Академический Документы

Профессиональный Документы

Культура Документы

6560 HB

Загружено:

giulio70Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6560 HB

Загружено:

giulio70Авторское право:

Доступные форматы

SERVICE HANDBOOK

PLAIN PAPER COPIER 65/5560

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

GENERAL PRECAUTIONS REGARDING THE INSTALLATION AND

THE SERVICE OF THE 6560

1. Transportation/Installation

• When transporting the copier, move it by the casters while lifting the stoppers.

The copier is quite heavy and weighs approximately 230 kg (507 lb); therefore, pay full attention

when handling it.

2. Installation

• Be sure to use a dedicated outlet with AC 115V/15A (220V, 230V, 240V/10A) or more for the

power source.

• The copier must be grounded for safety.

Never ground it to a gas pipe or a water pipe.

• Select a suitable place for installation.

Avoid excessive heat, high humidity, dust, vibration and direct sunlight.

Also provide proper ventilation as the copier emits a slight amount of ozone.

• To insure adequate working space for copying operations, keep a minimum clearance of 80 cm

(32") on the left, 80 cm (32") on the right and 10 cm (4") in the rear.

3. Service of Machines

• Basically, be sure to turn the main switch off and unplug the power cord during service.

• Be sure not to touch high temperature sections such as the exposure lamp, the fuser unit, the

damp heater and their periphery.

• Be sure not to touch high-voltages sections such as the chargers and the high-voltage transformer.

• Be sure not to touch rotating/operating sections such as gears, belts, pulleys,etc.

• When servicing the machines with the main switch turned on, be sure not to touch live sections

such as the lamp terminal etc.

• Use suitable measuring instruments and tools.

65/5560 PRECAUTIONS 1 MAY.1997 © TOSHIBA CORP.

4. Main Service Parts for Safety

• The thermofuse,thermistor,fuse,breaker and door switches,thermostat etc. are particularly important

for safety.Be sure to handle/install them properly.

5. Notice Labels

• Be sure to check the rating plate and the notice labels such as "Unplug the power cord during

service" ,"Hot area" ,etc. to see if there is any dirt on their surface or if they are properly stuck to

the copier during servicing.

6. Disposition of Consumable Parts/Packing Materials

• Regarding the recovery and disposal of the copier, supplies, consumable parts and packing

materials, it is recommended to follow the relevant local regulations or rules.

7. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related documents. Be careful not to reassemble small parts such as

screws, washers, pins, E-rings, toothed washers in the wrong places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Precautions Against Static Electricity

• The PC board must be stored in an anti-electrostatic bag and handled carefully using a wristband,

because the ICs on it may be damaged due to static electricity.

MAY.1997 © TOSHIBA CORP. 2 65/5560 PRECAUTIONS

1. SPECIFICATIONS, ACCESSORIES AND OPTIONS

1.1 Specifications

1.2 Accessories

1.3 Options

1.4 System List

COSMOS

Texts from 1-1 to 1-5 in the 6560 Service Handbook

are the same as texts from 1-1 to 1-5 in the 6560

Service Manual .

Do you refer to the 6560 Service Manual ?

OK Skip Cancel

65/5560 SPECIFICATIONS 1-1 MAY.1997 © TOSHIBA CORP

2. ADJUSTMENT

2.1 TOSHIBA Supplies List

COSMOS

Text 2-1 in the 65/5560 Service Handbook is same as

text 20-2 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 ADJUSTMENT 2-1 MAY.1997 © TOSHIBA CORP.

2.2 List of Adjustment Jigs Used

COSMOS

Text 2-2 in the 65/5560 Service Handbook is same as

text 20-1in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 2-2 65/5560 ADJUSTMENT

2.3 Error Codes

When either the CLEAR PAPER( )or CALL SERVICE( ) symbol appears,press the CLEAR/

STOP and "8"keys simuitaneously and the corresponding error code will be displayed.To clear the

error code,turn off the power.

Code Machine status

E1 Paper jam inside thr copier

E2 Paper jam near fuser unit

E3 Paper remaining inside the copier when the main switch is turned on

E4 The front cover is opened during copying

E5 Paper misfeed in LCF and manual feeding and paper jam in front of the aligning roller

E8 Paper misfeed (ADD)

E9 Paper misfeed (pedestal)

EC Paper misfeed (ADF)

ED Paper misfeed in ADF transport unit

EE Paper misfeed in ADF exit/reverse unit

C3 Abnormal serial transmission between main CPU and sub-CPU

C5 The optical system will not initialise;the optical system is locked

C7 Heat roller thermistor is open-circuited,

CB ADF feed motor locked

CC ADF transport motor locked

A0 Abnormal signal transmission in PFC interface

A1 Faulty charger wire cleaning operation

A2 ADD malfunction

A3 PFC (paper feed controller) malfunction

A4 Sorter malfunction

A5 Abnormal signal transmission between main CPU and IPC

A6 Abnormal signal transmission in sorter interface

A7 Abnormal signal transmission in ADF interface

A9 Blown exposure lamp or defective AES

65/5560 ADJUSTMENT 2-3 MAY.1997 © TOSHIBA CORP.

2.4 DIP Switch/Jumper/VR Functions

(1) Logic PC board

Jumper Name When shipped Remarks

JP1

ì

JP1 UNT No jumper Jumper:Factory adjustment mode

(open) No jumper:Normal mode

Note: Replacement PC boards are supplied with the jumper

PWA-F-LGC-154/155 installed.

Be sure to cut it when replacing the PC boards.

(2) Paper feed control PC board

JP3

(TP-SG) VR FUNCTION

íí VR1

VR2 For adjustment ofthe paper width guide position of the

R61

R60

VR2

stack guide unit.

PWA-F-PFC-154/155

Note: Adjustoment procedure

Plus terminal of the tester Minus COM terminal of the tester Adjustment value VR

Aroow side of R60 JP3(TP-SG) 0~0.1V VR2

(3) Paper feed drive PC board

VR Function

R19

R40

R39

VR1 For adjustment of the PFP lower aligning value.

VR2

VR1

VR3

ë ë ë

VR2 For adjustment of the PFP middle aligning value.

VR3 For adjustment of the PFP upper aligning value.

JP25

(TP-SG)

Note: Adjustment procedure

Plus teminal of the tester Minus COM terminal Adjustment value VR

PWA-F-PFD-152 of the tester

Arrow side of R19 JP25(TP-SG) 0~0.1V VR1

Arrow side of R39 JP25(TP-SG) 0~0.1V VR2

Arrow side of R40 JP25(TP-SG) 0~0.1V VR3

MAY.1997 © TOSHIBA CORP. 2-4 65/5560 ADJUSTMENT

(4) ADF logic PC board

At power on Duning independent operation mode

DIP switch ON OFF ON OFF

1 Independent Normal mode Feeding mode Drive system

operation check mode

mode

2 Original set Original set Duplex Single-sided

PWA-F-LGC-758

by switchback by direct feeding mode feeding mode

↑ stopping

3 USA/Canada Europe Aging mode Multifeeding

version version without paper mode

4 E2PROM Normal mode Not used Not used

1 2 3 4 5 initialigation

5 Not used Normal mode 2 in 1 mode OFF

Note: The independent operation mode is performed as in the following procedure;set the DIP switch 1

to its ON position and turn on the power.Select the menu of the independent operation mode and

then open and close the jam release cover or the ADF cover.

65/5560 ADJUSTMENT 2-5 MAY.1997 © TOSHIBA CORP.

2.5 Self-Diagnosis Modes

Mode Input Definition Cleaning Display after selection

Code method

All-LEDs-lit "01" All LEDs on the control panel are lit. C/S

Aging mode "02" Aging (ADF does not operate) "09" AGING 100% 0

Test mode "03" Motor test and input/output check "09" TEST MODE C 100% C

Test mode "04" Motor test and input/output check "09" TEST MODE C 100% C

Adjustment "05" Adjustment of items "09" TEST MODE A 100% A

mode

Forced ready "06" Forced entry of ready mode

mode

Aging mode "07" Aging (includes ADF) "09" AGING 100% 0

Setting mode "08" System switchover and setting of each "09" TEST MODE D 100% D

priority mode,PM counter,etc.

Note: To access the desired diagnostic mode,turn on the power switch while pressing the appropriate

keys.

<Procedure>

•All-LEDs-lit mode(01):

0 1 / PWR → All LEDs light → C/S → Exit

•Aging mode(02 or 07):

0 2 / PWR ↑ → Aging → C/S → 0 9 →Exit

( 0 7 ) PRINT ←

•Test mode(03 or 04)

For these test modes,refer to 2.5.1 and 2.5.2.

•Adjustment mode(05):

For this mode,refer to"2.5.3 Adjustment Mode".

•Forced ready mode(06):

PWR → 0 6 → Forced ready

Note:This mode is for checking the paper feeding operation only.

•Setting mode(08):

For this mode,refer to"2.5.4 Setting mode".

Note: C/S : Press the CLEAR/STOP key

PWR : Turn on the power switch

INT : Press the INTERRUPT key

E/S : Press the ENERGY SAVER key

MAY.1997 © TOSHIBA CORP. 2-6 65/5560 ADJUSTMENT

Quick reference chart for self-diagnostic mode

Power On

"02" "07"

"01" (With ADF) "03/04" "05" "08"

*2

"C"

All the displays on Adjustment

Warming up the control panel llt

Aging Test mode mode Setting mode

"P" "C" "09" "09" "09"

"06"

Stops momentarily "05"

Standby

*1

*1: In case of "05"+

"P":PRINT key on. power on only

"C":CLEAR/STOP key on. *2: Copies cannot be made

65/5560 ADJUSTMENT 2-7 MAY.1997 © TOSHIBA CORP.

