Академический Документы

Профессиональный Документы

Культура Документы

Designing of Flexible Pavement by Using Geosynthetic Material (Cotton Fiber)

Загружено:

GRD JournalsОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Designing of Flexible Pavement by Using Geosynthetic Material (Cotton Fiber)

Загружено:

GRD JournalsАвторское право:

Доступные форматы

GRD Journals- Global Research and Development Journal for Engineering | Volume 6 | Issue 1 | December 2020

ISSN- 2455-5703

Designing of Flexible Pavement by using

Geosynthetic Material (Cotton Fiber)

B Mary Devika

Department of Civil Engineering

Vishnu Institute of Technology, Bhimavaram, Andhra Pradesh

B Durga Vara Prasad K Suseela

Department of Civil Engineering Department of Civil Engineering

Vishnu Institute of Technology, Bhimavaram, Andhra Vishnu Institute of Technology, Bhimavaram, Andhra

Pradesh Pradesh

Abstract

Soil stabilization is the process which involves enhancing the physical properties of the soil in order to improve the strength,

durability etc. by blending additives. By blending cotton fibers to the soil the CBR values will improve and thickness of

pavement layer also reduces. By the application of soil stabilization method in construction the cost gets reduced. The liquid

limit of the soil with addition of cotton fibers was found to be decreasing when compared to liquid limit of soil alone. The plastic

limit of the soil decreases with the blending of fibers. The shrinkage limit of the soil was increased with increase in fibers. The

MDD of the soil with addition of cotton fibers by weight of soil is found to be increasing upto 0.75% after that it decreases and

the corresponding OMC is decreased with addition of fibers. The shear strength of soil decreased substantially with addition of

cotton fibers. The CBR value of the soil increased substantially. Different tests were conducted in order to determine the

different characteristics and properties of the red soil and obtained with following results. The liquid limit of the soil alone was

found to be 36.6%. The MDD of the soil with addition of 0.25%, 0.5% cotton fibers by weight of soil is found to be decreased by

0.84% and 0.76% , 1.0% cotton fibers by weight of soil is found to be increased by 0.11 % and 16.98% respectively and the

corresponding OMC is decreased by 15.62%, 21.87% and 33.75% respectively. The shear strength of the soil with the addition

of 0.25%, 0.5%, 0.75% and 1% of cotton fibers is found to be decreased by 38.57%, 38.57%, 35.25% and 5.85%. The CBR

value of the soil with addition of 0.25%, 0.5%, 0.75% and 1.0%, cotton fibers by weight of soil is found to be expanded. flexible

pavement design thickness before stabilization is obtained as 450mm and after stabilization is obtained as 250mm.The estimated

cost for constructing flexible pavement before stabilization of soil is obtained as 4018051 Rs/Km and after stabilization of soil is

obtained as 3721895 Rs/Km. the estimated cost after stabilization is found to be decreased by 7.35%.

Keywords- Cotton Fiber, CBR Test, Stabilization

I. INTRODUCTION

The land is used everywhere for different structures, from ordinary buildings to skyscrapers, bridges to airports, and from rural

roads to expressways. All the civil engineering structures are located on different soil sheets. Soil can be elucidating as a material

consisting of rock particles, sand, silt, and clay. On average 1 lakh sq. km area is covered by lateritic soil deposits, 5 lakh sq. km

area is covered by sand dunes and 3 lakh sq. km area is covered by black cotton soil. Geo synthetics are synthetic products made

from many types of polymers which may be either woven or Non-Woven. Polymers are used to enhance the characteristics of

soil and have provided a practical way of constructing civil engineering structures economically. In this study, we are employing

bamboo fibers as geosynthetic material for the stabilization of soil. Soil properties differ greatly and the construction of

structures depends on the soil's bearing capacity, so to increase the load-bearing capacity, we need to stabilize the soil. Soil

gradation is also a very significant function to keep in mind when dealing with soils. The soils may be well-graded, which is

desirable since they have fewer voids or graded uniformly, which although sound stable, has more voids. During the construction

phase, if weak soil strata are encountered, the usual practice followed is replacing the weak soil with some other good quality

soil. The cost of subgrade preparation by replacing the poor soil with good quality soil is higher than that of subgrade preparation

by using various stabilization techniques to stabilize the locally available soil. Stabilization can effectively increase the strength-

giving parameters of the soil to the required amount. It enhances the strength of the soil, thus, improving the soil bearing

capacity. It is more economical both in terms of cost and energy to improve the bearing capacity of the soil rather than going for

a deep foundation or raft foundation ItIt is often used on slopes to provide the soil with more stability. Sometimes soil

stabilization is also used to stop soil erosion or formation of dust, which is very useful mainly in dry and arid weather. For soil

water-proofing, stabilization is often done; this prevents water from entering the soil and thus protects the soil from losing its

strength. It makes it easier to decrease the change in soil volume due to changes in temperature or moisture content.

