Академический Документы

Профессиональный Документы

Культура Документы

Presentation of Mega Container Carrier

Загружено:

ioanaureche0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров1 страница- Korean shipyard Hyundai Heavy Industries and classification society Germanischer Lloyd presented a design study for a 13,000 TEU container ship that could enter service in the near future.

- The ship would be 382 meters long and have two main engines with twin propellers to power its speed of 25.5 knots. This twin drive configuration was determined to be only marginally more expensive than a single engine design.

- Extensive calculations and tests were conducted over 1.5 years to validate the design, which separates the deckhouse and engine room for improved visibility and fuel tank protection. The yard is now accepting orders for ships based on this innovative design.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ- Korean shipyard Hyundai Heavy Industries and classification society Germanischer Lloyd presented a design study for a 13,000 TEU container ship that could enter service in the near future.

- The ship would be 382 meters long and have two main engines with twin propellers to power its speed of 25.5 knots. This twin drive configuration was determined to be only marginally more expensive than a single engine design.

- Extensive calculations and tests were conducted over 1.5 years to validate the design, which separates the deckhouse and engine room for improved visibility and fuel tank protection. The yard is now accepting orders for ships based on this innovative design.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

36 просмотров1 страницаPresentation of Mega Container Carrier

Загружено:

ioanaureche- Korean shipyard Hyundai Heavy Industries and classification society Germanischer Lloyd presented a design study for a 13,000 TEU container ship that could enter service in the near future.

- The ship would be 382 meters long and have two main engines with twin propellers to power its speed of 25.5 knots. This twin drive configuration was determined to be only marginally more expensive than a single engine design.

- Extensive calculations and tests were conducted over 1.5 years to validate the design, which separates the deckhouse and engine room for improved visibility and fuel tank protection. The yard is now accepting orders for ships based on this innovative design.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Presentation of Mega Container Carrier:

Korean Yard Now Accepting Orders

Hamburg, 30 September 2005 - With an On the other hand, the single-engine variant

innovative design study for a 13,000 TEU leads to several difficulties that have not been

container ship, Germanischer Lloyd and the solved as yet. The output of a 14-cylinder

Korean yard Hyundai Heavy Industries (HHI) engine is not enough to achieve the required

are showing just how big container carriers will speed, whereas a 16-cylinder engine would be

be in the near future. Before over 100 too large. As regards propeller size, HHI

customers at the Container Forum, Mr D.S. believes that the maximum has been reached

Cho, Executive Vice President of HHI, and with a diameter of 9.5 m and a weight of 110 t.

Jan-Olaf Probst, Ship Type Manager for What is more, the single-screw design involves

Container Ships at Germanischer Lloyd, a great risk of cavitation; the extremely high

presented their new ship design with two main shaft power also represents a hazard.

engines and two propellers. All the relevant With a view to meeting the SOLAS

calculations have been carried out and the requirements for bridge visibility on such a

design completely approved by Germanischer large ship, the design envisages the

Lloyd; the Korean yard is now accepting separation of deckhouse and engine room.

orders. The innovative arrangement of the deckhouse

The ship is 382 metres long and 54.2 metres in the forward part of the ship permits an

wide, and has a draught of 13.5 m. The 6,230 increase in container capacity and a reduction

containers below deck are stacked in 10 tiers in ballast water. The international regulations

and 19 rows, while the 7,210 deck containers on the protection of fuel tanks are also

are stowed in 21 rows. Powered by two 45,000 satisfied with this design, because they are

kW engines, the vessel's speed is 25.5 knots. located in the protected area below the

The design study is characterized by two deckhouse. Another welcome result of this

technical innovations: the cooperation partners innovation is reduced bending and increased

decided on a twin drive configuration and the stiffness of the hull.

separation of deckhouse and engine room. Over a period of one and a half years, the

The question as to what propulsion powers cooperation partners Germanischer Lloyd and

and arrangements are needed to achieve the Hyundai Heavy Industries performed

desired speed of 26 knots may be answered calculations for all components of the ship.

by diverse technical approaches: in the early The study investigated the layout of the ship,

phase of detailed calculations, not only the the number of containers and their stowage,

twin drive, but also the possibilities offered by the design of the fuel tanks, and also provided

one main engine, as well as one main engine for strength analyses. Further aspects included

with an additional pod drive, were considered. slamming calculations, propulsion plants,

The cost estimate for the various drive engine room design and vibration analyses. In

configurations, never before done by a addition to towing experiments, tank model

shipyard, indicated that a twin propulsion tests were also carried out at Hyundai in

system was only negligibly more cost-intensive respect of parametric rolling, with the support

than the variant with only one main engine. of Germanischer Lloyd. At the same time,

programs developed by Germanischer Lloyd

From the technical standpoint, the aspect of were used to examine the behaviour of the

absolute safety is a major argument for the ship in a seaway, especially parametric rolling.

twin drive. In the event of an engine failure, the Moreover, exhaust emission tests were

ship would remain manoeuvrable and could conducted to determine the optimum position

reach a safe harbour under its own steam. The for the funnels.

main-engine and shaft sizes correspond to

those of a 4,000 TEU carrier. More than 15 The production period for such a ship lies at 9

years of experience and smooth operation to 10 months. Owing to the great workload of

speak in favour of this size of propulsion unit. the yard, delivery before 2009 will not be

Engines and propellers of this size are in possible.

widespread use, making the maintenance and

procurement of spare parts both easy and

cost-effective.

