Академический Документы

Профессиональный Документы

Культура Документы

I Beam Detailed Summary

Загружено:

Salvatore ShwИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

I Beam Detailed Summary

Загружено:

Salvatore ShwАвторское право:

Доступные форматы

Strap 2018.

00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 1

Prepared by: Date: 24/10/19

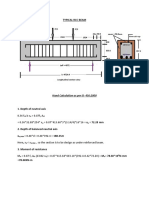

Detailed Results Table for Beam 1 - 7

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

Beam: 214 49 X3 (Major axis)

1, 2, 3,

4, 5, 6, 20.00

7 Fixed-3 Fixed-3 (Table 13,14)

CONSTRAINTS DESIGN DATA

- Sections : Check - Kx = 1.00 - Ky = 1.00

- Steel Grade: S275 - Allow. Slend. : 250 (compr.) 300 (tens.)

- Allowable Deflection : 1/200

- Tension Area Reduction Factor : 1.00

INTERMEDIATE SUPPORTS

L= 2.86 5.72 8.58 11.44 14.30 17.16

Lat.-Tors. + + + + + +

Compress. Y Y Y Y Y Y

Section: UB 457x191x98

Ix = 45730.0 Iy = 2347.00cm4 Sx = 2232 Sy = 379.0cm3 Area = 125.0

hw = 467.20 bf = 192.80mm tw = 11.40 tf = 19.60mm

J = 121.00 x = 25.70 u = 0.88

DESIGN COMBINATION = 2

M2 Moment Diagram

-1.00

1.27 1.27

Moments at Intermediate Supports:

0.17 0.31 0.00 -0.28 -0.46 -0.99

Max. AXIAL Force = 9.09 (tens.), -11.14 (compr.) Max. SHEAR Force = 0.80

M3 Moment Diagram

-1.72 -1.72

221.53

Moments at Intermediate Supports:

107.1 182.03 220.35 220.63 182.83 108.3

Max. AXIAL Force = 9.09 (tens.), -11.14 (compr.) Max. SHEAR Force = 40.41

SECTION CLASSIFICATION: *** PLASTIC ***

Limiting Ratios: Plastic Compact Semi-Compact

d/t= 35.75 < 80.8 100.5 121.4 (e = 1.019 R = 0.003 )

b/t= 4.92 < 9.2 10.2 15.3

** Design Strength (py ) = 265.0 **

Strap 2018.00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 2

Prepared by: Date: 24/10/19

Detailed Results Table for Beam 1 - 7

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

DESIGN EQUATION FACTORS VALUES RESULT

V2 Shear Fv/Pv < 1.00 Av = 53.26 Fv = 40.41

(4.2.3) Pv = 878.80 0.05

M3 Moment M S = 2232.00 M = 221.53

< 1.00 Z = 1957.62 Mc = 591.48 0.37

(4.2.5.2) Mc

Notes: LOW Shear Load Used for Moment Design

M2 Moment M S = 379.00 M = 1.27

< 1.00 Z = 243.46 Mc = 96.78 0.01

(4.2.5.2) Mc

Notes: LOW Shear Load Used for Moment Design

Deflection defl. defl =

< 1.00 0.08048 0.80

L / 200

Combined (Mx )z1 (My )z2 n = 0.00336 Mx = 221.53

Stresses ( ) + ( ) My = 1.27

(Local) (Mrx) (Mry) Mrx = 591.47 0.15

(4.8.2.3) Mry = 96.78

(4.8.3) < 1.00 z1 = 2.00

z2 = 1.00

Axial F (kL/r)x =31 F = 11.14

Force < 1.00 (kL/r)y =66 Ag = 125.00

(4.7.4) Agpc pc = 203.49 0.00

Slender. reduct. x = 0.30 y = 1.00

Note: Strut Selection from table 23(b)

Lateral Sx = 2232.00 M = 221.53

Torsional M*mLT pb = 221.59 Ma = M*mLT

Buckling < 1.00 Le = 2.86 Ma = 221.44

(4.3.6) Mb mL = 1.00 Mb = 494.59 0.45

beam NOT LOADED = 1.00

- = 54.00

(B.2) ( u= 0.88 v = 0.93 Le/ry = 66.1 )