All rights reserved by www.grdjournals.com 30

Designing of Flexible Pavement by using Geosynthetic Material (Cotton Fiber)

(GRDJE/ Volume 6 / Issue 1 / 006)

II. LITERATURE REVIEW

A. AyushMithal and Dr. ShalinuShukla

The effectiveness of the use of geotextiles as a soil stabilization reinforcement material for various engineering works was

studied by AyushMithal and Dr. ShalinuShukla. Their aims were to study and implement geotextile properties (such as physical

properties, mechanical properties, hydraulic properties, endurance properties and durability properties), geotextile fibers (natural

and synthetic fibers), geotextile types, geotextile functions, geotextile application, geotextile properties, and geotextile

properties., and impact of geotextiles on the environment. They have concluded that, due to the versatility of functions of

geotextiles they can be used in many important civil engineering works. Not only does the use of geotextiles lower building

costs, but it also lowers maintenance costs.

B. Harshita Bairagi et al

Harshita Bairagi et al., studied the effectiveness of jute fibers in controlling the swelling behavior of black cotton soil measured

in lab with and without use of randomly reinforced jute fibers in the soil. Their objectives were to assess the soil's CBR values

and unconfined compressive strength. The different tests conducted were sieve analysis, Atterbegs limits, differential swelling

test, proctor test, CBR test and unconfined compression test. They concluded from the test that there was a significant

improvement in the shrinkage limit, optimum moisture, dry density, CBR value and soil shear strength, and the swelling

behaviour was also reduced by the addition of jute fibers to black cotton soil.

III. EXPERIMENTAL INVESTIGATION

The Highway Research Board (HRB) classifies the soil strata as black cotton soil and uses effective sampling methods, such as

the Core Cutter Method. To test the features such as Atterbegs Limits, i.e. Using Liquid Limit Casagrande Process, Plastic limit

by rolling the sample to a thread of 3 mm diameter, Shrinkage limit with Shrinkage apparatus, Optimum Moisture Content,

Grading by Sieve Analysis and Maximum Dry Density with Standard Proctor Test and California Bearing Ratio Test as well.

The determination of the properties such as liquid limit, plastic limit, shrinkage limit, optimum moisture content, maximum dry

density, CBR value, and shear strength for different concentrations of Geosynthetic material with black cotton.

Using pavement design catalogues published by IRC SP: 20-2002, the pavement thickness design will be done. The

road estimate is carried out by considering items such as Jungle Cutting, Roadway and Drains Earthwork Excavation,

compacting and grading, etc., as per SR 2014-15 and suggested specifications for the stabilization mixture of Bamboo fibers as

Geo Synthetic material. Using Unconfined Compression Test to conduct four days of soaked CBR and Shear test.

In order to determine the various characteristics and properties of the soil, different experiments were performed. The procedure

for each of the tests is described below.

A. Wet Sieve Analysis

By mechanical analysis, the distribution of the grain size is found. If the percentage fines are more there is a need to conduct wet

sieve analysis.

B. Liquid Limit Test

The Casagrande test was performed to study the liquid limits of the soil. Using Casagrande's apparatus or the standard liquid

limit test apparatus, the liquid limit is usually calculated by a mechanical method. The liquid limit is defined according to this

method as the moisture content at which 25 blows or drops in the standard liquid limit apparatus will just close a groove of

standardized dimensions cut by a specified amount in the sample by the grooving tool.

C. Cone Penetration Method

Another method used to test the soil's liquid limit is the method of cone penetration. The liquid limit of the soil is defined by the

cone penetration method as the water content in the soil sample when the penetration depth of the standard cone is 20 mm. The

depths to which the standard metal cone penetrates into soil paste samples prepared in 5 seconds with different water contents are

measured.

