Академический Документы

Профессиональный Документы

Культура Документы

Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically Referenced

Загружено:

Vinit ChoudharyИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Model 3:1 Pilot Ratio, Vented Counterbalance Valve - Atmospherically Referenced

Загружено:

Vinit ChoudharyАвторское право:

Доступные форматы

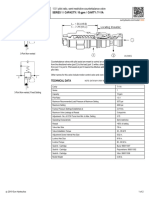

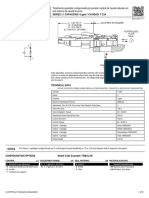

MODEL 3:1 pilot ratio, vented counterbalance valve - atmospherically referenced

CAEA SERIES 2 / CAPACITY: 30 gpm / CAVITY: T-2A

snhy.com/CAEA

3-Port Atmospherically Referenced

Atmospherically vented counterbalance valves with pilot assist are meant to control an overrunning load. The check

valve allows free flow from the directional valve (port 2) to the load (port 1) while a direct-acting, pilot-assisted relief

valve controls flow from port 1 to port 2. Pilot assist at port 3 lowers the effective setting of the relief valve at a rate

determined by the pilot ratio. Backpressure at port 2 does not affect the valve setting because the spring chamber

is atmospherically referenced.

Other names for this valve include motion control valve and over-center valve.

3-Port Atmospherically Referenced, Non-adjustable

TECHNICAL DATA NOTE: DATA MAY VARY BY CONFIGURATION. SEE CONFIGURATION SECTION.

Cavity T-2A

Series 2

Capacity 30 gpm

Pilot Ratio 3:1

Maximum Recommended Load Pressure at Maximum Setting 3075 psi

Maximum Setting 4000 psi

Factory Pressure Settings Established at 2 in³/min.

Maximum Valve Leakage at Reseat 5 drops/min.

Check Cracking Pressure 25 psi

Adjustment - No. of CCW Turns from Min. to Max. Setting 5

Operating Characteristic Standard

Reseat >85% of setting

Valve Hex Size 1 1/8 in.

Valve Installation Torque 45 - 50 lbf ft

Adjustment Screw Internal Hex Size 5/32 in.

Locknut Hex Size 9/16 in.

Locknut Torque 80 - 90 lbf in.

Seal kit - Cartridge Buna: 990302007

Seal kit - Cartridge Viton: 990302006

Model Weight 0.83 lb.

c 2019 Sun Hydraulics

1 of 2

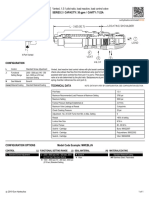

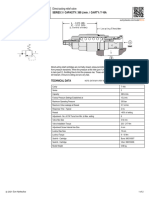

CONFIGURATION OPTIONS Model Code Example: CAEALHN

CONTROL (L) FUNCTIONAL SETTING RANGE (H) SEAL MATERIAL (N) MATERIAL/COATING

L Standard Screw Adjustment H 1000 - 4000 psi (70 - 280 bar), 3000 psi N Buna-N Standard Material/Coating

C Tamper Resistant - Factory Set (210 bar) Standard Setting V Viton /AP Stainless Steel, Passivated

I 400 - 1500 psi (28 - 105 bar), 1000 psi /LH Mild Steel, Zinc-Nickel

(70 bar) Standard Setting

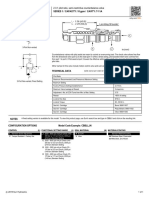

TECHNICAL FEATURES

Counterbalance valves should be set at least 1.3 times the maximum load induced pressure.

Turn adjustment clockwise to decrease setting and release load.

Full clockwise setting is 200 psi (14 bar).

Approximately 1 drop (0,07 cc) of fluid will pass from the pilot area to the vented spring chamber every 4000 cycles.

Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages.

Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit.

This valve has positive seals between all ports.

With vented valves, a lower pilot ratio may be required to achieve machine stability compared to non-vented valves.

Three-port vented valves are atmospherically referenced and considered problem solvers for existing circuits using non-vented valves. Over time, the vented valves

may leak externally or allow moisture into the spring chamber. Four-port vented counterbalance valves are recommended for new applications.

All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size).

Corrosion resistant cartridge valves are intended for use in corrosive environments and are identified by the model code suffix /AP for external stainless steel

components, or /LH for external zinc-nickel plated components. See the CONFIGURATION section for all options. For further details, please see the Materials of

Construction page located under TECH RESOURCES.