2.5.1 Input Signal Check (03/04)

In the "03" or "04" test mode, the following input signal conditions can be checked by pressing the

appropriate keys.

lWhen automatic exposure is selected

Indicator Copy-size LED Original-size LED

key LED UNIVERSAL/ UNIVERSAL/

Operation A4/LD A3/LG B4/LT A5/ST A4/LD A3/LG B4/LT A5/ST

OTHER OTHER

TNR-HOP-SW BVD1 ∗ BVD2 ∗ WP ∗ CD ∗ DEV-SW CLN-M-SW L-DOOR-SW

(1)key Opened Battery Battery's Write IC card Connected ON Opened

living life protect

EXIT-SW T-FUL-SW

(2)key Paper Toner full

loaded

CNT(JPI) R-DOOR-SW CTRSIG DF-CNT

(3)key Connected Opened Connected Connected

TNR-EMP-SW CLN-T-SW APS-C APS-F HOME-SW LNS-SW APS-STR-SW MRR-SW

(4)key Toner empty On Paper loaded Paper loaded Home Home Closed On

position position

ADD-PEM-SW GUIDE-HOME-SW ADD-STP-SW STP-HOME-SW LCFDOOR

(5)key Paper Home Paper Home Closed

loaded position loaded position

EMP2-SW TUP2-SW PSTP2-SW FEED2-SW CST2-SW

(6)key Paper Top Paper Paper loaded Cassette

loaded position loaded loaded

EMP3-SW TUP3-SW PSTP3-SW FEED3-SW CST3-SW

(7)key Paper Top Paper Paper loaded Cassette

loaded position loaded loaded

EMP4-SW TUP4-SW PSTP4-SW FEED4-SW CST4-SW

(8)key Paper Top Paper Paper loaded Cassette

loaded position loaded loaded

LCF-EMP-SW T-UP-SW P-STP-SW T-DWN-SW

(9)key Paper loaded Top position Paper Bottom

loaded position

ADD-STR-SW LCF-FEED-SW ADD-JAM-SW LCF LCFKEY M-FEED-SW

(0)key Paper loaded Paper Paper LCF loaded On Paper

loaded loaded loaded

lWhen manual exposure is selected

Indicator Copy-size LED Original-size LED

key LED UNIVERSAL/ UNIVERSAL/

Operation A4/LD A3/LG B4/LT A5/ST OTHER A4/LD A3/LG B4/LT A5/ST OTHER

DF-OPN-SW TURN-SNS SIZE-SNS EMP-SNS REG-SNS

(1)key COVER-SW Paper Paper Paper Paper

Opened loaded loaded loaded loaded

Note:*:Only for machines which have an optional IC card installed

<Procedure>

0 3 → PRINT → EXP → Digital key → PWR OFF →0 9

↑

PWR (To clear)

Note: 03 →With initialization before test mode is entered

(

04 →Without initialization

ORIGINAL COPY

A4

(LD)

• means that when the particular key is pressed and the

A3

(LG) condition shown exists,the LED will light.(Input signal is "H" level)

B4 • means that the LED does not light if the condition shown

(LT)

exists.(Input signal is "L"level)

A5

(ST)

UNIVERSAL

(OTHER)

MAY.1997 © TOSHIBA CORP. 2-8 65/5560 ADJUSTMENT

2.5.2 Output Signal check (03/04)

In the "03"or"04"test mode,the folloeing output signal conditions can be checked by entering appropiate

codes.

Code Function Stop code Code Function

1 DRM-MOT ON 11 OFF 30 HV-M ON/OFF

*1 2 FED-MOT ON 12 OFF (Main charger output)

3 RGT-MOT ON 13 OFF 31 HV-TR ON/OFF

4 HTR-MOT ON 14 OFF (Transfer charger output)

5 DEV-MOT ON 15 OFF 32 HV/AC ON/OFF

6 TNR-MOT ON 16 OFF (Transfer charger output)

7 OPT-FAN-MOT HIGH 17 LOW 33 EXP-LAMP ON/OFF *8

8 EXIT-FAN-MOT HIGH 18 LOW 34 GBIAS ON/OFF

9 AUG-MOT ON 19 OFF (Transfer bias output)

41 ADD-FED-MOT ON 51 OFF 35 PRE-TR-C4 ON/OFF

42 ADD-RGT-MOT(Stack) ON 52 OFF 37 SCRP-SOL ON/OFF

43 ADD-RGT-MOT(Feed) ON 53 OFF 38 MANUAL-SOL ON/OFF

Group1

61 PD-MOT ON 71 OFF 48 ADD-SOL ON/OFF

*2 62 FD2-CLT 49 GATE-SOL ON/OFF

FD3-CLT ON 72 OFF 81 ADF-FEED-MOT(CW) ON/OFF

FD4-CLT 82 ADF-FEED-MOT(CCW) ON/OFF

*2 63 RGT2-CLT 83 ADF-CLU ON/OFF

Group3

RGT3-CLT ON 73 OFF ADF-BELT-MOT(CW)

RGT4-CLT 84 ADF-CLU ON/OFF

65 DEV-FAN ON 75 OFF ADF-BELT-MOT(CCW)

67 BTM-FAN HIGH 77 LOW 85 ADF-FEED-MOT(CCW) ON/OFF

68 CH-FAN ADF-BELT-MOT(CW)

ON 78 OFF

HTR-FAN ADF-CLU

86 STP-SOL

*3 20 SCN-MOT FLP-SOL ON/OFF

21 LNS-MOT ADF-CLU

22 MRR-MOT BRKE

23 CLN-MOT

24 DCM-MOT

Group2

25 CLN-TR-MOT Changes direction

*4 26 TRAY-MOT(LCF) each time the PRINT

*5 45 STOP-MOT key is pressed.

*6 46 GUIDE-MOT

*7 64 TR2-MOT(PFP)

TR3-MOT(PFP)

TR4-MOT(PFP)

*1 The feed motor will rotate in the direction appropriate for the cassette loaded at the time of the output signal

check.

*2 For FD2~4-CLT and RGT2~4-CLT,the clutch appro priate for the cassette loaded at the time of the output signal

check will be driven.

*3 The scanning motor will run at the correct speed for the reproduction ratio selected(and displayed)at the time of

the output signal check.

*4 The tray motor moves the tray up when the PRINT key is pressed once,and is turned off when the tray-up switch

is turned on.When the PRINT key is pressed a second time,it moves the tray down and is turned off when the

tray-down switch is turned on.

*5 The length guide motor performs initalisation when the PRINT key is pressed once.When the PRINT key is

pressed a second time, it moves the paper length guide to the widest setting position and then is turned off.When

the PRINT key is pressed a third time,it moves the paper length guide in for a narrow setting and is turned off

when the length guide home switch is turned on.

*6 The width guide motor widens the paper width guide when the PRINT key is pressed once and is turned off when

the width guide home switch is turned on.When the PRINT key is pressed a second time,it narrows the paper

width guide until the A4-R size position and then is turned off.When the PRINT key is pressed a third time,it,widens

the guide until the A3 size position and is turned off.

*7 For TR2 to 4-MOT,the motor appropriate for the cassette loaded at the time of output signal check is chosen.When

the PRINT key is pressed once, the motor moves the tray up and is turned off when TUP2 to 4-SW is turned

on.When the PRINT key is pressed a second time,it moves the tray down and is turned off after a set time lag.

*8 The exposure lamp stays on for 5 sec.and then goes off automatically.

65/5560 ADJUSTMENT 2-9 MAY.1997 © TOSHIBA CORP.

<Procedure>

Group(1)

0 3 / 0 4 Operation Stop

↓→ Code → PRINT → → → PRINT →0 9 → Warm-UP

PWR (ON) Code

Group(2)

0 3 / 0 4 ↓ ↓→ PRINT Operation → C/S → Test mode standby

→ Code →

PWR (one-way) → 0 9 → Warm-up

Group(3)

Test mode

0 3 / 0 4 Operation Operation → C/S → standby

↓→ Code ↓→ PRINT → → PRINT →

PWR (ON) (OFF) → 0 9 → Warm-up

MAY.1997 © TOSHIBA CORP. 2-10 65/5560 ADJUSTMENT

2.5.3 Adjustment Mode (05)

In this mode,the following adjustment items can be corrected or changed(see the Adjustment Code

List for "05"Mode). To access this code,turn on the power while pressing the "0"and"5"keys.

Adjustment item Code Keys to adjust with keys to store with Remarks

Auto-toner sensor 0 Zoom keys INTERRUPT See 2.6 for details.

Exposure 1~10 Digital keys/ INTERRUPT See 2.7 for details.

14~17 ZOOM keys

*Automatic adjustment 49 Not needed Not needed See 2.7 for details.

for exposure

HVT output 38~40,41,44 ZOOM keys INTERRUPT See 2.10 for details.

Registration 53~58 Digotsl keys INTERRUPT See 2.8.5 for details.

Other adjustment Except for Digital keys INTERRUPT Refer to Adjustment

above codes code list

<Procedure>

0 5

↓ → Code → PRINT → ADJUST → INT → E/S →0 9

PWR ↑

Memory set Test copy Exit

∗ 0 5

→ 49 → PRINT → Automatic adjustment →0 9

PWR for automatic exposure

Exit

65/5560 ADJUSTMENT 2-11 MAY.1997 © TOSHIBA CORP.

Adjustment Code List ("05")

Code Name Allowable Initial Contents

No. Input values Value*

0 Auto-toner sensor 0~255 128 •The larger the value,the larger the sensor output,

•About 3 minutes after this mode has been started,this

value changes automatically to make the sensor output

2.45V~2.55V.

