Академический Документы

Профессиональный Документы

Культура Документы

Construction Service Project Scheduling Analysis Using Critical Path Method (CPM), Project Evaluation and Review Technique (PERT)

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Construction Service Project Scheduling Analysis Using Critical Path Method (CPM), Project Evaluation and Review Technique (PERT)

Авторское право:

Доступные форматы

Volume 6, Issue 2, February – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Construction Service Project Scheduling Analysis

Using Critical Path Method (CPM), Project

Evaluation and Review Technique (PERT)

Popy Yuliarty Novia Nila S Rini Anggraini

Department of Industrial Engineering Department of Industrial Engineering Department of Mechanical

Universitas Mercu Buana Universitas Mercu Buana Engineering

DKI Jakarta, Indonesia DKI Jakarta, Indonesia DKI Jakarta, Indonesia

Abstract:- The success or failure of a project is largely To overcome this problem, the researcher makes a

determined by the planning and control of the project. study using the Critical Path Network (CPM) and Project

The failure of project implementation was due to lack of Evaluation and Review Technique (PERT) Methods. By

planning and lack of ineffective control so that project using the CPM and PERT methods, it can be seen in more

activities became inefficient. This resulted in delays, detail about the time difference between the initial

reduced quality of work, and unexpected costs of conditions and the repair conditions, when the initial

implementation. Problems in this research object is a conditions often experience delays in processing time from

delay in completing a gondola project because there are preparation to completion and result in poor quality [5].

several obstacles or problems that occur. Optimization of Therefore, it must be noted which work should get more

working time is quite important for companies in attention because if the work is delayed it will affect the

working on projects, because in this work time efficiency results of other work [6]. This research will answer the

is needed because the gondola is needed by the client. question of how to determine the optimal time for project

The implementation of the project requires optimal completion and how to determine the critical path to get

project planning using the CPM (Critical Path Method) more attention compared to other activities on the

and PERT methods. With the CPM method, 13 critical contrusction service project.

activities were obtained, with total duration of 55 days

was also applied to the Gantt Chart. And with the PERT II. METHODS

method (Program Evaluation and Review Technique)

obtained 13 critical activities, and a total duration of 53 The situation faced here is that there is a difference

days with a probability of project completion is 86.65%. between the project implementation time and the

predetermined project plan time. The project planning time

Keywords:- Project Management, CPM,PERT, Activities is usually shorter than the project implementation time [7].

The analysis technique used in this research is the CPM

I. INTRODUCTION (Critical Path Method) and PERT (Project Evaluation and

Review Technique) approaches.

The construction of a construction project has

objective goals that must be in line with strategic goals, thus A. Stage 1 : CPM analysis

the performance of a project will affect its achievement [1] . At this stage a network analysis is carried out using the

Projects generally have a deadline, which must be completed CPM method. To be able to set up a CPM network, research

before or at the agreed time. However, in reality in the field, requires several steps [8]. The steps in compiling a CPM

there are still many project completion times that are network are:

delayed or not completed on schedule [2]. Projects are Review and identify the project scope, describe it, break

dynamic, non-routine, multi-activity with varying intensity, it down into activities or groups of activities that are

short cycles, have starting and ending points, and limited project components.

funds [3]. According to [4] in a project it is necessary to Rearrange the components in point 1, into links in the

confirm the relationship between activities to plan a project. order according to the dependency logic.

CV. KCT collaborates with PT. GKL in working on gondola Provide an estimated timeframe for each of the activities

projects, which is usually when PT. GKL won the project resulting from the breakdown of the project scope.

tender, entrusted to CV. KCT. The problem in this company Identify the critical path (critical path) and float on the

is an internal problem, namely the implementation of the network.

gondola project that was not completed on time.During the

implementation of the gondola project in 2019-2020 there Perform forward and backward calculations. From the

were 5 projects that have been completed, but 3 of the 5 two calculations, it is identified which activities are on the

projects have experienced delays / delays. critical path.