Incorporates the Sun floating style construction to minimize the possibility of internal parts binding due to excessive installation torque and/or cavity/cartridge

machining variations.

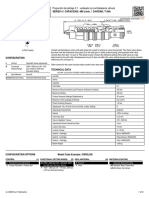

PERFORMANCE CURVES

c 2019 Sun Hydraulics

2 of 2

Вам также может понравиться

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanОценок пока нет

- Model 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 4.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveAnurag JainОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveJavier AriasОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveLennyn Mamani VenturaОценок пока нет

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveДокумент2 страницыModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance Valveதமிழன் இராமசாமிОценок пока нет

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveДокумент2 страницыModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanОценок пока нет

- CBEALBN Full en Us LetterДокумент2 страницыCBEALBN Full en Us Letterangelo.araza0913Оценок пока нет

- CBCY Full en Us LetterДокумент2 страницыCBCY Full en Us LetterVentas Control HidráulicoОценок пока нет

- Model 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 2.3:1 Pilot Ratio, Standard Capacity Counterbalance ValveErasmo LimaОценок пока нет

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValvemateusT850Оценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveAlaa saidОценок пока нет

- CACLLGN en Us A4Документ1 страницаCACLLGN en Us A42fqdw8s8yxОценок пока нет

- Model 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveДокумент2 страницыModel 1.5:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveVignesh PandiyanОценок пока нет

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanОценок пока нет

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanОценок пока нет

- Model 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент2 страницыModel 1.5:1 Pilot Ratio, Standard Capacity Counterbalance ValveVignesh PandiyanОценок пока нет

- CBGH Full en Us LetterДокумент2 страницыCBGH Full en Us LetterPrakash VasudevanОценок пока нет

- Model Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveДокумент2 страницыModel Anti-Shock, Pilot-Operated, Balanced Poppet Relief ValveJustinОценок пока нет

- CBEALAN Full Es Metric LetterДокумент2 страницыCBEALAN Full Es Metric Letternicole tapiaОценок пока нет

- Sun Hydraulics MWEB-LJN Technical SpecificationsДокумент1 страницаSun Hydraulics MWEB-LJN Technical SpecificationsJustinОценок пока нет

- Model 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AДокумент2 страницыModel 3:1 Pilot Ratio, Vented Counterbalance Valve: SERIES 4 / CAPACITY: 480 L/min. / CAVITY: T-24AАндрей9Оценок пока нет

- Sun Hydraulics CWEL Technical SpecificationsДокумент1 страницаSun Hydraulics CWEL Technical SpecificationsJustinОценок пока нет

- Model Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveДокумент1 страницаModel Vented, 3:1 Pilot Ratio, Load Reactive, Load Control ValveRonildo - HydraparОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveДокумент1 страницаModel 3:1 Pilot Ratio, Standard Capacity, Loadadaptive™ Counterbalance ValveAlexis PeñaОценок пока нет

- Model 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityДокумент2 страницыModel 50%, Accumulator Sense, Pump Unload Valve - Pilot CapacityleosignareОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент1 страницаModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveMuhtadin RizkiОценок пока нет

- Modelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaДокумент1 страницаModelo Proporción de Pilotaje 2:1, Restrictiva Contrabalance VálvulaErasmo LimaОценок пока нет

- CBEWLJN Full en Metric A4Документ2 страницыCBEWLJN Full en Metric A4Ηρακλης ΤσαπραζηςОценок пока нет

- RPGC Full en Us A4Документ2 страницыRPGC Full en Us A4zapchasty29Оценок пока нет

- 5 - Counter Balance Valve TSCA 70-10 - CBCHДокумент4 страницы5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevОценок пока нет

- CCCALBN Full en Us LetterДокумент2 страницыCCCALBN Full en Us Letterisaiahsamsonm_948069Оценок пока нет

- Direct-Acting Relief Valve: DownloadДокумент2 страницыDirect-Acting Relief Valve: Downloadaristi51Оценок пока нет

- CBCA Es Metric A4Документ1 страницаCBCA Es Metric A4martin.riosОценок пока нет

- CBCALHN-EAC Full en Us LetterДокумент5 страницCBCALHN-EAC Full en Us LetterVentas Control HidráulicoОценок пока нет