1 Manual exposure(100%) 0~255 128 •The larger the value,the lighter the image.

•The adjustment sequence must be

2 Manual exposure(154%) 0~255 128 1→2→3→4→5→6→7→8→9→10.

3 Manual exposure(50%) 0~255 128

4 Manual exposure(200%) 0~255 128

5 Manual exposure(100%) 0~255 128

6 Manual exposure(154%) 0~255 128

7 Manual exposure(50%) 0~255 128

8 Manual exposure(200%) 0~255 128

9 Allowable exposure step 0~255 128 The larger the value,the lighter the light range.

range(light)

10 Allowable exposure step 0~255 128 The smaller the value,the darker the dark range.

range(dark)

14 Manual photo exposure 0~255 128 •The larger the value,the lighter the image.

(100%) •The adjustment sequence must be 14→15→16→17.

15 Manual photo exposure 0~255 128

(154%)

16 Manual photo exposure 0~255 128

(50%)

17 Manual photo exposure 0~255 128

(200%)

20 Aligning roller speed 0~15 10 Each time the numerical value is increased by "1",the

adjustment reproduction ratio in the movement direction increases

by approximately 0.15%.

Range;-1.17%(reduction)to +1.05%(enlargement)

21 Drum speed adjustment 0~15 12 Each time the numerical value is increased by"1",the

reproduction ratio in the movement direction increases

by approximately 0.10.

Range:-0.77%(reduction)to +0.69%(enlargement)

22 Heat roller speed adjustment 0~15 8 Each time the numerical value is increased by"1",the

heat roller motor speed increases by 0.06%.

Range:-0.75%(reduction)to +0.71%(enlargement)

25 Leading edge of image shift 0~15 8 Each time the numerical value is increased by "1",the

(100%) image shift moves 0.5mm toward the trailing edge of

the paper without changing the position of the image

26 Leading edge of image shift 0~15 8 relative to the paper.

(200%)

27 Leading edge of image shift 0~15 8

(50%)

28 PFP motor speed 0~15 8 Motor ratings can be adjusted by the following ranges:

0:-1.19% 1:-1.03%

2:-0.88% 3:-0.73%

---------- ----------

---------- 13:+0.76%

14:+0.91% 15:+1.06%

*The initial value means the one that is set by the BC-RAM initialize program, and does not mean the one set at the

factory before shipment.

MAY.1997 © TOSHIBA CORP. 2-12 65/5560 ADJUSTMENT

Code Name Allowable Initial Contents

No. Input values Value

30 Leading edge of edge 0~15 8 Each increase by "1" will move the edge erasing position

erasing or the leading (trailing) edge of the paper 0.5mm toward

the trailing edge of the paper.

31 Trailing edge of edge erasing 0~15 8

32 Editing position adjustment 0~15 8 Each increase by"1"will move the editing position 0.5mm

(100%) toward the trailing edge of the paper(feed

side).Adjustment should be made in the order of

33 Editing position adjustment 0~15 8 32→33→34.

(200%)

34 Editing position adjustment 0~15 8

(50%)

35 Leading-edge void adjust- 0~15 8 Each time the numerical value is increased by"1",only

ment the void moves 0.5mm toward the trailing edge of the

paper.

36 Trailing-edge void adjust- 0~15 8

ment

38 Main charger output 0~255 128 The larger the value,the higher the output.(Not

necessary to adjust)

39 High-voltage transformer 0~255 128 The larger the value,the higher the output.

(transfer)output

40 High-voltage transformer 0~255 128 The larger the value,the higher the output.

(separation/developer bias)

output

41 Pre-transfer discharger 0~255 128 The larger the value, the higher the output.

transformer output

42 Main charger output 0~255 205 When the numerical value is increased, the output

(photo mode) increases

44 Separation DC output 0~255 185 The lager the value, the higher the separation DC

welghted output.

45 LCD contrast adjustment 0~255 150 The larger the value, the brighter the LCD panel.

49 Automatic adjustment for - - Automatically adjusts the automatic exposure based on

automatic exposure the manual exposure.

53 Registration(LCF/100%) 0~15 8 Each time the unmerical value is increased by "1",the

image advances approximately 0.8mm toward the

54 Registration(LCF/200%) 0~15 8 leading edge.The adjustment sequence is

53→54→55→56→57→58.

55 Registration(LCF/50%) 0~15 8

56 Registration(manual/100%) 0~15 8

57 Registration(PFP/100%) 0~15 8

58 Registration(ADD/100%) 0~15 8

60 Lens position(100%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

61 Mirror position(100%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

65/5560 ADJUSTMENT 2-13 MAY.1997 © TOSHIBA CORP.

Code Name Allowable Initial Contents

No. Input values Value

62 Lens position(200%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

63 Mirror position(200%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

64 Lens position(50%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.2mm toward the

enlargement direction.

65 Mirror position(50%) 0~99 50 Each time the numerical value is increased by "1",the

lens moves approximately 0.1mm toward the

enlargement direction.

68 Automatic adjustment of – – Remove all of the paper from the LCF and PFP cassettes

remaining paper quantity when the adjustment is performed.

indication(no paper loaded)

69 Automatic adjustment of – – Install 4,000 sheets of paper in the LCF and the 500

remaining paper quantity sheets of paper in each of the PFP cassettes when the

indication( paper loaded) adjustment is performed.

70 Remaining paper quantity 0~31 3 These adjustments are made manually when the

indication(LCF/no paper remaining paper quantity becomes down to half or less.

loaded) After the adjustment of code 68 is performed,conduct

these adjustments if necessary.

71 Remaining paper quantity 0~31 2 In case the variational ratio of the remaining paper

indication(upper cassette quantity indication is slower than the decrease ratio of

/no paper loaded) the actual quantity of sheets of paper,increase the

numerical value.

72 Remaining paper quantity 0~31 2 (Example)When" "symbol suddenly changes to

indication(middle cassette/ " "symbol.

no paper loaded)

73 Remaining paper quantity 0~31 2

indication(lower cassette/

no paper loaded)

74 Remaining paper quantity 0~31 4/3** These adjustments are made manually when more than

indication(LCF/ paper half of the paper remains.After the adjustment of code

loaded) 69 is perfomed,conduct these adjustments if necessary.

In case the remaining paper quantity indication is

75 Remaining paper quantity 0~31 2/3** displayed as greater than the actual quantity of sheets

indication(upper cassette of paper,increase the numerical value.

/paper loaded) (Example)" "symbol should be actually displayed,but

" "symbol is displayed.

76 Remaining paper quantity 0~31 4/8** **LT series/A4 series

indication(middle cassette/

paper loaded)

77 Remaining paper quantity 0~31 7/3**

indication(lower cassette/

paper loaded)

79 Carriage control of the 0~2 – 0:Normal control

leading edge of the image 1:To slow down the acceleration to the leading edge of

the image.

2:To increase the pre-scanning amount to the leading

edge of the image.

80 Aligning value(LCF) 0~15 8 Each time the numerical value is increased by"1",the

amount of slack increases by approximately 1.9 mm.

81 Aligning value(manual) 0~15 8

82 Aligning value(PFP) 0~15 7

83 Aligning value(ADD) 0~15 7

84 ADF aligning value(1st 0~15 8 Each time the numerical value is increased,the original

page) moves toward the paper feed side.

85 ADF aligning value(2nd 0~15 8 Each time the numerical value is increased,the original

page) moves toward the exit side(original stopper side).

**Europe (A4 series) / U.S.A. and Canada (LT series)

MAY.1997 © TOSHIBA CORP. 2-14 65/5560 ADJUSTMENT

Code Name Allowable Initial Contents

No. Input values Value

86 Aligning value 0~15 7 Each time the numerical value is increased by "1", the

(long size paper/upper cassetle) amount of slack increases by approximately 1.9 mm.

87 ADF aligning value 0~15 8 Each time the numerical value is increased, the gap

(2in1 original gap) between originals increases.

88 ADF leading edge position 0~15 8 Each time the numerical value is increased, the original

(in 2in1 mode) shifts to the paper supply side on the copier (that is,

moves away from the original stopper). This is carried

out after adjustment "87"(ADF aligning value).

90 Auto-toner sensor 0~255 128 The auto-toner adjustment value is indicated.

adjustment value This value can be changed.

99 Real-time clock adjustment 0~63 0 0~31 :Negative calibration:Max.-5.35sec./month/step

32~63:Positive calibration:Max.+10.7sec./month/step

0,32 :Correction deactivated

65/5560 ADJUSTMENT 2-15 MAY.1997 © TOSHIBA CORP.

2.5.4 Setting Mode (08)

In thismode, the various special modes listed in the Setting Code List can be set or changed.

<Procedure>

0 8

↓ → Code → PRINT → Ste/change → INT → 0 9

PWR a value

Memorize Clear

Code Name Allowable Initial Contents

No. Input values Value*

0 Date/time input 13digits - Year/month/date/day/hour/minute/second

1 Date indication 0~3 2 (Example)0:5/25 1:25/5 2:25.May 3:25.May

2 Time indication 0,1 0/1** (Example)0:15:30 1:PM 3:30

4 Auto sort mode 0~3 0 The sort mode is selected automatically when the

original is placed on the ADF.

0: Deactivated

1: Staple sort

2: Sort

3: Group

5 Automatic duplex mode 0~3 0/1** The duplex mode is selected automatically when the

original is placed on the ADF.

0: Deactivated

1: (single-sided to dual-sided) is selected

2: (dual-sided to dual-sided) is selected

3: (dual-sided to single-sided) or (single-sided to dual-

sided) is selected according to the message.

6 Setting temperature of the 0~15 0 0:200°C 1:197°C 2:199°C 3:200°C 4:202°C 5:204°C

heat-roller surface 6:206°C 7:208°C 8:210°C 9:212°C 10:214°C 11:216°C

12:218°C 13:221°C 14:223°C 15:224°C

∗Never set to a value of 8 or more.

