Академический Документы

Профессиональный Документы

Культура Документы

Concrete Truck Plant Pre-Acceptance Checklist

Загружено:

Mohamed El NasharИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concrete Truck Plant Pre-Acceptance Checklist

Загружено:

Mohamed El NasharАвторское право:

Доступные форматы

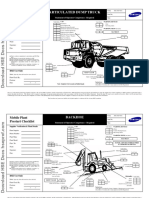

CONCRETE TRUCK PLANT PRE-ACCEPTANCE CHECKLIST

PLANT DETAILS

Plant Owner: Address: Ph:

Plant Make: Plant Model: Plant Serial No: Hours / KM’s:

Roads Reg No: Reg Expiry: Project Registration No: Project Asset No:

Last Service Date / Hrs: Next service Date / Hrs:

MINIMUM REQUIREMENTS (If the minimum requirements are not met, a plant sticker will not be issued and the item of plant is not to commence work)

Verif Check Requirement Verify Chec Requirement

y k

Operator and Maintenance Manual available Plant Hazard Assessment Sighted & Current (within 2 yrs):

Logbook / Service Records (checked ok): Plant Hazard Assessment Inspection Date: / /

Audible Alarm and other Warning Devices fitted, operable and Daily Prestart Inspection Checklist is available for use.

suitable for site conditions

Fire Extinguisher Fitted and charged

Revision No: 1 Document Number: JH-FRM-PAE-001-51 Page 1 of 3

When printed this document is an uncontrolled version and must be checked against the IMS electronic version for validity

Issue Date: 22/10/2014 Printed: 07/04/2014

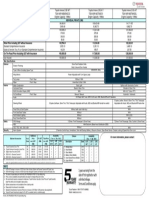

Verify Check Engine

Verif Engine mountings

Verify Check Cabin Check Environmental

y Engine guarding

Cleanliness Clean, free of organic materials (mud, dirt, weeds or Exhaust guarding

Handrails and ladders fitted and secure seeds) prior to arrival Oil leaks/check levels

Seat – adjustments operational secure Engine baffling or noise reduction equipment fitted as

Coolant leaks/check levels

Seat belt fitted and in good working order per manufacturers specifications

Smoke from internal combustion engines should not be Coolant system

UHF Radio Fitted (If not fitted, has a hand held

visible for more than ten seconds Vee belt condition

radio been supplied)

Air cleaner system

First Aid Kit, triangle and road reflectors available

Instructions: Verify Box to be ticked by Owner / Supplier / Operator prior to Battery condition / mounting

Warning devices and other lights (flashing, head, arrival onsite. Check Box to be ticked after visual inspection by the project

tail, etc) are appropriate for the environment in Verify Check Bowl

which plant is being used. (check environment No build-up of concrete

noise criteria particularly if working out of hours) around bowl

Instruments operational & labelled U bolts mounting bowl to truck

Levers / Controls Operational frame

Brakes system operational

Pedals in good condition

Discharge Shute and height

Air conditioning operational TYRES – Record Tread Depth (if required) adjuster working

Wipers / Washers operational Access ladder clean and

Rear View Mirrors POS 1 (LF) ____mm POS 2 (RF) ____mm undamaged to bowl

Windows not damaged Wash down water present and

POS 3 (LF2) ____mm POS 4 (RF2) ____mm

Verify Check Hydraulics System operational

Rams POS 5 (LR3) ____mm POS 6 (RR3) ____mm Bowl spins in both directions

Hoses / Connectors Hoses / connectors

POS 7 (LR4) ____mm POS 8 (RR4) ____mm Speed controls operational

Pins / Mounting

(check for excessive wear, leaks and creep) Check for excessive wear,

leaks and creep

Verify Check Running Gear

Bowl control from cabin

Tyres / Wheels undamaged

Bowl control from remote

Hand brake is operational

Brake operational

Body pivot mounts

Hoist mounting bolts

PLANT OWNER / OCCUPIER

PLANT VERIFIER

I certify that the described plant has met the inspection criteria stipulated within this checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