IJISRT21FEB430 www.ijisrt.com 477

Volume 6, Issue 2, February – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

B. Stage 2 : PERT analysis IV. DISCUSSION

At this stage, PERT analysis is carried out to determine

the duration of each work from the data that has been 1. Critical Path Method. The initial step in creating a

obtained and to determine the probability of the company network using the CPM method is to detail each activity

reaching the target schedule. To be able to apply the PERT then proceed with the stage of determining the sequence

method, research requires the following steps: of dependence between one activity and another, because

Determine the estimated activity time in the formation of a network using the CPM method, it

Determine the standard deviation of project activities is necessary to know what preceded activities because

Determine the variety of activities from project activities future activities can be carried out after activities

Knowing the probability of reaching the schedule target beforehand or in other words can be done in parallel [10].

a. Relationship Between Project Activities. The relationship

III. RESULT between activities is arranged into a chain or network

diagram for the Activity On Node (AON) in the

Description of Activities. In this step, an assessment and following order as shown in figure 1:

identification of the project scope is carried out by

G H

describing and breaking it down into activities or groups 3

3

5

5

3

3

5

5

13 8

of activities that are project components. This H1 H2

F 3 5 3 5

arrangement is done based on experience and or data in 3

3

10

5

5 3

6

5 3

4

5

G4 I

the project in the past [9].The details of its activities are A B C D E F1 F2

5

5

10

10 G6 H3

5

5

10

10

3 3 4 7 5 5 3

0 1 0 1 0 1 0 1 1 3 3

as shown in Table 1 below : 0

5

1 0

2

1 0

2

1 0

5

1 1

1

3 4

8

5

5

5

4

10

10

G5

3

3

5 3

2

5

5 10

5 10

F3 6

3 4

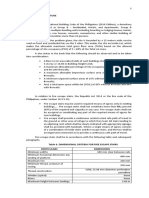

Activities Duration Delay 4 5

Type of work 7

code (days) (days) G1 G2 G3

5 10 5 10 5 10

Create gondola design & - 5 10 5 10 5 10

A 5 3 9 5

spesification Fig 1:- AON Network Diagram

B Material selection 2 -

Ordering material & 2 b. Critical Path Method. The critical path in this packaging

C 2 packaging project is a path that consists of a series of

negotiating

Purchase & deliveri of 3 activities which in case of delay will result in overall

D 5 delay [11]. This step is preceded by performing forward

material

E Material checking 1 2 and backward calculations. The forward calculation is

done to determine the Early Start (ES) and Early Finish

Steel Frame fabrication - (EF), while the backward calculation is to determine the

F 10

work Latest Start (LS) and Latest Finish (LF). From these two

Cutting steel rods - calculations, it can be identified the critical path that can

F1 according to the type and 8 be calculated float / slack, which is the allowance for the

dimension of need completion time of an activity.

Basic painting for anti- - Forward Calculation. For advanced calculations in the

F2 4

rust table above, the Activity On Node (AON) network

Making a transportation - diagram is as shown in figure 2 below :

F3 7

system

G Erection work 13 - 25

G

38 38

H

46

3 5 3 5

13 8

Measurement of setting 1

G1 3 H1 H2

plate & anchor plate 15

3

F

25

5

42

3

48

5

48

3

52

5

10 6 4

Drilling and planting of - 27

G4

34 52

I

55

G2 9 5 10 5 10

angkur 0

A

5 5

B

7 7

C

9 9

D

14 14

E

15 15

F1

23 23

F2

27

7

39

G6

42 48

H3

50 3

0 1 0 1 0 1 0 1 1 3 4 5 5 10 3 5 3 5

G3 Anchor tensile test 5 1 5 2 2 5 1 8 4

27

G5

33

3 2

5 10

F3 6

G4 Gondola frame erection 7 - 15

4

7

22

G5 Gondola basket assembly 6 - G1 G2 G3

22 25 25 34 34 39

Instalation of steel slings 2 5

3

10 5

9

10 5

5

10

G6 3

& gondola basket Fig 2:- Advanced Calculation AON Network Diagram

H Post erection work 8 -

Check of instalation & 1 Backward Count. In the countdown, the calculation

H1 6 moves from the event terminal to the event core. In the

joints

H2 Re-painting anti-rust pain 4 - backward calculation, this project is intended to find out

the time or date of the most recent project end in order to

H3 Gondola test 2 -

be able to start and end each activity without delaying the

I Finishing 3 - entire project completion period. Here is the equation for

Table 1:- Types of Project Activities the countdown. The countdown network diagram