Critical Segment from 8.58 to 11.44 on +z flange

Segment End Moments: 220.35 and 220.63

Overall F mxMx myMy Mx = 221.53 Mb = 494.59

Buckling - + + My = 0.28 pyZy= 64.52 0.45

Simplified Agpcy Mb pyZy mx = 1.00 my = 0.21

(4.8.3.3.1) < 1.00

Overall Fc Mx My Pcx = 3213.49

Buckling + + < 1 Pcy = 2543.66 Mx = 221.53

Check - Pc Max May mx = 1.00 Max = 494.80 0.45

Exact my = 0.21 My = 0.28

(4.8.3.3.2) Mb Mcy May = 451.58

lateral tor. Max= Pc=Pcy May= mlt = 1.00

buckling mlt my(1+F/Pcy)

Note: EXACT approach governs

Strap 2018.00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 3

Prepared by: Date: 24/10/19

Detailed Results Table for Beam 8 - 14

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

Beam: 215 50 X3 (Major axis)

8, 9, 10,

11, 12, 13, 20.00

14 Fixed-3 Fixed-3 (Table 13,14)

CONSTRAINTS DESIGN DATA

- Sections : Check - Kx = 1.00 - Ky = 1.00

- Steel Grade: S275 - Allow. Slend. : 250 (compr.) 300 (tens.)

- Allowable Deflection : 1/200

- Tension Area Reduction Factor : 1.00

INTERMEDIATE SUPPORTS

L= 2.86 5.72 8.58 11.44 14.30 17.16

Lat.-Tors. + + + + + +

Compress. Y Y Y Y Y Y

Section: UB 457x191x98

Ix = 45730.0 Iy = 2347.00cm4 Sx = 2232 Sy = 379.0cm3 Area = 125.0

hw = 467.20 bf = 192.80mm tw = 11.40 tf = 19.60mm

J = 121.00 x = 25.70 u = 0.88

DESIGN COMBINATION = 2

M2 Moment Diagram

-0.06 -0.06

0.15

Moments at Intermediate Supports:

0.08 0.01 0.04 0.05 0.05 0.14

Max. AXIAL Force = 14.58 (tens.), -17.27 (compr.) Max. SHEAR Force = 0.07

M3 Moment Diagram

-6.15 -6.15

218.00

Moments at Intermediate Supports:

109.4 181.60 216.69 217.88 184.94 114.25

Max. AXIAL Force = 14.58 (tens.), -17.27 (compr.) Max. SHEAR Force = 44.07

SECTION CLASSIFICATION: *** PLASTIC ***

Limiting Ratios: Plastic Compact Semi-Compact

d/t= 35.75 < 80.4 99.8 121.0 (e = 1.019 R = 0.005 )

b/t= 4.92 < 9.2 10.2 15.3

** Design Strength (py ) = 265.0 **

Strap 2018.00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 4

Prepared by: Date: 24/10/19

Detailed Results Table for Beam 8 - 14

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

DESIGN EQUATION FACTORS VALUES RESULT

V2 Shear Fv/Pv < 1.00 Av = 53.26 Fv = 44.07

(4.2.3) Pv = 878.80 0.05

M3 Moment M S = 2232.00 M = 218.00

< 1.00 Z = 1957.62 Mc = 591.48 0.37

(4.2.5.2) Mc

Notes: LOW Shear Load Used for Moment Design

Deflection defl. defl =

< 1.00 0.08010 0.80

L / 200

Combined (Mx )z1 (My )z2 n = 0.00521 Mx = 218.00

Stresses ( ) + ( ) My = 0.15

(Local) (Mrx) (Mry) Mrx = 591.46 0.14

(4.8.2.3) Mry = 96.78

(4.8.3) < 1.00 z1 = 2.00

z2 = 1.00

Axial F (kL/r)x =32 F = 17.27

Force < 1.00 (kL/r)y =66 Ag = 125.00

(4.7.4) Agpc pc = 203.49 0.01

Slender. reduct. x = 0.31 y = 1.00

Note: Strut Selection from table 23(b)

