Академический Документы

Профессиональный Документы

Культура Документы

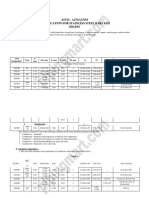

Astm A653a 653M 4

Загружено:

Barbado BlancoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Astm A653a 653M 4

Загружено:

Barbado BlancoАвторское право:

Доступные форматы

A 653/A 653M

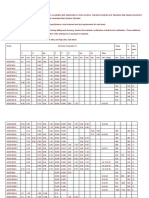

TABLE 2 Chemical Requirements

Composition, %—Heat Analysis Element, max (unless otherwise shown)

Designation Carbon Manganese Phosphorus Sulfur Aluminum, minA CuB NiB CrB MoB VC CbC Ti

D,E

CS Type A 0.10 0.60 0.030 0.035 ... 0.20 0.20 0.15 0.06 0.008 0.008 0.30

CS Type BD,E,F 0.02 to 0.15 0.60 0.030 0.035 ... 0.20 0.20 0.15 0.06 0.008 0.008 0.30

CS Type CD,E 0.08 0.60 0.100 0.035 ... 0.20 0.20 0.15 0.06 0.008 0.008 0.30

FS Type AD,E,G 0.10 0.50 0.020 0.035 ... 0.20 0.20 0.15 0.06 0.008 0.008 0.30

FS Type BD,E,G 0.02 to 0.10 0.50 0.020 0.030 ... 0.20 0.20 0.15 0.06 0.008 0.008 0.30

DDSH 0.06 0.50 0.020 0.025 0.01 0.20 0.20 0.15 0.06 0.008 0.008 0.30

EDDSI 0.02 0.40 0.020 0.020 0.01 0.20 0.20 0.15 0.06 0.008 0.008 0.30

A

Where an ellipsis (. . .) appears in this table, there is no requirement, but the analysis shall be reported.

B

The sum of copper, nickel, chromium, and molybdenum shall not exceed 0.50 % on heat analysis. When one or more of these elements are specified, the sum does

not apply; in which case, only the individual limits on the remaining elements shall apply.

C

For steels having a carbon content of 0.02 % or less, the limit for columbium is 0.045 % maximum.

D

For CS and FS, specify Type B to avoid carbon levels below 0.02 %.

E

When a deoxidized steel is required for the application, the purchaser has the option to order CS to a minimum of 0.01 % total aluminum.

F

CS Type B describes the typical Commercial Quality product previously included in this specification.

G

Shall not be furnished as a stabilized steel.

H

The producer has the option to furnish as a stabilized steel.

I

Shall be furnished as a stabilized steel.

TABLE 3 Chemical RequirementsA

Composition, %—Heat Analysis Element, max

(unless otherwise shown)

Designation

Car- Manga- Phos- Sul-

CuB NiB CrB MoB VC CbC,D Ti

bon nese phorus fur

SS Grade

33 [230] 0.20 ... 0.04 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

37 [255] 0.20 ... 0.10 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

40 [275] 0.25 ... 0.10 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

50 [340] Class 1 and 2 0.25 ... 0.20 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

50 [340] Class 3 0.25 ... 0.04 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

80 [550] 0.20 ... 0.04 0.04 0.20 0.20 0.15 0.06 0.008 0.008 0.30

HSLAS Type AE

40 [275] 0.20 1.20 ... 0.035 ... 0.20 0.15 0.06 0.008 0.008 0.30

50 [340] 0.20 1.20 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

60 [410] 0.20 1.35 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

70 [480] 0.20 1.65 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

80 [550] 0.20 1.65 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

HSLAS Type BE,F

40 [275] 0.15 1.20 ... 0.035 ... 0.20 0.15 0.06 0.008 0.008 0.30

50 [340] 0.15 1.20 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

60 [410] 0.15 1.20 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

70 [480] 0.15 1.65 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

80 [550] 0.15 1.65 ... 0.035 0.20 0.20 0.15 0.06 0.008 0.008 0.30

A

Where an ellipsis (. . .) appears in this table there is no requirement, but the analysis shall be reported.