Activity On Node (AON) is shown in Figure 3

IJISRT21FEB430 www.ijisrt.com 478

Volume 6, Issue 2, February – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

G H

25

31

13

38

44

38

44

8

46

52

following is the Activity On Node (AON) network diagram

F H1

48

H2

52

for the project's critical path in Figure 5:

15 25 42 48

21 31 42 48 48 52

10 6 4

G4 I

27 34 52 55 G H

25 38 38 46

A B C D E F1 F2 32 39 G6 H3 52 55

15 15 23 7 42 50 3 29 42 42 50

0 5 5 7 7 9 9 14 14 23 27 39 48

13 8

0 5 5 7 7 9 9 14 14 15 20 28 28 32 39 42 50 52

5 2 2 5 1 8 4 G5 3 2

27 33

F H1 H2

15 25 40 46 46 50

33 39

F3 6

15 22 19 29 40 46 46 50

10 6 4

15 22 G4 I

7 27 34 50 53

A B C D E F1 F2 30 37 G6 H3 50 53

15 15 23 7 40 48 3

0 5 5 7 7 9 9 14 14 23 27 37 46

G1 G2 G3

22 25 25 34 34 39 14 18 26 37 40 48 50

0 5 5 7 7 9 9 14 15 26 30

5 2 2 5 1 8 4 G5 3 2

22 25 25 34 34 39 27 33

3 9 5

31 37

F3 6

Fig 3:- The countdown network diagram Activity On Node 15

15

21

21

6

(AON)

G1 G2 G3

21 24 24 32 32 37

21 24 24 32 32 37

Total Float Calculation. Total Float is the amount of time

3 8 5

Fig 5:- PERT AON Critical Path Network Diagram

that the completion time of an activity can be postponed

without affecting the quickest time of completion of the

Based on the calculation of variance and standard

overall project. This stage is the stage of determining the

deviation, the time to complete activities that pass through

critical path, which is the longest implementation path,

the critical path is 1,802 days. By using a normal curve of

which determines the project completion time.

the probability of the project completion time using the

Critical Path. The critical path is the path with the longest

following formula:

amount of time compared to all other possible passes.

The duration of the overall Project completion time is 55 𝑇(𝑑) − ∑ 𝑇𝑒 𝑘𝑟𝑖𝑡𝑖𝑠

days.Therefore, another way that can also be used to find 𝑧=

the critical path is by calculating the length of each 𝑆

55 − 53

existing path. The critical path can be seen in Figure 4 𝑧=

below: 1.802

𝑧 = 1.11 ̴ 0.8665

G H

25 38 38 46

31

13

44 44

8

52

From the figures above, the figure is 0.8665 in table Z

15

F

25 42

H1

48 48

H2

52 normal distribution, then the possibility of completing the

21

10

31

27

G4

34

42

6

48 48

4

52

52

I

55

project in 53 days is 86.65%. This means that the completion

0

A

5 5

B

7 7

C

9 9

D

14 14

E

15 15

F1

23 23

F2

27

32

7

39

39

G6

42 48

H3

50

52

3

55 of the project analyzed using the CPM method has a great

0

5

5 5

2

7 7

2

9 9

5

14 14

1

15 20

8

28 28

4

32

27

G5

33

39

3

42 50

2

52

chance of being completed with the duration given by the

15

F3

22

33

6

39

company.

15 22

7

22

G1

25 25

G2

34 34

G3

39 3. Results of Comparative Analysis of CPM and PERT.

