Академический Документы

Профессиональный Документы

Культура Документы

Ceramic Materials Properties

Загружено:

Intanasa NurdentiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ceramic Materials Properties

Загружено:

Intanasa NurdentiАвторское право:

Доступные форматы

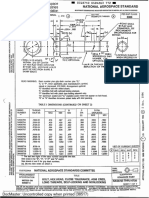

Ceramic Properties Standard

Alumina Zirconia Carbides

PlasmaPure-UC™ DURA-Z™ YTZP YTZP SC-RB UltraSiC™

Porcelain Mullite AD-85 AD-90 AD-94 AD-96 FG-995 AD-995 AD-998 ZTA WC PureSiC® HR PureSiC® LR

Alumina (TTZ) (Sintered) (HIPed) (SC-2) (SC-30)

Zirconia-Toughened MgO Partially Y2O3 Partially Y2O3 Partially Reaction Bonded Direct Sintered CVD Silicon Carbide CVD Silicon Carbide

Nom. 85% Al2O3 Nom. 90% Al2O3 Nom. 94% Al2O3 Nom. 96% Al2O3 Nom. 98.5% Al2O3 Nom. 99.5% Al2O3 Min. 99.8% Al2O3 Min. 99.9% Al203 Tungsten Carbide

Alumina Stabilized Zirconia Stabilized Zirconia Stabilized Zirconia Silicon Carbide Silicon Carbide > 99.9995% > 99.9995%

Properties* Units Test

Density gm/cc ASTM-C20 2.40 2.80 3.42 3.60 3.70 3.72 3.80 3.90 3.92 3.92 4.01 5.72 6.02 6.07 3.10 3.15 14.90 3.21 3.21

Crystal Size Average MICRONS THIN-SECTION – 10 6 4 12 6 6 6 6 3 2 35 1 1 12 5 2 3 - 10 3 - 10

Water Absorption % ASTM-373 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Gas Permeability – – – 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Color – – WHITE TAN WHITE WHITE WHITE WHITE WHITE IVORY IVORY IVORY WHITE IVORY IVORY GREY BLACK BLACK GRAY BLACK BLACK

MECHANICAL

Flexural Strength (MOR) 20° C MPa (psi x 10 ) 3

ASTM-F417 130 (19) 170 (25) 296 (43) 338 (49) 352 (51) 358 (52) 375 (54) 379 (55) 375 (54) 400 (58) 450 (65) 900 (130) 1240 (180) 1720 (250) 462 (67) 480 (70) 1550 (225) 468 (68) 517 (75)

Elastic Modulus 20° C GPa (psi x 106) ASTM-C848 104 (15) 150 (22) 221 (32) 276 (40) 303 (44) 303 (44) 350 (51) 370 (54) 370 (54) 386(56) 360 (52) 200 (29) 210 (30) 210 (30) 393 (57) 410 (59) 627 (91) 462 (67) 434 (63)

Poisson’s Ratio 20° C – ASTM-C848 – – 0.22 0.22 0.21 0.21 0.22 0.22 0.22 0.22 0.23 0.30 0.23 0.23 0.20 0.21 – 0.21 0.21

Compressive Strength 20° C MPa (psi x 103) ASTM-C773 590 (86) 550 (80) 1930 (280) 2482 (360) 2103 (305) 2068 (300) 2500 (363) 2600 (377) 2500 (363) 2700 (392) 2900 (421) 1750 (254) 2500 (363) 2500 (363) 2700 (363) 3500 (507) 5000 (725) – –

GPa (kg/mm ) 2

KNOOP 1000 gm 5.9 (600) 7.4 (750) 9.4 (960) 10.4 (1058) 11.5 (1175) 11.5 (1175) 13.7 (1400) 14.1 (1440) 14.1 (1440) 14.5 (1480) 14.4 (1475) 11.8 (1200) 12.7 (1300) 12.7 (1300) 26 (2500) 26 (2800) 16 (1630) 27 (2750) 27 (2750)

Hardness

R45N ROCKWELL 45 N 60 70 73 75 78 78 82 83 83 86 85 77 81 81 – – – – –

Tensile Strength 25° C MPa (psi x 10 ) 3

ACMA TEST #4 – – 155 (22) 221 (32) 193 (28) 221 (32) 248 (36) 262 (38) 248 (36) 283 (41) 290 (42) 483 (70) – – 307 (44.5) – – – –

Fracture Toughness K(I c) Mpa m1/2 NOTCHED BEAM 2 2 3-4 3-4 4-5 4-5 4-5 4-5 4-5 4-5 5-6 11 13 13 4 4 >6 3.5 3.5