D. Plastic Limit Test

It is necessary to perform plastic limit testing in order to study the Atterbegs limit. The plastic limit (PL) is the water content at

which the soil rolled into a thread of the smallest possible diameter begins to crumble and is 3 mm in diameter.

E. Shrinkage Limit Test

In a remolded soil sample, the shrinkage limit (SL) is the maximum water content, expressed as a percentage of the Oven dry

weight, where any further reduction in the water content does not cause the soil sample to decrease in volume or shrink.

All rights reserved by www.grdjournals.com 31

Designing of Flexible Pavement by using Geosynthetic Material (Cotton Fiber)

(GRDJE/ Volume 6 / Issue 1 / 006)

F. Compaction Test

To study the density of the soil and its corresponding optimum moisture content, the Standard Proctor Test is performed. Soil

compaction is a mechanical process by which, by eliminating air voids, the soil particles are constrained to be packed more

tightly together. Soil compaction causes air voids to decrease and dry density to increase as a result. This can result in an increase

in the shearing strength..

G. Unconfined Compression Test

By performing an unconfined compression test, the shear strength of the soil is determined. Unconfined compression tests are

performed on specimens of cohesive soil. If the lateral confining pressure σ3 is equal to 0, the test can be considered as a special

case of the tri-axial compression test. The cylindrical test specimen may then be mounted directly in a compression testing

system and the compressive load applied to it.

H. California Bearing Ratio (CBR) Test

The CBR test denotes a measure of the resistance of the standard plunger under controlled test conditions to the penetration of

the soil or flexible pavement material.

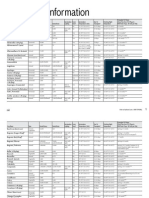

IV. ANALYSIS OF DATA

Graph 1: Compaction Curve for Black cotton soil + 0.50% fibres

Graph 2: Compaction Curve for Black cotton soil + 0.75% fibres

Graph 3: Compaction Curve for Black cotton soil + 1 % fibres

All rights reserved by www.grdjournals.com 32

Designing of Flexible Pavement by using Geosynthetic Material (Cotton Fiber)

(GRDJE/ Volume 6 / Issue 1 / 006)

Graph 4: Compaction Curve for Red soil + 0.25% fibers

Graph 5: Compaction Curve for Red soil + 0.5% fibers

Graph 6: Compaction Curve for Red soil + 0.75% fibers

V. DESIGN OF FLEXIBLE PAVEMENT

Designing pavement constructed on soil that is not stabilized.

The commercial vehicles per day =0 to 15 veh/day.

The CBR value of soil as tested = 1.82 percentage

From the above graph, considering curve A the thickness of pavement =450mm.

Thickness of Sub Base material = 250mm.

All rights reserved by www.grdjournals.com 33

Designing of Flexible Pavement by using Geosynthetic Material (Cotton Fiber)

(GRDJE/ Volume 6 / Issue 1 / 006)

Thickness of Base Coarse material =160mm.

Thickness of Surface Coarse material = 40mm.

Designing pavement to be constructed on stabilized soil

The commercial vehicles per day= 0 to 15 veh/day.

The CBR value of soil as tested = 5.40 %.

From the above graph, considering curve thickness of pavement = 250mm

VI. RESULT AND DISCUSSION

1) The following conclusions are taken on the basis of the current experimental study.

2) The black cotton soil sample has been classified as A-7-6, according to the Highway Research Board classification

3) There is substantial increase in MDD with increase in addition of fibers upto 0.75% by weight beyond which it decreased.

4) There is substantial decrease in OMC with increase in addition of fibers.

5) In unconfined compression test it was observed that the shear strength of the soil has increased with the increase in

percentage of cotton fibers, when compared to that of shear strength of soil tested without fiber.

6) The shear strength of the soil is maximum when 1% (by weight of soil) of cotton fibers is added to it. Hence in order to

obtain higher shear resistance 1% of fibers (by weight of soil) can be considered as the optimum fiber content.

7) The California bearing ratio (CBR) of the soil alone is obtained as 1.82% and it increased to 5.41% after stabilizing it with

optimum percentage of cotton fibers.

8) In the case of red soil there is substantial increase in MDD with increase in addition of fibers.

9) In unconfined compression test it was observed that the shear strength of the soil has decreased with the increase in

percentage of cotton fibers, when compared to that of shear strength of soil tested without fiber.

10) The California bearing ratio (CBR) of the soil alone is obtained as 4.28% and there substantial increase.