22

3

25 25

9

34 34

5

39

In this research, the methods used for scheduling are

Fig 4:- AON Critical Path Network Diagram CPM and PERT. The comparison of the working time of the

gondola project with these two methods can be seen in the

2. PERT (Project Evaluation Review Technique) Method. table 2 and figure 6 below:

Like the CPM method, PERT also uses an arrow chart to

illustrate the project trajectory. In terms of understanding

and calculation, critical activity is the same, the critical Description CPM PERT Difference

path or float in PERT is known as slack. The difference

Time (days) 55 53 2

between CPM and PERT which is clearly visible is in the

Table 2:- Comparison of Time Using the CPM and PERT

estimation of activity duration [12]. If in CPM the time is

Methods

estimated with certainty (deterministically), then in

PERT there are 3 time estimates, namely:

By using PERT network planning to improve the

a. Optimistic time (To), namely the possibility that

project work system, each related section can understand the

activities can be completed in a shorter time.

process flow in detail, know which activities can be carried

b. The most frequent occurrence (Tm), namely the

out in parallel / concurrently, and prioritize activities that are

estimated time that usually occurs under normal

considered critical so that they do not affect the overall

conditions.

project delay. When compared with the results of the

c. Time pessimistic (Tp), which is the possibility that the

completion of this gondola project, which was completed in

activity can be completed in a longer time.

113 days, with the improvement of the work system and the

use of the PERT method, this time efficiency was 60 days

Referring to the information above, time estimation

faster.By using the PERT method, a Gantt Chart for project

data for optimistic time and pessimistic time are needed.

implementation can be made.

This data was obtained through interviews and discussions

with field parties. Based on the calculation of slack using the

PERT method, 13 critical trajectories were found, namely:

A, B, C, D, E, F3, G1, G2, G3, G6, H1, H2, and I. day. The

IJISRT21FEB430 www.ijisrt.com 479

Volume 6, Issue 2, February – 2021 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

V. CONCLUSION [8]. M. Jufriyanto and M. Z. Fathoni, “Project

Development Management of Rungkut Tower

The conclusions of this study are: Apartments with Critical Path Method Approach and

1. Project completion using the CPM scheduling method is Pert,” Int. J. Sci. Eng. Inf. Technol., 2019.

55 days. The PERT project method can be completed in [9]. T. I. Julkarnaen, L. Herlina, and Kulsum, “Analisa

53 days. Meanwhile, without using these two methods, Perbaikan Penjadwalan Perakitan Panel Listrik

the project completion time will take 113 days. From Dengan Metode CPM dan PERT ( Studi Kasus : PT .

both the CPM and PERT methods by considering the Mega Karya Engineering ),” J. Tek. Ind. Untirta,

actual ideal conditions, the PERT method produces a 2015.

shorter duration of completion of the entire project [10]. A. Rijaluddin and A. P. Ajie, “PENERAPAN

compared to the CPM method. PENJADWALAN WAKTU MENGGUNAKAN

2. Activities that are considered critical in the gondola METODE CPM (CRITICAL PATH METHODE)

project are activities A (making gondola designs), B DAN PERT PADA PEMBANGUNAN GEDUNG

(material selection), C (ordering materials and INSTALASI RAWAT JALAN RSUD

negotiating), D (purchasing and delivering materials), E MAJALENGKA,” J-Ensitec, 2020.

(checking materials), F3 (manufacture of anchoring [11]. S. R. Jannah, L. Muzdalifah, and E. F. Kurniawati,

system), G1 (measurement of setting plate & anchor “Optimasi waktu penjadwalan proyek pembangunan

plate)), G2 (drilling and planting of anchors), G3 (tensile perumahan menggunakan Critical Path Method

anchor test), G6 (mounting steel slings on gondola (CPM) /Program Evaluation and Review Tehnique

baskets), H1 (checking all installations and joints) , H2 (PERT) dan Simulasi Monte Carlo (Studi Kasus CV.