Thermal Conductivity 20° C W/m K ASTM-C408 5.0 3.5 16.0 16.7 22.4 24.7 27.5 30.0 30.0 35.0 27.0 2.2 2.2 2.2 125.0 150.0 100.0 115.0 115.0

Coefficient of Thermal

25-1000° C 1X 10-6/°C ASTM-C372 4.9 5.3 7.2 8.1 8.2 8.2 8.2 8.2 8.2 8.1 8.3 10.2 10.3 10.3 4.3 4.4 5.1 4.6 4.6

Expansion

THERMAL

Specific Heat 100° C J/kg*K ASTM-E1269 – 950 920 920 880 880 880 880 880 870 885 400 400 400 800 800 – 665 665

Thermal Shock Resistance ∆ Tc °C NOTE 3 – 300 300 250 250 250 200 200 200 200 300 350 350 350 400 300 – – –

Maximum Use Temperature °C NO-LOAD COND. 1400 1700 1400 1500 1700 1700 1700 1750 1750 1750 1500 500 1500 1500 1000 1600 1000 1600 1600

Dielectric Strength ac-kV/mm (ac V/mil) ASTM-D116 – 9.8 (248) 9.4 (240) 8.3 (210) 8.3 (210) 8.3 (210) 8.7 (220) 8.7 (220) 8.7 (220) 8.7 (220) 9.0 (228) 9.4 (240) 9.0 (228) 9.0 (228) – – – – –

Dielectric Constant 1 MHz 25° C ASTM-D150 5.9 6.0 8.2 8.8 9.1 9 9.6 9.7 9.8 9.8 10.6 28.0 29.0 29.0 – – – – –

ELECTRICAL

Dielectric Loss (tan delta) 1 MHz 25° C ASTM-D150 0.0024 0.002 0.0009 0.0004 0.0004 0.0002 0.0002 0.0001 0.0001 <0.0001 0.0005 0.001 0.001 0.001 – – – – –

Volume Resistivity 25° C ohm-cm ASTM-D1829 – > 1014 > 1014 > 1014 > 1014 > 1014 > 1014 > 1014 > 1014 > 1015 > 1014 > 1013 > 1013 > 1013 < 103 < 105 < 103 > 106 < 0.10

500° C ohm-cm ASTM-D1829 – 5 x 1012 4 x 108 4 x 108 4 x 109 4 x 109 2 x 1010 2 x 1010 2 x 1010 1 x 1012 2 x 109 2 x 105 2 x 104 2 x 104 < 103 < 103 < 103 – –

1000° C ohm-cm ASTM-D1829 – 3 x 105 – 5 x 105 5 x 105 1 x 106 2 x 106 2 x 106 2 x 107 1 x 107 3 x 106 < 103 < 103 < 103 < 103 < 103 < 103 – –

Impingement – NOTE 4 – – 1.00 0.45 0.52 0.50 0.48 0.47 0.47 0.47 0.41 0.63 0.20 0.20 0.14 0.12 0.12 0.03 0.02

WEAR

Rubbing – NOTE 4 – – 1.00 0.36 – 0.60 – – – – 0.49 0.57 0.20 0.20 – – – – –

The chart is intended to illustrate typical properties. Engineer- Notes: 4. Wear Resistance – Impingement tests are run using a dry

CoorsTek, Amazing Solutions, and PureSiC are registered trademarks of CoorsTek, Inc.

ing data is representative. Property values vary somewhat with 1. Data Measurements – All data measurements are typical and fused alumina abrasive. Rubbing tests are run using a dry

PlasmaPure-UC, Dura-Z, and UltraSiC are trademarks of CoorsTek, Inc.

method of manufacture, size, and shape of part. Any suggested made at room temperature unless otherwise noted. 240 grit fused alumina abrasive. The indices in the chart are

applications are not made as a representation or warranty that calculated by dividing the material volume loss by the volume

the material will ultimately be suitable for such applications. 2. Composition Control – all CoorsTek ceramic compositions loss of an AD-85 alumina control. The lower in the index, the

The customer is ultimately responsible for all design and mate- are controlled using modern chemical, spectrographic, and better the wear resistance.

rial suitability decisions. Data contained herein is not to be con- X-ray fluorescent methods.

CoorsTek, Inc. 800.821.6110 toll free info@coorstek.com strued as absolute and does not constitute a representation or 5. Dielectric Strength numbers represent measurements on

16000 Table Mountain Parkway 303.271.7000 tel www.coorstek.com warranty for which CoorsTek assumes legal responsibility. Any 3. Thermal Shock Resistance – Tests are run by quenching samples that were 0.25” thick.

warranty or representation for which CoorsTek is responsible samples into water from various elevated temperatures. The

Golden, CO 80403 USA 303.271.7009 fax shall be subject to a separately negotiated agreement. change in temperature where a sharp decrease in flexural *Ceramic property values vary somewhat with method of

strength is observed is listed as DTc. manufacture, size, and shape of part. Close control of values of

most properties can be maintained if specified.

