Академический Документы

Профессиональный Документы

Культура Документы

Ram Pump DTU S1

Загружено:

Andri Betmanto100%(1)100% нашли этот документ полезным (1 голос)

265 просмотров12 страницThe DTU S1 hydraulic ram pump is a steel machine, using a 3 / 4" or 1" diameter galvanised drive pipe, that can lift water up to a height of 80 meters. It was designed for water supply to small groups of houses from minor sources of water such as springs and small streams. The pump has been designed to be made in small workshops with welding equipment and a pillar drill.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe DTU S1 hydraulic ram pump is a steel machine, using a 3 / 4" or 1" diameter galvanised drive pipe, that can lift water up to a height of 80 meters. It was designed for water supply to small groups of houses from minor sources of water such as springs and small streams. The pump has been designed to be made in small workshops with welding equipment and a pillar drill.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

265 просмотров12 страницRam Pump DTU S1

Загружено:

Andri BetmantoThe DTU S1 hydraulic ram pump is a steel machine, using a 3 / 4" or 1" diameter galvanised drive pipe, that can lift water up to a height of 80 meters. It was designed for water supply to small groups of houses from minor sources of water such as springs and small streams. The pump has been designed to be made in small workshops with welding equipment and a pillar drill.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 12

DTU

Ram Pump Programme

Q_

2

~

Q_

,

UJ

~

TECHNICAL

11 ~

RELEASE 0 l1Ie name "S I" stan ds fo r a Steel pump with a drive pipe up to 1" in diameter.

hydraulic ram pump

A ram pump is powered by falling water. Water from a stream or spring is diverted and dropped through a drive pipe into the pump. The power of the falling water is used to pump some of the water where it is wanted. The amount of power in the falling water limits how high you can pump, and how much water you can pump. Generally, the more water you drop and the further you let it fall, the more power there will be.

The DTU S1 hydraulic ram pump is a steel machine, using a 3/4" or 1" diameter galvanised drive pipe, that can lift water up to a height of 80 meters. It was designed for water supply to small groups of houses from minor sources of water such as springs and small streams. It is being used successfully in many African countries.

The pump has been designed to be made in small workshops with welding equipment and a pillar drill. A lathe can be useful but is not essential.

In areas where the water source flow varies greatly during the year, more than one pump can be installed, all sharing the same delivery pipe as shown in the drawing below.

Distribution system. for domestic: use. A tank is always recommended.

Delivery pipa. rising ailihe way along lts length (no ups and downs). The pipe should

be buried where possible a nd protected if it has to be above ground.

Use 20mm diameter plastic pressure pipe for the delivery pipe if there is one pump in the sytem, and one size larger if there are two.

Drive pipe. securely fi~e d

Drive tank

Waste water overflow

Pumps secured to a cradle

.. -.,....;;._ ~ into concrete

~ \.--::::~

~\:~---

t

TECHNICAL

11

RELEASE

UJ Z o

-

I-

o

::J a:

Ico

z

a: w Cf)

::J

. .

0... ~ ::J D...

.;;-

UJ

::J Io

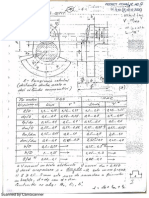

AN EXPLODED VIEW OF THE DTU SI PUMP

Snifter valve

PARTS LIST

Air vessel

Pump body

Oelivery valve plate Impulse valve plate Rubber gasket (x 3) Oelivery valve rubber

(diameter 46mm & thickness 3mm) Impulse valve rubber (diameter 40mm & thickness 6mm) Snifter valve rubber

(diameter 50mm & thickness 1 .5 to 2mm)

Impulse valve stem (length 130mm, M8 thread 30mm from top, 60mm from bottom)

Impulse valve stop bar Impulse valve plug Impulse valve weight 6 x 50mm M6 bolls

2 x 70mm M8 bolts

25 x M8 washers

22x M6nuts

4xM8

SOmm bolls

Delivery valve

Air vessel

CROSS SECTION THROUGH ASSEMBLED

DEliVERY VALVE IMPULSE VALVE

"t=1iJ fWd'" J

Cha.mfered side

270mm

PLAN OF PUMP CRADLE

ri) ~ Valve stem lock nuts e

Impulse valve

Impulse valve plate

.... _------- lock nuts

e ...

