Академический Документы

Профессиональный Документы

Культура Документы

CSC Cummins (PT) Speed Control PS 04181

Загружено:

marsh2002Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CSC Cummins (PT) Speed Control PS 04181

Загружено:

marsh2002Авторское право:

Доступные форматы

Product Specification

04181

CSC

Speed Control for

Cummins PT* Fuel System Superior

Performance with

Dual Dynamics

State-of-the-Art Fuel

Limiting

Accepts Load

Sharing Accessories

Isochronous Control

No Mechanical Drive

or Hydraulic Supply

Required

12 or 24 Volt

Operation

APPLICATIONS UL/cUL Listed; CE

Compliant

The CSC speed control is designed for precise Gain and stability adjustments tailor the

control of diesel engines. This quick and simple controls response to the specific engine

retrofit enables you to utilize analog and digital application. Each set of dynamics is

Woodward power management products on independently set to provide the exact engine

Cummins engines equipped with a PTTM* response needed at a specific condition. The

fuel pump. Available for 12 Vdc or 24 Vdc choice of dynamics is selected by a switch. The

applications, the CSC control furnishes state- switch may be a part of the auxiliary breaker

of-the-art start fuel limiting and superior contacts in a generator system, or could be

performance with dual dynamics. automatically set by other changes in the

process being powered.

DESCRIPTION

EASY INSTALLATION

The CSC interfaces directly with the Cummins

EFC rail valve which is mounted inside the The CSC is designed to use existing wiring for

Cummins PT fuel pump. The control works a clean, straightforward installation. No

with normally closed electronic fuel control modifications to the factory-installed control

actuators. The CSCs dual dynamics ensure fast system wiring nor to the factory calibrations of

synchronization with stable parallel operation. the fuel system are needed. A rugged cast

Load sharing devices are available for use in aluminum housing permits installation on the

paralleled applications. engine skid.

*PT is a trademark of Cummins Engine Company, Inc.

OPTIONS

The CSC speed control is compatible with a full line of which drive pumps, compressors, or other mechanical or

Woodward accessories providing for various levels of electrical loads. It can control inlet or exhaust pressure.

precision control of electrical generation or other processes.

Accessories for power systems that can be connected to the AUTOMATIC GENERATOR LOADING

CSC speed control include: CONTROL (AGLC)

(Product Specification 82399)

GENERATOR LOAD SENSOR

Product Specification 82314) The AGLC provides for soft loading or unloading of a

generator set into or out of a load-sharing system at

The Generator Load Sensor is used with the CSC control controlled rates, and tracks the load to provide smooth

to provide droop or isochronous load-sharing capabilities. transfer of power when loading or unloading. Requires a

It allows the use of the SPM-A Synchronizer, Process and Load Sensor.

Import/ Export Control, Automatic Generator Load

Control (AGLC), Automatic Power Transfer and Load AUTOMATIC POWER TRANSFER AND

Control (APTL), or Digital Synchronizer and Load LOAD CONTROL (APTL)

Control (DSLC). (Product Specification 82380)

SPM-A SYNCHRONIZER The APTL can provide bumpless paralleling and adjustable

(Product Specification 82383) speed ramps for load and unloading the unit controlled by

The SPM-A Synchronizer may be installed for a fully the CSC. The control allows peak shaving, import-export

automatic synchronizing, paralleling, and load-sharing and low and high limits for generator control. Requires a

system. Load Sensor.

RAMP GENERATOR DIGITAL SYNCHRONIZER AND LOAD

(Manual 82476) CONTROL (DSLC)

(Product Specification 02006)

The Ramp Generator is connected to add linear ramp times

of up to 25 seconds. For exponential ramp times up to four The DSLC is an integrated generator control that performs

seconds, a capacitor can be connected to the CSC control. speed and phase matching, synchronizing, generator load

sensing and controlling, isochronous load sharing and

PROCESS AND IMPORT/EXPORT CONTROL process/import-export control and replaces motor-operated

(Product Specification 02013) potentiometers (MOPs) with digital tuning.

The Process and Import/Export Control maintains a

certain flow, pressure, power, or other output of engines

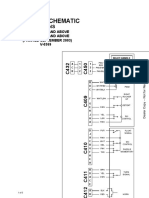

1 Shielded wire to be twisted pairs with CSC

shield grounded at one end only. SPEED CONTROL

2 No, 12 AWG or 14 AWG stranded wire.

Must be as short as possible.