I certify that I have verified that the described plant has met the inspection criteria stipulated within this checklist and is being serviced and maintained in accordance with the manufacturer’s specifications

Name: Signature: Date:

Name: Signature: Date:

Вам также может понравиться

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Concrete Truck Plant Pre-Acceptance ChecklistДокумент2 страницыConcrete Truck Plant Pre-Acceptance ChecklistHerey VixionersОценок пока нет

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- Concrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistДокумент2 страницыConcrete-Boom-Pump-Truck-Plant-Pre-Acceptance ChecklistTFattahОценок пока нет

- Jumbo Drilling Rig Plant Pre Acceptance ChecklistДокумент3 страницыJumbo Drilling Rig Plant Pre Acceptance ChecklistRubén López LemaОценок пока нет

- Boom Placer ChecklistДокумент3 страницыBoom Placer ChecklistAlves Edattukaran100% (3)

- Concrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsДокумент2 страницыConcrete Boom Pump Truck Pre-Acceptance Checklist: Plant DetailsBassam HSEОценок пока нет

- JH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistДокумент3 страницыJH FRM Pae 001 06 Dozer Plant Pre Acceptance ChecklistYoung Lin SaengОценок пока нет

- JH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 15 Drum Roller Plant Pre Acceptance ChecklistStansilous Tatenda NyagomoОценок пока нет

- Drill Rig Plant Pre Acceptance ChecklistДокумент2 страницыDrill Rig Plant Pre Acceptance ChecklistRubén López Lema100% (1)

- JH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 11 Excavator Plant Pre Acceptance ChecklistAnwar DeenОценок пока нет

- JH FRM Pae 001 60 Piling Rig Plant Pre Acceptance ChecklistДокумент2 страницыJH FRM Pae 001 60 Piling Rig Plant Pre Acceptance ChecklistMuhammad Shahzad100% (1)

- Piling Rig Plant Pre-Acceptance ChecklisДокумент3 страницыPiling Rig Plant Pre-Acceptance Checklisosama F. MohamedОценок пока нет

- Inspection Hiap CraneДокумент2 страницыInspection Hiap CranePurwanroОценок пока нет

- Horizontal Directional Drill Rig Plant Pre-Acceptance ChecklistДокумент2 страницыHorizontal Directional Drill Rig Plant Pre-Acceptance ChecklistEdiPrawiraSimanjuntakОценок пока нет

- JAPL-F-HE-007-Concrete Pump ChecklistДокумент1 страницаJAPL-F-HE-007-Concrete Pump ChecklistAli HassanОценок пока нет

- Vacuum Truck Plant Pre-Acceptance ChecklistДокумент3 страницыVacuum Truck Plant Pre-Acceptance Checklistحماية منتجОценок пока нет

- JAPL-F-HE-007-Concrete Pump ChecklistДокумент1 страницаJAPL-F-HE-007-Concrete Pump ChecklistFarrukh IjazОценок пока нет

- Heavy Equipment ChecklistДокумент18 страницHeavy Equipment Checklistfullbar9Оценок пока нет

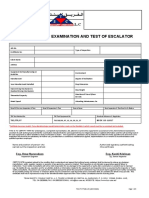

- ESCALATOR-Bk Gulf OnlyДокумент3 страницыESCALATOR-Bk Gulf OnlySHARAFUDHEEN TKОценок пока нет

- Subcon ItpДокумент6 страницSubcon ItpManu MohanОценок пока нет

- Earth Moving EquipmentsДокумент2 страницыEarth Moving EquipmentsSHARAFUDHEEN TKОценок пока нет

- Heavy Equipment Inspection Checklist TürkçeДокумент18 страницHeavy Equipment Inspection Checklist TürkçeErdal Margarito Karpuz100% (2)