~ ....... -------- Steel washer

~ .... Plug disc

........ _---

______ Impulse valve rubber

.... ---- Weight disc

To putthe pump together you will need two open ended 13mm spanners.

Pump body

Feet to attach to crad!e

Pump repair

Putting the pump back together Assembly of the pump is shown in the exploded view drawing, but the following important points need to be kept in mind:

m Assembling the delivery valve

Put together the delivery valve plate, the rubber and the boll. Make sure the side of the plate with the cha mfered ho les is on the opposite side to the rubber, and that the rubber is on top.

Screw on the first nut until it is finger tight and then undo it by one turn. Care must be taken not to overtighten the bolt and nuts as this will affect the performance of the valve. Next, screw on the other nul and tighten it up against the first Use the spanners to lighten them firmly together. This will lock them together, and also allow a small up-and-down movement of the bolt and rubber.

~ Assembling the snifter valve

Put the 'sha ped' bolt and washe r together, feed the bolt through the valve rubber, then push this through the pump body. Make sure that the shaped curve of the bolt head and washer align with the curvature of the body.

Screw on the first nut until it is only finger tight. If the nut is 0 n too tight the rubber will curl away from the pump body and will need to be slackened off slightly. Then screw on the second nut and tighten the two nuts firmly together using the spanners. Then check that the rubber has not distorted. If it has, slacken the nuts half a turn and tighten the outer one again.

@] Assembling the air vessel and delivery valve

Align the delivery valve, air vessel, pump body and rubber gasket mounting holes and feed through the bolts. Make sure the delivery valve is the correct way up (the valve rubber facing

upwards) and then tighten the nuts by hand. Use the spanners

WARNING - Before attempting to remove the air to tighten each nut and bolt a little at a time. working around the

vessel, always release the pressure in it slowly. An flange. This will draw the assembly together evenly.

ideal system will have a gate valve or one-way valve I~ Assembling the impulse valve

and a union fitted between the air vessel and the The first parts to assemble are the valve stem, discs and rubber,

bottom of the delivery pi pe and the optional bleed Screw two nuts onto the longer threaded end of the ste m up to

screw filted to the air vessel. With the pump stopped, the end of the thread. Push a steel washer on up to the nuts.

close the gate valve in the delivery pipe to stop it Follow this with the valve plug disc, with the chamfered side

draining back. If a one-way valve is fitted it will close towards the nut. Slide the valve rubber up against this, then the

automatically. Then loosen the bleed screw to release weight disk with the chamfered side facing away from the

the pressure in the air vessel. If none of the above are rubber. Follow this with another steel washer. Screw a nut up to

them until it is finger Ught. Thread on another nut and use the

fitted, the only other way to release the pressure in spanners to tighten the nuts together. This part of the assembly

the air vessel is to loosen each of the a ir vessel fla nge./ is sometimes known a8 the valve plug.

bolts one turn at a time until the water and air escapes Hold the impulse valve plate and the valve plug together, with

through the join at the flange. You wilt certainly get the chamfered side of the plate a pposlte to the side against

wet this way. which the valve rubber presses. Slide the stop bar onto the top 01 the stem and thread II nul loosely on the stem.

Push the two 10 nger bolts throug h the ends of the stop bar and thread two nuts onto each. Use spanners to lock the nuts tightly. AUgn the valve assembly, pump body and rubber gasket and feed through the nange bolts.

Thread on the four washers and nuts by ha nd, then use the spanners to tighten the two shorter bolts that hold down the valve plate. Again care must be taken to ensure that these nuts are tightened evenly. The next step is to ma ke sure the closed valve plug is centred in the valve plate hole before tightening down the two remaining nuts that secure the stop bar. To check the alignment, open and close the valve manually turning the valve plug to make sure it does not catch on the hole in the valve plate.

Now you on Iy need to set the stroke len gth of the valve for the pump to be ready for use.

If the pump stops or starts delivering less water than usual, it may require adjustment or repair.

Look at the pump and if there is no obvious fault start it again if you can. Watch the pump and listen for irregular pumping or unusual noises. A worn impulse valve, for example, is usually obvious because water squirts through when the valve is closed. Some parts of your ram pump may need occasional replacement the frequency of this will depend on how hard the pump is working and on the cleanliness of the drive water.