3

4 Open for minimum fuel.

5 For positive ground systems, switch

and fuse to be located in series with

battery (-) and terminal 2. Positive

terminal becomes chase ground. Leads

from battery to terminals 1 & 2 must

be direct and not pass through dis-

tribution points.

6 Approx. speed change with trim poten-

tiometer:

+/- 2.5% using a 1 K potentiometer

+/- 5.0% using a 2 K potentiometer

7 Approx. 1 second ramp time per 50 UF.

Capacitor specifications: 200 UF max;

15 WVDC minimum. Less than 30 UA DC

leakage current over temp range.

8 Idle range approx. 25% to 100% of rated

using 50K potentiometer.

9 Use a 10 amp fuse (3 AG or GLH type)

PLANT WIRING DIAGRAM

SPECIFICATIONS

SUPPLY VOLTAGE

12 Volt Control ..............................................................1016 Vdc. Power consumption: 60 W max. A battery charger

must be capable of at least 7 A when the governor is

energized.

24 Volt Control ..............................................................2032 Vdc. Power consumption: 95 W max. A battery charger

must be capable of at least 5 A when the governor is

energized.

Steady State Speed Band ............................................±½ of 1% of rated speed

Fuse and Wiring ............................................................a 10 A slow-blow fuse or circuit breaker must be installed in the

non-grounded battery lead. Battery leads are routed directly to

the speed control, not through any distribution points.

Magnetic Pickup (MPU) ................................................1.5 Vrms min.; 100 Hz min. during cranking.

ADJUSTMENTS

Stability and Gain ........................................................these adjustments set the CSC speed controls response to

match the individual engine characteristics. Slow and fast

response settings are provided with the CSC control.

Rated Speed ................................................................set by a 25-turn internal potentiometer.

Idle Speed ....................................................................a 50 kΩ potentiometer can be connected to set the idle

speed at 25%100% of rated speed.

Speed Trim (Optional) ..................................................a 1 KΩ potentiometer is used for a ±2.5% speed change; a

2 KΩ potentiometer is used for a ±5% speed change.

Ramp Time, Idle/Rated (Optional) ..............................an optional capacitor can add up to four seconds of

acceleration and deceleration control. An optional ramp

generator may be used for longer times.

Start Fuel Limit ..............................................................adjusted with an internal 10-turn potentiometer. The limit sets

the maximum terminal shaft position until 95% of the selected

(idle or rated) speed is attained. Start Fuel Limit is re-established

when the magnetic pickup frequency drops to 5% of rated

speed or lower.

ENVIRONMENT/PHYSICAL

Operating Temperature ..............................................-40 to +75 °C (-40 to +167 °F)

Classification ..............................................................UL, cUL, CE Compliant

Mounting ......................................................................engine skid mountable in any configuration

3800 N. Wilson Ave. DECLARATION OF INCORPORATION

P.O. Box 3800

Loveland, CO, U.S.A. In accordance with the EMC Directive 89/336/EEC and its amendments, this controlling device,

80539-3800 manufactured by Woodward Governor Company, is applied solely as a component to be

Ph: 1 970-663-3900 incorporated into an engine prime mover system. Woodward Governor Company declares that

Ph: 1 800-835-5182 this controlling device complies with requirements of EN50081-2 and EN50082-2 when put into

Fax: 1 970-962-7050 service per the installation and operating instructions outlined in the product manual.

NOTICE: This controlling device is intended to be put into service only upon incorporation into

www.woodward.com an engine prime mover system that itself has met the requirements of the above Directive and bears

the CE mark.

International Plants

Australia, New South Wales

Brazil, Campinas

China, Tianjin

Germany, Aken/Elbe & Kelbra

India, Haryana

Japan, Tomisato & Kobe

Netherlands, Hoofddorp &

Rotterdam

Singapore

United Kingdom, Reading,

England, & Prestwick, Scotland

United States, Colorado[2],

Illinois[3], Michigan[2], New York,

South Carolina, Tennessee

Regional Sales Offices

Canada, Québec

China, Beijing

Czech Republic, Plzen

Germany, Tettnang

Korea, Pusan

Mexico, Mexico City

New Zealand, Christchurch

Poland, Warsaw

United Arab Emirates, Abu Dhabi

United States, Alabama,

California, Illinois, Pennsylvania,

Texas, Washington

Distributors & Service

Woodward has a network of

distributors and service facilities. For 041-214

your nearest representative call 1

800-835-5182 or see the Worldwide

Directory on our web site.