- Fire Suppression System PDFДокумент2 страницыFire Suppression System PDFBurik8Оценок пока нет

- 010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDДокумент1 страница010 Pre-Job Safety Checklist (Rivision 2) - UPDATEDLijo John100% (1)

- RollerДокумент2 страницыRollerengr.haseebbalochОценок пока нет

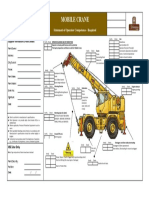

- 8 - Mobile Plant Checklist - Mobile CraneДокумент1 страница8 - Mobile Plant Checklist - Mobile Craneahmed draiОценок пока нет

- Section C, Exhibit 1 - Example Equipment Inspection ChecklistsДокумент5 страницSection C, Exhibit 1 - Example Equipment Inspection ChecklistsArturo Ramos AlvezoОценок пока нет

- Mobile Plant ChecklistДокумент2 страницыMobile Plant Checklistosama F. MohamedОценок пока нет

- (Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)Документ12 страниц(Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)pdrichОценок пока нет

- 01 INSP 0001 Articulated DTruck CheckДокумент1 страница01 INSP 0001 Articulated DTruck CheckBarock NaturelОценок пока нет

- Exhibit D3 Inspection and Test Plan (ITP)Документ12 страницExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarОценок пока нет

- Asc 20n 0649 c1 (Block Cutting Machine)Документ1 страницаAsc 20n 0649 c1 (Block Cutting Machine)AkhilОценок пока нет

- Layered Process Audit ChecklistДокумент1 страницаLayered Process Audit ChecklistMuniyappan TОценок пока нет

- 16 INSP 0016 One Engine Scraper CheckДокумент1 страница16 INSP 0016 One Engine Scraper CheckBarock NaturelОценок пока нет

- Cy009 Cyansmart User Manual RuДокумент94 страницыCy009 Cyansmart User Manual RuТемирлан ТоктогуловОценок пока нет

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedДокумент2 страницыEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaОценок пока нет

- Evidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be CollectedДокумент2 страницыEvidence Plan: Competency Standard: Unit of Competency: Ways in Which Evidence Will Be Collectedhussain DiamlaОценок пока нет

- Checklist For Purchasing Capital EquipmentДокумент1 страницаChecklist For Purchasing Capital EquipmentAbhishek SrivastavaОценок пока нет

- I. Nature of The Inspection: Manual Operated MillingДокумент17 страницI. Nature of The Inspection: Manual Operated MillingSasa MonicaОценок пока нет

- Mobile Plant Checklist - ForkliftДокумент1 страницаMobile Plant Checklist - Forkliftosama F. MohamedОценок пока нет

- Domestic Water Heat Exchangers Pre-Functional Checklist: Statement of ReadinessДокумент3 страницыDomestic Water Heat Exchangers Pre-Functional Checklist: Statement of Readinessnitroxx7Оценок пока нет

- PFMEA at Wave Soldering-21 Dec 2016Документ50 страницPFMEA at Wave Soldering-21 Dec 2016arum100% (1)

- Roller Plate Compactor Inspection ChecklistДокумент1 страницаRoller Plate Compactor Inspection Checklistarunjith rОценок пока нет

- StartupДокумент1 страницаStartupbundajoseph148Оценок пока нет

- FM-087 Plant Pre Acceptance Checklist - APS042 Skid SteerДокумент2 страницыFM-087 Plant Pre Acceptance Checklist - APS042 Skid SteerWenceslao JaimesОценок пока нет

- 3.roller Compactor ChecklistДокумент2 страницы3.roller Compactor ChecklistSuresh Praba PОценок пока нет

- Power Curve v82Документ11 страницPower Curve v82sanjeev kumarОценок пока нет

- Concrete PumpsДокумент2 страницыConcrete PumpsSHARAFUDHEEN TKОценок пока нет

- Loader: Mobile Plant Prestart ChecklistДокумент1 страницаLoader: Mobile Plant Prestart Checklistfdfddf dfsdfОценок пока нет