Lateral Sx = 2232.00 M = 218.00

Torsional M*mLT pb = 221.59 Ma = M*mLT

Buckling < 1.00 Le = 2.86 Ma = 217.81

(4.3.6) Mb mL = 1.00 Mb = 494.59 0.44

beam is LOADED

- = 54.00

(B.2) ( u= 0.88 v = 0.93 Le/ry = 66.1 )

Critical Segment from 8.58 to 11.44 on +z flange

Segment End Moments: 216.69 and 217.88

Overall F mxMx myMy Mx = 218.00 Mb = 494.59

Buckling - + + My = 0.05 pyZy= 64.52 0.45

Simplified Agpcy Mb pyZy mx = 1.00 my = 0.80

(4.8.3.3.1) < 1.00

Overall Fc Mx My Pcx = 3205.50

Buckling + + < 1 Pcy = 2543.66 Mx = 218.00

Check - Pc Max May mx = 1.00 Max = 495.02 0.45

Exact my = 0.80 My = 0.05

(4.8.3.3.2) Mb Mcy May = 119.98

lateral tor. Max= Pc=Pcy May= mlt = 1.00

buckling mlt my(1+F/Pcy)

Note: EXACT approach governs

Strap 2018.00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 5

Prepared by: Date: 24/10/19

Detailed Results Table for Beam 21

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

Beam: 216 51 X3 (Major axis)

15, 16, 17,

18, 19, 20, 20.00

21 Fixed-3 Fixed-3 (Table 13,14)

CONSTRAINTS DESIGN DATA

- Sections : Check - Kx = 1.00 - Ky = 1.00

- Steel Grade: S275 - Allow. Slend. : 250 (compr.) 300 (tens.)

- Allowable Deflection : 1/200

- Tension Area Reduction Factor : 1.00

INTERMEDIATE SUPPORTS

L= 2.86 5.72 8.58 11.44 14.30 17.16

Lat.-Tors. + + + + + +

Compress. Y Y Y Y Y Y

Section: UB 457x191x98

Ix = 45730.0 Iy = 2347.00cm4 Sx = 2232 Sy = 379.0cm3 Area = 125.0

hw = 467.20 bf = 192.80mm tw = 11.40 tf = 19.60mm

J = 121.00 x = 25.70 u = 0.88

DESIGN COMBINATION = 2

M2 Moment Diagram

-1.20 -1.20

0.87

Moments at Intermediate Supports:

-0.22 -0.27 0.02 0.28 0.45 0.86

Max. AXIAL Force = 17.31 (tens.), -20.35 (compr.) Max. SHEAR Force = 0.72

M3 Moment Diagram

-12.73 -12.73

195.69

Moments at Intermediate Supports:

87.53 156.48 192.81 195.55 164.20 98.66

Max. AXIAL Force = 17.31 (tens.), -20.35 (compr.) Max. SHEAR Force = 40.89

SECTION CLASSIFICATION: *** PLASTIC ***

Limiting Ratios: Plastic Compact Semi-Compact

d/t= 35.75 < 80.2 99.4 120.8 (e = 1.019 R = 0.006 )

b/t= 4.92 < 9.2 10.2 15.3

** Design Strength (py ) = 265.0 **

Strap 2018.00

*** For demonstration purposes only ***

UTEM Truss E Code: BS5950

Detail Summary Page: 6

Prepared by: Date: 24/10/19

Detailed Results Table for Beam 21

Moments: kN*meter , Forces: kN , Stresses: mPa , Section prop.: cm.