(repainting anti-rust paint), and I (finishing). From the Granada Property),” Pros. SNasPPM, 2018.

calculation of the PERT method, the probability value or [12]. P. Yuliarty, R. Anggraini, and T. Wastiono,

probability of completing the gondola project is 86.65%. “PENJADWALAN PROYEK MESIN AUTO

This means the possibility of completion of the gondola ASSEMBLY MEMBRANE REGULATOR

project by CV. KAT on time is quite high. VALVE DI PT. OMG METODE CRITICAL PATH

METHOD (CPM),” Ind. Inov. J. Tek. Ind., 2020,

REFERENCES doi: 10.36040/industri.v10i1.2531.

[1]. A. Dwiretnani and A. Kurnia, “OPTIMALISASI

PELAKSANAAN PROYEK DENGAN METODE

CPM (CRITICAL PATH METHODE),” J. Talent.

Sipil, 2018, doi: 10.33087/talentasipil.v1i2.8.

[2]. A. E. Husin, F. Fahmi, S. Rahardjo, I. P. Siregar, and

B. D. Kussumardianadewi, “M-PERT and lean

construction integration on steel construction works

of warehouse buildings,” Int. J. Eng. Adv. Technol.,

2019.

[3]. M. Kholil, B. Nurul Alfa, and M. Hariadi,

“Scheduling of House Development Projects with

CPM and PERT Method for Time Efficiency (Case

Study: House Type 36),” 2018, doi: 10.1088/1755-

1315/140/1/012010.

[4]. M. Kholil, B. N. Alfa, and Supriyanto,

“Optimization of Production Process Time with

Network/PERT Analysis Technique and SMED

Method,” 2018, doi: 10.1088/1757-

899X/453/1/012050.

[5]. D. W. Arian, “Manajemen Operasi Jasa,” Manaj.

Operasi, 2014.

[6]. M. Hanefi Calp and M. Ali Akcayol, “Optimization

of project scheduling activities in dynamic CPM and

PERT networks using genetic algorithms,” arXiv.

2019, doi: 10.19113/sdufbed.35437.

[7]. A. Maulana and F. Kurniawan, “TIME

OPTIMIZATION USING CPM, PERT AND PDM

METHODS IN THE SOCIAL AND

DEPARTMENT OF KELAUTAN BUILDING

DEVELOPMENT PROJECT GRESIK DISTRICT,”

IJTI (International J. Transp. Infrastructure), 2019,

doi: 10.29138/ijti.v2i2.784.

IJISRT21FEB430 www.ijisrt.com 480

Вам также может понравиться

- Waterfall Model Case StudyДокумент6 страницWaterfall Model Case StudyAkor Murthy50% (2)

- DPL MDДокумент3 страницыDPL MDCoy IngramОценок пока нет

- Computer Science Capstone Project: Course DescriptionДокумент7 страницComputer Science Capstone Project: Course DescriptionGrantham UniversityОценок пока нет

- Project Management CourseworkДокумент17 страницProject Management CourseworkEqui AgbasiОценок пока нет

- 1 It Infrastructure Project Phase I1Документ4 страницы1 It Infrastructure Project Phase I1Hicham ZMОценок пока нет

- BPMN Bpel MappingДокумент6 страницBPMN Bpel Mappingthiagocastro78100% (1)

- Installation GuideДокумент9 страницInstallation GuidesakkhanОценок пока нет

- Scrum and Agile MethodsДокумент23 страницыScrum and Agile MethodsAdnan QutubuddinОценок пока нет

- SPM Unit 2 NotesДокумент19 страницSPM Unit 2 NotesMAYANK RAGHAVОценок пока нет

- Database Project and Documentation GuidelinesДокумент18 страницDatabase Project and Documentation GuidelinesChristianTedOchoa0% (1)

- BSBPMG410Документ8 страницBSBPMG410Tanmay JhulkaОценок пока нет

- Software Testing Question BankДокумент17 страницSoftware Testing Question BankPusba NathanОценок пока нет

- Review QuestionsДокумент4 страницыReview QuestionsM Anwar Sadeed0% (1)

- Mca Project Report Guidelines and FormatsДокумент11 страницMca Project Report Guidelines and Formatsvikram AjmeraОценок пока нет

- Project Scheduling B07K ASSIGNMENT 8Документ5 страницProject Scheduling B07K ASSIGNMENT 8CRAIG JOSEPHОценок пока нет

