5 mm of insulation from each wire within the cable.

5. Run the cable through the PG13.5 gland (leave sufficient length for

connection purposes) from the slave, and screw it into the corresponding

bottom right hole of the master COBO (Slave 1 or Slave 2).

6. Insert the stripped wires into the clamp strips on the ACCO, in the master

COBO.

7. Label the cable, as shown in Apply Labels to COBO (Section 2.5.1.1).

The power cable between the slaves and the master is connected from the

master end.

2.5.4 Connect Abis Cable

Connect a 75 or 120 Ohm 1. Ensure that the jumpers for impedance selection on ABISCO are in park

Abis cable to the BTS: position (120 Ohm).

2. Prepare the Abis cable.

3. Cut the cable to the required length.

4. Run the Abis cable through the PG13.5 gland on the top left part of the

COBO (for more information, see Run Cables Through PG Glands (Section

2.5.1.3)).

5. Insert the Abis cable into the clamp strips, as shown in the following figures:

Connect the 120 ohm Abis cable from the COBO

Abis 1 Abis 1 Abis 2 Abis 2

TXC RXC TXC RXC

Abis 1 Abis 1 Abis 2 Abis 2

TXS RXS TXS RXS

75

W G Y G BL P BR P Ohm

120

QUAD 2 Jumpers

QUAD 1 in park position

G − Grey

Y − Yellow

W − White

Rubber sleeve 120 ohm P − Purple

BR − Brown

BL − Blue

42 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

Connect the 75 Ohm Abis cable to the COBO.

Abis 1 Abis 1 Abis 2 Abis 2

TXC RXC TXC RXC

Abis 1 Abis 1 Abis 2 Abis 2

TXS RXS TXS RXS

Jumpers in

active position

1 3 2 4

75 ohm

Rubber sleeve

6. Label the Abis cable on the COBO side (as shown in Apply Labels to

COBO (Section 2.5.1.1)).

7. Tighten the cable gland, as shown in the following figure.

Ensure that the cable gland is tightened correctly so that the unit will fit

into position easily.

M20 cable gland 60°

The 75 or 120 Ohm Abis cable is connected.

3BK 20460 0001 RJZZA Ed.15 43 / 52

2 Install A9110 BTS

2.5.5 Connect External Alarm Cables

Note: It is important to note the following:

Each A9110 unit has 8 inputs for external alarms, so it is possible to connect

24 external alarms for the maximum configuration (3 units)

Up to 3 alarm cables can be connected per unit

For more information about connecting the external sensors, see

Site-Specific Information (Section 1.2.2).

Connect the external 1. Cut the alarms cable to the necessary length.

alarms cable to the 2. Prepare the alarms cable as shown in the following figures:

micro BTS:

For X102, X104, X105, X106, X107, X112 and X115 connectors on

ABISCO (old / new variant)

44 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

For external alarm cables (master or slave), using 2 L907 Cables (old

ABISCO variant)

AL1/AL5 AL2/AL6

G W P BL

AL3/AL7 AL4/AL8

G Y P BR

QUARTE 2

QUARTE 1

Rubber sleeve

G − Grey

Y − Yellow

W − White

P − Purple

BR − Brown

BL − Blue

Alarm Alarm

cable 2 cable 1

For external alarm cables (master or slave), using 2 L907 Cables (new

ABISCO variant).

AL1 AL2

G − Grey

Y − Yellow

W − White G W P BL QUARTE 1

P − Purple

BR − Brown

AL3 AL4

BL − Blue

G Y P BR

AL5 AL6

QUARTE 2

G W P

BL

AL7 AL8

P BR

G Y

QUARTE 1 QUARTE 2

Rubber Rubber

sleeve sleeve

Alarm Alarm

cable 2 cable 1

Alarm cable 2 Alarm cable 1

3. Run the external alarm cable through the PG11 gland.

4. Run the alarms cable through the PG13.5 gland on the top left part of the

COBO (see Run Cables Through PG Glands (Section 2.5.1.3) ).