7 Access control mode active 0~2 0 0: Access control mode deactivated

1: Access control mode activated(copier)

2: Access control mode activated(IC card)

8 Version change 0~2 0/1** 0: EUR(A4/A3/FOLIO),1:UC(LT/LD)

2: JPN(A4/B4)

9 Actual-size reproduction 0,1 0 0: 100%,1:101%

ratio

10 Timer mode 0~10 3 If there is no control panel operation during the ready

status for a certain length of time as shown below,the

copy-mode automatic resetting function is performed.

Resetting operation start time is:

1: 15 sec.,2: 30 sec.,3: 45 sec.,4: 60 sec.,-----

10: 150 sec.

0: Deactivates the copy-mode automatic resetting.

11 Auto power saving 0~12 0/3** Auto power saving operates n minutes after ready status

is reached.The functions are:

0: Deactivated

1: After 5 minutes

2: After 10 minutes

n: After n ×5 minutes

12 MAX9 0~2 0 Copy quantity

0: max.999,1:max.9,2:max.99

13 Paper-feed retrial 0,1 0 0: Feed-retrial mode

1: No-feed-retrial mode

*** 14 Cassette priority selection 0~4 1 0: A4/LT priority

1: LCF priority

2: Upper cassette priority

3: Middle cassette priority

4: Lower cassette priority

*The initial value means the one that is set by the BC-RAM initialize program, and does not meaus the one set at the factory

before shipment.

**Europe(A4 series)/U.S.A.and Canada(LT series)

***This selection is made only when the FC key is pressed or when auto-resetting works.

MAY.1997 © TOSHIBA CORP. 2-16 65/5560 ADJUSTMENT

Code Name Allowable Initial Contents

No. Input values Value

15 Exposure priority selection 0~2 0 0: Auto exposure priority

1: Manual exposure priority

2: Photo exposure priority

3: Toner save priority

16 A3 double count 0,1 0 0: Single count

1: Double count

17 Manual-feed auto-start 0,1 0 0: PRINT key starting

1: Auto-start

18 ADF mode selection 0,1 0 0: ADF mode

1: SDF mode

19 Sort mode selection 0~3 0 The mode selected when power is turned ON

0: Non sort

1: Staple sort

2: Sort

3: Group

20 Edge erasing priority 0~2 0 0: Deactivated

selection 1: Edge erasing priority

2: Automatic edge erasing priority

21 Automatic cassette 0,1 1 0: Deactivated

selection 1: Activated

22 APS priority selection 0,1,2 1 0: Deactivated

1: APS priority

2: AMS priority

23 Detection of manually placed 0,1 0 Detects manually placed original

original 0: Deactivated

1: Activated

24 APS start timing 0~15 5 0: 0 sec.,1: 100 msec,2: 200 msec

n: n×100 msec

27 ADF¥APS mode 0,1 0 0: Detection of every sheet of paper

1: Detection of only the first sheet

31 Paper size(LCF) 0~15 3/4** 1: A5-R 2: ST-R/B5

3: LT 4: A4

32 Paper size(upper cassette) 0~15 6/7** 5: B5-R 6: LT-R

7: A4-R 8: Sheet insertion

33 Paper size(middle cassette) 0~15 11/14** 9: Cover seet 10: COM/FOLIO

11:LG 12: B4

34 Paper size(lower cassette) 0~15 13/4** 13: LD 14: A3

**LT series/A4 series

38 Upper heater setting during 0~9 0 0: 190°C 5: 160°C

energy saving 1: Heater off 6: 170°C

2: 130°C 7: 180°C

3: 140°C 8: 190°C

4: 150°C 9: 200°C

39 Selection of paper size 0: Enabled

enabled by cassette key 0~2 0 1: Not allowed

2: Cover sheet and sheet insertion only enabled

43 Resettable counter display, 0~3 0 0: Deactivated

original counter display 1: Resettable counter only displayed

2: Original counter only displayed

3: Resettable counter and original counter displayed

46 Toner save mode 0.1 1 0: Deactivated

1: Selectable with IMAGE/PHOTO Key

2: Activated

**Europe(A4 series)/U.S.A.and Canada(LT series)

65/5560 ADJUSTMENT 2-17 MAY.1997 © TOSHIBA CORP.

Code Name Allowable Initial

No. Input values Value Contents

50 Paper retry counter 0~999,999 000000

53 Exposure burnout detection 0~2 0 0: Activated at all times

1: Activated only at automatic exposure

2: Deactivated

56 Auto shut-off 16/12** Auto shut-off to force when it was left for a following

0~16/0~15** contorol time (Same OFF state as weekly Timer)

0:3 1:5 2:10 3:15 4:20 5:25

6:30 7:40 8:50 9:60 10:70

11:80 12:90 13:100 14:110 15:20

16:150 17:180 18:210 19:240(min)

20: ∞

69 PM counter setting value 0~999,999 0 Other than 0: PM call when set value ≤ Copy count

(Total) (code"79")

79 Current PM counter value 0~999,999 0 Current copy quantity

(Total)

80 Telephone number 14 digits 0 Telephone numbers of up to 14 digits can be

entered.Use the HELP key to enter hyphens(min.).

86 LCF tray lock counter 0.1 0 0: Normal

1: LCF forced paper OFF state (LCF tray does not move)

89 C7 counter 0~3 0 Heat-roller thermistor breakdown counter

0~2:Normal operation

3:Copier does not operate

91 Copy counter of unit 0~999,999 000000

~97

Code Unit name

NO.

91 ADD

92 ADF

93 SBF

94 LCF

95 Upper cassetle(PFP)

96 Middle cassetle(PFP)

97 Lower cassetle(PFP)

98 The setting value of the drum ∗1 0~15 0:800V 1:830V 2:840V 3:850V

4:860V 5:870V 6:880V 7:890V

surface potential 8:900V 9:910V 10:920V 11:930V

12:940V 13:950V 14:960V 15:970V

∗Never set to a value of 5 or more.

108 Error alarm 0~2 0 Changing the number of alarm sounds when an error

occurs

0: No sound

1: 5 times

2: ∞

109 Universal paper 0~14 1/9** 1 A5-R 6 FOL10 11 LT-R

2 B5 7 B4 12 LG

3 B5-R 8 A3 13 COMP

4 A4 9 ST-R 14 LD

5 A4-R 10 LT

134 TOSHIBA Rogo Display. 0~1 0 Turning on the power supply Rogo is displayed on the

Message display.

0: Display

1: No Display

135 Front access sorter 0~1 0 After the end of copying the stacked copy paper is

unloading mode pushed out into each bin.

(MG-2011) (When the MG-2011 is connected and a mode other

than the multi-stacking mode is selected)

0: Function

1: No Function

**Europe(A4 series)/U.S.A.and Canada(LT series)

MAY.1997 © TOSHIBA CORP. 2-18 65/5560 ADJUSTMENT

2.5.5 How to Register/Change ID Codes (access control mode)

COSMOS

Text 2-19 in the 65/5560 Service Handbook is same

as text 2-19 in the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook?

OK Skip Cancel

65/5560 ADJUSTMENT 2-19 MAY.1997 © TOSHIBA CORP.

Return Skip

76/7560 S/H

2.6 Auto-Toner Sensor Adjustment

At the initial machine setup or when the developer material is replaced,the auto-toner sensor needs

to be adjusted.

<Key Operation>

<Display, Supplementary Explanation>

0 5

TEST MODE A 100% A

POWER

↓

: Enter code

0

↓ Auto-toner sensor output voltage: X.XXV

↓

PRINT XXX ZZZ ←

(operation state of WAIT 100%

ò

developer, drum, etc.) Numerical value corresponding

to auto-toner adjusting value

After about two minutes, "XXX" and "ZZZ" automatically

start to change. Then the following is displayed:

ò Stops changing

↓

↓

XXX ZZZ

ADJUST MODE 100%

↓

ZOOM Adjust so that "XXX" on the display panel is within the

permissible range only when outside of range 245 to 255.

XXX ZZZ

ZOOM UP key Increases Increases

ZOOM DOWN key Decreases Decreases

* Auto-toner sensor output range: 2.45 to 2.55V

↓

INT

(developer, drum, TEST MODE A 100% A

etc. stop)

↓

0 9 : Cancel adjustment

mode.

MAY.1997 © TOSHIBA CORP. 2-20 65/5560 ADJUSTMENT

Return Skip

76/7560 S/H

2.7 Exposure Adjustment

At the initial machine set-up or when the light distribution is adjusted, the exposure needs to be

adjusted. Adjustment must be also performed in accordance with any special request of the user.

Adjustment order

Manual exposure Automatic adjustment

Manual exposure Automatic exposure

of automatic exposure

100% → 154%→50%→200% → 50∼ 200% → 100% →154% →50% →200% → C1

(1) (2) (3) (4) (49) (5) (6) (7) (8)

Manual photo

Light gradataion Dark gradation exposure Manual photo exposure

→ → → →

154% →50%→ 200%

C1 100%

100% 100%

(9) (10) (14) (15) (16) (17)

Note: In the dotted-line squares are the adjustment to be performed according to any special request of the user.

1) Setting of the exposure electric potential output value

Adjust the above items by following the procedures below using the operation keys while comparing

adjustment values stored to memory for each item and copies made under those conditions.

<Key Operation> <Display,Supplemntary Explanation>

0 5

TEST MODE A 100% A

POWER ↑

∗→ ↓

·Code becomes "ZZZ"according to the entire

code.

DEGITAL KEYS ·The order of above adjustment is fixed.

