Академический Документы

Профессиональный Документы

Культура Документы

Olympia Electronics Product Warranty Details

Загружено:

ThanosEleftheroudisИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Olympia Electronics Product Warranty Details

Загружено:

ThanosEleftheroudisАвторское право:

Доступные форматы

WARRANTY

Olympia Electronics guarantees the quality, condition and operation of the goods. The period of warranty

is specified in the official catalogue of Olympia Electronics and also in the technical leaflet, which

accompanies each product. This warranty ceases to exist if the buyer does not follow the technical

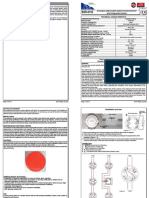

instructions included in official documents given by Olympia Electronics or if the buyer modifies the goods Analogue addressable rate-of-rise heat detector

provided or has any repairs or re-setting done by a third party, unless Olympia Electronics has fully BSR-6160 with integrated isolator

agreed to them in writing. Products that have been damaged can be returned to the premises of our

company for repair or replacement, as long as the warranty period is valid.

TECHNICAL CHARACTERISTICS

Olympia Electronics reserves the right to repair or to replace the returned goods and to or not charge the

buyer depending on the reason of defection. Olympia Electronics reserves the right to charge or not the COMMUNICATION PROTOCOL Olympia A Protocol

buyer the transportation cost. MAIN VOLTAGE 11-30V DC

HEAD OFFICE STANDBY CONSUMPTION 90μΑ

72nd km. O.N.R. Thessaloniki-Katerini ALARM CONSUMPTION 2.5mA (with activated LED)

P.C. 60300 P.O. Box 06 Εginio Pierias Greece TEMPERATURE SENSITIVITY Adjustable from 57 to 90 in 1.5oC steps

www.olympia-electronics.gr INDICATORS Alarm LED

info@olympia-electronics.gr OUTPUT Remote LED driver

CLASS A1R/A1S

MAXIMUM LOOP CURRENT (Ic max, -L in/out) 1A

MAXIMUM SWITCH CURRENT (Is max, -L in/out) 5A

MAXIMUM SERIES RESISTANCE (Zc max, -L in-out) 100mΩ

MAXIMUM LEAKAGE CURRENT

25mA pulses (6ms duration every 2sec)

IN ISOLATION MODE (IL max, -L in/out)

ISOLATION VOLTAGE (Vso min-max) 9.3 - 10.6

RECONNECT VOLTAGE (Vsc min-max) 10.7 - 12.7

DEGREES OF COVER PROTECTION IP42

PRODUCED IN ACCORDANCE WITH EN 54-5, EN 54-17

ο

OPERATING TEMPERATURE RANGE -40 to 70 C

RELATIVE HUMIDITY Up to 95%

CONSTRUCTION MATERIALS ABS/PC

EXTERNAL DIMENSIONS 103 (d) x 48 (h) mm

TYPICAL WEIGHT 145 gr.

GUARANTEE 2 years

Thank you for your trust in our products

Olympia Electronics - European manufacturer

GENERAL

The user have to read carefully the following instructions, in order to be properly informed and keep them

for future use.

The BSR-6160 is an analogue addressable heat detector which integrates the function of rate-of-rise

heat detection and it can work with any fire panel supports Olympia A Protocol. It can be adjusted to detect

multiple levels of heat offering flexibility and rich functionality. Also, it integrates a short circuit isolation

circuit which is automatically activated and disconnects the defective node from the remaining loop,

allowing it to be located by the panel.

The detector sends to the main panel an analogue value which depends on the heat. The value is 100 at

57oC and increases proportionally to 120 at 90oC. When a sudden increase in temperature is detected the

detector sends the value of 121.

By default the panel is set to sound an alarm when the temperature is 57 oC. The user can change this

setting from the panel for each detector and define any level of temperature between the lower and the

upper limits, specifying the sensitivity of the system depending on the requirements of each site. Also, the

user can select A1R or A1S working mode through the panel.