REFERENCES

[1] M. Young, The Technical Writer’s Handbook. Mill Valley, CA: University Science, 1989. Sujit Kawade, Mahendra Mapari, Mr.Shreedhar Sharana”

Stabilization of Black cotton soil with lime and Geo-grid”

[2] Vegulla Raghudeep, ”Improvement in CBR value of black cotton soil by stabilization it with vitrified polish waste”

[3] Ayush Mittal, Shalinee Shukla “GEOTEXTILE: AN OVERVIEW”

[4] Harshita Bairagi “International journal of engineering sciences and research technology

[5] Vikas Rameshrao Kulkarni “Experimental study of stabilization of B.C. soil by using Slag and Glass fibers”

[6] Olug benga O. Amu1, Akinwole A. Adetuberu” Characteristics of cotton Leaf Ash Stabilization on Lateritic Soil in Highway Construction”

[7] John Paul V. Antony Rachel Sneha M. ” Effect of random inclusion of cotton fibers on strength behaviour of flyash treated black cotton soil”

[8] I.S: 2720 (Part I)-1983 : “Indian standard for preparation of dry soil samples for various tests”, Bureau of Indian Standards Publications, New Delhi.

[9] I.S: 2720 (Part IV)-1985: “Indian standard for grain size analysis”, Bureau of Indian Standards Publications, New Delhi.

[10] I.S: 2720 (Part IV)-1985: “Indian standard for grain size analysis”, Bureau of Indian Standards Publications, New Delhi.

[11] I.S: 2720 (Part V)-1985: Indian standard for determination of liquid limit and plastic limit”, Bureau of Indian Standards Publications, New Delhi.

[12] I.S: 2720 (Part VII)-1980: “Indian standard for determination of water content- Dry density relationship using light compaction”, Bureau of Indian

Standards Publications, New Delhi.

[13] I.S: 2720 (Part X)-1991 : “Indian standard for determination of unconfined compressive strength”, Bureau of Indian Standards Publications, New Delhi

[14] I.S: 2720 (Part XX)-1992 : “Indian standard for determination of Linear Shrinkage”, Bureau of Indian Standards Publications, New Delhi

[15] I.S: 2720 (Part XVI)-1965: “Indian standard for laboratory determination of CBR”, Bureau of Indian Standards Publications, New Delhi

All rights reserved by www.grdjournals.com 34

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Central Florida Rain Garden ManualДокумент30 страницCentral Florida Rain Garden ManualFree Rain Garden Manuals and More100% (1)

- BOQ Approach RoadДокумент4 страницыBOQ Approach RoadApollo RajkumarОценок пока нет

- Seed-Borne Virus Diseases of PlantsДокумент32 страницыSeed-Borne Virus Diseases of PlantsMuhammad Boota Sarwar100% (3)

- SCHEDULE OF Materials BOQ-ZAHANATIДокумент20 страницSCHEDULE OF Materials BOQ-ZAHANATILenny Erasto100% (4)

- Design and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankДокумент5 страницDesign and Analysis of Underground Circular & Rectangular Water Tank and Intze Water TankGRD JournalsОценок пока нет

- Automatic Face Recognition Attendance System Using Python and OpenCvДокумент7 страницAutomatic Face Recognition Attendance System Using Python and OpenCvGRD Journals100% (1)

- Mechanical Properties of Sustainable Concrte Using Local Limestone Powder As Partial Replacement of CementДокумент4 страницыMechanical Properties of Sustainable Concrte Using Local Limestone Powder As Partial Replacement of CementIsaias Garcia SanchezОценок пока нет

- Optimization of Xanthan Gum Fermentation Utilizing Food WasteДокумент11 страницOptimization of Xanthan Gum Fermentation Utilizing Food WasteGRD JournalsОценок пока нет

- Concrete Mixed Design For C30Документ2 страницыConcrete Mixed Design For C30raju_420034520Оценок пока нет

- Image Based Virtual Try On NetworkДокумент4 страницыImage Based Virtual Try On NetworkGRD JournalsОценок пока нет

- GRDJEV06I060005Документ7 страницGRDJEV06I060005GRD JournalsОценок пока нет

- Chronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningДокумент8 страницChronic Kidney Disease Stage Prediction in HIV Infected Patient Using Deep LearningGRD JournalsОценок пока нет