Currently stored adjustment value

↓

PRINT YYY ZZZ

ADJUST MODE XXX%

code # XXX

1,5,11 100 Newly entered adjustment values (default: YYY)

2,6,12 154 ·To darken: value smaller than YYY

↓ 3,7,13 50 ·To lighten: value larger than YYY

4,8,14 200

ZOOM : Adjustment 9,10 Any value

[numerical keys] Adjustment of variable step exposure (codes #9 and 10) are

not related with the copy reproduction ratio.

Values "ZZZ" are stored in BC-RAM in place of "YYY"

↓

INT

TEST MODE A 100% A

↓

ENERGY SAVER : Output test chart COPYING 100% A

*1: You can make only single-sided copies. (You cannot make dual-

sided copies.)

→ To readjust, go to∗ *2: Test copies can be made immediately after starting the test mode.

When outputing this test chart, match to the desired reproduction

ratio and exposure conditions for adjustment.

↓

: Cancel adjustment

0 9 mode.

65/5560 ADJUSTMENT 2-21 MAY.1997 © TOSHIBA CORP.

Return Skip

76/7560 S/H

2) Automatic exposure adjustment

• Adjust manual exposure (100%), and then carry out automatic exposure adjustment.

• Place a blank sheet of A3 paper on the original glass, and close the ADF with the original aligned

against the original scale.

• After completing the above preparations, follow the procedure below to automatically adjust.

<Key Operation>

<Display, Supplementary Explanation>

0 5 TEST MODE A 100% A

POWER

↓

49 : Enter code Adjustment values for the

reproduction ratio displayed

at XXX are displayed.

↓

: Start of automatic YYY

PRINT adjustment ADJUST MODE XXX%

During automatic adjustment,

display changes as follows:

↓ 100->154->50->200

Display returns to test

mode, and automatic

adjustment ends

TEST MODE A 100% A

↓

: Cancel adjustment

0 9 mode.

MAY.1997 © TOSHIBA CORP. 2-22 65/5560 ADJUSTMENT

Return Skip

76/7560 S/H

2.8 Adjustment of Drum/Aligning Roller/Heat Roller Speed,Aligning Value,Registration,Leading

Edge of Edge Erasing,Trailing Edge of Edge Erasing,Leading Edge of Image Shift, Editing

Position,Leading-Edge Void and Trailing-Edge Void.

<Adjustment procedure>

Aligning roller

Drum speed Heat roller speed Aligning value

→

speed

→ → LCF Manual PFP ADD

→

→ → →

(21) (20) (22) (80) (81) (82) (83)

Leading edge of edge erasing Leading edge of Editing position Leading edge void

Registration

→

Trailing edge of edge erasing

→

image shift

100% 200% 50%

→ 100% 200% 50%

→ Trailing edge void

→ → → →

(53) ~ (58) (30) ~ (31) (25) (26) (27) (32) (33) (34) (35)→(36)

(Note) In the dotted-line squares are the items which normally do not require adjustment.

Follow the procedure below to adjust each of the adjustment value so that the measured values

obtained from the test chart satisfy the specifications. Immediately after starting test mode "05",

only single-sided test charts (normal copies) can be output with the ENERGY SAVER key.

<Key Operation> <Display,Supplemntary Explanation>

0 5

TEST MODE A 100% A

POWER

∗→ ↓ Adjustment value stored

Copy mode key : Set the copy mode using the to BC-RAM

paper size, original size and Selected code #

cassette keys.

↓ YYY ZZ

ADJUST MODE XXX%

DEGITAL KEYS

Preset copy reproduction ratio

Adjustment Code Adjustment Item

PRINT 20~22,30~34 Edge erasing, Aligning value,

80~84 etc

53~58 Registration

(100%)

25~27 Leading edge of image shift

35 Leading edge void

↓

: Enter adjustment 36 Trailing edge void

DEGITAL KEYS value

↓

: Value ZZZ is stored in New adjustment value displayed

INTERRUPT place of value YYY.

YYY ZZZ

ADJUST MODE XXX%

↓

ENERGY SAVER : Output test chart TEST MODE A 100% A

→ To readjust, go to ∗

COPYING 100% A

↓ *1: You can make only single-sided copies. (You cannot make dual-

: Cancel adjustment sided copies.)

0 9

mode. *2: Test copies can be made immediately after starting the test mode.

When outputing this test chart, match to the desired reproduction

ratio and exposure conditions for adjustment.

65/5560 ADJUSTMENT 2-23 MAY.1997 © TOSHIBA CORP.

2.8.1 Drum Speed Adjustment AJ:Codes 21

2.8.2 Aligning Roller Speed Adjustment AJ:Code 20

2.8.3 Heat Roller Speed Adjustment AJ:Code 22

2.8.4 Aligning Value Adjustment AJ:Code 80~83

2.8.5 Registration Adjustment AJ:Codes 53 to 58

2.8.6 Leading Edge of Edge Erasing, Trailing Edge of Edge Erasing AJ: Code 30, 31

2.8.7 Leading Edge of Image Shift AJ: Code 25 to 27

2.8.8 Editing Position (adjusting trimming and masking) AJ: Code 32 to 34

2.8.9 Leading-Edge Void and Trailing-Edge Void AJ: Code 35, 36

COSMOS

Texts from 2-24 to 2-33 in the 65/5560 Service

Handbook are the same as texts from 2-24 to 2-33 in

the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 2-24 65/5560 ADJUSTMENT

Return Skip

76/7560 S/H

2.9 Automatic Adjustment of Remaining Paper Quantity

(1) Before automatic adjustment, prepare following the instructions in the following table.

Code 68 (no paper) 69 (paper)

PFP Remove all paper Place 500 sheets of paper in all PFP cassettes, and 4,000 sheets

LCF in the LCF and PFP. of paper in the LCF. (The LCF elevator must be lowered as far as

possible.)

(2) Set the PFP cassettes in the copier, and mount the LCF. Then, close the LCF door.

(3) Follow the procedure below to carry out automatic adjustment.

<Operation Keys> <Display, Supplementary Explanation>

0 5

POWER TEST MODE A 100% A

↓

DEGIAL KEYS : Enter code.

↓

PRINT : Automatic adjustment starts. The paper selection LED flashes during automatic

adjustment.

* Automatic adjustment does not start if a cassette or LCF is not properly in place, or the

LCF door is open.

Paper selection

display

End of Automatic Adjustment

TEST MODE A 100% A

Successful : Paper selection display lights.

Error : Paper selection display flashes, and automatic adjustment must

be carried out again.

↓

C/S : Ended.

Note: Before carrying out automatic adjustment by code 69, the user must set the paper (type and size)

in actual use in the PFP and LCF.

MAY.1997 © TOSHIBA CORP. 2-34 65/5560 ADJUSTMENT

2.10 Check/Adjustment of High-voltage Transformer

When replacing the high-voltage transformer,check and adjust the main charger,transfer

charger,separation charger,and developer bias voltage.

2.10.1 Check/Adjustment of Transfer Charger/Separation Charger/Pre-transfer Discharge Charger

(1) Separation

Items to Check before Adjustment

Check that the charger wire is positioned correctly and is clean. Also check that the separation

charger guide is correctly positioned.

Check that the developer unit is installed, and that the magnetic brush is in contact with the drum.

Check that the developer unit turns when a copy is being made. Check also that the toner density

is set sufficiently high.

Check that the copy paper is flat and dry.

Check that the aligning rollers rotate correctly.

Check the output of the grid (for the main charger).

Check that the transfer output is at the set value.

Check that the developer bias is appropriate.

Check that the transfer/separation charger case is earthed. Check also that the high-voltage

transformer is earthed.

CAUTIONS

(1) When pockmarks occurs:

When irregularities (pockmarks) are generated on the halftone areas, reduce the separation output.

Note:

Do not reduce the output excessively. Otherwise, the separation ability will decrease.

(2) Defective separation:

When defective paper separation occurs despite the charger wires being clean, or when the user is

likely to use a large quantity of thin paper, raise the output.

Note:

Do not increase the output excessively, otherwise pockmarks will be generated and the separation

ability will decrease.

65/5560 ADJUSTMENT 2-35 MAY.1997 © TOSHIBA CORP.

(2) Adjustment Procedure

Remove the developer unit, release the cleaning blade, and install the drum jig on the cleaner unit

and set on the copier.

*The jig earth lead must be fixed to the copier frame.

Connecting and Setting the Digital Tester

Transfer Separation Pre-transfer

Setting Range DC200mV AC200mV DC200mV

(-) COM terminal Pin 3 of jig (black cable)

Connection

(+) Terminal Pin 1 of jig (red cable)

Drum jig (current measuring jig)

Red cable

Earth fixture Drum jig

Flow-in measurement connector

(+)terminal

Black cable

(-)COM terminal

Digital tester

MAY.1997 © TOSHIBA CORP. 2-36 65/5560 ADJUSTMENT

Follow the adjustment procedure below.

<Key Operation> <Display, Supplementary Explanation>

0 5 TEST MODE A 100% A

POWER

∗→

↓

0 : Enter code Currently stored adjustment value

Newly entered adjustment value

↓ ↓ (default:XXX)

→

XXX YYY ZZ

↓ ADJUST MODE 100% Selected code #

PRINT

↓

: Adjust so that display voltage of the digital

ZOOM tester satisfies the values in the following table.

Digital tester

Adjustment code Item (adjustment standard voltage value)

39 Transfer DC -78~ -88mV

RMS AC 133~ 151mV

40 Separation

AVG AC 127~ 144mV

41 Pre-transfer DC 40~ 56mV

↓

INT Value YYY is stored in place of value XXX.

→ To readjust, go to ∗

↓

: Cancel adjustment

0 9 mode.

65/5560 ADJUSTMENT 2-37 MAY.1997 © TOSHIBA CORP.

2.10.2 Check/Adjustment of Main charger/Separation DC

Remove the developer unit.