5. Insert the external alarm cable into the clamp strips.

3BK 20460 0001 RJZZA Ed.15 45 / 52

2 Install A9110 BTS

6. Label the external alarms cable on the COBO side (as shown in Apply

Labels to COBO (Section 2.5.1.1)).

7. For each A9110 BTS installed, you must attach the following straps:

Between the PMS_AL and AXIN4

Between the COBO_AL and AXIN5.

The external alarm cables are connected to the master and slaves.

2.5.6 Connect IEB Cables

Note: IEB cables are only connected when installing slaves.

Connecting the IEB cable to the micro BTS units is not an installation task;

this task is performed by the commissioning team after the micro BTS are

connected to the COBO.

Connect the IEB cables 1. Label the IEB cable at master and slave side (as shown in Apply Labels to

between the master and COBO (Section 2.5.1.1)).

the slaves: 2. Connect the IEB PG11 glands to the COBO on the master and the slaves,

as shown in the following figure.

SLAVE 2 MASTER SLAVE 1

To SLAVE 2 To SLAVE 1

3. Use tie wraps to fix the IEB cables from the master to the slaves.

The IEB cables are connected between the master and the slaves.

46 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.6 Install the Fan Hat (Option)

This section tells you how to:

Fix the fan hat to the cover

Connect the fan hat to the COBO

Install the front cover and connect the fan.

Note: If the fan is installed, it is mandatory to install the cover.

Fan version 3BK 08681 AB requires the G-PG11 kit (reference 3BK 26853

AAAA) listed in Installation Kits (Section 1.4.1.2).

2.6.1 Fix Fan Hat to Cover

Fix the fan hat to the 1. Unpack the fan hat.

cover: 2. Separate the top cover from the front cover, if necessary.

3. Attach the fan hat (4) to the front cover (6) with the 3 screws provided,

as shown in the following figure.

1, 4 : the fan hat

2 : power supply cable for fan

3 : fan alarm cable

5 : where to fix with screws

6 : BTS front cover

7 : sticky support to apply (for fixing the cables with tie wraps)

8 : cables fixed along the cover

4. Run the fan cables along the cover, along the bottom of the casing.

5. Fix the cables on to the cover with the sticky supports and tie wraps provided.

3BK 20460 0001 RJZZA Ed.15 47 / 52

2 Install A9110 BTS

The fan hat is fixed to the cover.

2.6.2 Connect the Cables at COBO

In the following figures:

1 indicates the fan power supply cable (MCAC)

2 indicates the cable for fan alarm (MCAL)

3 indicates a connector for the MCAL cable

4 indicates a connector for the MCAC cable.

The following figures show how to connect the cables on the COBO for the:

Old ABISCO

1

48 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

New ABISCO

1

Connect the fan cables 1. Open the COBO.

on the COBO: 2. Replace the PC cap with the PG gland before inserting the MCAC cable (1).

For more information about the PG gland, see Run Cables Through PG

Glands (Section 2.5.1.3)

3. Run the MCAC cable (3BK 08954 AAaa) (1) through the PG gland into

the COBO.

4. Connect the MCAC cable (1) to the connector (4).

5. Replace the PC cap with the PG gland before inserting the MCAL cable

(3BK 08953 AAαα) (2) into the COBO.

6. Connect the MCAL cable (2) to the alarm connector (3), respecting the wire

polarity (brown — left, white — right).

Note: The fan alarm must be connected to external alarm number 4, as shown in

the following figure.

Old ABISCO

X104,

X115

3

X105,

X112

X100: MMI BROWN WHITE

X106,

X110

X107,

X102

4 1

New ABISCO X104,

X115

3

X105,

X112

X100: MMI BROWN WHITE

X107

X106,

X102

The fan cables are connected to the COBO.