They are composed by two parts. A plastic base which is placed on the ceiling and the main body of the

detector which fits on the plastic base with a simple rotation to the right. The detectors have a 360o visible

led and a remote led driver which are light up constantly in case of detection of fire, till cancelled from the

panel. Also, they are staying lit even if the sirens are silenced from the panel, so the detector which

detected the alarm is visible. They are turned off only when a reset command is given from the panel. The

indicator led blinks every 10 sec indicating the connection status with the main panel.

Page 4 from 4 921616000_09_002 Page 1 from 4 921616000_09_002

SETTING THE ADDRESS

Each detector must have a unique address, with which it is recognised from the panel. It is forbidden for

Installation process

Connection

two devices in the same loop to have the same address. To set it up you can use the function of changing with exterrnal

address point as described in the user manual of the panel. tening Mounting base LED

fas 1 Side marks

2

INSTALLATION

The detectors should be placed in the ceiling in visible points without side obstacles, away from places

that are barely ventilated or with strong air currents and water vapor. Each detector covers an area of 50 UT +

-

O

IN /

m2 while the distance between two detectors should not be more than 15m. Also, they must be placed at

O

UT

+

least 50 cm away from fluorescent lamps. Cable diameter should be from 0.5 to 2.5mm. 5 5

R

N

MAINTENANCE & FUNCTIONAL TESTING

I

Indicating - -R

The detector has fault diagnosis function, which automatically informs you when detector replacement is de LED

tachment

required. This function combined with periodic manual testing ensure maximum security level. It is

suggested to carry out a test every 6 months or after a change in the position of the sensor. A key element Figure 1

of its proper function is the air to be able to freely circulate inside it. So be careful not to block the openings 1. Remove the detector from its base rotating to the left till the side marks are aligned.

of the outer cover. Before the manual testing procedure it is suggested to enable the special “walk in test” 2. Fasten the base with the supplied mounting materials (point 5).

mode from the panel. 3. Connect the power cables (minding the correct polarity) according to the requirements of the

installation (Figure 1, 2).

CAUTION !! 4. Place the detector carefully so that the side marks are on the same position and rotate the detector

After installation the device must not be covered with dust or be painted or anything else happen that will clockwise until it locks. Power the device and after 3-5 seconds it is ready for operation.

block the air to get to the sensor. Special attention must be given during the installation and the use of the

device, since the user assumes full responsibility for proper operation afterwards. CONNECTION

1. + IN/OUT: Connect to (+L) of the loop.

2. - IN: Connect to (-L) of the loop.

3. - OUT: Connect to (-L) of the loop.

Additional features of the device : 4. - R : External LED connection.

- Integration of dynamic algorithms for noise and false alarm rejection. 5. : Connected to the cable’s shield (when shield is used).

- Automatic fault diagnosis.

- Adjustable temperature alarm level for maximum flexibility.

- 360o optically visible LED. Loop Loop Loop

UID:

In every device there is a double sticker with the UID (Unique Identifier) number. This number is

unique for each device. N

N

+

-

IN

IN

/OU

/OU

T

T

-R

-

-R

O -

UT O

UT

+

I

-

IN

/OU

T

-R

-

O

UT

CN2

N

PE +L -L +L -L

I

+

-

IN

IN OUT

/OU

T

-R

-

O

UT

Figure 2 Loop

N N

+

I

-

-

IN

IN

/OU

/OU

T

T

-R

-R

- -

O O

UT UT

Page 2 from 4 921616000_09_002 Page 3 from 4 921616000_09_002

Вам также может понравиться

- Analogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorДокумент2 страницыAnalogue Addressable Optical Smoke and Rate-Of-Rise Heat Detector With Integrated IsolatorThanosEleftheroudisОценок пока нет

- Analogue Addressable Optical Smoke Detector With Integrated IsolatorДокумент2 страницыAnalogue Addressable Optical Smoke Detector With Integrated IsolatorThanosEleftheroudisОценок пока нет

- Horizontal Line Parallel To The Ceiling: Technical CharacteristicsДокумент2 страницыHorizontal Line Parallel To The Ceiling: Technical CharacteristicsThanosEleftheroudisОценок пока нет

- 63000Документ4 страницы63000designselvaОценок пока нет

- Guia de ReciclajeДокумент1 страницаGuia de ReciclajeMadd000Оценок пока нет

- 50W Single Output Switching Power Supply Spec SheetДокумент3 страницы50W Single Output Switching Power Supply Spec SheetNikiОценок пока нет