In the case of main charger: the digital tester must

be connected as follows:

• Setting Range 1,000 VDC

• (+)terminal Connect to main charger rail.

• (-)terminal Fix earth to the copier frame.

Follow the procedure below to adjust. (+) terminal

<Key Operation> <Display, Supplementary Explanation>

0 5 TEST MODE A 100% A

POWER

∗→

↓

Main Charger 38

DEGITAL KEYS : Enter code. Separation DC 44

↓ ↓

XX YYY ZZ

PRINT ADJUST MODE 100%

↓

ZOOM

Main Charger Adjust by the ZOOM key so that the digital tester display

voltage is within the range -780 to -800V.

Separation DC Check that XXX is 185.

If XXX is not 185, adjust the ZOOM key so that YYY is

185.

↓

INT Value YYY is stored in place of value XXX.

∗

→ To read just, go to .

↓

0 9 : Cancel adjustment mode.

MAY.1997 © TOSHIBA CORP. 2-38 65/5560 ADJUSTMENT

2.10.3 Check/Adjustment of Developer Bias

If fogging occurs all over the copy despite the fact that there is no underexposure or overtoning,

rotate VR1(white) clockwise to increase the bias output.

Note:

If the bias output is raised excessively:,

• The image contrast will deteriorate,

• Bias leaking is liable to occur,

• Carrier is liable to adhere to the drum, resulting in its becoming damaged.

• Don't touch the VR (Vdc).

Remove the developer unit and cleaner unit.

Connect the + terminal of a digital tester to the connector J73 and the - COM terminal to the frame

ground. (The selected range of the degital tester must be "DC 100V" .)

Door switch bracket Frame ground

J73

(-) COM terminal

(+)terminal

Small Large

Digital tester

VR(Vdc) VR1 for developer bias

(Blue) adjstment(White)

(3) Follow the adjustment procedure below.

<Key Operation> <Display, Supplementary Explanation>

0 5

TEST MODE A 100% A

POWER

40 : Enter code Currently stored adjustment value : Selected code #

↓ ↓

↓ XXX YYY 40

ADJUST MODE 100%

↓

(adjustment) Make sure that the voltage is 200 VDC+2V using the digital tester.

Turn VR1 if adjustment is required.

↓

INT : End

65/5560 ADJUSTMENT 2-39 MAY.1997 © TOSHIBA CORP.

2.11 Setting the Surface Potential Output Value

2.12 Automatic Drum Surface Potential and Manual Exposure Adjustment

2.13 Setting of the Exposure Electric Potential Output Value

The above mentioned functions 2.11 through 2.13 are not included with the 6560.

MAY.1997 © TOSHIBA CORP. 2-40 65/5560 ADJUSTMENT

2.14 Adjustment of Carriage Drive Belt

2.15 Image Inclination and Distortion

2.15.1 Image Inclination

2.15.2 Image Distortion

2.16 Light Distribution

2.17 Lens Position (focus) Adjustment

2.18 Adjustment of Focus and Lateral Reproduction Ratlo

2.19 Adjustment of Side Deviation in Feeding

2.20 Checking and Adjustment of the Magnetic Brush Thickness(leveler)

2.21 Drum/Sleeve Gap Adjustment

2.22 Developer-Pole Position Adjustment

2.23 Heat Roller Pressure Adjustment

2.24 Stack Guide Unit Adjustment

2.25 Adjustment of ADD Pick-Up Roller Position

COSMOS

Texts from 2-41 to 2-55 in the 65/5560 Service

Handbook are the same as texts from 2-42 to 2-56 in

the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook ?

OK Skip Cancel

65/5560 ADJUSTMENT 2-41 MAY.1997 © TOSHIBA CORP.

2.26 Adjustment of Decurler Tension Roller

The decurler unit is provided with a tension roller,

and has such a structure that four levels of tension

can be set by changing the position of the slave

roller (see the right figure).

(1) Loosen the adjustment plate fixing screwes

provided one each for the front and the rear.

Decurler Belt

(2) Fix the bush, which holds the slave roller, into

one of the grooves with carved numbers (1- Driving Gear

4) on the adjustment plate.

Note: 1.Select the same number (groove) for the

front and the rear. (Otherwise, it would

Spring

cause a skew.)

Bush Slave Roller

2.Fix the bush into the groove in such a Driving Roller

way that no opening is made between the

bush and the adjustment plate. Fixing

screw

3.The number set at the factory before

shipment is 1.

Tension Roller

(3) Tighten the adjustment plate fixing screwes Adjustment Plate

of both of the front and the rear.

MAY.1997 © TOSHIBA CORP. 2-56 65/5560 ADJUSTMENT

2.27 Change of the Paper Size

2.27.1 LCF paper size

COSMOS

Text 2-57 in the 65/5560 Service Handbook is same

as text 2-58 in the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook ?

OK Skip Cancel

65/5560 ADJUSTMENT 2-57 MAY.1997 © TOSHIBA CORP.

Return Skip

76/7560 S/H

2.27.2 PFP paper size

When shipped, the 7650/7550 is set for A4-R/LT-R in the upper cassetle,A3/LG in the middle

cassetle, and A4/LD in the lower cassetle. However,use the following procedure to change the size

if requested to do so by the user.

Mechanical change

(1) Pull out the cassetle to be changed, take out the stopper screw(1 screw each for feed and exit sides)

and then remove the cassette from the copier.

Exit side

Feed side

Stopper screw

Stopper screw

(2) Remove the cassette side walls at the front

Cassette side walls

and rear(2 screws each), move them to the

paper size marked on the cassette guides, Screws Screws

and then tighten the screws.

(3) Remove the back plate(1 screw), move it to

the paper size marked on the base frame, and

then tighten the screw. Cassette

Back plate Cassette guide

Fig. 6.2-3

(4) Slide the transparent cover for the cassette

size label to the right to remove it.

Transparent cover

(5) Replace the cassette size label with one for

the new paper size and then reinstall the

transparent cover.

(6) Slide the cassette info the copier and tighten

the 2 stopper screws.

Cassette

MAY.1997 © TOSHIBA CORP. 2-58 65/5560 ADJUSTMENT

Return Skip

76/7560 S/H

Electrical Changes

•The electrical settings must be changed according to the procedure below when mechanical changes

have been made.

•After changing the electrical settings, select the cassette that has been changed using the

CASSETTE key, and make sure that the LED for the set paper size lights.

(1) When setting by entering a code

<Key Operation> <Display, Supplementary Explanation>

0 8 TEST MODE D 100% D

Cassette Code

POWER

LCF 31

↓ Upper 32

DEGITAL KEYS : Enter the code (select the cassette) Middle 33

Lower 34

↓ ↓

↑

PRINT XX XX YY

SYSTEM MODE 100%

Setting value of selected cassette

Paper Size Setting Value Paper Size Setting Value

A5-R 1 Insert sheet 8

B5,ST-R 2 Cover 9

LT 3 FOLIO,COMP 10

A4 4 LG 11

B5-R 5 B4 12

LT-R 6 LD 13

↓

A4-R 7 A3 14

DEGITAL KEYS

: Enter the setting of the new paper size.

New setting value is displayed

↓

XX ZZ YY

SYSTEM MODE 100%

↓

INT : Store the new paper size setting value (ZZ) in the memory.

TEST MODE D 100% D

↓

0 9 :Cancel adjustment

mode.

(2) When setting by touch panel

<Key Operation>

Cassette select key : Select cassette.

↓

Program : Change to program mode selection screen.

↓

Cassette select icon : Change to cassette size specification screen.

↓

Paper size key : Press key of new paper size.

↓

END

65/5560 ADJUSTMENT 2-59 MAY.1997 © TOSHIBA CORP.

2.28 Adjustment of ADF Height

2.29 Adjustment of Image Inclination In ADF Feeding

2.30 Adjustment of Transport Force of Separation Unit

2.31 Adjustment of ADF Solenoid

2.31.1 Shutter Solenoid

2.31.2 Flapper Solenoid

2.32 APS Start Switch

2.33 Adjustment of Side Deviation in ADF Feeding

COSMOS

Texts from 2-60 to 2-65 in the 65/5560 Service

Handbook are the same as texts from 2-61 to 2-66 in

the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 2-60 65/5560 ADJUSTMENT

2.34 The Setting Temperature of the Heat-Roller Surface and the Setting Pressure of the

Heat Roller

2.35 The Adjustment of Fuser Entrance Guide

COSMOS

Texts from 2-66 to 2-68 in the 65/5560 Service

Handbook are the same as texts from 2-70 to 2-72 in

the 76/7550 Service Handbook.

Do you refer to the 76/7550 Service Handbook ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 2-66 65/5560 ADJUSTMENT

3 GENERAL DESCRIPTION

3.1 Front/Rear Vlew

3.1.1 Front Sectional View except Drive System

COSMOS

Text 3-1 in the 65/5560 Service Handbook is same as

text 2-3 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-1 MAY.1997 © TOSHIBA CORP.

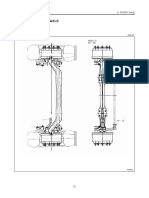

3.1.2 Front Drive System

3.1.3 Rear Drive System

3.1.4 Automatic Document Feeder (ADF) Front Sectional View

COSMOS

Texts from 3-2 to 3-4 in the 65/5560 Service Handbook

are the same as texts from 2-4 to 2-6 in the 76/7550

Service Manual.

Do you refer to the 76/7550 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-2 65/5560 GENERAL

3.2 Electrical Parts Layout

3.2.1 DC Electrical Parts (Copier)

(1) DC Electrical Parts Except Motors (Upper Unit)

COSMOS

Text 3-5 in the 65/5560 Service Handbook is same as

text 2-5 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-5 MAY.1997 © TOSHIBA CORP.