3BK 20460 0001 RJZZA Ed.15 49 / 52

2 Install A9110 BTS

2.6.3 Install Front Cover and Connect Fan

Install the front cover 1. Assemble the front and back parts of the front cover with fan hat, as shown

with fan hat on the BTS in the following figure.

and connect the fan:

2. Tighten the screws on the bottom of the cover

3. Lock the fan hat with the key at the top.

4. Connect the fan, as shown in the following figure.

Connect the:

Power supply input (1) from the fan to the power supply output (3)

from COBO

Alarm cable output (2) from the fan to the alarm input cable (4) to COBO.

The front cover with fan hat is installed on the BTS and the fan is connected.

50 / 52 3BK 20460 0001 RJZZA Ed.15

2 Install A9110 BTS

2.7 Close the Covers

Close the cover of the 1. Close the COBO cover using the three screws provided with the kit.

COBO: 2. Fix the front cover on the back cover, if required, as shown in the following

figure.

3. Loop the IEB cables into bottom cover, if required.

4. Put any unconnected ends of antenna jumpers into the bottom cover.

5. Adjust the metallic plate on the COBO cover so that it fits correctly with the

bottom cover lock, as shown in the following figure.

6. Close and lock the bottom cover, as shown in the following figure.

7. Close and lock the power box.

The COBO is closed.

3BK 20460 0001 RJZZA Ed.15 51 / 52

2 Install A9110 BTS

2.8 Before You Leave

Before you leave, you must:

1. Close and lock the cabinet door. Return the key to the site manager.

2. Remove all unused equipment

3. Clean the site.

4. Return the completed forms relating to the operation to base.

52 / 52 3BK 20460 0001 RJZZA Ed.15

Вам также может понравиться

- 9125 TC Inst ManualДокумент64 страницы9125 TC Inst ManualAniq AhmedОценок пока нет

- 9100 Compact BTS EVO InstallationДокумент84 страницы9100 Compact BTS EVO InstallationAniq AhmedОценок пока нет

- Alcatel BSS: External Alarm Box Installation and Commissioning ManualДокумент32 страницыAlcatel BSS: External Alarm Box Installation and Commissioning ManualYasser AlqadhiОценок пока нет

- Extension CCPДокумент30 страницExtension CCPrjskalu123 123Оценок пока нет

- Alcatel-Lucent GSM: 9110-E Micro BTS Commissioning ManualДокумент70 страницAlcatel-Lucent GSM: 9110-E Micro BTS Commissioning Manualdvvdvv100% (1)

- A9119 BTS InstalationДокумент66 страницA9119 BTS Instalationsohappy3Оценок пока нет

- Synchronize BTS Master Slave PDFДокумент32 страницыSynchronize BTS Master Slave PDFMukul MandalОценок пока нет

- Synchronize BTS Master - SlaveДокумент32 страницыSynchronize BTS Master - SlaveMoustapha AttoОценок пока нет

- Alcatel LucentДокумент30 страницAlcatel LucentKelvin KabondoОценок пока нет

- E 02Документ86 страницE 02strahinjatomcicОценок пока нет

- Abis Via Satellite ActivationДокумент30 страницAbis Via Satellite ActivationSABER1980Оценок пока нет

- Manual Speeduino EFIДокумент88 страницManual Speeduino EFIAssisОценок пока нет

- BTS Indoor DC Installation ManualДокумент62 страницыBTS Indoor DC Installation ManualTinh DongОценок пока нет

- Speeduino ManualДокумент75 страницSpeeduino Manualyashwanthkrishnan44Оценок пока нет

- Speeduino ManualДокумент57 страницSpeeduino ManualPeter McCracken100% (3)

- Speeduino Manual PDFДокумент58 страницSpeeduino Manual PDFgiapy0000Оценок пока нет

- Speeduino Manual PDFДокумент58 страницSpeeduino Manual PDFgiapy0000Оценок пока нет

- TSP303Plus Operation Manual 2.2.1 enДокумент76 страницTSP303Plus Operation Manual 2.2.1 enpankajrawatextraОценок пока нет