Tools you will need:

2 x 13mm ring/open end spanners to disassemble and assemble the pump

2 x Adjustable wrenches - to loosen a union joint on the delivery pipe (if fitted)

Taking the pump apart

Depending on the fault it may be necessary to disassemble the impulse valve andlor the air vessel. Before attempting to take apart the pump:

[!J Make sure that the drive pipe valve Is closed and the impulse valve is open. This will allow you to worle: on the impulse valve ONLY.

Ig] Depressurise the air vessel.

/

Checks /

[!J Check the deliVery valve rubber for wear a nd blockage of the valve holes.

@! Check that the snifter valve is in good condition.

@] Remove the impulse valve and check the impulse valve rubber. Check the nuts on the valve stem and check for excessive wear of the ste rn. Raplace things if necessary.

~ Check the pump body is firmly bolted down, then

reassemble the pump, ensuring that all bolts are greased.

,.. Spare parts to keep on the sHe

- impulse, delivery and snifter valve rubbers

- an impulse valve stem

- a few spare MB nuts, bolts and washers

The Development Technology Unit (DTU)

•.• " Department of Engineering University of Warwick, Coventry CV4 7AL UK ;£ Tel: 4-4 (0)1203523122 FAX: 44 (0)1203 418922

Installation nates

The DTU S1 pump should be installed in a properly designed system_ To prevent vibration causing breakages, It should be firmly bolted to a steel frame (called a pump cradle) that is half buried in a concrete base. The cradle is usually made from 40 x 40mm angle iron and will vary in size depending on the number of pumps installed. Hole locations for just one pump are shown on the previous page.

All pipes in the system should be supported firmly, and buried where possible. The drive and delivery tanks should be constructed on good foundations by experienced tradesmen. Pipe joints to the drive tank should alJowthe pipes to move slightly without damaging the tank walls or leaking badly.

Starting and stopping the ram pump

Although ram pumps often start very easily, they can be awkward the first time they are run. To start the pump:

[!]

Make sure that any valve fitted on the delivery pipe is open and then open the drive pipe valve. Water win flow out of the open impulse valve until it suddenly shuts. If it reopens automatically, the pump should continue to run on its own. If it does not, you must prime the delivery system as described in Step 2 alongside.

To stop the pump, hold the impulse valve stem up to close it or shut the valve at the bottom of the drive pipe.

Push down on the top of the impulse valve stem with your foot to reopen it (wear strong boots). Again, water will flow out of the open impulse valve until it suddenly shuts, then push down immediately to re-open the valve. Keep helping the valve to re-open until it will do so by itself_

Tuning for best performance

The DTU 81 can be tuned to adjust performance. This is done by changing the up and down movement of the impulse valve, which is normally set to about 12mm. Tuning is usually done to achieve either the maximum delivery flow or the most efficient use of the drive water available.

Maximum delivery

When there is plenty of drive water available, the pump can be tuned to deliver as much water as possible. To do this, remove all washers from the impulse valve stem so that the valve has as much up and down movement as possible.

WARNING: - this also puts the pump parts under greater stress and makes them wear more quickly.

Low drive flow

If the pu mp uses more drive flow than is available it wlll soon stop. If this happens it must be tuned to use Jess. The impulse valve should be tuned down to use 90-95% afthe water available from the source. To tune the pump down, add washers onto the impulse valve stem so that the valve has less up and down movement. The shorter the stroke, the smaller the amount of drive flow needed, and the less water is delivered. The minimum stroke length is about 7mm.

Routine maintenance

VVhile the pump is running normally, a visit should be made once a week to check that bolts are tight and that there are no leaks. Once a month an inspection of the whole system should be carried out. It is also recommended that a log book is kept to record the checks and repairs that have been made.

Monthly maintenance check list (without stopping the pump):

[] Inspect all the joints to check for leaks. (3) Clean any filters installed in the system.

jgl Check if there is sufficient air in the air ~ Remove excess silt or debree from tanks or from

vesse1. This can be done by listening behind the intake dam or weir if necessary.

carefully to the pump. If there is insufficient ffil Walk along all pipes looking for damage. Also,

air in the air vessel, the pump will be much inspect the tanks for leaks, particularly at pipe

louder than usual. This means that the snifter joints,

valve is probably blocked and will need to be

cleared.

a..

a.

Q

Q 1-- 0

VI -.r -I

(/.l :g

J:q a..