- Need of SPMДокумент3 страницыNeed of SPMranydi0% (2)

- Strengths of Primavera P6Документ3 страницыStrengths of Primavera P6hashim malikОценок пока нет

- Software Engineering and Project ManagementДокумент23 страницыSoftware Engineering and Project ManagementUmair Aziz KhatibОценок пока нет

- Testing Team and Development TeamДокумент33 страницыTesting Team and Development TeamAryaman Singh100% (1)

- R19 Devops Unit-5Документ8 страницR19 Devops Unit-5KaarletОценок пока нет

- Case Studies 8Документ4 страницыCase Studies 8KapildevОценок пока нет

- Se 5&2Документ40 страницSe 5&2SAJIN PОценок пока нет

- Software Project ManagmentДокумент3 страницыSoftware Project ManagmentMani DkmОценок пока нет

- SEMP Template - ABC EducationДокумент9 страницSEMP Template - ABC EducationCVSCEducationFundОценок пока нет

- BUS 504 Assignment 2 Dec 2013Документ4 страницыBUS 504 Assignment 2 Dec 2013RaselAhmed082Оценок пока нет

- Project Scope StatementДокумент3 страницыProject Scope StatementMaryam MalikОценок пока нет

- Software Development Life CycleДокумент28 страницSoftware Development Life CycleAhmed BaniMustafaОценок пока нет

- Technology Management Tools: S-CurveДокумент18 страницTechnology Management Tools: S-CurveFS SYCOОценок пока нет

- Feasibility Report Crime File Management System For Bahirdar Police StationДокумент11 страницFeasibility Report Crime File Management System For Bahirdar Police StationTadilo getanehОценок пока нет

- M-S-215 Static Cone PenetrometerДокумент4 страницыM-S-215 Static Cone PenetrometerJunpieter GultomОценок пока нет

- Softwre Project ManagementДокумент24 страницыSoftwre Project Managementkakoli19801980Оценок пока нет

- Asl Testing - Template Test PlanДокумент12 страницAsl Testing - Template Test PlanBalaji ElanchezhiyanОценок пока нет

- The Bcs Professional Examinations BCS Level 5 Diploma in IT April 2008 Examiners' Report IT Project ManagementДокумент12 страницThe Bcs Professional Examinations BCS Level 5 Diploma in IT April 2008 Examiners' Report IT Project ManagementOzioma Ihekwoaba100% (1)

- BM AssignmentДокумент7 страницBM AssignmentAli ShehrwaniОценок пока нет

- DB211 - Unit 9 Assignment BДокумент8 страницDB211 - Unit 9 Assignment BTim Williams0% (2)

- Video Library Management System ProjectДокумент2 страницыVideo Library Management System ProjectDeep DeepОценок пока нет

- Cost Management: PMP Study Guide (PMBOK 6th Edition)Документ7 страницCost Management: PMP Study Guide (PMBOK 6th Edition)abhasОценок пока нет

- I Make Erp Documentation VERSION B1.05.1231Документ12 страницI Make Erp Documentation VERSION B1.05.1231Ahmad Takiyuddin Bin SaadОценок пока нет

- "Routine Management System": Project Report OnДокумент26 страниц"Routine Management System": Project Report OnSonali AnandОценок пока нет

- Project Management Plan - Moraleta's GroupДокумент9 страницProject Management Plan - Moraleta's GroupAxiahle Duarte PrüdenteОценок пока нет

- Agile Software DevelopmentДокумент26 страницAgile Software DevelopmentsamuelОценок пока нет

- Project ManagementДокумент5 страницProject ManagementCaroline Diersen DownenОценок пока нет

- Software Development Process: IS 274: Object Oriented Analysis and DesignДокумент44 страницыSoftware Development Process: IS 274: Object Oriented Analysis and DesignSTANLEY RICHARDОценок пока нет

- Unit 9 Assignment 2 BriefДокумент3 страницыUnit 9 Assignment 2 BriefHannahОценок пока нет