- Gear MotorДокумент13 страницGear Motorhaziq sulaimanОценок пока нет

- Bin Washer-OqДокумент11 страницBin Washer-OqValeria Carlo BorroОценок пока нет

- 03 INSP 0003 Compactor CheckДокумент1 страница03 INSP 0003 Compactor CheckBarock NaturelОценок пока нет

- Standard Commissioning Procedure For Building Exhaust Fans: General NotesДокумент9 страницStandard Commissioning Procedure For Building Exhaust Fans: General NotesAbdul Mohid SheikhОценок пока нет

- Checklists: Title: Checklist For Preventive Maintenance of EquipmentsДокумент1 страницаChecklists: Title: Checklist For Preventive Maintenance of Equipmentsjp mishraОценок пока нет

- Check Point For MixerДокумент1 страницаCheck Point For MixerDilnesa EjiguОценок пока нет

- Vi Precommissiong Final (Part B)Документ6 страницVi Precommissiong Final (Part B)Koushik Dey100% (1)

- EscalatorДокумент2 страницыEscalatorSHARAFUDHEEN TKОценок пока нет

- Fat ProcedureДокумент50 страницFat ProcedureDin AizuОценок пока нет

- Tooo': oOO OO.Документ28 страницTooo': oOO OO.ediasianagriОценок пока нет

- University of Evansville: Wm. C. Mitchell Software Racing by The Numbers Wingeo3 Suspension Geometry SoftwareДокумент8 страницUniversity of Evansville: Wm. C. Mitchell Software Racing by The Numbers Wingeo3 Suspension Geometry Softwarekadir_ÜnalОценок пока нет

- ECU Immo EpromsДокумент5 страницECU Immo EpromsclseguraОценок пока нет

- Notice: Grant of Petition For Decision of Inconsequential Noncompliance: General Motors CorporationДокумент2 страницыNotice: Grant of Petition For Decision of Inconsequential Noncompliance: General Motors CorporationJustia.comОценок пока нет

- 2011 Harley-Davidson Touring Models Parts Catalog PDFДокумент314 страниц2011 Harley-Davidson Touring Models Parts Catalog PDFAiddie Ghazlan0% (1)

- Articulated Trucks: Tam Thoi Gui Bo Ve Cac Thiet Bi Xay Dung. Mai Con Se Gui Bo Ve Thiet Bi Va .N TaiДокумент41 страницаArticulated Trucks: Tam Thoi Gui Bo Ve Cac Thiet Bi Xay Dung. Mai Con Se Gui Bo Ve Thiet Bi Va .N Taiasananth795055Оценок пока нет

- Starter Motors & AlternatorsДокумент21 страницаStarter Motors & AlternatorsDiego Alexander Ochoa Roa0% (1)

- Texas InsuranceДокумент1 страницаTexas InsuranceRambo50% (2)

- OMG Ergos 3 8-10 TA-3 Forklift Truck Specs PDFДокумент4 страницыOMG Ergos 3 8-10 TA-3 Forklift Truck Specs PDFBeyzaОценок пока нет

- Part Manual 345dl Vol2Документ851 страницаPart Manual 345dl Vol2Rizqi Huda100% (1)

- CSR2 World Fastest Times & TunesДокумент10 страницCSR2 World Fastest Times & TunesBryan Hawkes100% (1)

- MY18 S-Class Sedan Operator PDFДокумент562 страницыMY18 S-Class Sedan Operator PDFPrastyo TyoОценок пока нет

- Alphard 2011 - Full BookДокумент9 страницAlphard 2011 - Full BookDudy Adhi Prasetyo100% (1)

- Efficycle - Fabrication Plan FormatДокумент22 страницыEfficycle - Fabrication Plan FormatTyhghjОценок пока нет