CORPORATE HEADQUARTERS/ OUTLINE DRAWING

AIRCRAFT CONTROLS

Rockford, IL, U.S.A.

1 815-877-7441

This document is distributed

for informational purposes only.

It is not to be construed as

creating or becoming part of

any Woodward Governor

Company contractual or

warranty obligation unless

expressly stated in a written

sales contract.

The DSLC is a registered

trademark of the Woodward

Governor Company. For more information contact:

© Woodward Governor

Company, 1997

All Rights Reserved

98/10/L

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 966 F Loader444 PDFДокумент14 страниц966 F Loader444 PDFmarsh2002Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaОценок пока нет

- Torque Converter Clutch TCCДокумент21 страницаTorque Converter Clutch TCCmarsh2002100% (2)

- InfoWorks ICM Overview 60 Mins PDFДокумент31 страницаInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- 381Документ8 страниц381Nidya Wardah JuhanaОценок пока нет

- Engine Wiring Diagram: 2800 SeriesДокумент2 страницыEngine Wiring Diagram: 2800 Seriesmarsh2002100% (4)

- Transmission Wiring PDFДокумент1 страницаTransmission Wiring PDFmarsh2002Оценок пока нет

- BPQ REV. 0 Interactive FormДокумент2 страницыBPQ REV. 0 Interactive FormcosmicbunnyОценок пока нет

- G3508 - 600kvaДокумент7 страницG3508 - 600kvaJim Patrick ChombaОценок пока нет

- ElencoДокумент56 страницElencomarsh2002100% (2)

- A67 - 03 Edc MS 6 - 4Документ10 страницA67 - 03 Edc MS 6 - 4marsh2002Оценок пока нет

- NessusДокумент23 страницыNessusShivaprakash TimmapurОценок пока нет

- sisEB48f374479loader g2444Документ1 страницаsisEB48f374479loader g2444marsh2002Оценок пока нет

- Blink Code List For WP12 Diesel EnginesДокумент12 страницBlink Code List For WP12 Diesel Enginesmarsh2002Оценок пока нет

- Product Model and NameplateДокумент4 страницыProduct Model and Nameplatemarsh2002Оценок пока нет

- Main Technical SpecificationsДокумент10 страницMain Technical Specificationsmarsh2002Оценок пока нет

- 966G II Wheel Loader AXJ00001-UP (MACHINE) POWERED BY 3176 Engine (SEBP3279 - 63) - Document StructureДокумент5 страниц966G II Wheel Loader AXJ00001-UP (MACHINE) POWERED BY 3176 Engine (SEBP3279 - 63) - Document Structuremarsh2002Оценок пока нет

- The Slewing Mechanism, Which Can Realized 360° Full-Circle Slewing, Consists of The Hydraulic Motor, The Planet-Gear Reducer, The Brake, The Driving Gear and The Slewing Ring and So OnДокумент3 страницыThe Slewing Mechanism, Which Can Realized 360° Full-Circle Slewing, Consists of The Hydraulic Motor, The Planet-Gear Reducer, The Brake, The Driving Gear and The Slewing Ring and So Onmarsh2002Оценок пока нет

- DTC P0778 Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2)Документ3 страницыDTC P0778 Pressure Control Solenoid "B" Electrical (Shift Solenoid Valve SL2)marsh2002Оценок пока нет

- 11 Appendix : Standard Hand Signals For Lifting OperationДокумент4 страницы11 Appendix : Standard Hand Signals For Lifting Operationmarsh2002Оценок пока нет

- 5.2 OutriggerДокумент11 страниц5.2 Outriggermarsh2002Оценок пока нет

- MID 039 - CID 0070 - FMI 02: Shutdown SISДокумент5 страницMID 039 - CID 0070 - FMI 02: Shutdown SISmarsh2002Оценок пока нет

- TroubleshootingДокумент6 страницTroubleshootingmarsh2002Оценок пока нет

- Important InstructionДокумент2 страницыImportant Instructionmarsh2002Оценок пока нет