DESIGN EQUATION FACTORS VALUES RESULT

V2 Shear Fv/Pv < 1.00 Av = 53.26 Fv = 40.89

(4.2.3) Pv = 878.80 0.05

M3 Moment M S = 2232.00 M = 195.69

< 1.00 Z = 1957.62 Mc = 591.48 0.33

(4.2.5.2) Mc

Notes: LOW Shear Load Used for Moment Design

M2 Moment M S = 379.00 M = 1.20

< 1.00 Z = 243.46 Mc = 96.78 0.01

(4.2.5.2) Mc

Notes: LOW Shear Load Used for Moment Design

Deflection defl. defl =

< 1.00 0.07046 0.70

L / 200

Combined (Mx )z1 (My )z2 n = 0.00614 Mx = 195.69

Stresses ( ) + ( ) My = 1.20

(Local) (Mrx) (Mry) Mrx = 591.45 0.12

(4.8.2.3) Mry = 96.78

(4.8.3) < 1.00 z1 = 2.00

z2 = 1.00

Axial F (kL/r)x =32 F = 20.35

Force < 1.00 (kL/r)y =66 Ag = 125.00

(4.7.4) Agpc pc = 203.49 0.01

Slender. reduct. x = 0.31 y = 1.00

Note: Strut Selection from table 23(b)

Lateral Sx = 2232.00 M = 195.69

Torsional M*mLT pb = 221.59 Ma = M*mLT

Buckling < 1.00 Le = 2.86 Ma = 194.24

(4.3.6) Mb mL = 0.99 Mb = 494.59 0.39

beam is LOADED

- = 54.00

(B.2) ( u= 0.88 v = 0.93 Le/ry = 66.1 )

Critical Segment from 8.58 to 11.44 on +z flange

Segment End Moments: 192.81 and 195.55

Overall F mxMx myMy Mx = 195.69 Mb = 494.59

Buckling - + + My = 0.28 pyZy= 64.52 0.40

Simplified Agpcy Mb pyZy mx = 0.99 my = 0.27

(4.8.3.3.1) < 1.00

Overall Fc Mx My Pcx = 3205.50

Buckling + + < 1 Pcy = 2543.66 Mx = 195.69

Check - Pc Max May mx = 0.99 Max = 498.27 0.40

Exact my = 0.27 My = 0.28

(4.8.3.3.2) Mb Mcy May = 357.05

lateral tor. Max= Pc=Pcy May= mlt = 0.99

buckling mlt my(1+F/Pcy)

Note: EXACT approach governs

Вам также может понравиться

- d7 PDFДокумент14 страницd7 PDFfarhadmrt6923Оценок пока нет

- APPENDIXДокумент100 страницAPPENDIXalyssa babylaiОценок пока нет

- Force Resultant On Beam: Shear (KN) Moment (KN-M) Shear (KN) Moment (KN-M) Shear (KN) Moment (KN-M)Документ15 страницForce Resultant On Beam: Shear (KN) Moment (KN-M) Shear (KN) Moment (KN-M) Shear (KN) Moment (KN-M)aayushi doshiОценок пока нет

- Typical RCC Beam: Hand Calculation As Per IS-456:2000Документ3 страницыTypical RCC Beam: Hand Calculation As Per IS-456:2000sanjusamsonОценок пока нет

- Documentgdftgdcbn GDF UygДокумент4 страницыDocumentgdftgdcbn GDF Uygradhouen msalmiОценок пока нет

- Structural Designs (Ultimate) : Force Lever Arm Moment V Ult M UltДокумент1 страницаStructural Designs (Ultimate) : Force Lever Arm Moment V Ult M Ultmbhanusagar.keynesОценок пока нет

- Mat Foundation Design PDFДокумент3 страницыMat Foundation Design PDFCivil Construction And TutorОценок пока нет

- Diseño de VigaДокумент8 страницDiseño de VigaHernan Ramiro Suyo LarutaОценок пока нет

- 1.5DL+1.5LL - 1500mm TRIB - CONTI. SUPPORTED - NAUS 01 PDFДокумент11 страниц1.5DL+1.5LL - 1500mm TRIB - CONTI. SUPPORTED - NAUS 01 PDFDinesh PatilОценок пока нет

- RC Foundation Design ACI318 V2018Документ6 страницRC Foundation Design ACI318 V2018lakshmi1011100% (1)

- Wall: Wall No.13 (3.3) M - Panel No. 348: 1.1. ReinforcementДокумент4 страницыWall: Wall No.13 (3.3) M - Panel No. 348: 1.1. ReinforcementAli Al-BashaОценок пока нет