B

The sum of copper, nickel, chromium and molybdenum shall not exceed 0.50 % on heat analysis. When one or more of these elements are specified the sum does

not apply; in which case, only the individual limits on the remaining elements shall apply.

C

The limits do not apply when HSLAS is specified.

D

For steels having a carbon content of 0.02 % or less, the limit for columbium is 0.045 % maximum.

E

Steel conforming to this designation commonly contains the strengthening elements columbium, nitrogen, phosphorus, or vanadium added singly or in combination.

F

The producer has the option to treat these steels by means of small alloy additions to effect sulfide inclusion control.

purchaser with as much information as possible to make an alloy steel. They presuppose “hard way” bending (bend axis

informed decision on the steel to be specified. Values outside of parallel to rolling direction) and reasonably good shop forming

these ranges are to be expected. practices. Where possible, the use of larger radii or “easy way”

7.3 When base metal mechanical properties are required, all bends are recommended for improved performance.

tests shall be conducted in accordance with the methods

specified in Specification A 924/A 924M. 8. Coating Properties

7.4 Bending Properties Minimum Cold Bending Radii— 8.1 Coating Weight [Mass]:

Structural steel and high-strength low-alloy steel are com- 8.1.1 Coating weight [mass] shall conform to the require-

monly fabricated by cold bending. There are many interrelated ments as shown in Table 1 for the specific coating designation.

factors that affect the ability of a steel to cold form over a given 8.1.2 Use the following relationships to estimate the coating

radius under shop conditions. These factors include thickness, thickness from the coating weight [mass]:

strength level, degree of restraint, relationship to rolling 8.1.2.1 1 oz/ft2 coating weight = 1.7 mils coating thickness,

direction, chemistry, and base metal microstructure. The table and

in Appendix X1 lists the suggested minimum inside radius for 8.1.2.2 7.14 g/m2 coating mass = 1 µm coating thickness.

90° cold bending for structural steel and high-strength low- 8.2 Coating Weight [Mass] Tests:

4

COPYRIGHT ASTM International

Licensed by Information Handling Services

Вам также может понравиться

- Extracto Norma ASTM A792Документ2 страницыExtracto Norma ASTM A792Christian Latorre VielmaОценок пока нет

- Brosur KHIДокумент16 страницBrosur KHIpangalengan zaxОценок пока нет

- Plates Steel MetalДокумент12 страницPlates Steel MetalAnonymous aWpx7nEОценок пока нет

- SM490 Ya-Yb ChemicalДокумент1 страницаSM490 Ya-Yb ChemicalJoko TrisnantoОценок пока нет

- Steel SpecificationsДокумент3 страницыSteel SpecificationsMazlan MansorОценок пока нет

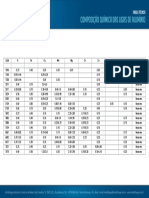

- Inóx 420ni Peso: Teor Encontrado Carb. Silício Cromo Ni MN MoДокумент1 страницаInóx 420ni Peso: Teor Encontrado Carb. Silício Cromo Ni MN MoAnonymous hj68hZmoОценок пока нет

- Norma ASTM-A276-A276MДокумент18 страницNorma ASTM-A276-A276MrecebimentoОценок пока нет

- Is 1030 GR340-570WДокумент2 страницыIs 1030 GR340-570WAnkit Singh100% (1)

- Chemical PropertiesДокумент1 страницаChemical PropertiesDanny TriwibowoОценок пока нет

- Alüminyum Alaşım Standartları Ve Element Içerikleri PDFДокумент1 страницаAlüminyum Alaşım Standartları Ve Element Içerikleri PDFFeratОценок пока нет

- Common Cast Steel Material Comparison ChartДокумент3 страницыCommon Cast Steel Material Comparison ChartJose Marval RodriguezОценок пока нет

- C Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostДокумент4 страницыC Si MN P S CR Mo Ni NB Ti Worknorme DIN BS Astm / Aisi GostSWPriestОценок пока нет

- Steel Bolts - Yield Strength: Parameters and PropertiesДокумент2 страницыSteel Bolts - Yield Strength: Parameters and PropertiesZAZZERA125Оценок пока нет