- The Bcs Professional Examinations BCS Level 5 Diploma in IT October 2009 Examiners' Report IT Project Management Section AДокумент10 страницThe Bcs Professional Examinations BCS Level 5 Diploma in IT October 2009 Examiners' Report IT Project Management Section AOzioma IhekwoabaОценок пока нет

- General Information: Instruction Manual Portable Static Cone PenetrometerДокумент4 страницыGeneral Information: Instruction Manual Portable Static Cone PenetrometerAbdelhamid ElgasaierОценок пока нет

- Software TestingДокумент32 страницыSoftware TestingJaiyanth Balasubramaniam100% (1)

- Software Project Management: Course TitleДокумент29 страницSoftware Project Management: Course TitleTALAT GHAFOORОценок пока нет

- Specifications: Model & Specification-Based Software TestingДокумент6 страницSpecifications: Model & Specification-Based Software TestingAyazОценок пока нет

- SDLC 121910301008Документ74 страницыSDLC 121910301008Radha Krishna - with youОценок пока нет

- P6V82Webb Sample Slides - UnlockedДокумент16 страницP6V82Webb Sample Slides - UnlockedSuhas JadhalОценок пока нет

- Standard Test Approach - SampleДокумент41 страницаStandard Test Approach - SampleajamaljacksonОценок пока нет

- What Is The Software Development Life Cycle?Документ12 страницWhat Is The Software Development Life Cycle?Rahul JainОценок пока нет

- Braindump JK0-017Документ87 страницBraindump JK0-017cremer.rikeОценок пока нет

- COMP1549 Advanced Programming Exam1213Документ13 страницCOMP1549 Advanced Programming Exam1213Yexeon ChewОценок пока нет

- Uml Deployment DiagramДокумент3 страницыUml Deployment DiagramMaryus SteauaОценок пока нет

- COCOMOДокумент21 страницаCOCOMOanirban_surОценок пока нет

- Requirements Management Plan A Complete Guide - 2019 EditionОт EverandRequirements Management Plan A Complete Guide - 2019 EditionОценок пока нет

- Osho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)Документ8 страницOsho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)International Journal of Innovative Science and Research TechnologyОценок пока нет

- Entrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisДокумент10 страницEntrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaДокумент6 страницImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Influence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaДокумент13 страницInfluence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaInternational Journal of Innovative Science and Research Technology100% (1)

- Sustainable Energy Consumption Analysis through Data Driven InsightsДокумент16 страницSustainable Energy Consumption Analysis through Data Driven InsightsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Detection and Counting of Fake Currency & Genuine Currency Using Image ProcessingДокумент6 страницDetection and Counting of Fake Currency & Genuine Currency Using Image ProcessingInternational Journal of Innovative Science and Research Technology100% (9)

- Utilization of Waste Heat Emitted by the KilnДокумент2 страницыUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictДокумент13 страницEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Auto Tix: Automated Bus Ticket SolutionДокумент5 страницAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleДокумент8 страницDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Smart Health Care SystemДокумент8 страницSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- An Overview of Lung CancerДокумент6 страницAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaДокумент10 страницDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerДокумент9 страницComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Ambulance Booking SystemДокумент7 страницAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningДокумент8 страницUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersДокумент33 страницыCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Predictive Analytics for Motorcycle Theft Detection and RecoveryДокумент5 страницPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsДокумент12 страницForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Blockchain Based Decentralized ApplicationДокумент7 страницBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- An Industry That Capitalizes Off of Women's Insecurities?Документ8 страницAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyОценок пока нет

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoДокумент6 страницStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Compact and Wearable Ventilator System For Enhanced Patient CareДокумент4 страницыCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Visual Water: An Integration of App and Web To Understand Chemical ElementsДокумент5 страницVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaДокумент6 страницFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueДокумент2 страницыParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesДокумент8 страницInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyДокумент19 страницSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldДокумент6 страницImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Predict The Heart Attack Possibilities Using Machine LearningДокумент2 страницыPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Question 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound CompoundДокумент4 страницыQuestion 1: As Shown in Figure 1. A 6-Pole, Long-Shunt Lap-Wound Compoundالموعظة الحسنه chanelОценок пока нет