- Evaluate The Performance of MongoDB NoSQL Database Using PythonДокумент5 страницEvaluate The Performance of MongoDB NoSQL Database Using PythonGRD JournalsОценок пока нет

- Simulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaДокумент13 страницSimulation and Prediction of LULC Change Detection Using Markov Chain and Geo-Spatial Analysis, A Case Study in Ningxia North ChinaGRD JournalsОценок пока нет

- Grdjev06i010003 PDFДокумент4 страницыGrdjev06i010003 PDFGRD JournalsОценок пока нет

- Design and Simulation of LNA Using Advanced Design Systems (ADS)Документ6 страницDesign and Simulation of LNA Using Advanced Design Systems (ADS)GRD JournalsОценок пока нет

- SBC 3023 Mini Project InstructionДокумент5 страницSBC 3023 Mini Project InstructionSaya AtulОценок пока нет

- SeedCropChart BallДокумент7 страницSeedCropChart BallRaluca ModoranОценок пока нет

- Pengaruh Cara Perbanyakan Vegetatif Terhadap Pertumbuhan Kopi Robusta (Coffea Canephora) Klon BP 308 Dan BP 534Документ8 страницPengaruh Cara Perbanyakan Vegetatif Terhadap Pertumbuhan Kopi Robusta (Coffea Canephora) Klon BP 308 Dan BP 534Laili HijriОценок пока нет

- Alternative Building MaterialsДокумент4 страницыAlternative Building MaterialsZubin Kenneth SamuelОценок пока нет

- Model Bankable ProjectsДокумент19 страницModel Bankable ProjectsChiranth ChandОценок пока нет

- Sandy SoilДокумент17 страницSandy SoilAnan S MaishnamОценок пока нет

- Sangare Sall SafiatouДокумент116 страницSangare Sall Safiatoushiksha torooОценок пока нет

- DAR2012 Vol 2Документ760 страницDAR2012 Vol 2AnupamMishraОценок пока нет

- Wheat: Technologies For Enhancing Productivity in Eastern IndiaДокумент37 страницWheat: Technologies For Enhancing Productivity in Eastern IndiaastuteОценок пока нет

- Experimental Investigation On Coir Geotextile Reinforced SubgradeДокумент5 страницExperimental Investigation On Coir Geotextile Reinforced SubgradeDipendra AwasthiОценок пока нет

- Garden of DreamsДокумент2 страницыGarden of DreamsKiran BasuОценок пока нет

- Noting Significant Details in A Selection ReadДокумент2 страницыNoting Significant Details in A Selection ReadMichaela Tandoc Muyano - Bernardo100% (2)

- Super Plasticizer (Retarder & Water Reducing) (Any Branded Company Etc.. FOSROC)Документ2 страницыSuper Plasticizer (Retarder & Water Reducing) (Any Branded Company Etc.. FOSROC)ghaghra bridgeОценок пока нет

- SWEET LIME (Citrus Limettioides) : June 2020Документ18 страницSWEET LIME (Citrus Limettioides) : June 2020ShabbirAli bhattОценок пока нет

- DalbergiasissooДокумент32 страницыDalbergiasissooprajesh612Оценок пока нет

- Home Garden Catalogue 2011-2013Документ57 страницHome Garden Catalogue 2011-2013Dan DanutОценок пока нет

- Factors in The Choice of Mix DesignДокумент31 страницаFactors in The Choice of Mix DesignMudduKrishna shettyОценок пока нет

- Plant TropismsДокумент3 страницыPlant TropismsNikko Gabriel AquinoОценок пока нет

- Quantity Estimates Box CulvertДокумент6 страницQuantity Estimates Box CulvertAshlesha DubeyОценок пока нет

- AAB Ahmednagar 22-12-2015 PDFДокумент1 страницаAAB Ahmednagar 22-12-2015 PDFbharatОценок пока нет

- Revised Indian Standard List After 30 March 2019Документ2 страницыRevised Indian Standard List After 30 March 2019Prashant MankarОценок пока нет

- Poster Li 0139453485Документ1 страницаPoster Li 0139453485Fadhil NoorОценок пока нет

- Dessert Rose Adenium ObesumДокумент8 страницDessert Rose Adenium ObesumDiego FariasОценок пока нет

- Experimental Investigation On Compressive Strength of PaverblockДокумент35 страницExperimental Investigation On Compressive Strength of PaverblockPachai ManiОценок пока нет