~ ~

C\J L

1-

~ E

ru E

~(\J

gtn

£1=:1 Q

0, W

z ..... E r:::l

E a.. E _J

a; <lIo W

no E .p .... ~

.p00 (/.l I....

Wtn -0 ° C/)

r

-01=1 I.ro z

~, .......

ZD W 0

"I

W t-

o... <X ..J

....... _J _J

o, o, <I ---- <I

I- W

t-I _J

Z <!

::J u

~ C/)

>- ~

D

CJ >.. t-

O I..

+'

....J c t-

O Go >- 0

:> ~ Z

Z 0 a

I u P=t

U :i o,

W u

l- i L

I.. :::J

d a.. r--

I- ;:ro -

Z ...... 0

<0- (IJ

W 0 ,....

L .....

>- l1.\

Q_ t" .0

0 iii E

....J I.. :l

0;0 C

W >

c; 01

> :::l C

W o§

1=1 to

......

0 o

0 IJI+'

M ~_g

....

0 VI

.c d

j,_ E

Q.I I....

.p °

a..(.,_

E

0'2 0

0 "aT-'

~I 1- E-u

E III

(]'I.::t,

~

x

ru

"<t ru

tn

LII_~_I 1=1 f

<I 0

'<t

_t

a.

"Ud

IlIU

0 "0

0 ~-u

0 <o Q.lc

....

I=t Q ~w

VI /'

no

III +'

a. o

0:::: a:

a.. a..

(,I) Q)

jrj c

Z .. ~"-..

0 ru

......

t-

U :g

W

C/) iii

<I ~

er o

o

o

o

o

. f

a

0 ...... E

E

Z

~ (/J

z

0

.....

VI

Z

W

:E

.....

1=1

..J

_J

<I -t

o in

E £. E £. o(\J ..010

~r:::::l ....... ,

0 .....

«~

!

(

I

I

..c 0

~+>

~"U >-.

_QQ.o"U

I :J ~ 0

+>Q.oP=l

V1 :0;:

" Q.o

Q.o "U V1

a. C III

& Q.o ClJ

I Q..."U>

VI Q.o s,

(:Q"U-

d<t

.. Q.I

'<t t. Q.!

,.£.£

M+>+'

I /

- -

Q.o t

\ 0

...0

! 1

I I

«- t

o o

I

(\I "U

--- in ClJ

o:;t I=l 3:

w

, _J

<[

f-- U

,_., :::.::

--- Z:::J (I)

f :J

i-. 0

>- !.. I--

t.:J~ I--

o Q.o _J

a. _J > w 0

0 o 0 (/,I z

u ZU V)

I.:i w

"U U u >

c wi

w t- !.. et:

d

1--> ...... ,.....

<t

z ...... -

0

we (/,I N

:E:>, '-

a.... ..... Q)

0- .0

_J~ E

Wa. ::J

>Z C

wI'::: OJ

~:::l C

"i

til

L-

a

Z

0

,_, 0

I- 0

U "<t-

W Q.o

(I) +>

<t E

<t 0.

£

VI Q.o

VI I-

Q.I <,

C Ol

.Y C

u "i

z o

+> s....

j;:l;

C (to

£ +>

0

£ S-

o o

....

Q.

0 Q.o

+> VI

"U

(to 0) Q.o

.s:

~ ill +>

s,

o Q.o

Q.o

a. VI

~ 0

u (to

+>

t "U 0

c 0:::

-c W

"<t- o/:; Q.o

CD

"U Q.o C

n; 0

+> _,

): <:I u,

CL £.

(to £

(II s:

+> z

CD ......

C Q.o

0 tI)

-' .Y Z

L.... o 0

E .....

Q.o VI

~l .£ 0 Z

l- I-- W

L

.....

A

_J

_J

<! o o .....

_,

I- W

...... ::,,:

Z:J _J

~ ;;. <I

U

>- '- (/)

0 LJ~

0) o~ w

_J> I-

D° <[

ZU _J

::r:i Q._

u!:!

w:t: LU

t-'- l.9 f"-

0 Z ......

Z t-~ <r 0

0 Z(,_ __j M

.-. WO L... ~

l- I>. Q)

U <I <I ...... .0

W 0.... .... V) E

(I) 0- ::J:

_j~ c

<I wa- C»

<I >~ c

W~ -~

R~ t'I:I

L-

0

0

-o

R

Ww

0 COf-

0 Z« 0

«_J (")

o a... J

2

C). w

Zr-

-$- -$- S« s,

«Cf) III .p

>,+-' e

0::« dill (lJ

00 E~ E..:t..

llJu

row ,..,"U L Q.o

- en J.£

:1:::> £:

EQ.< Iflu

J- o "U 0

\{) -- ttl

'-' III _ ::E

+-';;.-..