- FT MEA DriverMeanWell 12W APV 12 SeriesДокумент2 страницыFT MEA DriverMeanWell 12W APV 12 Seriescristo.nieto1Оценок пока нет

- 100W Single Output Switching Power Supply: SeriesДокумент2 страницы100W Single Output Switching Power Supply: SeriesRAJОценок пока нет

- 75W Single Output Switching Power Supply: SeriesДокумент3 страницы75W Single Output Switching Power Supply: SeriesJeffrey BaldwinОценок пока нет

- 60W Single Output Switching Power SupplyДокумент1 страница60W Single Output Switching Power SupplypopaadicljОценок пока нет

- Ower Mplifiers: Rem-S Series-Power AmplifiersДокумент4 страницыOwer Mplifiers: Rem-S Series-Power AmplifiersМаксым КовальськыйОценок пока нет

- SCP 35 SpecДокумент3 страницыSCP 35 SpecTeoОценок пока нет

- 5W DC-DC Regulated Single Output Converter: SeriesДокумент1 страница5W DC-DC Regulated Single Output Converter: SeriesStuxnetОценок пока нет

- Apollo 55000-875Документ2 страницыApollo 55000-875BrunoОценок пока нет

- MDR 100 24Документ2 страницыMDR 100 24Samdan NamhaisurenОценок пока нет

- SLTE-415N 800W Rectifier ModuleДокумент2 страницыSLTE-415N 800W Rectifier ModuleTuan MinhОценок пока нет

- Ad 549Документ18 страницAd 549Hai NguyenОценок пока нет

- PowerSupply DR 100 12Документ2 страницыPowerSupply DR 100 12Preda AndreiОценок пока нет

- Marine: On-Board With ConfidenceДокумент4 страницыMarine: On-Board With Confidenceabduallah muhammadОценок пока нет

- DVI 980/982 Gas Burner Safety ControlДокумент6 страницDVI 980/982 Gas Burner Safety ControlSerghei BotnaruОценок пока нет

- DRP 240 SpecДокумент2 страницыDRP 240 SpecEfren AcostaОценок пока нет

- 10W Single Output Industrial DIN Rail Power Supply: SeriesДокумент2 страницы10W Single Output Industrial DIN Rail Power Supply: SeriesCiprian BalcanОценок пока нет

- Deep Sea 3110 ManualДокумент2 страницыDeep Sea 3110 ManualfwagnergomesОценок пока нет

- Dse 3110 PDFДокумент2 страницыDse 3110 PDFMr Min Kyaw ThuОценок пока нет

- E SyboxДокумент2 страницыE Syboxnle_16948Оценок пока нет

- PSP 1000 Spec 1179932Документ3 страницыPSP 1000 Spec 1179932Tuyên VũОценок пока нет

- Jameco Part Number 1943385: Distributed byДокумент8 страницJameco Part Number 1943385: Distributed byadrianioantomaОценок пока нет

- Ca Series: Proven ReliabilityДокумент7 страницCa Series: Proven Reliabilitymaria chiara pieroniОценок пока нет

- 40W LED Driver Constant Current Multiple LevelsДокумент12 страниц40W LED Driver Constant Current Multiple LevelsAfro GumОценок пока нет

- PB 600 24Документ5 страницPB 600 24Tráng Nguyễn VănОценок пока нет

- EDM M (X)Документ8 страницEDM M (X)Ramin RrОценок пока нет

- S 40 SpecДокумент2 страницыS 40 SpecJennifer FreemanОценок пока нет

- Addressable Twin Input/output Unit With Integrated Isolator: Technical CharacteristicsДокумент7 страницAddressable Twin Input/output Unit With Integrated Isolator: Technical CharacteristicsThanosEleftheroudisОценок пока нет

- LPHC 18 Spec-1291712Документ3 страницыLPHC 18 Spec-1291712carОценок пока нет

- DR 100 SpecДокумент2 страницыDR 100 SpecPreda AndreiОценок пока нет

- SMU02 SpecДокумент2 страницыSMU02 SpecAdityaPermanaIIОценок пока нет

- ST13007DFP: High Voltage Fast-Switching NPN Power TransistorДокумент7 страницST13007DFP: High Voltage Fast-Switching NPN Power Transistorserrano.flia.coОценок пока нет