- Speeduino ManualДокумент75 страницSpeeduino ManualCruz StarzОценок пока нет

- Tutorial ATmega ScribДокумент60 страницTutorial ATmega ScribCarlosOlivierОценок пока нет

- Seismic Acquisition, Land System Equipment.Документ205 страницSeismic Acquisition, Land System Equipment.Carlos Terraza OyagaОценок пока нет

- Alcatel BSS: G2 BSC Commissioning ManualДокумент61 страницаAlcatel BSS: G2 BSC Commissioning ManualNavdeepSPОценок пока нет

- Speeduino ManualДокумент86 страницSpeeduino ManualLuciano Malanca100% (1)

- Ez-Screen 14/30 MM Safety Light Curtain: Instruction ManualДокумент97 страницEz-Screen 14/30 MM Safety Light Curtain: Instruction ManualSatish SaweОценок пока нет

- Ud7000 Parte 1 V19Документ56 страницUd7000 Parte 1 V19LaurentEuniceОценок пока нет

- A7670 ESE Installation ManualДокумент42 страницыA7670 ESE Installation ManualTran Tuan NghiaОценок пока нет

- 9153 OMC-R Installation PDFДокумент64 страницы9153 OMC-R Installation PDFMobinetsОценок пока нет

- UM-30201120-ENG - VX120+ FEB - 2020 - Rev3.0.1Документ228 страницUM-30201120-ENG - VX120+ FEB - 2020 - Rev3.0.1Joshua Rodas RocaОценок пока нет

- KohlerДокумент80 страницKohlerroberto carlos herreraОценок пока нет

- Vacon NX Service Manual Vacon NX Service ManualДокумент72 страницыVacon NX Service Manual Vacon NX Service ManualAlexey100% (1)

- Ba281 en PDFДокумент30 страницBa281 en PDFvictor baccaОценок пока нет

- Barco UserGuide R5905724 01 ICMP-Web-Commander-user-guideДокумент55 страницBarco UserGuide R5905724 01 ICMP-Web-Commander-user-guideeeyyee GsОценок пока нет

- Ba880 VLR60-251 enДокумент34 страницыBa880 VLR60-251 enluislisinОценок пока нет

- Alcatel-Lucent GSM: Merge G2 TC To 9125 TCДокумент32 страницыAlcatel-Lucent GSM: Merge G2 TC To 9125 TCYasser AlqadhiОценок пока нет

- M 179996 920ibci Integrator Enus ReveДокумент44 страницыM 179996 920ibci Integrator Enus ReveArnas RisqiantoОценок пока нет

- BSC Evolution Hardware A9130Документ108 страницBSC Evolution Hardware A9130haiquan74Оценок пока нет

- Ud7000 Parte 2 V19Документ134 страницыUd7000 Parte 2 V19LaurentEuniceОценок пока нет

- B QR 210L/350/500: Arcoi EalityДокумент141 страницаB QR 210L/350/500: Arcoi Ealityoscar_gar75Оценок пока нет

- PHXG-91B, PHWX-81B, Phwu-81b PDFДокумент143 страницыPHXG-91B, PHWX-81B, Phwu-81b PDFJorge Armando LaiОценок пока нет

- WSC Tecnomanager: Operator ManualДокумент56 страницWSC Tecnomanager: Operator ManualVitaliy RyzhovОценок пока нет

- Barco Xlm-hd30 ManualДокумент133 страницыBarco Xlm-hd30 Manualtonymontana2009Оценок пока нет

- Man E3262 LE202, E3268 LE212 Operating Instructions ManualДокумент118 страницMan E3262 LE202, E3268 LE212 Operating Instructions Manualthuan vu vanОценок пока нет

- Jupiter BT2 ENДокумент61 страницаJupiter BT2 ENkędzierzawyОценок пока нет

- Installation Manual: Digital Diagnostic Junction BoxДокумент72 страницыInstallation Manual: Digital Diagnostic Junction BoxHarukaAoiОценок пока нет