Q_o:::J"U

+,00

d _S2

~a..

a.....s::: a.

0 E OJ.p §

0

f t 1 E Olea.

0 Co

.... ~ a..

0 u, (J)..s:::

+" Sop

<[ <I 1ls"O

CO ..s:::CL

0 .p1ll0

o::t ~ 0.4-

<i-1lJ

VI 0"U "U

(lI

Vl L +" Vl

-$- (lI III C :J

e +-,0.1

x. IlJL(lI

U E IlJ 0. E

£ o <i- -- E

+-' - <i- Q.

"U -- Z

"U~

Q,o III .....

+" dlllQl V)

d C_S2+' Z

Q_ L III 0

llJo

a (lI +-'+-,<U VJ

(]\ -.:- (J) c ..c z

R c u+-' W

~I o <UQj ::E:

..c III 4-

t..... I-cO Cl

_J

'_j

<r ~

w

...... 0

>

n,

0

l- I-

(I)

W _J

> UJ

_J I-

<[ e::::

> -c

Q_

w 0

(;?

_J

:::l

Q_

:::E

...... \

.....

-<

I- W

........ ~ >- _J

Z :J _j <r

=> >.. D=t u

>- !... :E' V)

-t' W

L:l c V) t

0 Co Vl

_J >

0 <[ Z

0 u 0

Z w ......

I .:i > I-

U ~ U

W ~ _J W

I- !... <[ Vl

0 >

I- ~ <[

f'-

Z ..... W .... <[

W 0 (I) 0

~ >. _J v

Q -+' => '-

0 ~ e, Il)

_J :E .a

s, E

w (If .....

> > :::l

E ...... c

W ;:::) (I) C)

q c:

3:

f:

0 .Y III

u;t:

-- 0 "U

£~

\IJ +"<'_ c

0

EllI :Y

£_c

\/).p U

r-, s:

(U "U1Il +"

Co

0 £

~~ £

llI£ (")

+>+"-o 0

III c III +' 111

EO+" 0)

~.£ U tf) C

"O+'L ..... 0

+" L...

s !....111 Q.1

Q.1(lj .2>-

E (J)~ "0

c s, Co

OOlll OJrl

q-~.Q U

Vl!....~ ,,0.

(1)£

-- Qj = 'V 3

Z ....... +"~ Q_

0 3~<lI +"

...... 0> Qj (lI

I- U --~ :YJ:

U III 1J 0; W-P

W -- > 0

V) t=I 0 l:J£

Q.t U

<[ !.... Q,£ !....-P

<[ a. V\ -P (lIO

.Q 3 .2£

.Q s: .2

::s I- (J) 30

G::O::S a::::+'

ZO

III s, Qj-P

WI £0.<: £3

1- 1- t=I +" I--- U

0

/ / z

U') 0

0)

•

If)

V

z k$~~~

0

.....

I-

U <I <[

LJ

(/)

<I

<[

v

(")

~ o o

.......

o o

......

t

<[

Ww all--

z« «-1 00..

C9r5

21--

$« «00 0:::« DO (/)W -00 I.:::l I--

....

-<

I- W

t"-1 :>!. ....J

Z :J W <r

:::J >.. I- u

s, er V1

>- ¥ ...l

l:.l c 0....

0 Ilo

...l > W

0

0 u >

z

:r: :l ...l

U !t <I:

W J: >

I- ~

a w .....

I- ~ (I) -

Z <+- ..J 0

W 0 :J l()

:E o, ....

c, >. L 4l

+' .c

0 ~ ...... E

_J s, ..... ::J

W Ilo (..? 1:=

> > C)

c:

W :J 1:=

J::::t °i

e

a 1

1

£ £

Z

.....

(I) z o

......

(I)

z W E

.....

q

__,

"Z}

III Vi

.. \.... I-~ I- W

If) "5 t z::J Z _J

v 0- W <r

Q,o :::J,:.. Z U

(J"\ ~ L L 0 Vl

>- ....