- Column NoteДокумент3 страницыColumn Notehassan amiriОценок пока нет

- Roof Truss (WarenДокумент29 страницRoof Truss (WarenJELLA TECHNOLOGIESОценок пока нет

- 1 Level:: 2.1 Material PropertiesДокумент4 страницы1 Level:: 2.1 Material PropertiesLýThườngKiệtОценок пока нет

- Guardhouse Coldes NewДокумент1 страницаGuardhouse Coldes NewMwesigwa AllanОценок пока нет

- Appendix B 1 Spread Footing Verification: Pad Footing: Axis A To C (Except Axis 5/C and 8/C) (Section 1.1)Документ7 страницAppendix B 1 Spread Footing Verification: Pad Footing: Axis A To C (Except Axis 5/C and 8/C) (Section 1.1)Civil Mex100% (1)

- Specific Verification Chapter 5Документ14 страницSpecific Verification Chapter 5Shatrughna BargeОценок пока нет

- Column Design SheetДокумент3 страницыColumn Design Sheetaimkcl90Оценок пока нет

- 1 Level:: 2.1 Material PropertiesДокумент4 страницы1 Level:: 2.1 Material PropertiesAli Al-BashaОценок пока нет

- Chequered-Plate CALCULATIONДокумент19 страницChequered-Plate CALCULATIONRamuAlagappan100% (2)

- Isolated Footing DesignДокумент10 страницIsolated Footing DesignSemahegn Gebiru100% (1)

- Chequered Plate PlatformДокумент3 страницыChequered Plate PlatformFilip RisteskiОценок пока нет

- Izračun Konzole FermentoraДокумент17 страницIzračun Konzole FermentoradinoОценок пока нет

- Analysis and Design of RC Beams (Version 5)Документ3 страницыAnalysis and Design of RC Beams (Version 5)Reuben James BangaoilОценок пока нет

- Reference: AISC Anchor Chair /pressure Vessel Handbook by Moss and BasicДокумент3 страницыReference: AISC Anchor Chair /pressure Vessel Handbook by Moss and Basicswarnamalini0% (1)

- Combined FootingДокумент15 страницCombined FootingAnish NeupaneОценок пока нет

- Project Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Документ2 страницыProject Designed By: Date: Client CPG Trang 9/11/2017 Code BS8110:1997 Checked By: Revision: JOB BKT 1Sơn Nguyễn-LêОценок пока нет

- ET Lab ReadingsДокумент5 страницET Lab ReadingsANANDKUMAR SОценок пока нет

- Repot From RobotДокумент5 страницRepot From RobotGEMPFОценок пока нет

- 1 Spread Footing: Foundation1 Number: 1: 1.1 Basic DataДокумент5 страниц1 Spread Footing: Foundation1 Number: 1: 1.1 Basic DataGEMPFОценок пока нет

- Base Plate DesignMS601a Good MahfuzДокумент4 страницыBase Plate DesignMS601a Good MahfuzDavid PuenОценок пока нет

- Tepo Sole Co., LTD: 1. General InformationДокумент3 страницыTepo Sole Co., LTD: 1. General InformationAlpha ScimathОценок пока нет

- Footing Design For Footing Type F: S (Kpa)Документ15 страницFooting Design For Footing Type F: S (Kpa)natnaelОценок пока нет

- Cold Vent Stack Foundation DesignДокумент13 страницCold Vent Stack Foundation Designdoverman0% (1)

- Gantry Girder DesignДокумент20 страницGantry Girder DesignMohammed Saleem Syed Khader100% (2)

- Base Plate Design MS601a - BS - CodeДокумент4 страницыBase Plate Design MS601a - BS - CodeRAMSОценок пока нет

- Combined FDN ColumnДокумент21 страницаCombined FDN ColumnGautam SharmaОценок пока нет

- Ref. Calculations Output: The Capacity of The Slab Basic MeshДокумент3 страницыRef. Calculations Output: The Capacity of The Slab Basic MeshOmar MokhtarОценок пока нет