- Fuente DC 440/24vdcДокумент3 страницыFuente DC 440/24vdcINGWIRBOОценок пока нет

- 699 Pressure SensorДокумент5 страниц699 Pressure SensormasgabanaОценок пока нет

- 480W Three Phase Industrial DIN RAIL Power Supply: SeriesДокумент2 страницы480W Three Phase Industrial DIN RAIL Power Supply: SeriesOSAMAОценок пока нет

- Datasheet Modulo Inversor Alto 20kVAДокумент2 страницыDatasheet Modulo Inversor Alto 20kVALuis CanepaОценок пока нет

- SCN 600 48 Mean WellДокумент7 страницSCN 600 48 Mean WellrekikОценок пока нет

- DR 120 24Документ2 страницыDR 120 24olimpiosurtarОценок пока нет

- 15W Single Output Power Supply SpecsДокумент2 страницы15W Single Output Power Supply SpecsAndres Rojas MayorgaОценок пока нет

- Lufft Power Supply 24V 4AДокумент2 страницыLufft Power Supply 24V 4AJose Luis IglesiasОценок пока нет

- DSE124 Data SheetДокумент2 страницыDSE124 Data SheetMuhammad Shoaib HussainОценок пока нет

- Automatic Autoclave ControllerДокумент2 страницыAutomatic Autoclave ControllerNumanОценок пока нет

- Dse 7110-20 UkДокумент4 страницыDse 7110-20 UkAnas BasarahОценок пока нет

- ITMA DC Module Converts Thermocouple to Analog OutputДокумент8 страницITMA DC Module Converts Thermocouple to Analog Outputtariq mahmoodОценок пока нет

- Ultra: Starting With QualityДокумент2 страницыUltra: Starting With QualityYahya SaifanОценок пока нет

- HBG-60P: 60W Constant Current Mode LED DriverДокумент5 страницHBG-60P: 60W Constant Current Mode LED DriverJuan Manuel JorqueraОценок пока нет

- Axicom IM Relay: Signal RelaysДокумент6 страницAxicom IM Relay: Signal RelaysSakulaОценок пока нет

- SMCGLCE6.5 Thru SMCGLCE170A, E3 SMCJLCE6.5 Thru SMCJLCE170A, E3Документ4 страницыSMCGLCE6.5 Thru SMCGLCE170A, E3 SMCJLCE6.5 Thru SMCJLCE170A, E3StuxnetОценок пока нет

- 65W Single Output Switching Power Supply: SeriesДокумент2 страницы65W Single Output Switching Power Supply: SeriesJojo KawayОценок пока нет

- DC Components Co., LTD.: 1N4001 Thru 1N4007Документ2 страницыDC Components Co., LTD.: 1N4001 Thru 1N4007nanodocl5099Оценок пока нет

- DC Components Co., LTD.: 1N4001 Thru 1N4007Документ2 страницыDC Components Co., LTD.: 1N4001 Thru 1N4007dianne r. gayapanaoОценок пока нет

- Katalog Techn Unterlagen Grossantriebe en PDFДокумент260 страницKatalog Techn Unterlagen Grossantriebe en PDFzaidОценок пока нет

- Detroit Spec Sheet Air Dryer CompressedДокумент1 страницаDetroit Spec Sheet Air Dryer CompressedRoland BielefeldtОценок пока нет

- NFM 05 SpecДокумент2 страницыNFM 05 SpecvvvОценок пока нет

- TC100N enДокумент15 страницTC100N enThanosEleftheroudisОценок пока нет

- BS-527_ENДокумент2 страницыBS-527_ENThanosEleftheroudisОценок пока нет

- JRC131689 01 PDFДокумент78 страницJRC131689 01 PDFThanosEleftheroudisОценок пока нет

- Fire Detection CatalogueДокумент72 страницыFire Detection CatalogueThanosEleftheroudisОценок пока нет

- BS-316 enДокумент22 страницыBS-316 enThanosEleftheroudisОценок пока нет

- Positioning of Sensors Guidelines PDFДокумент3 страницыPositioning of Sensors Guidelines PDFSerge RinaudoОценок пока нет