- Unit 3 Approaches To The Study of Medieval Urbanisation : StructureДокумент20 страницUnit 3 Approaches To The Study of Medieval Urbanisation : StructureSunil SunilОценок пока нет

- En 10143-1993Документ7 страницEn 10143-1993Eduardo TeixeiraОценок пока нет

- Lesson 2 Principles of Cooperative ConversationДокумент9 страницLesson 2 Principles of Cooperative Conversationdelilah o balladОценок пока нет

- FMDS0102Документ69 страницFMDS0102hhОценок пока нет

- Listening Lesson PlanДокумент3 страницыListening Lesson PlanPınar AkgünОценок пока нет

- ZEOS-AS ManualДокумент2 страницыZEOS-AS Manualrss1311Оценок пока нет

- 1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalДокумент2 страницы1.1. CHILLER 1.2. Centrifugal: 5.2.hrizontalShah ArafatОценок пока нет

- (LS 1 English, From The Division of Zamboanga Del SurДокумент17 страниц(LS 1 English, From The Division of Zamboanga Del SurKeara MhieОценок пока нет

- Key Concepts: Adding and Subtracting FractionsДокумент7 страницKey Concepts: Adding and Subtracting Fractionsnearurheart1Оценок пока нет

- ExerciseДокумент10 страницExerciseNguyen Mai QuynhОценок пока нет

- Symptoms and DiseasesДокумент8 страницSymptoms and Diseaseschristy maeОценок пока нет

- A Research Paper On DormitoriesДокумент5 страницA Research Paper On DormitoriesNicholas Ivy EscaloОценок пока нет

- Storage Tank Design Calculation - Api 650: Close Floating RoofДокумент32 страницыStorage Tank Design Calculation - Api 650: Close Floating RoofhgagОценок пока нет

- Additional Material On CommunicationДокумент15 страницAdditional Material On CommunicationSasmita NayakОценок пока нет

- Executive Summary: 0.1 Name of The WorkДокумент12 страницExecutive Summary: 0.1 Name of The WorkDevdoot SahuОценок пока нет

- Missing Person ProjectДокумент9 страницMissing Person ProjectLaiba WaheedОценок пока нет

- Certification Roadmap 11-30-16Документ1 страницаCertification Roadmap 11-30-16Cristian Gavilanes MontoyaОценок пока нет

- Brittan Bradford ResumeДокумент2 страницыBrittan Bradford Resumeapi-574584381Оценок пока нет

- ECON 304 Course ContentДокумент2 страницыECON 304 Course ContentAanand JhaОценок пока нет

- 01 AirCircuitBreakers LV10 102021 EN 202111301146249676Документ136 страниц01 AirCircuitBreakers LV10 102021 EN 202111301146249676bkОценок пока нет

- Discussion 2: OOA: Case Study Robot in MazeДокумент17 страницDiscussion 2: OOA: Case Study Robot in MazeArmmetОценок пока нет

- G120D Getting Started 0418 en-USДокумент94 страницыG120D Getting Started 0418 en-USHamadi Ben SassiОценок пока нет

- Loading and Hauling Dump Truck: DumperДокумент2 страницыLoading and Hauling Dump Truck: DumperRJОценок пока нет

- The Roosh ProgramДокумент2 страницыThe Roosh ProgramVal KerryОценок пока нет

- Load Dwe Eigh Ing D Devi Ice: For R Elev Vators SДокумент28 страницLoad Dwe Eigh Ing D Devi Ice: For R Elev Vators SNaren AnandОценок пока нет

- UntitledДокумент41 страницаUntitledLinear Algebra & Multivariate CalculusОценок пока нет

- Nguyen Ngoc-Phu's ResumeДокумент2 страницыNguyen Ngoc-Phu's ResumeNgoc Phu NguyenОценок пока нет

- Seventh Pay Commission ArrearsДокумент11 страницSeventh Pay Commission Arrearssantosh bharathyОценок пока нет