- Base Plate Design MS601a - BS - CodeДокумент4 страницыBase Plate Design MS601a - BS - CodeCivil StructureОценок пока нет

- Design of Slabs: Input DataДокумент6 страницDesign of Slabs: Input Datagewegw3gОценок пока нет

- BS TableДокумент17 страницBS TableAwais HameedОценок пока нет

- 3a SBCДокумент2 страницы3a SBCvine videosОценок пока нет

- UntitledДокумент3 страницыUntitledPhal KhemraОценок пока нет

- RampДокумент5 страницRampephremОценок пока нет

- Eurobeam From Greentram Software: Typical Calculations Produced by The Pre-Release VersionДокумент2 страницыEurobeam From Greentram Software: Typical Calculations Produced by The Pre-Release VersionPrabhumk07Оценок пока нет

- Strut Analysis and Design at - 10.00Документ4 страницыStrut Analysis and Design at - 10.00SGOCTОценок пока нет

- STEELW Results CombinatioДокумент2 страницыSTEELW Results CombinatioD.V.Srinivasa RaoОценок пока нет

- ColumnДокумент4 страницыColumnShokry AlkissyОценок пока нет

- Column F1 From Roof Floor To Second Floor: Compression 25.45kN 1/E-F 1/F-HДокумент7 страницColumn F1 From Roof Floor To Second Floor: Compression 25.45kN 1/E-F 1/F-HJong_Tien_Iou_7605Оценок пока нет

- Example 2 Simply Supported Beam - Flanged Section PDFДокумент7 страницExample 2 Simply Supported Beam - Flanged Section PDFWee Ren100% (1)

- Beam (1 To 5) KhiteshДокумент7 страницBeam (1 To 5) KhiteshdamanОценок пока нет

- Sloped FootingДокумент19 страницSloped FootingBala ChandarОценок пока нет

- Column ResultsДокумент3 страницыColumn ResultsJayОценок пока нет

- Design of Elevated TanksДокумент24 страницыDesign of Elevated TanksEng.Hesham AL-HelaleeОценок пока нет

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationОт EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationОценок пока нет

- PURLINДокумент5 страницPURLINSalvatore ShwОценок пока нет

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDДокумент1 страницаUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwОценок пока нет

- AssemblyДокумент4 страницыAssemblySalvatore ShwОценок пока нет

- Factory - Checkered Plate For StaircaseДокумент1 страницаFactory - Checkered Plate For StaircaseSalvatore ShwОценок пока нет

- Untuk Tetuan China Tangxing Equipment (M) SDN BHDДокумент1 страницаUntuk Tetuan China Tangxing Equipment (M) SDN BHDSalvatore ShwОценок пока нет

- Material RateДокумент1 страницаMaterial RateSalvatore ShwОценок пока нет

- Staff Quarters - StaircaseДокумент3 страницыStaff Quarters - StaircaseSalvatore ShwОценок пока нет

- Top & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKДокумент1 страницаTop & Bot Chord - Shs 50X50X4Mm THK Internal Chord - Shs 38X38X3Mm THKSalvatore ShwОценок пока нет

- Z7 - Purlin 200X75X1.6Документ1 страницаZ7 - Purlin 200X75X1.6Salvatore ShwОценок пока нет

- Strap: Structural Analysis ProgramsДокумент2 страницыStrap: Structural Analysis ProgramsSalvatore ShwОценок пока нет

- 2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Документ1 страница2 Nos 12Mm THK M.S Plate 2 Nos M16 Bolts Grade 8.8Salvatore ShwОценок пока нет

- C Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XДокумент1 страницаC Purlin Design Calculation With Single Sag Rods: y 2 3 3 3 3 3 6 4 Y-Y X-XSalvatore ShwОценок пока нет

- My Travel PassДокумент3 страницыMy Travel PassSalvatore ShwОценок пока нет

- FlowДокумент105 страницFlowretheepОценок пока нет

- Sdfghjklzxcvbnmqwertyuiopasdf: Digital Simulation LabДокумент57 страницSdfghjklzxcvbnmqwertyuiopasdf: Digital Simulation LabRahul ChowdariОценок пока нет