- Ws - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaДокумент1 страницаWs - No. C Si MN P S CR Mo Ni NB Ti Ws - No. DIN BS Astm / Aisi Gost % % % % % % % % % % Germany Great Britain USA RussiaHassan MostajabОценок пока нет

- Material SpecДокумент456 страницMaterial SpecAyush Narang70% (10)

- Micro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpaДокумент4 страницыMicro-Alloyed Steels: High-Strength Steels With Yield Strengths Up To 550 MpacurtisvaleroОценок пока нет

- Micro Alloyed Steels Voestalpine EN 30102020Документ4 страницыMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociОценок пока нет

- Spectru EtabsДокумент34 страницыSpectru EtabsOctavian CicuОценок пока нет

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterДокумент1 страницаYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterJOSE LOZADA MENDIETAОценок пока нет

- AS2074 CastSteel Specifications PDFДокумент5 страницAS2074 CastSteel Specifications PDFZac NastОценок пока нет

- Dimenzije I Tezine LimovaДокумент2 страницыDimenzije I Tezine LimovaSinisa SimbaОценок пока нет

- 1 Composicao Quimica Das Ligas de AluminioДокумент1 страница1 Composicao Quimica Das Ligas de AluminioNorberto A. GhiggiОценок пока нет

- Back Up Volume Pembangunan Jalan Ruas Jalan Cutcut - Munggal Tahun Anggaran 2020Документ13 страницBack Up Volume Pembangunan Jalan Ruas Jalan Cutcut - Munggal Tahun Anggaran 2020'Budi Kaos HitamОценок пока нет

- Cast Iron Material Comparison Chart PDFДокумент1 страницаCast Iron Material Comparison Chart PDFavnishchauhan8_46499Оценок пока нет

- Cast Iron Material Comparison Chart ASTM CompilationДокумент1 страницаCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaОценок пока нет

- Cast Iron Material Comparison Chart ASTM CompilationДокумент1 страницаCast Iron Material Comparison Chart ASTM CompilationCésar Cristov León OrtegaОценок пока нет

- ABS Grade AH36, ABS Grade EH36, ABS Grade DH36, ABS Grade FH36 Steel Plate For Shipbuidling and RepairingДокумент2 страницыABS Grade AH36, ABS Grade EH36, ABS Grade DH36, ABS Grade FH36 Steel Plate For Shipbuidling and Repairingaini lutunaОценок пока нет

- ASTM Materials Composition: EmailДокумент1 страницаASTM Materials Composition: EmailLakshmi NarayananОценок пока нет

- 6-Carbon SteelsДокумент20 страниц6-Carbon SteelsMunim DarОценок пока нет

- Blade DesignДокумент2 страницыBlade Designtpa1962Оценок пока нет

- BladedesignДокумент2 страницыBladedesigndiogenesrobertoОценок пока нет

- EN 16983 (Ex DIN 2093) Dim 2Документ3 страницыEN 16983 (Ex DIN 2093) Dim 2Roby MastreОценок пока нет

- Steel Specification PDFДокумент8 страницSteel Specification PDFPeter AntonyОценок пока нет

- Spring Steel Chemical CompositionДокумент5 страницSpring Steel Chemical CompositionSunil Dinanath Joshi100% (1)

- 0.3 0.15 2.0 Progressivo: Aliquota Marginale Aliquota Media Elasticità Dell'imposta Al Reddito Regime Di ImposizioneДокумент18 страниц0.3 0.15 2.0 Progressivo: Aliquota Marginale Aliquota Media Elasticità Dell'imposta Al Reddito Regime Di ImposizionemОценок пока нет

- B221M 1388261-1Документ16 страницB221M 1388261-1hh774747Оценок пока нет

- Graficos TP9Документ2 страницыGraficos TP9AnsleОценок пока нет

- AsdfafaДокумент1 страницаAsdfafaAhmed NabilОценок пока нет

- Api 5L "'Документ1 страницаApi 5L "'Felipa ShanОценок пока нет

- Calcul Fier BetonДокумент2 страницыCalcul Fier BetonContus FirmasОценок пока нет