- Pump Unload Pilot Valve SUN QPABДокумент2 страницыPump Unload Pilot Valve SUN QPABankesh_ghoghariОценок пока нет

- Model Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenДокумент2 страницыModel Normally Closed, Balanced Poppet, Logic Element - Pilot-To-OpenjuampacervantesОценок пока нет

- Contrabalance SunHydraulicДокумент2 страницыContrabalance SunHydraulicMatias Oñate ArriagadaОценок пока нет

- Model 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveДокумент1 страницаModel 2.3:1 Pilot Ratio, Semi-Restrictive Counterbalance ValveCorradoОценок пока нет

- Sun Hydraulics-Cbca Lan EccДокумент5 страницSun Hydraulics-Cbca Lan EcchendntdОценок пока нет

- Modelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaДокумент2 страницыModelo Proporción de Pilotaje 5:1, Venteado (A) Contrabalance VálvulaManuel Patricio Gonzalez SanhuezaОценок пока нет

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент1 страницаModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparОценок пока нет

- Model Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AДокумент2 страницыModel Direct-Acting Relief Valve: Series 2 / Capacity: 50 GPM / Cavity: T-3AJustinОценок пока нет

- Modelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoДокумент2 страницыModelo Totalmente Ajustable Compensado Por Presión Control de Caudal Válvula Con Anti-Retorno de Caudal InversoErasmo LimaОценок пока нет

- Sun Hydraulics FDBA-LANДокумент2 страницыSun Hydraulics FDBA-LANJustinОценок пока нет

- FREA Full en Us A4Документ2 страницыFREA Full en Us A4Rodrigo LisboaОценок пока нет

- Model 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityДокумент2 страницыModel 20%, Accumulator Sense, Pump Unload Valve With Check - Pilot CapacityGamal El Deen KamalОценок пока нет

- RDFALWN-CAM S Full en Us LetterДокумент5 страницRDFALWN-CAM S Full en Us LetterJustinОценок пока нет

- Model 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveДокумент1 страницаModel 10:1 Pilot Ratio, Standard Capacity Counterbalance ValveANDRESОценок пока нет

- RDDA - Direct-Acting Relief ValveДокумент3 страницыRDDA - Direct-Acting Relief ValveD ŠpokauskasОценок пока нет

- Cbcalin ValveДокумент2 страницыCbcalin ValveArun51092Оценок пока нет

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveДокумент2 страницыModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalОценок пока нет

- Pressure Reducing - Relieving Valve PRFBДокумент3 страницыPressure Reducing - Relieving Valve PRFBkocho79Оценок пока нет

- SUN RPGC-LAN (Relief Valve)Документ3 страницыSUN RPGC-LAN (Relief Valve)ful islamОценок пока нет

- RDHA Full en Metric LetterasdДокумент2 страницыRDHA Full en Metric LetterasdessamОценок пока нет

- SUN RPGC-JCN (Relief Valve)Документ3 страницыSUN RPGC-JCN (Relief Valve)ful islamОценок пока нет

- Model 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveДокумент1 страницаModel 4.5:1 Pilot Ratio, Ultra-Restrictive Counterbalance ValveRinaldo BompieriОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Clamping Elements Bonded Disc Packs LBDДокумент2 страницыClamping Elements Bonded Disc Packs LBDVinit ChoudharyОценок пока нет

- Balancing Rotor No 1 - 22-02-2020Документ1 страницаBalancing Rotor No 1 - 22-02-2020Vinit ChoudharyОценок пока нет

- Balancing Rotor No 1 - 24-01-2020Документ1 страницаBalancing Rotor No 1 - 24-01-2020Vinit ChoudharyОценок пока нет

- Balancing Rotor No 2 - 06-03-2020Документ1 страницаBalancing Rotor No 2 - 06-03-2020Vinit ChoudharyОценок пока нет

- 1ZLMD - 1223Документ1 страница1ZLMD - 1223Vinit ChoudharyОценок пока нет

- Book - Goindigo.in Skylights Cgi-Bin Skylights - Cgi Sid A9Документ2 страницыBook - Goindigo.in Skylights Cgi-Bin Skylights - Cgi Sid A9Vinit ChoudharyОценок пока нет

- WEG CFW300 User Manual 10003325037 en Es PT PDFДокумент153 страницыWEG CFW300 User Manual 10003325037 en Es PT PDFmaurosergiorovettaОценок пока нет