- Ex Ec IIA T6 GC: Technical CharacteristicsДокумент7 страницEx Ec IIA T6 GC: Technical CharacteristicsValcu Gabriel OctavianОценок пока нет

- 4 Zone Panel With One Extinguish Output: GeneralДокумент13 страниц4 Zone Panel With One Extinguish Output: GeneralThanosEleftheroudisОценок пока нет

- Emergency Lighting Ceiling Mounted Self-Testing 3 Hour Autonomy LED SignДокумент2 страницыEmergency Lighting Ceiling Mounted Self-Testing 3 Hour Autonomy LED SignThanosEleftheroudisОценок пока нет

- Addressable Twin Input/output Unit With Integrated Isolator: Technical CharacteristicsДокумент7 страницAddressable Twin Input/output Unit With Integrated Isolator: Technical CharacteristicsThanosEleftheroudisОценок пока нет

- F-001-043 - Tunnel LightДокумент4 страницыF-001-043 - Tunnel LightThanosEleftheroudisОценок пока нет

- F 002 009 Box 535 - EngДокумент2 страницыF 002 009 Box 535 - EngThanosEleftheroudisОценок пока нет

- BS-1638, BS-1642, BS-1646: Conventional Fire Detection Panels 8, 12 and 16 ZonesДокумент47 страницBS-1638, BS-1642, BS-1646: Conventional Fire Detection Panels 8, 12 and 16 ZonesThanosEleftheroudisОценок пока нет

- Bs 636Документ10 страницBs 636ali kuşçuОценок пока нет

- GR-408/6L GR-409/3L GR-409/6L GR-408/3LДокумент5 страницGR-408/6L GR-409/3L GR-409/6L GR-408/3LThanosEleftheroudisОценок пока нет

- Technical Characteristics: A-1900 Test CardДокумент2 страницыTechnical Characteristics: A-1900 Test CardThanosEleftheroudisОценок пока нет

- GR-409/12L GR-408/12L: For Led Module Specs (See Page 3)Документ5 страницGR-409/12L GR-408/12L: For Led Module Specs (See Page 3)ThanosEleftheroudisОценок пока нет

- Self Testing Maintained Emergency Luminaires With White Led'SДокумент5 страницSelf Testing Maintained Emergency Luminaires With White Led'SThanosEleftheroudisОценок пока нет

- Non Maintained Emergency Luminaires With White Power LEDsДокумент4 страницыNon Maintained Emergency Luminaires With White Power LEDsThanosEleftheroudisОценок пока нет

- Installation Instructions: Non Maintained/Maintained Emergency Luminaires With White LedsДокумент2 страницыInstallation Instructions: Non Maintained/Maintained Emergency Luminaires With White LedsThanosEleftheroudisОценок пока нет

- Installation Instructions: Non Maintained/Maintained Emergency Luminaires With White LedsДокумент2 страницыInstallation Instructions: Non Maintained/Maintained Emergency Luminaires With White LedsThanosEleftheroudisОценок пока нет

- PLD-25/CBS: Cbs Emergency Led Illumination SignДокумент2 страницыPLD-25/CBS: Cbs Emergency Led Illumination SignThanosEleftheroudisОценок пока нет

- 230V Central Battery System: Installation Programming UseДокумент39 страниц230V Central Battery System: Installation Programming UseThanosEleftheroudisОценок пока нет

- GR-8600 24VDC Address Central Battery System Installation and Programming ManualДокумент44 страницыGR-8600 24VDC Address Central Battery System Installation and Programming ManualThanosEleftheroudisОценок пока нет

- Installation Guide For GR-6500 Addressable Control Panel For Emergency LuminairesДокумент24 страницыInstallation Guide For GR-6500 Addressable Control Panel For Emergency LuminairesThanosEleftheroudisОценок пока нет

- 24V Central Battery System: Installation Programming UseДокумент37 страниц24V Central Battery System: Installation Programming UseThanosEleftheroudisОценок пока нет

- Basic Principles of Fiber Optic CommunicationДокумент3 страницыBasic Principles of Fiber Optic CommunicationHumayra Anjumee100% (2)