CI 0 t.:l c o,

-<1: Q,o (") o ~ :E

s, 0

O~ i .....l 0 U

V? t a. DU

U Z VI OJ Z:l w

V?

....... 0 U+, IU >

...... ~1Jl u-

CI I- wf _J

U a Q 1- d <[ r--

W W (") -u ~ > -

> ~ til = 0

(I) > f: +' t-

_j c; Z .... W (I)

<:[ <I 04- a. W 0 (I) ~

IU

> <I >0 £.x ::E.;... _J ..0

a. U o...+' :J E

w as(ll ~ as DVi Q_ :J

(I) I- V! L J,£ _j s, :E c

_J -- <l: CO ~d IIIU W 11> ...... a

:J :J o >~ c

Q_ L Q.V') Ilt W::J _. '3:

V?

~ £ U :E p m

..... ....... VI ~

~'ru~ '0

w

0\ I-

Q Z«

«....J

Ua..

C,9aJ (lI

<l1

ZI- +>Vl

... ----- $:« VlVl

Qj

«(f) Ec

0::« £ --

r------- rod

DO +"

(f)W EV)

-(f) 0(1)

I::::> \....Vl

I- 4-::::

til W

til m Ilt

If) +" -o~

in --0 VI od

a E..Q

(D If) -u w

~ t: VIC»

.- c

-- Qj

VI EU-,

a..L..Q

+'°Vi

s, t;.? 4. VI

0 So

r------ .Q llI(l1Q.

0 I > t_

VI ot_':+=

v Vl

r-< r------- > o c,

0 I

s, (lJ

~IU a.. L a..

WIJ: d+'

I- I-..Q III

0

a Z

"t

IX

<!

j::q ~. 0

I r-,

Vl

Vl E £

0 W

IX l- f £

U (/)

Z

W ... _---- W ......

> - > (I)

_J _J 0 z

<[ ,----- <r r<'l 0

> > \-u ......

(/)

w w z

t;.? (/} W

d ::E

_j _j (lI

:::J :J s, Q

o, 0- J:

:E ::L I- _J

...... 0 <::> ....... _J

(\J (\J co <I

Y >-

_J

s::Q

L

W

(,I)

(,I)

<I

- If)

W .....

>

_J

<t:

>

a:: 3: (II

w w 0)

t-- > C

L... o

,_. W ~-

Z L...

(,I) 0

(J) 0...

0

I- t. (lI >.

(lI.£'+-O

.£+'00

VI P=I

dO(1l

~+>Lo.

:} £.

00-0+'3 W

(lido... f-

0.>

~dL(lI Z«

o x ::J...c «.....J

s::Q VI U +> Un..

E C!)~

E Zf-

ru 3:«

E «(J)

EID 0::«

Uo....:; 00

VlID (J)W

<I ~ VI -(J)

LIIl I::>

L (lI (lI

If) (11+' C f-

(") _Q1lI..::( W

<I -- _Q ~.~ CO

:J ._ s:

a::: ell- s z:

W 0

> 1-

U

n, w

0 (,I)

}- <I III

<I ~Vl

O+'

s::Q:J

Z

ex)

~oo I s, III <I.... -t>

III Q.lE ""'0 0_

I~

o a ....

>. <::i o P=I

0. E :s n,

1

L\

a E

III VI E

~ ~ +'

E :J Z

d Z ,_.

.c «i V)

4- u z

Vl a

+> .....

Vl

0 Z

00. W

L

co ....

r t=l:

a _j

....l

~ <I E E (Y)

4- o

£ j E C

E E E

u co I Vl~

~t.~ L (l; III Q.I +> C .Q<lJ.Y "EU ~d~ :s . _ _c

0:::t=l:1-

>-

_j

fq

::E

W

(,I)

(,I)

<I a

0 .-

oc5 -<

W

t-

<I

....l

Q_

W

>

....l

<I •

>

>-

n:.

w

>

......

....l

W

1=1

Q\

1=1 -:;<

_,

t- W

....... ),( w _j

Z ::J

=:l > <I

,:, ....l U

>- L <I Vl

+' >

CJ c

0 Ito

_J > 0:::

a

0 u W Vl

Z I- W

I :i L... ......