- STANDARD - ASTM A653 - Brief DescriptionДокумент7 страницSTANDARD - ASTM A653 - Brief DescriptionSeyong ParkОценок пока нет

- Tabel VCДокумент1 страницаTabel VCgame downloadОценок пока нет

- Bacheo SuperficialДокумент6 страницBacheo SuperficialgabrielОценок пока нет

- Thành phần hóa học thép - Steel bars for concrete reinforcementДокумент3 страницыThành phần hóa học thép - Steel bars for concrete reinforcementDuẩn VũОценок пока нет

- Bar Bending Schedule BBSДокумент8 страницBar Bending Schedule BBSsandip santpalОценок пока нет

- Entrada Excel PDFДокумент2 страницыEntrada Excel PDFKM DegraciaОценок пока нет

- Annex A: (Normative)Документ6 страницAnnex A: (Normative)calvente27Оценок пока нет

- GB 700 88Документ5 страницGB 700 88trungОценок пока нет

- QuadriДокумент76 страницQuadrisvenОценок пока нет

- 001 AggregateДокумент4 страницы001 Aggregatevanessa ImlerОценок пока нет

- Alüminyum AlaşımlarıДокумент11 страницAlüminyum AlaşımlarıMahmut IspirОценок пока нет

- Planilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Документ2 страницыPlanilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Lenny Viteri EnriquezОценок пока нет

- Alloy Steel ChartДокумент4 страницыAlloy Steel Chartmodi_mihirОценок пока нет

- A/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)Документ6 страницA/t A1/t1+ (A/l-A1/l1) / (A2/l2-A1/l1) (A2/t2-A1/t1) (Linear Interpolation Formula)phan hoang diepОценок пока нет

- How To Evaluate For PAUTДокумент6 страницHow To Evaluate For PAUTphan hoang diepОценок пока нет

- Ambion: Wearnes CambionДокумент2 страницыAmbion: Wearnes CambionalexanderОценок пока нет

- Database Management Systems: Understanding and Applying Database TechnologyОт EverandDatabase Management Systems: Understanding and Applying Database TechnologyРейтинг: 4 из 5 звезд4/5 (8)

- 5 Canadian Wood-Frame House ConstructionДокумент3 страницы5 Canadian Wood-Frame House ConstructionBarbado BlancoОценок пока нет

- Application Menu: Quick Access Toolbar:: RibbonДокумент10 страницApplication Menu: Quick Access Toolbar:: RibbonBarbado BlancoОценок пока нет

- 4 Canadian Wood-Frame House ConstructionДокумент3 страницы4 Canadian Wood-Frame House ConstructionBarbado BlancoОценок пока нет

- Chapter Summary Chapter Test Questions Chapter Drawing ProjectsДокумент10 страницChapter Summary Chapter Test Questions Chapter Drawing ProjectsBarbado BlancoОценок пока нет

- Figure 1-26: Relative CoordinatesДокумент10 страницFigure 1-26: Relative CoordinatesBarbado BlancoОценок пока нет

- Chapter Two: Circles and Drawing Aids Chapter Two: Circles and Drawing AidsДокумент10 страницChapter Two: Circles and Drawing Aids Chapter Two: Circles and Drawing AidsBarbado BlancoОценок пока нет

- Subsection B: T-180 EvaluationДокумент1 страницаSubsection B: T-180 EvaluationBarbado BlancoОценок пока нет

- A360 16 Spec and Commentary 8Документ1 страницаA360 16 Spec and Commentary 8Barbado BlancoОценок пока нет

- Material EquilentДокумент16 страницMaterial EquilentShoaib JadoonОценок пока нет

- DPP-13 (Coordination Compound) PDFДокумент3 страницыDPP-13 (Coordination Compound) PDFAvishek BiswasОценок пока нет

- Global Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017Документ30 страницGlobal Overview of Ore-Based Metallics: Amm Dri & Mini-Mills Conference - November 2017NtlОценок пока нет