(2) DC Electrical Parts except Motors (Lower Unit)

COSMOS

Text 3-6 in the 65/5560 Service Handbook is same as

text 2-8 in the 76/7550 Service Manual.

Do you refer to the 76/7550 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-6 65/5560 GENERAL

(3) Motors

COSMOS

Text 3-7 in the 65/5560 Service Handbook is same as

text 2-7 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-7 MAY.1997 © TOSHIBA CORP.

3.2.2 AC Electrical Parts (Copier)

COSMOS

Text 3-8 in the 65/5560 Service Handbook is same as

text 2-8 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-8 65/5560 GENERAL

3.2.3 Electrical Parts of Automatic Document Feeder (ADF)

COSMOS

Text 3-9 in the 65/5560 Service Handbook is same as

text 2-11 in the 76/7550 Service Manual.

Do you refer to the 76/7550 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-9 MAY.1997 © TOSHIBA CORP.

3.3 Symbols and Functions of Electrical Parts

COSMOS

Texts from 3-10 to 3-18 in the 65/5560 Service

Handbook are the same as texts from 2-10 to 2-18 in

the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-10 65/5560 GENERAL

3.4 Wire-Harness Location Diagrams

3.4.1 Location Diagram for Upper Unit

COSMOS

Text 3-19 in the 65/5560 Service Handbook is same

as text 2-19 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-19 MAY.1997 © TOSHIBA CORP.

3.4.2 Location Diagram for Lower Unit

COSMOS

Text 3-20 in the 65/5560 Service Handbook is same

as text 2-24 in the 76/7550 Service Manual.

Do you refer to the 76/7550 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-20 65/5560 GENERAL

3.5 AC Wire-Harness Connection Diagram

COSMOS

Text 3-21 in the 65/5560 Service Handbook is same

as text 16-4 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-21 MAY.1997 © TOSHIBA CORP.

3.6 DC Wire-Harness Connection Diagram

3.6.1 Copier DC Wire-Harness Connection Diagram

COSMOS

Text 3-22 to 3-23 in the 65/5560 Service Handbook is

same as text 17-3 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-22 65/5560 GENERAL

3.6.2 ADF DC Wire-Harness Connection Diagram

COSMOS

Text 3-24 in the 65/5560 Service Handbook is same

as text 17-5 in the 76/7550 Service Manual.

Do you refer to the 76/7550 Service Manual ?

OK Skip Cancel

MAY.1997 © TOSHIBA CORP. 3-24 65/5560 GENERAL

3.7 Control Block Diagram

COSMOS

Text 3-25 in the 65/5560 Service Handbook is same

as text 17-1 in the 65/5560 Service Manual.

Do you refer to the 65/5560 Service Manual ?

OK Skip Cancel

65/5560 GENERAL 3-25 MAY.1997 © TOSHIBA CORP.

4. PERIODIC MAINTENANCE

•Inspection every 200,000 Copies

(1) Preparation

1) Ask the key operator about the present machine conditions and note them down.

2) Before starting the maintenance work, make and retain a few sample copies for later

comparison.

3) Turn off the power switch and disconnect the power cord plug.

(2) The periodic inspection should be conducted in accordance with the Periodic Inspection Check

List shown below. Perform the inspection by referring to the figures, as well as to the

explanations in the Service Manual when necessary.

(3) After the inspection has been completed, plug in the machine and turn the power switch on, and

confirm the general operation of the machine by making a few copies and comparing them to

those made previously.

•Inspection and Overhaul every 800,000 Coples

(1) Replace all the consumables.

(2) Check to see if there is any damage to parts of the driving section (gears, pulleys, timing belts, etc.).

Replace parts on principle if damaged.

(3) Check to see if there is any damage or peeling of adhered parts (tape, Mylar sheet, etc.).

Replace any affected parts.

(4) Check to see if all the switches and sensors operate properly. Replace them if they are not

operating properly.

(5) Clean the inside of the machine thoroughly.

Note: For inspection and maintenance of the PFP, remove the PFP upper aligning unit and the

PFP feed units from the copier

4.1 Perlodic Inspection Check List

Symbols used in the periodic inspection check list

Cleaning Lubrication Replacement Date

(A) Cleaning with alcohol (V) Vacuoline (100)Every 100,000 copies Customer's

(L) Launa 40 (200) Every 200,000 copies name

(P) Cleaning with heat roller

(400) Every

cleaner(RC60) Application Same thereafter Machine

Cleaning with soft pad, No.

(SI) Silicone Oil ( ) Replace in event of

cloth, or cleaner deformation or other Inspector

(W) White grease(Molycoat)

(vacuum cleaner) (M) Molytherm damage

(D) Cleaning with a slightly

Remarks

damp cloth

65/5560 PERIODIC 4-1 MAY.1997 © TOSHIBA CORP.

Periodic Inspection Check List

Clean at Lubricate at Replace Check Remarks

Area Item to check 200,000 200,000 ×1,000 while

copies copies copies on

Cleaner 1. Overall unit ¡

2. Main blade (200) *1

3. Toner bag Conducted

(100) by key

operator

4. Recovery blade ¡ ( ) *2

5. Drum bushing ¡

6. Separation claw ¡ (400) ¡ *3

7. Fur Brush (200)

7-1. Used toner-transport auger (W) *13

drive sections(front,rear)

Drum 8. Drum shaft ¡ or(A)

9. Drum (400) *4

10. Ozone filter (for the exit fan) (400)

10-1. Ozone filter (for the developer fan) (400)

Original 11. Glass ¡ or(A)

holder

Optical 12. Mirror 1 ¡

system 13. Mirror 2 ¡

14. Mirror 3 ¡

15. Mirror 4 ¡

16. Mirror 5 ¡

17. Mirror 6 ¡

18. Slit glass ¡ Both sides

19. Reflector ¡

20. Lens ¡

21. Exposure lamp ( ) ¡

22. Copy area indicator ¡

22-1. Harf tone patch ¡

23. Automatic exposure sensor ¡ ¡

24. Automatic paper-size detector ¡ ¡

25. Reproduction mechanism ¡

(mirror)

26. Reproduction mechanism ¡

(lens)

27. Slider sheet(front, rear) ¡ or (L) ( )

28. Air filter ¡ (200) *5

Charger 29. Case (D) *6

31. Charger wire (Main/transfer/ (200)( ) ¡ *6

separation)

32. Terminal contact ¡

MAY.1997 © TOSHIBA CORP. 4-2 65/5560 PERIODIC

Clean at Lubricate at Replace Check Remaks

Area Item to check 200,000 200,000 ×1,000 While

copies copies copies on

Charger 33. Charger wire cleaner (200)

(main/pre-transfeer/transfer/separation)

35. Pre-transfer guide ¡

35-1. Grid (for main charger) (200)

Devel- 36. Overall unit ¡

oper 37. Developer material (200) *7

unit 38. Front shield ¡ ( )

38-1. Oil seal (mixer shaft) *15

39. Guide roller ¡ or(A) ( )

40. Duct bottom ¡

40-1. Duct filter clean at

800,000

copies

41. Toner hopper drive worm gear (W)

Paper 42. Pick-up roller (A) (100)( ) *LCF:(200)

feed 43. Feed roller (A) (100)( ) *LCF:(200)

system 44. Separation roller (A) (100)( ) *LCF:(200)

45. Aligning roller (A) ( )

46. Paper guide ¡

47. Brush ¡ ( )

48.Transport belt ¡ ( )

49. Paper-feed system drive gears (W)

(tooth faces)

50. GCB bushings and plastic (L)

bushings

Fuser 52. Upper heat roller(Teflon roller) ¡ or(P) (400) *8

unit 53. Lower heat roller(rubber roller) ¡ or(P) (400) *8

54. Upper separation claw ¡ or(P) (400)( ) *9

55. Lower separation claw ¡ or(P) ( ) *9

56. Heat roller cleaning roller (200) *10

57. Cleaning felt roller (200) *10

58. Press roller cleaning roller (200) *10

59. Upper and lower thermistors ¡ or(P) ( )

60. Heat roller guide ¡or(P)

61. Heat roller exit guide ¡or(P)

62. Paper dust recovery bracket ¡

63. Exit roller (A)

64. Heat roller and cleaning rollers (SI)

drive gears

65. Cleaning roller bushings (SI)

65/5560 PERIODIC 4-3 MAY.1997 © TOSHIBA CORP.

Clean at Lubricate at Replace Check Remarks

Area Item to check 200,000 200,000 ×1,000 While

copies copies copies on

ADD 66. ADD pick-up roller (A) (100)( )

and 67. ADD feed roller (A) (100)( )

decurler 68. ADD separation roller (A) (100)( )

69. Transport rollers 1 to 4 (A) ( )

70. ADD aligning roller (A) ( )

71. GCB bushings and plastic (L)

bushings

72. Drive gears(tooth faces) (W)

73. ADD exit gate and ADD exit (A)

roller

73-1. Decurler belt ¡

73-2. Decurler bushings (L)

73-3. Decurler gear (W)

PFP 74. PFP pick-up roller (A) (100)( )

75. PFP feed roller (A) (100)( )

76. PFP separation roller (A) (100)( )

77. PFP aligning roller (A) ( )

78. Paper guide ¡

79. Tray drive worm wheels and (W) *11

gears(tooth faces)

80. PFP drive gears(tooth faces) (W)

81. GCB bushings and plastic (L)

bushings

ADF 82. ADF pick-up roller (A) (400)

83. ADF feed roller (A) (400)

84. ADF separation belt (A) (400)

85. Transport belt (A) (400)

86. ADF aligning roller (A)

87. ADF reverse rollers (A)

88. ADF empty sensor ¡

89. ADF aligning sensor ¡

90. ADF size sensor ¡

91. Turn guide sensor ¡

92. ADF Timing sensor ¡

LCF 93. Gears (W) *14

94. Worm and worm wheel (W) *14

95. Worm shaft (L) *14

96. Wire pulley (L) *14

97. Slit for the elevator tray (w)

Others 98. Clamshell lock section (w) *12

MAY.1997 © TOSHIBA CORP. 4-4 65/5560 PERIODIC

Front section view (upper unit)

65/5560 PERIODIC 4-5 MAY.1997 © TOSHIBA CORP.