© 2008 CoorsTek F0801 8510-1042 Rev. J

Вам также может понравиться

- GMW 3059Документ7 страницGMW 3059Ricardo VitorianoОценок пока нет

- GQAДокумент26 страницGQARaduz HaduzОценок пока нет

- Supplier Quality Management A Complete Guide - 2021 EditionОт EverandSupplier Quality Management A Complete Guide - 2021 EditionОценок пока нет

- Mil PRF 31032.2166 PCB PDFДокумент27 страницMil PRF 31032.2166 PCB PDFEricОценок пока нет

- Unified Thread StandardДокумент4 страницыUnified Thread StandardFredОценок пока нет

- Mil PRF 85285eДокумент24 страницыMil PRF 85285eAnes HalilovićОценок пока нет

- Mil PRF 85285eДокумент24 страницыMil PRF 85285emurphygtОценок пока нет

- Mil STD 2223Документ96 страницMil STD 2223Standards IndiaОценок пока нет

- Logistics Engineering - WikipediaДокумент7 страницLogistics Engineering - WikipediaBambang Darmawan SapingiОценок пока нет

- Types, AsДокумент23 страницыTypes, AsAnanthanarayananОценок пока нет

- Anexa 3 BI261Документ69 страницAnexa 3 BI261ahmadove1Оценок пока нет

- ACList 20180808Документ3 страницыACList 20180808mahmood750Оценок пока нет

- Special Process Audit Check Sheet - PlatingДокумент8 страницSpecial Process Audit Check Sheet - PlatingHariprasanth ChandranОценок пока нет

- Supplier Performance ManagementДокумент6 страницSupplier Performance ManagementYogesh Sharma100% (1)

- Technical Specfication - en 1563 - SGДокумент4 страницыTechnical Specfication - en 1563 - SGstores svaplОценок пока нет

- A-A-59316 SpecДокумент5 страницA-A-59316 SpecddionatosОценок пока нет

- Ph-Ec InfoДокумент4 страницыPh-Ec InfoNick ChooОценок пока нет

- HC2.03.55 Rev 3 - HD Inspection Lighting SystemsДокумент6 страницHC2.03.55 Rev 3 - HD Inspection Lighting SystemsHa TranОценок пока нет

- Rma New Blank PC ReturnДокумент1 страницаRma New Blank PC Returnarshadsamudh3100% (1)

- Mil I 24768Документ35 страницMil I 24768Rahul Goud100% (1)

- Flex Circuit Design GuideДокумент4 страницыFlex Circuit Design GuidejmorfeosОценок пока нет

- Cqi 11v2 Special Process Plating System Assessment PDFДокумент15 страницCqi 11v2 Special Process Plating System Assessment PDFaadmaadmОценок пока нет

- As9100D Gap Analysis Tool 9. Evaluation Gap Analysis QuestionnaireДокумент6 страницAs9100D Gap Analysis Tool 9. Evaluation Gap Analysis Questionnairechandravel sankarakumar100% (1)

- Engine MRO Overall ProcessДокумент6 страницEngine MRO Overall ProcessMihai ConstantinescuОценок пока нет

- Austempered Ductile Iron Castings: Standard Specification ForДокумент9 страницAustempered Ductile Iron Castings: Standard Specification ForRaja Hone0% (1)

- Stainless Steel Flat ProductsДокумент15 страницStainless Steel Flat Productsstrip1Оценок пока нет

- MOM - Control PlanДокумент17 страницMOM - Control PlanraghulramasamyОценок пока нет

- Dfars PDFДокумент3 страницыDfars PDFSergio GallardoОценок пока нет

- VRSДокумент8 страницVRSCОценок пока нет

- PSWДокумент2 страницыPSWLinda G. CordovaОценок пока нет

- 03 Knowledge Sharing 7 QC ToolsДокумент107 страниц03 Knowledge Sharing 7 QC Toolsravi javaliОценок пока нет

- Iso 4540 1980 FR en PDFДокумент8 страницIso 4540 1980 FR en PDFTSA Bekasi Raya100% (1)

- OBS - 510 - Rev 01 - Eng MilliporeДокумент4 страницыOBS - 510 - Rev 01 - Eng MilliporeSakthy ArunaОценок пока нет

- Carbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)Документ12 страницCarbon Steel Billets, Blooms, Slabs and Bars For Forgings - Specification (Fifth Revision)SreenathaОценок пока нет

- Procedure For New DevelopmentsДокумент2 страницыProcedure For New DevelopmentsspdhimanОценок пока нет