- 1tne968902r1101 Ai561s500 Analog Input Mod 4ai U IДокумент2 страницы1tne968902r1101 Ai561s500 Analog Input Mod 4ai U IMartinCastilloSancheОценок пока нет

- PT2313L PDFДокумент3 страницыPT2313L PDFMaugrys Castillo100% (1)

- Communication System Block Diagram (Basic)Документ5 страницCommunication System Block Diagram (Basic)Syed AfzalОценок пока нет

- Chapter 1 - Pic16f887 OverviewДокумент38 страницChapter 1 - Pic16f887 OverviewTung NguyenОценок пока нет

- Adva FSP 3000Документ16 страницAdva FSP 3000giorgio802000Оценок пока нет

- P1022 Qoriq Integrated Processor Design Checklist: Application NoteДокумент41 страницаP1022 Qoriq Integrated Processor Design Checklist: Application NoteDanielle AtkinsОценок пока нет

- IoT Based Weather STation For Farmers in VillagesДокумент12 страницIoT Based Weather STation For Farmers in Villagessanchit jainОценок пока нет

- DatasheetДокумент7 страницDatasheetDarcio TolottiОценок пока нет

- 27012471-SISO Wall Mount Antenna DatasheetДокумент1 страница27012471-SISO Wall Mount Antenna DatasheetСергей МирошниченкоОценок пока нет

- Playstation (Console) : Manufacturer Product Family Type Generation Retail Availability PlaystationДокумент22 страницыPlaystation (Console) : Manufacturer Product Family Type Generation Retail Availability Playstationro_venancioОценок пока нет

- Infineon IRFZ44N DataSheet v01 - 01 ENДокумент9 страницInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoОценок пока нет

- PM410 00351Документ20 страницPM410 00351cedric depauwОценок пока нет

- Centralised Systems CB For Emergency LightingДокумент3 страницыCentralised Systems CB For Emergency Lightingnicky_balanОценок пока нет

- User Manual 5638061Документ28 страницUser Manual 5638061Rodrigo OriveОценок пока нет

- Introduction to Erbium Doped Fiber Amplifier (EDFA) DesignДокумент16 страницIntroduction to Erbium Doped Fiber Amplifier (EDFA) DesignArifiana Satya NastitiОценок пока нет

- Plant Maintenance, Proof of Performance and Signal Leakage Rev (1) - AДокумент255 страницPlant Maintenance, Proof of Performance and Signal Leakage Rev (1) - AhailemebrahtuОценок пока нет

- CHAPTER 3 Design Methodology 3.1 MethodologyДокумент4 страницыCHAPTER 3 Design Methodology 3.1 MethodologyRuth EnormeОценок пока нет

- Arabsat 5CДокумент5 страницArabsat 5Chidrogen.h.786786Оценок пока нет

- Inter Trip RelayДокумент10 страницInter Trip RelayNam Hoai Le100% (1)

- HG240641Документ1 страницаHG240641sdk00Оценок пока нет

- Est Can BusДокумент32 страницыEst Can BusRuben EstradaОценок пока нет

- Fault Passage IndicatorДокумент5 страницFault Passage Indicatorbibhas_samantaОценок пока нет

- Shaftpower Operating InstructionsДокумент23 страницыShaftpower Operating InstructionsThomas Liontos100% (2)

- OJT Weekly Report Edit For HardboundДокумент8 страницOJT Weekly Report Edit For HardboundveliantmОценок пока нет

- Lecture 2 - Digital TelevisionДокумент40 страницLecture 2 - Digital TelevisionGerald Emmanuel100% (1)

- Ec2305 Transmission Lines and Waveguides L T P C 3 1 0 4Документ1 страницаEc2305 Transmission Lines and Waveguides L T P C 3 1 0 4durgadevikarthikeyanОценок пока нет

- History of MicroprocessorsДокумент37 страницHistory of MicroprocessorsWessam Essam0% (1)

- Nokia N79 Service ManualДокумент21 страницаNokia N79 Service ManualgbabumailОценок пока нет

- AM Loop AntennasДокумент8 страницAM Loop AntennasSaung SunnahОценок пока нет