- Cat Rescind ARBДокумент1 страницаCat Rescind ARBSean CrossОценок пока нет

- 2002 Volvo S60 Owners ManualДокумент37 страниц2002 Volvo S60 Owners ManualAbd El-Rhman M. El-RotelОценок пока нет

- Quote: Be Forward Co., LTDДокумент1 страницаQuote: Be Forward Co., LTDMilano JamesОценок пока нет

- FALCON 370 - 420 Wheel - GBДокумент4 страницыFALCON 370 - 420 Wheel - GBKaung Sett LynnОценок пока нет

- Front Final Drive: SectionДокумент38 страницFront Final Drive: SectionSilvio ServinОценок пока нет

- National NBT45 PDFДокумент20 страницNational NBT45 PDFesilvarОценок пока нет

- Technical Inspection SheetДокумент10 страницTechnical Inspection SheetDeepak AgrawalОценок пока нет

- SupercarДокумент3 страницыSupercarsigne.soderstrom1785Оценок пока нет

- Car and DriverДокумент138 страницCar and DriverNagendra Singh Ranawat100% (1)

- By Group 5-: Fizza Beg Aayushi Gupta Nida Tanveer Sameeya Mirza Anam Beg Reesha Masood Maria Sufia UshbaДокумент34 страницыBy Group 5-: Fizza Beg Aayushi Gupta Nida Tanveer Sameeya Mirza Anam Beg Reesha Masood Maria Sufia UshbaAbhilashОценок пока нет

- Innova PM Ipte - 3Документ1 страницаInnova PM Ipte - 3CalvinОценок пока нет

- 2012 FIAT 500 Abarth Owners ManualДокумент358 страниц2012 FIAT 500 Abarth Owners ManualFiat500USAОценок пока нет

- ASR (Anti Slip Regulation)Документ2 страницыASR (Anti Slip Regulation)Sudhakar Spartan100% (2)

- Volvo 850 Owners Manual 1996Документ265 страницVolvo 850 Owners Manual 1996Yu Wei LauОценок пока нет

- Grove GMK5275 PDFДокумент28 страницGrove GMK5275 PDFvpizarro_23100% (1)

- 2012 Chevrolet Sonic LT 1.8L Diagrama de MotorДокумент9 страниц2012 Chevrolet Sonic LT 1.8L Diagrama de MotorRubenОценок пока нет

- Vin FastДокумент4 страницыVin FastHạnh TrươngОценок пока нет

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsОт EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsРейтинг: 5 из 5 звезд5/5 (4)

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsОт EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsРейтинг: 4.5 из 5 звезд4.5/5 (17)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionОт EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionРейтинг: 5 из 5 звезд5/5 (2)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsОт EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsОценок пока нет

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Why We Drive: Toward a Philosophy of the Open RoadОт EverandWhy We Drive: Toward a Philosophy of the Open RoadРейтинг: 4.5 из 5 звезд4.5/5 (21)

- High-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionОт EverandHigh-Performance Cams & Valvetrains: Theory, Technology, and Selection: Theory, Technology, and SelectionОценок пока нет

- How to Drive: Real World Instruction and Advice from Hollywood's Top DriverОт EverandHow to Drive: Real World Instruction and Advice from Hollywood's Top DriverРейтинг: 4 из 5 звезд4/5 (17)

- Maintenance Excellence: Principles, Practices, and Future TrendsОт EverandMaintenance Excellence: Principles, Practices, and Future TrendsОценок пока нет

- Competition Engine Building: Advanced Engine Design and Assembly TechniquesОт EverandCompetition Engine Building: Advanced Engine Design and Assembly TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Trucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsОт EverandTrucking Business Startup: Build a Long-Term, Highly Profitable Trucking Company From Scratch in Just 30 Days Using Up-to-Date Expert Business Success SecretsРейтинг: 5 из 5 звезд5/5 (2)