- Material Groups and StandardsДокумент1 страницаMaterial Groups and StandardsJohn Rymar LameraОценок пока нет

- Bombay Non Ferrous Metals Association LTDДокумент43 страницыBombay Non Ferrous Metals Association LTDSushant Jain67% (3)

- MSM GTU Study Material E-Notes Unit-5 23112020052908AMДокумент14 страницMSM GTU Study Material E-Notes Unit-5 23112020052908AMVijayОценок пока нет

- 1 Introduction of The Blast Furnace ProcessДокумент9 страниц1 Introduction of The Blast Furnace Processhemant patilОценок пока нет

- The Role of Manganese On Microstructure of High Chromium White Cast IronДокумент7 страницThe Role of Manganese On Microstructure of High Chromium White Cast IronKhairul MuzafarОценок пока нет

- Jis G 4053-2008 JPДокумент14 страницJis G 4053-2008 JPTran Tien AnhОценок пока нет

- Report On Weldability of StainlessДокумент67 страницReport On Weldability of StainlessPradeep LakumОценок пока нет

- Ligne: Système de Canalisation Et Passerelles À EncastrementДокумент66 страницLigne: Système de Canalisation Et Passerelles À EncastrementTaoufik AlouiОценок пока нет

- Boiler Pressure Parts - Straight TubesДокумент2 страницыBoiler Pressure Parts - Straight TubesLTE002Оценок пока нет

- Metalography and Microstructures of Stainless Steels and Maraging SteelsДокумент32 страницыMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraОценок пока нет

- b205g - MS Plus - 201601Документ32 страницыb205g - MS Plus - 201601Alexandre SouzaОценок пока нет

- Fundamentals of Fire AssayДокумент37 страницFundamentals of Fire AssayAnonymous FfIxH2o9Оценок пока нет

- What Is Stainless Steel EN PDFДокумент0 страницWhat Is Stainless Steel EN PDFsssf-dobojОценок пока нет

- P.O.Box 261 Owings Mills, MD 21117 USAДокумент1 страницаP.O.Box 261 Owings Mills, MD 21117 USARenny DevassyОценок пока нет

- 011-Astm A 131 2008 Structural Steel For Ships PDFДокумент7 страниц011-Astm A 131 2008 Structural Steel For Ships PDFgraduateОценок пока нет

- Designation System of Screws and BoltsДокумент3 страницыDesignation System of Screws and BoltsGiri DharanОценок пока нет

- Properteis Ofrefractory Metals and Metals PDFДокумент48 страницProperteis Ofrefractory Metals and Metals PDFBasavaraj N.CОценок пока нет

- D1.6-2017 (First Proof) (Received 03-15-2017) 242Документ1 страницаD1.6-2017 (First Proof) (Received 03-15-2017) 242mrОценок пока нет

- Non Ferrous Metal RecycleДокумент7 страницNon Ferrous Metal RecycleApratim MahajanОценок пока нет

- PDF Geberit Concealed Cisterns Covert Affairs Alpha 2023 enДокумент21 страницаPDF Geberit Concealed Cisterns Covert Affairs Alpha 2023 enci8g1Оценок пока нет

- Jarabe de Coco MP May 2018Документ1 страницаJarabe de Coco MP May 2018Raul PerezОценок пока нет

- Metallurgy IITДокумент8 страницMetallurgy IITAdiChemAdi100% (2)

- Spare Parts ListДокумент4 страницыSpare Parts ListFuqingliОценок пока нет

- Hydrothermal Hydrochloric Acid RegenerationДокумент70 страницHydrothermal Hydrochloric Acid RegenerationLeventОценок пока нет

- AWS D10.4-86R - Recommended Practices For Welding Austenitic Chromium - Nickel Stainless Steel Piping and TubingДокумент40 страницAWS D10.4-86R - Recommended Practices For Welding Austenitic Chromium - Nickel Stainless Steel Piping and TubingqaОценок пока нет

- A829Документ4 страницыA829Deepak GovindanОценок пока нет

- Materials Question From My BookДокумент54 страницыMaterials Question From My BookRavinder Antil100% (6)