- Atys c25 Ats Controller Installation and Operating Manual 2022-09-549780 enДокумент42 страницыAtys c25 Ats Controller Installation and Operating Manual 2022-09-549780 enHabbil TamageОценок пока нет

- Suflante Huber - BA381-ENДокумент30 страницSuflante Huber - BA381-ENRotheHunterОценок пока нет

- USM-Visual Space Manager-ENGДокумент86 страницUSM-Visual Space Manager-ENGCosmin AnghelОценок пока нет

- JAKARTA EE Server Faces 3.0Документ453 страницыJAKARTA EE Server Faces 3.0andperzОценок пока нет

- RFP For Server Augmentation and Storage RFP For Server Augmentation and Storage RFP For Server AugmentationДокумент46 страницRFP For Server Augmentation and Storage RFP For Server Augmentation and Storage RFP For Server AugmentationpallavitiwariwwwОценок пока нет

- TP 6834Документ48 страницTP 6834Brandon AtzОценок пока нет

- Survivor Sst3 Technical Manual: Direct Thermal Label PrinterДокумент50 страницSurvivor Sst3 Technical Manual: Direct Thermal Label PrinterJairo David Cardoza BrenesОценок пока нет

- Manual NexusДокумент100 страницManual NexusDavid EguezОценок пока нет

- Manual LKДокумент80 страницManual LKDiego Alonso Nuñez MedinaОценок пока нет

- Lebe0049 02Документ313 страницLebe0049 02Bilel Ben SlamaОценок пока нет

- Liebert NX 480vДокумент108 страницLiebert NX 480vWilliam AlvarezОценок пока нет

- FDS 5000 en From HW 200Документ106 страницFDS 5000 en From HW 200Krittaphak Hacheyram0% (1)

- Elmo Rletschle V-VC 202 User ManualДокумент32 страницыElmo Rletschle V-VC 202 User ManualFirdhaus JaniОценок пока нет

- Radio Network Design Training Session 4 Hanoi 20th Feb 04Документ15 страницRadio Network Design Training Session 4 Hanoi 20th Feb 04phantd_hcmОценок пока нет

- Optimisation Manual: BASE N.v./s.aДокумент27 страницOptimisation Manual: BASE N.v./s.aphantd_hcmОценок пока нет

- GSM & GPRSДокумент19 страницGSM & GPRSphantd_hcmОценок пока нет

- Multiple Access and Modulation in GSM: Extension School Harvard UniversityДокумент17 страницMultiple Access and Modulation in GSM: Extension School Harvard Universityphantd_hcmОценок пока нет

- Mobifone 4G/5G Trial Band 2600MhzДокумент23 страницыMobifone 4G/5G Trial Band 2600Mhzphantd_hcm100% (1)

- Provisional Acceptance Test PAT Report FДокумент5 страницProvisional Acceptance Test PAT Report Fphantd_hcmОценок пока нет

- A9110 Functional DescriptionДокумент232 страницыA9110 Functional Descriptionphantd_hcmОценок пока нет

- BTS A9100 Maintaince PDFДокумент146 страницBTS A9100 Maintaince PDFphantd_hcmОценок пока нет

- RBS 9100 - Hardware Description PDFДокумент708 страницRBS 9100 - Hardware Description PDFphantd_hcmОценок пока нет

- BTS Terminal PDFДокумент152 страницыBTS Terminal PDFphantd_hcmОценок пока нет

- File Server Resource ManagerДокумент9 страницFile Server Resource ManagerBùi Đình NhuОценок пока нет

- Micromine TutorialДокумент5 страницMicromine TutorialFerdinand Siahaan100% (1)

- User Manual ManoScanДокумент58 страницUser Manual ManoScanNurul FathiaОценок пока нет

- DIFFERENCE BETWEEN Intrior Design and DecorationДокумент13 страницDIFFERENCE BETWEEN Intrior Design and DecorationSadaf khanОценок пока нет