- Effective Auditing of Purchasing & Subtier Supplier Control ProcessesДокумент40 страницEffective Auditing of Purchasing & Subtier Supplier Control ProcessesJHBernardoОценок пока нет

- WI-PUR-02 Criteria - Supplier Audit Frequency EvaluationДокумент1 страницаWI-PUR-02 Criteria - Supplier Audit Frequency EvaluationRakesh ChauhanОценок пока нет

- Zinc Plating: Randhir Kumar Singh Asst Professor OpjitДокумент16 страницZinc Plating: Randhir Kumar Singh Asst Professor OpjitRahul PandeyОценок пока нет

- MIL-I-24768 (Insulation, Plastics, Laminated, Thermosetting General Specification For)Документ35 страницMIL-I-24768 (Insulation, Plastics, Laminated, Thermosetting General Specification For)ccorp0089Оценок пока нет

- Nyloc Nut Is 7002 PDFДокумент11 страницNyloc Nut Is 7002 PDFsanjibkrjana0% (1)

- GA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Документ26 страницGA-SRC-0002 Cosmetic Inspection Guidelines For Mechanical Components (Rev 1.0)Manoj Pai D100% (1)

- PPAP Template InspectionXpertДокумент14 страницPPAP Template InspectionXpertda_reaper_dasОценок пока нет

- Dead Endclamp Failure AnalysisДокумент26 страницDead Endclamp Failure AnalysisRK KumarОценок пока нет

- D0031 (2012-N) NES: Marking of Polymeric PartsДокумент16 страницD0031 (2012-N) NES: Marking of Polymeric PartsDiego CamargoОценок пока нет

- Mil DTL 53022FДокумент22 страницыMil DTL 53022FVictor ParvanОценок пока нет

- Flooring Spec No RDSO-2017-CG-05 For Rubberized FlooringДокумент15 страницFlooring Spec No RDSO-2017-CG-05 For Rubberized FlooringIshanОценок пока нет

- Houston Impact of J-STD-001F and IPC-A-610F ChangesДокумент36 страницHouston Impact of J-STD-001F and IPC-A-610F Changes安靖Оценок пока нет

- SABRE Edition 2Документ40 страницSABRE Edition 2edgarОценок пока нет

- Adhesion of PolymersДокумент21 страницаAdhesion of PolymersKorso91087Оценок пока нет

- Safety Data-Sheet According To Regulation (EC) No. 1907/2006 (REACH)Документ6 страницSafety Data-Sheet According To Regulation (EC) No. 1907/2006 (REACH)gro loka100% (1)

- Iso Dis 16232-3 2005-08 enДокумент22 страницыIso Dis 16232-3 2005-08 enMarekОценок пока нет

- Engineering Standards: Material Specification Metals GM6435MДокумент6 страницEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovОценок пока нет

- Nas 6704Документ7 страницNas 6704Konelek AeroОценок пока нет

- The World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionДокумент2 страницыThe World's Choice For Corrosion Protection The World's Choice For Corrosion ProtectionSquidwardОценок пока нет

- DP Test ReportДокумент1 страницаDP Test ReportSanjay KumarОценок пока нет

- Vendor Rejection and Debit PolicyДокумент6 страницVendor Rejection and Debit PolicysharanОценок пока нет

- Packaging Specification Data Sheet: (FORM 150NA)Документ17 страницPackaging Specification Data Sheet: (FORM 150NA)Saravana kumar NagarajanОценок пока нет

- Cipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Документ8 страницCipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Marvin CubeОценок пока нет

- Inspeccion de GalvanizadoДокумент22 страницыInspeccion de GalvanizadoacuaroscarОценок пока нет

- Mil PRF 46010HДокумент17 страницMil PRF 46010HGoogle UserОценок пока нет

- 8510-1417 Replacement Bladders & KitsДокумент2 страницы8510-1417 Replacement Bladders & KitsCesar MoraОценок пока нет

- Monno CeramicsДокумент6 страницMonno Ceramicsanon_287333801Оценок пока нет

- Ceramic Materials PropertiesДокумент1 страницаCeramic Materials PropertiesIntanasa NurdentiОценок пока нет

- 8510-1042 Ceramic Material Properties PDFДокумент1 страница8510-1042 Ceramic Material Properties PDFMelih AltıntaşОценок пока нет

- 2019년 중소기업 전략기술로드맵 22 무기화학Документ274 страницы2019년 중소기업 전략기술로드맵 22 무기화학SLОценок пока нет

- 8510-1447 Zero-Maintenance Pulsation DampenersДокумент2 страницы8510-1447 Zero-Maintenance Pulsation DampenersdharmeswarОценок пока нет