U u ..... ....l

W ~ Z 00.

t- L (,I) ::E

d W

l- ~ 00 Vl

Z V) r--

... >- <I .....

W a 0

:E 0:: r--

Q_ >.. W

+' > L-

a iii tV

_J L ..... ..c

W Ito _j E

> > W ~

<:: Cl c

W ::J C)

~ c

'j

~

0 !

o {")

+'

C

as E.Y as u L as :J..s:::

VlU o

(lI

::E

Вам также может понравиться

- Autogreder 14 MДокумент28 страницAutogreder 14 MDanielОценок пока нет

- Ecuatia Eliptica PDFДокумент22 страницыEcuatia Eliptica PDFAnaОценок пока нет

- Hydraulic Clutch Pedal SystemДокумент3 страницыHydraulic Clutch Pedal SystemRamakrishnan RangaОценок пока нет

- FisaTehnologica-3 2 FT2 - 87Документ67 страницFisaTehnologica-3 2 FT2 - 8717ges100% (1)

- Transistor DatasheetДокумент12 страницTransistor Datasheetrevanthkumar80Оценок пока нет

- Campian - V 1989 Automobile TotДокумент463 страницыCampian - V 1989 Automobile TotZoltan Leitner100% (1)

- Victrix-24-TT-2ErP - 1039151 - 003Документ48 страницVictrix-24-TT-2ErP - 1039151 - 003Admin TestОценок пока нет

- Vana Fluture BiplanaДокумент51 страницаVana Fluture BiplanaMaryus GeambyОценок пока нет

- 15 KTLXG 3Документ85 страниц15 KTLXG 3Filev EdwardОценок пока нет

- SMR40Документ4 страницыSMR40michaelliu123456Оценок пока нет

- CVN PsiДокумент154 страницыCVN PsiAdrian ParaschivОценок пока нет

- Piese ms230Документ15 страницPiese ms230casile85Оценок пока нет

- Referat Medic Specialist Psihiatrie Dna. DR - Zamsa LAVINIAДокумент2 страницыReferat Medic Specialist Psihiatrie Dna. DR - Zamsa LAVINIAMihaela CirdeiОценок пока нет

- Manual de Diagnosticare Si Reparatie: Sistem de Injectie Secventiala de Gaz Landi Renzo - OMEGAS LoganДокумент34 страницыManual de Diagnosticare Si Reparatie: Sistem de Injectie Secventiala de Gaz Landi Renzo - OMEGAS LoganAlex RaduОценок пока нет

- Libretto G230 IngleseДокумент52 страницыLibretto G230 IngleseMesara Kod KokijaОценок пока нет

- TMPS Manual Szdalos Tp400 Solar Tpms Wireless Manual PDFДокумент32 страницыTMPS Manual Szdalos Tp400 Solar Tpms Wireless Manual PDFMitchel Jammal S100% (1)

- Piezoelectric Injection SystemsДокумент12 страницPiezoelectric Injection SystemsbestceramicerОценок пока нет

- Vane Fluture Si AdaptoareДокумент32 страницыVane Fluture Si Adaptoarebotas georgianaОценок пока нет

- Switched Systems, Stability of Switched Systems in Sense of LyapunovДокумент200 страницSwitched Systems, Stability of Switched Systems in Sense of LyapunovMamdouh KhudaydusОценок пока нет

- Fuel InjectionДокумент18 страницFuel InjectionshihabОценок пока нет

- User Manual For P12S01Документ40 страницUser Manual For P12S01Behrouz HajianОценок пока нет

- Ccmai ArboreДокумент13 страницCcmai ArboreEduard Gheorghe100% (1)

- 2009diode CatalogДокумент92 страницы2009diode CatalogAnonymous lQyR2IWОценок пока нет

- Technical Specification: Rolls-Royce Marine AsДокумент4 страницыTechnical Specification: Rolls-Royce Marine AsRASOUL KHADIBIОценок пока нет

- UFD14Документ31 страницаUFD14Satay ChillyОценок пока нет

- Demontare Cutie Viteze NivaДокумент10 страницDemontare Cutie Viteze NivaCatalinSSОценок пока нет

- Electric Circuit PDFДокумент2 страницыElectric Circuit PDFMohamed HarbОценок пока нет