- English Idioms and PhrasesДокумент384 страницыEnglish Idioms and Phrasesthwe thweОценок пока нет

- Characteristics of Victorian BritainДокумент3 страницыCharacteristics of Victorian BritainmwaqasenggОценок пока нет

- Koehring ManualДокумент56 страницKoehring ManualKyle A. Nolan100% (3)

- Rastriya Swayamsewak SanghДокумент60 страницRastriya Swayamsewak SanghRangam Trivedi100% (3)

- Etymological Wordplay in Ovid's Pyramus and ThisbeДокумент5 страницEtymological Wordplay in Ovid's Pyramus and Thisbeignoramus83Оценок пока нет

- Nexus 1500+ Power Quality Meter User Manual - E154713Документ362 страницыNexus 1500+ Power Quality Meter User Manual - E154713Antonio BocanegraОценок пока нет

- Empowerment TechnologyДокумент2 страницыEmpowerment TechnologyRegina Mambaje Alferez100% (1)

- Syllabus ClinPhar143Документ2 страницыSyllabus ClinPhar143Angel GoОценок пока нет

- Instrumentation Design BasicsДокумент28 страницInstrumentation Design BasicsCharles ChettiarОценок пока нет

- 2018-3-27 MIDAS Civil Presentation Curved BridgesДокумент57 страниц2018-3-27 MIDAS Civil Presentation Curved BridgesShishir Kumar NayakОценок пока нет

- BRB Personal Care Cost Effictive Guide Formulation Edition 2019Документ28 страницBRB Personal Care Cost Effictive Guide Formulation Edition 2019Abdulrahman HamdanОценок пока нет

- Minolta Spotmeter f-1 PDFДокумент50 страницMinolta Spotmeter f-1 PDFmacpator100% (1)

- Test Plan TemplateДокумент3 страницыTest Plan TemplateMurtazaОценок пока нет

- Design and Fabrication of Light Electric VehicleДокумент14 страницDesign and Fabrication of Light Electric VehicleAshish NegiОценок пока нет

- Umihara Et Al-2017-Chemistry - A European JournalДокумент3 страницыUmihara Et Al-2017-Chemistry - A European JournalNathalia MojicaОценок пока нет

- PE 12 Q3 WK1-2 Understanding On Health Related FitnessДокумент8 страницPE 12 Q3 WK1-2 Understanding On Health Related FitnessEmarkzkie Mosra OrecrebОценок пока нет

- 67 9268Документ34 страницы67 9268Salvador ReyesОценок пока нет

- Concor PI CCDS 11 All StrengthsДокумент10 страницConcor PI CCDS 11 All Strengthsgigid afandiОценок пока нет

- A3 Report Template Checklist - SafetyCultureДокумент4 страницыA3 Report Template Checklist - SafetyCulturewarriorninОценок пока нет

- UBO - Lecture 07 - Implementing and Managing Organisational ChangeДокумент0 страницUBO - Lecture 07 - Implementing and Managing Organisational ChangeShahNooraniITОценок пока нет

- Parker (T6, T6D) Hydraulic Vane PumpsДокумент12 страницParker (T6, T6D) Hydraulic Vane PumpsMortumDamaОценок пока нет

- 27 Technip Energies - JD (PWD Students Only)Документ1 страница27 Technip Energies - JD (PWD Students Only)0901EE201067 KUNAL JOLLY SAXENAОценок пока нет

- CE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreДокумент8 страницCE - 441 - Environmental Engineering II Lecture # 11 11-Nov-106, IEER, UET LahoreWasif RiazОценок пока нет

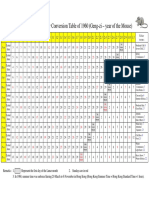

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Документ1 страницаGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamОценок пока нет

- Compact Switch: Series 96201, 96211, 96221Документ2 страницыCompact Switch: Series 96201, 96211, 96221Sales DIGIHU100% (1)

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsДокумент24 страницыSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalОценок пока нет