MAY.1997 © TOSHIBA CORP.

4-6

97 :W

74 75 74 76 75 74 76 75 76 77 77

65/5560 PERIODIC

Front section view (lower unit)

Rear side view (upper unit)

65/5560 PERIODIC 4-7 MAY.1997 © TOSHIBA CORP.

80 :W

Rear side view (lower unit)

80 :W

3

MAY.1997 © TOSHIBA CORP. 4-8 65/5560 PERIODIC

84 83 88 82

89 90

86 92 85 87 91

ADF front section view

Explanation of items in the "REMARKS" column of the Periodic Inspection Check List

*1 Main blade

If poor cleaning occurs due to the adhesion of paper dust, etc. before the specified number of copies

for replacement have been reached, the edge of the blade has been damaged.

Replace the blade if necessary,while change fur brush siwuitaneously.

*2 Recovery blade

If the edge of the blade is damaged, replace the blade regardiess of the number of copies made so

far.

*3 Separation claw

If any abnormal condition (e.g. coating wear) is observed on the tip of separation claw and ifthe mark

of the separation claw is observed on the copy image, replace the claw regardless of the number of

copies made so far.

Clean the tip of the claw by lightly wiping with a dry cloth. In addition, be sure to apply patting powder

(lubricant) to the separation claw after cleaning the claw and when replacing the claw or drum.

*4 Drum

Refer to section 5.2 "Inspection and Cleaning of the OPC Drum".

*5 Air filter

If the air filter is dirty, replace it.

*6 Charger wire and case

Clearn the charger case and the charger wire with a cloth which should be soaked in water and then

squeezed tightly.

*7 Developer material

After replacing the developer material, be sure to adjust the auto-toner sensor.

*8 Upper and lower heat rollers

Refer to section 5.4 "Checking and Cleaning of the Upper and Lower Heat Rollers".

65/5560 PERIODIC 4-9 MAY.1997 © TOSHIBA CORP.

*9 Separation claws

If the tip of any of the separation claws is chipped, replace it regardless of the number of copies

made so far. If toner adhering to a separation claw is forcibly scraped off, it may be damaged.

Therefore,if the tip of the claw is heavily coated with toner, replace the claw.

*10 Cleaning felt roller, heat roller cleaning roller and cleaning felt roller

Refer to section 5.5 "Checking and Replacing of the Cleaning Felt Roller, Heat Roller Cleaning

Roller and Cleaning Felt Roller".

*11 Tray drive worm wheels and gears.

Apply white grease to the tray drive worm wheels and gears.

79 :W

MAY.1997 © TOSHIBA CORP. 4-10 65/5560 PERIODIC

*12 Clamshell lock section

Apply white grease to the clamshell lock section.

*13 Used toner-transport auger drive sections

Apply white grease to the used toner-transport auger drive sections(front and rear).

–Front side– –Rear side–

65/5560 PERIODIC 4-11 MAY.1997 © TOSHIBA CORP.

*14 LCF drive sections

*15 Oil Seal (mixer shaft)

When 800k has been reached, replace the oil seals

(four) of the developer mixer shaft. When replacing,

Developer frame

apply grease (Alvania No.2) shown as below.

(Nozzle mixer)

Oil seal Outside

1. Push the new oil seal in parallel to the mounting

holes of the developer frame (or the nozzle

mixer). Inside Grease

* Pay attention to the direction that the oil seal is

assembled. (See figure on right.)

Oil seal

2. Apply a uniform coating of grease to the inside

surface of the oil seal.

• Amount: Two large drops

• Grease: Alvania No.2

3. Wipe off any surplus grease that oozes out from

inside.

Mixer shaft

Coat the entire periphery of the mixer shaft with

grease (Alvania No.2) and assemble the bearing.

Mixer shaft Bearing

MAY.1997 © TOSHIBA CORP. 4-12 65/5560 PERIODIC

4.2 Oiling Cycle Table

Oiling Cycle

Number Item to Lubricate Tyre of oil

Number of coples ×1000

7-1 Used toner-transport auger drive section (front, White grease 200

rear)

41 Toner hopper drive worm gear White grease 200

49 Paper-feed system drive gears (tooth faces) White grease 200

50 GCB bushings and plastic bushings Launa 40 200

64 Heat roller and cleaning rollers drive gears Silicone oil 200

65 Cleaning roller bushings Siliconeoil 200

71 GCB bushings and plastic bushings Launa 40 200

72 ADD drive gears (tooth faces) White grease 200

73-2 Decurler bushings Laua 40 200

73-3 Decurler gear White grease 200

79 Tray drive worm wheels and gears (tooth faces) White grease 200

80 PFP drive gears (tooth faces) White grease 200

81 GCB bushing and plastic bushings Launa 40 200

93 Gears White grease 200

94 Worm and worm wheel White grease 200

95 Worm shaft Launa 40 200

96 Wire pulley shaft Launa 40 200

97 Slit for the elevator tray White grease 200

98 Clamshell lock section White grease 200

* The number is the same as that in the Periodic Inspection Check List.

Notes:

1) Do not apply oil to the rollers,belt and belt pulley.

65/5560 PERIODIC 4-13 MAY.1997 © TOSHIBA CORP.

4.3 Repracement Schedule of Disposable Parts and Supplies

Replacement Cycle *4

Number Parts Name Code Number of copies ×1000 P.#.

2 Main blade ASM-S-BL7550 200 P.56 - #.46

3 Toner bag PS-TB6550 100 P.59 - #.19

PS-TB6550E (For Europe)

6 Separation claw (drum) K-CLAW-DRUM(4 pcs.) 400 P.57 - #.29

7 Fur brush B-6560 200 P.56 - #.32

9 Drum PS-OD6560 400 P.48 - #.1

10 Ozone filter (for the exit fan) K-FILTER-TNR 400 P.60 - #.8

10-1 Ozone filter (for the developer fan) K-FILTER-DEV-2 400 P.50 - #.26

28 Air filter(developer unit) FILTER-DEV 200 P.50 - #.25

Charger wire WIRE-CH-PT-060*398(main) P.47 - #.13

31 (main/pre-transfer/transfer/separation) WIRE-CH-PT-060*409(transfer and 200 P.30 - #.25

separation:3pcs.)

WIRE-CH-PT-354(pre-transfer) P.57 - #.11

Charger wire cleaner K-BASE-PAD-CH-M(main) P.47 - #.9

33 (main/transfer/separation) K-BASE-PAD-TR(transfer) 200 P.30 - #.18

K-BASE-PAD-SEP(separation) P.30 - #.19

35-1 Grid(for main charger) GRID-154 200 P.47 - #.22

37 Developer material PS-ZD6560 200 P.202 - #.2

1

42 Pick-up roller(manual/LCF) K-ROL-P/U-CW-H(manual) 100* P.27 - #.25

K-ROL-PICK-2(LCF) 200*1 P.26 - #.7

1

43 Feed roller(manual/LCF) K-ROL-FED-CW-H(manual) 100* P.27 - #.22

1

K-ROL-FEED-2(LCF) 200* P.26 - #.7

44 Separation roller(LCF) K-ROL-SPT-CW-H 200 P.26 - #.37

44-1 Separation roller (manual) K-ROL-SPT-URT 100 P.29 - #.59

52 Upper heat roller ASM-HR7550U 400 P.33 - #.1

53 Lower heat roller ASM-HR6550L 400 P.33 - #.2

54 Upper separation claw(fuser unit) K-SCRAPER-HR 400 P.34 - #.33

56 Heat roller cleaning roller PS-SR6550H 200 P.34 - #.42

57 Cleaning felt roller PS-ZB6550H 200 P.34 - #.41

58 Press roller cleaning roller PS-SR7550L 200 P.34 - #.9

2

66 ADD pick-up roller ROL-PICK-ADD 100* P.22 - #.39

2

67 ADD feed roller K-ROL-FEED-1 100* P.22 - #.9

2

68 ADD separation roller K-ROL-SPT-CCW-H 100* P.22 - #.17

74 PFP pick-up roller K-ROL-P/U-CCW-H(3 pcs.) 100*3 P.11 - #.43

3

75 PFP feed roller K-ROL-FEED-1(3 pcs.) 100* P.11 - #.21

3

76 PFP separation roller K-ROL-SPT-CCW-H(3 pcs.) 100* P.12 - #.21

82 ADF pick-up roller ROL-ORG-IN-714 400 P.88 - #.4

83 ADF feed roller K-ROL-FEED-714 400 P.88 - #.5

84 ADF separation belt BLT/R-SEPARATE(4 pcs.) 400 P.89 - #.9

85 Transport belt(ADF) BELT-DF-714 400 P.83 - #.1

MAY.1997 © TOSHIBA CORP. 4-14 65/5560 PERIODIC

Notes:

* The number is the same as that in the Periodic Inspection Check List.

*1 Indicates a manual feed or LCF feed count.

*2 Indicates an ADD feedcount.

*3 Indicates a feed count for each PFP stage.

*4 Refer to PARTS LIST.

65/5560 PERIODIC 4-15 MAY.1997 © TOSHIBA CORP.

4.4 PM Kit (200K Kit)

[Copier interior arrangement]

t5 e3 w2 !0

10 !3