- EEEA CursuriДокумент55 страницEEEA CursuriTavi PetrisorОценок пока нет

- 1 3015 enДокумент20 страниц1 3015 enAbbas AhmedОценок пока нет

- Analiza Seriilor CronologiceДокумент32 страницыAnaliza Seriilor CronologiceDeanna LambОценок пока нет

- My Inventions Nikolas TeslaДокумент34 страницыMy Inventions Nikolas TeslaRaj OberoiОценок пока нет

- Comenzi MS DOSДокумент4 страницыComenzi MS DOSkapppyОценок пока нет

- Rear AxleДокумент6 страницRear AxleThomas A. EDISSONОценок пока нет

- Indrum Qualica en PDFДокумент183 страницыIndrum Qualica en PDFVeronicaNistorОценок пока нет

- AS3000 Flyer E PDFДокумент2 страницыAS3000 Flyer E PDFcostelchelariuОценок пока нет

- Group 1 InletДокумент52 страницыGroup 1 InletHafizal Opnb100% (1)

- Dictionar Feroviar RO-ENДокумент222 страницыDictionar Feroviar RO-ENonesunnyday100% (1)

- DM DM N S W V V DM DM: Diagrama Indicata NerotunjitaДокумент6 страницDM DM N S W V V DM DM: Diagrama Indicata NerotunjitaAndreea LicaОценок пока нет

- Selsin Motori I Pokazivanje PravcaДокумент6 страницSelsin Motori I Pokazivanje PravcaSlobodan KojicОценок пока нет

- Grundfosliterature UPA Homebooster PDFДокумент28 страницGrundfosliterature UPA Homebooster PDFStefan DumitruОценок пока нет

- Part1 r31Документ217 страницPart1 r31Prica Petrica IulianОценок пока нет

- FluidPower Chapters1-4Документ61 страницаFluidPower Chapters1-4Ayman EsaОценок пока нет

- LPG Divider BeltsДокумент3 страницыLPG Divider BeltsVzdrževanje KromberkОценок пока нет

- My Inventions: The Autobiography of Nikola TeslaДокумент56 страницMy Inventions: The Autobiography of Nikola TeslaPANDASKOALAОценок пока нет

- Veritas Grinder Tool RestДокумент2 страницыVeritas Grinder Tool Restwoodbee2Оценок пока нет

- Connecting Rod 2016Документ28 страницConnecting Rod 2016Sathish KumarОценок пока нет

- Manual Minimoto Sport RacerДокумент20 страницManual Minimoto Sport RacerMike NickersonОценок пока нет

- ECAC Report 29 - Ver 3 - Vol 2Документ126 страницECAC Report 29 - Ver 3 - Vol 2ruido.barajasОценок пока нет

- ModTech2015 Program Book of AbstractsДокумент293 страницыModTech2015 Program Book of AbstractsBuluc GheorgheОценок пока нет

- Operating Manual Linear Actuators: MC55/24 - MC55/230 - MC55Y MC65/24 - MC65/230 - MC65YДокумент24 страницыOperating Manual Linear Actuators: MC55/24 - MC55/230 - MC55Y MC65/24 - MC65/230 - MC65YDejan DosljakОценок пока нет

- Procedure How To Install Autodesk ProductДокумент3 страницыProcedure How To Install Autodesk ProductRaymond Roy Ocariza ArantonОценок пока нет

- Mpc03lv - LH User ManualДокумент15 страницMpc03lv - LH User ManualTran Tien Dat0% (1)

- FXMQ20 140pve PDFДокумент20 страницFXMQ20 140pve PDFSetyagagaОценок пока нет

- Initiere in Radiogoniometria de Amator PDFДокумент128 страницInitiere in Radiogoniometria de Amator PDFPc PcОценок пока нет

- W.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsДокумент51 страницаW.RT. Reciprocating Air Compressor Explain The Cause of The Following FaultsSri VasanОценок пока нет

- Condeser Tubing and Removal, DocДокумент6 страницCondeser Tubing and Removal, Docdebu1985Оценок пока нет

- Home-Made Hydraulic Ram Pump 2005Документ50 страницHome-Made Hydraulic Ram Pump 2005Dlorah OalZepol100% (1)

- MT 170Документ4 страницыMT 170mafambaОценок пока нет

- Circulation Pump A27-A30angДокумент11 страницCirculation Pump A27-A30angpavan3229100% (1)