- Electrical Circuit Diagram 470-3hДокумент1 страницаElectrical Circuit Diagram 470-3hmarsh2002Оценок пока нет

- Details of Excitation System of AlternatorДокумент4 страницыDetails of Excitation System of Alternatormarsh2002Оценок пока нет

- 751 Wiring Schematic: OptionsДокумент6 страниц751 Wiring Schematic: Optionsmarsh2002Оценок пока нет

- MST 9000 Auto Signal Operation StepsДокумент11 страницMST 9000 Auto Signal Operation Stepsmarsh2002Оценок пока нет

- BLN 95 9041Документ5 страницBLN 95 9041marsh2002Оценок пока нет

- Detail 02 Eave Gutter With Protruding Roof Detail 01-A Ridge Detail Saddle RoofДокумент1 страницаDetail 02 Eave Gutter With Protruding Roof Detail 01-A Ridge Detail Saddle Roofmin miniОценок пока нет

- Tramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyДокумент2 страницыTramlink Low-Floor Light Rail Vehicle: Rostocker Strassenbahn Ag, Rostock, GermanyLuca Marius CristianОценок пока нет

- Introduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsДокумент53 страницыIntroduction To R: Shanti.S.Chauhan, PH.D Business Studies ShuatsShanti Swaroop ChauhanОценок пока нет

- Case Study FormatДокумент2 страницыCase Study FormatMarianel Antiqueña EspinosaОценок пока нет

- ABB Ability Safety Plus For Hoists BrochureДокумент12 страницABB Ability Safety Plus For Hoists BrochureCarlos Bruno MatosОценок пока нет

- 3.14. TR-069 WAN Management...Документ6 страниц3.14. TR-069 WAN Management...duculeteОценок пока нет

- SWIMS Directory of LibrariesДокумент17 страницSWIMS Directory of LibrariessudakshinaroyОценок пока нет

- Logic GatesДокумент19 страницLogic GatesblazespiritОценок пока нет

- Chapter 5 - Decision Making and LoopingДокумент94 страницыChapter 5 - Decision Making and LoopingAcapSuiОценок пока нет

- Eminence Deltalite II 2515Документ1 страницаEminence Deltalite II 2515Suto BandОценок пока нет

- Electrical Load For Indoor UnitsДокумент2 страницыElectrical Load For Indoor UnitsMD BILAL ASLAMОценок пока нет

- A Car Parking Guard Circuit Using Infrared SensorДокумент9 страницA Car Parking Guard Circuit Using Infrared Sensorhamed razaОценок пока нет

- 990 Vibration Transmitter Datasheet-141612mДокумент14 страниц990 Vibration Transmitter Datasheet-141612mloopkkОценок пока нет

- Make A Project of Calculator in Visual BasicДокумент9 страницMake A Project of Calculator in Visual BasicCHITRA MINI96% (23)

- GRT655 GRT655L Product Guide ImperialДокумент20 страницGRT655 GRT655L Product Guide ImperialDanilo UrruchurtoОценок пока нет

- Ductle Iron Spec1Документ8 страницDuctle Iron Spec1윤병택Оценок пока нет

- Kevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterДокумент37 страницKevin D Thomas - Activated Carbon and Lemon Peels As Adsorbent For Removing Oil From Waste WaterRejinОценок пока нет

- DE GUZMAN - Module 2 Activity No. 2Документ4 страницыDE GUZMAN - Module 2 Activity No. 2Alvin De GuzmanОценок пока нет

- Original Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwДокумент32 страницыOriginal Instructions Alkuperäiset Ohjeet Αρχικýj Οδηγßεj: Rev. 4 5/31/11 BrwnikosvitalОценок пока нет

- Aes MatlabДокумент32 страницыAes MatlabbalajithrillerОценок пока нет

- MARTA: 2012 KPMG Phase II Final DraftДокумент114 страницMARTA: 2012 KPMG Phase II Final DraftthomaswheatleyОценок пока нет

- Email Id of Controllers PDFДокумент10 страницEmail Id of Controllers PDFAbhishek KumarОценок пока нет

- Blue Solar Charge Controller MPPT: NOT AcceptedДокумент12 страницBlue Solar Charge Controller MPPT: NOT Accepted1382aceОценок пока нет

- If Then ElseДокумент10 страницIf Then Elseapi-297910907Оценок пока нет