- Chapter 4 - Axial LoadingДокумент33 страницыChapter 4 - Axial LoadingMaipenrai Memee100% (1)

- OhanianДокумент118 страницOhanianCristopher MorianoОценок пока нет

- October 2015 Paper 1 AnswersДокумент20 страницOctober 2015 Paper 1 AnswersJaco RademeyerОценок пока нет

- Jun 2004 Flow SphereДокумент41 страницаJun 2004 Flow SpherehquynhОценок пока нет

- Atomic PhysicsДокумент24 страницыAtomic PhysicsReddyvari VenugopalОценок пока нет

- SimXpert R3.2 Motion Workspace GuideДокумент262 страницыSimXpert R3.2 Motion Workspace GuidepaulkastleОценок пока нет

- 9.3 Motors and Generators NotesДокумент18 страниц9.3 Motors and Generators NotesAmeena TohmeyОценок пока нет

- Solution of MHD Effect On Transient Free Convection Flow Past A Vertical Plate With Variable Temperature and Chemical Reaction of First Order.Документ6 страницSolution of MHD Effect On Transient Free Convection Flow Past A Vertical Plate With Variable Temperature and Chemical Reaction of First Order.IOSRjournalОценок пока нет

- 2014 Bo Zhou PHD Thesis ImportantДокумент227 страниц2014 Bo Zhou PHD Thesis ImportantMasihullah EbadiОценок пока нет

- Box Girder Bridge DecksДокумент53 страницыBox Girder Bridge DecksManvendra NigamОценок пока нет

- Physics As Book AnswersДокумент18 страницPhysics As Book AnswersSadat Sadman Saad100% (4)

- LAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Документ9 страницLAB 3 ENERGY LOSS IN PIPE AND FITTINGS - 23sept2016Ahmad Raz AkmalОценок пока нет

- 2 Dp2 Prestress Losses FullДокумент12 страниц2 Dp2 Prestress Losses FullChandeshwor ShahОценок пока нет

- Exp 7 Abst, Intro, and AtqДокумент6 страницExp 7 Abst, Intro, and AtqChali HaineОценок пока нет

- 247251661class Xi Physics PDFДокумент297 страниц247251661class Xi Physics PDFShikhar YadavОценок пока нет

- 1 s2.0 S0301562917302077 MainДокумент9 страниц1 s2.0 S0301562917302077 MainFabian Torres RoblesОценок пока нет

- Phase RuleДокумент3 страницыPhase Rulekalyanivishal777Оценок пока нет

- PROBLEM 4.156: SolutionДокумент11 страницPROBLEM 4.156: SolutionYennifer OrtegozaОценок пока нет

- SPIRE 206-Railway Tower-FOS2.0-5.4SQM - Trunkate To 15mДокумент147 страницSPIRE 206-Railway Tower-FOS2.0-5.4SQM - Trunkate To 15mmithunОценок пока нет

- Simple Harmonic Motion Multiple Choice-2013!07!11Документ5 страницSimple Harmonic Motion Multiple Choice-2013!07!11Vishal NanwaniОценок пока нет

- Vibration Analysis Report OnДокумент7 страницVibration Analysis Report OnCesar SampaioОценок пока нет

- Scheme of Examination: B. TECH. (3 Semester) Mechanical EngineeringДокумент144 страницыScheme of Examination: B. TECH. (3 Semester) Mechanical EngineeringNikhil Aggarwal0% (1)

- 3c-Torque MC Practice Problems-ANSWERSДокумент4 страницы3c-Torque MC Practice Problems-ANSWERSruuki25Оценок пока нет

- Principal StressДокумент20 страницPrincipal StressAnup KashyapОценок пока нет

- DR Rajbal SinghДокумент18 страницDR Rajbal Singhsayed sahilОценок пока нет

- Physical Pharmacy Principles ReviewerДокумент7 страницPhysical Pharmacy Principles ReviewerAntonio CharismaОценок пока нет

- Aerodynamic BasicsДокумент124 страницыAerodynamic BasicsChanaka DilshanОценок пока нет