- J4 Diagrama ElectricoДокумент148 страницJ4 Diagrama ElectricoJuan Rafael Vilchez SanchezОценок пока нет

- WelinLambie Marine Davit Technical ManualДокумент90 страницWelinLambie Marine Davit Technical ManualJustin BondОценок пока нет

- OTb DiagonsticДокумент2 страницыOTb DiagonsticBhushan KalgaonkarОценок пока нет

- ZX210H-5G Valve Control CompleteДокумент14 страницZX210H-5G Valve Control Completefebru100% (1)

- Catalog 60Документ34 страницыCatalog 60judas1432Оценок пока нет

- Trolley Weight EstimationДокумент7 страницTrolley Weight EstimationRaj KumarОценок пока нет

- RT22-677 Cooking 592 E-84 E-85 ErrorДокумент2 страницыRT22-677 Cooking 592 E-84 E-85 ErrorpasantitoОценок пока нет

- Maspric ATS - M V02 LowresДокумент25 страницMaspric ATS - M V02 LowresvenkatОценок пока нет

- General Outline of Inventory in StockДокумент10 страницGeneral Outline of Inventory in Stocksalhi9676Оценок пока нет

- Review Review Review Review M M M M Ssss OHE OHE OHE OHEДокумент61 страницаReview Review Review Review M M M M Ssss OHE OHE OHE OHETushar100% (2)

- Manual de OkumaДокумент36 страницManual de OkumaIng Roberto CisnerosОценок пока нет

- Ventmed Bipap Brochure DS-7&8Документ2 страницыVentmed Bipap Brochure DS-7&8aderahmainiОценок пока нет

- Remanufactured Wabco ECUs & Actuators - H L SmithДокумент2 страницыRemanufactured Wabco ECUs & Actuators - H L SmithYoùssef ModesteОценок пока нет

- Sungrow ST68KWH-50HV Datasheet PDFДокумент2 страницыSungrow ST68KWH-50HV Datasheet PDFNicolás Herrera SapunarОценок пока нет

- Ex 3 Speed Control of Slip Ring Induction MotorДокумент4 страницыEx 3 Speed Control of Slip Ring Induction MotorAjay TejaОценок пока нет

- 24lc21 KullanimiДокумент8 страниц24lc21 KullanimiskiziltoprakОценок пока нет

- Underground Drilling Common / Boomer DCS: System Knowledge and Troubleshooting Training 10. MaintenanceДокумент42 страницыUnderground Drilling Common / Boomer DCS: System Knowledge and Troubleshooting Training 10. Maintenancefranco avilaОценок пока нет

- API 610 Major Changes From 5th Through 10th Editions 2Документ1 страницаAPI 610 Major Changes From 5th Through 10th Editions 2ahmedОценок пока нет

- SASSCO Intermediate Check Instruction SheetДокумент4 страницыSASSCO Intermediate Check Instruction SheetStudent ForeignОценок пока нет

- Caterpillar D6Документ3 страницыCaterpillar D6RasoolKhadibi100% (1)

- GG 3904 01 enДокумент2 страницыGG 3904 01 enSamprit BasuОценок пока нет

- MID 130 PID 161 Input Shaft Rotation Speed PDFДокумент4 страницыMID 130 PID 161 Input Shaft Rotation Speed PDFTun Tun Win KseОценок пока нет

- Weishaupt Valve Proving System VPS 504S2Документ6 страницWeishaupt Valve Proving System VPS 504S2diab ali100% (1)

- FADZXcv SXДокумент1 страницаFADZXcv SXMohamed SelimОценок пока нет

- Product Information.: Technical Training. N47TU EngineДокумент66 страницProduct Information.: Technical Training. N47TU EngineAndreAPL100% (1)

- Acb Master Pact CatalogueДокумент159 страницAcb Master Pact CatalogueariessukmawanОценок пока нет

- SDI PDP Repair Manual: Colour TelevisionДокумент77 страницSDI PDP Repair Manual: Colour TelevisiontommyyОценок пока нет

- Maintenance and Instruction Manual 1. Transport: Galperti TechДокумент7 страницMaintenance and Instruction Manual 1. Transport: Galperti TechDavid C HouserОценок пока нет

- Datasheet PDFДокумент4 страницыDatasheet PDFJose Luis Guanchez CarrilloОценок пока нет