Вам также может понравиться

- Pounder's Marine Diesel Engines and Gas TurbinesОт EverandPounder's Marine Diesel Engines and Gas TurbinesРейтинг: 4 из 5 звезд4/5 (15)

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysОт EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Venus 5300Документ6 страницVenus 5300Pablo CastroОценок пока нет

- Modern RoRo Design PDFДокумент9 страницModern RoRo Design PDFSoner Çetin100% (1)

- 07 GrubisicДокумент17 страниц07 GrubisicDoy J JoyoОценок пока нет

- Advanced Machinery With CRP Propulsion For Fast Rpax Vessels PDFДокумент17 страницAdvanced Machinery With CRP Propulsion For Fast Rpax Vessels PDFfabricel82Оценок пока нет

- Development of 8 700 TEU Type Mega Container Carrier: United Inc. IncДокумент5 страницDevelopment of 8 700 TEU Type Mega Container Carrier: United Inc. Incgeorgekc77Оценок пока нет

- LNG MitsubishiДокумент4 страницыLNG Mitsubishireade2011Оценок пока нет

- Design of The Evolutionary LNG Carrier "Sayaendo"Документ0 страницDesign of The Evolutionary LNG Carrier "Sayaendo"Nik NykoОценок пока нет

- Type 0 Super Vessel, Dockwise Vanguard, Provides 110,000 Metric Tonnes of PossibilityДокумент4 страницыType 0 Super Vessel, Dockwise Vanguard, Provides 110,000 Metric Tonnes of PossibilityMuhammad KhanОценок пока нет

- MV TonsbergДокумент4 страницыMV Tonsbergalison_15796310Оценок пока нет

- The Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonДокумент15 страницThe Propulsion of A 12 500TEU Container Ship: JS Carlton, Lloyd's Register, LondonŞansal DikmenerОценок пока нет

- Auricula.: NotesДокумент9 страницAuricula.: NotesAditya RaoОценок пока нет

- Quantum 9000Документ36 страницQuantum 9000FuchsbauОценок пока нет

- Propulsion Trends in Container VesselsДокумент28 страницPropulsion Trends in Container VesselsFuchsbauОценок пока нет

- Deconstructing The Propulsion ConundrumДокумент13 страницDeconstructing The Propulsion ConundrumNajmul Puda PappadamОценок пока нет

- Deltamarin Roro ReferencesДокумент28 страницDeltamarin Roro ReferencesrafaОценок пока нет

- Pem Fuel CellДокумент5 страницPem Fuel CellIshwar ChandraОценок пока нет

- Diesel Electric PropulsionДокумент77 страницDiesel Electric PropulsionAnuraag Diyya100% (1)

- Scale UpДокумент4 страницыScale UpMohamed RadwanОценок пока нет

- Design of The Evolutionary LNG Carrier "Sayaendo"Документ21 страницаDesign of The Evolutionary LNG Carrier "Sayaendo"Keith ThomasОценок пока нет

- Fuel Cell Methanol Reformer System For Submarines - HP4a - 9 - Krummrich - Rev0605Документ8 страницFuel Cell Methanol Reformer System For Submarines - HP4a - 9 - Krummrich - Rev0605Bùi Xuân ĐứcОценок пока нет

- 890405-Big Dumb Booster TechnologiesДокумент6 страниц890405-Big Dumb Booster TechnologiesntrscribeОценок пока нет

- Modern Technology in Ship Building IndustryДокумент17 страницModern Technology in Ship Building IndustrySwapnil Rupaye100% (2)

- Quantum 9000 PDFДокумент36 страницQuantum 9000 PDFДмитрий ЗинченкоОценок пока нет

- Nigel Gee - Izar Pentamaran ConceptДокумент14 страницNigel Gee - Izar Pentamaran ConceptrmdowlandОценок пока нет

- TOXOPEUS - Manoeuvring Aspects of Fast Ships With PodsДокумент15 страницTOXOPEUS - Manoeuvring Aspects of Fast Ships With PodstonimakroneОценок пока нет

- Concept Design of A Bulk Carrier Retrofit With LNG FUELДокумент7 страницConcept Design of A Bulk Carrier Retrofit With LNG FUELHenrique costa melloОценок пока нет

- First Principle Applications in RoRo-Ship Design PDFДокумент7 страницFirst Principle Applications in RoRo-Ship Design PDFFerdy Fer DОценок пока нет

- Marine Design AnswersДокумент6 страницMarine Design AnswersAmit SinghОценок пока нет

- Design Aspects and Applications of DeepДокумент9 страницDesign Aspects and Applications of DeepFederico BabichОценок пока нет

- Design Aspects and Applications of Deep-V Hull Forms To High Speed CraftsДокумент9 страницDesign Aspects and Applications of Deep-V Hull Forms To High Speed CraftsAnibal Puchi OpazoОценок пока нет

- Delta Mar in Tanker ReferencesДокумент27 страницDelta Mar in Tanker ReferenceschmatiasОценок пока нет

- Archives 24Документ138 страницArchives 24RogerОценок пока нет

- Floating Cranes UkДокумент14 страницFloating Cranes Ukrajumj66Оценок пока нет

- Gastech: Kazuaki YuasaДокумент16 страницGastech: Kazuaki YuasabernardinodinoОценок пока нет

- Conceptual Planning of Jebel Ali New Container TerminalДокумент8 страницConceptual Planning of Jebel Ali New Container TerminalAlejandro GarnicaОценок пока нет

- BMTDSL Aegir Conpaper Pacific Jan06Документ10 страницBMTDSL Aegir Conpaper Pacific Jan06DUNCAN0420Оценок пока нет

- Propulsion Trends in Container VesselsДокумент28 страницPropulsion Trends in Container VesselsAdrianMictarОценок пока нет

- CLT SMM2014 PresentationДокумент29 страницCLT SMM2014 PresentationEmine DağОценок пока нет

- Sample 1Документ1 страницаSample 1pavaniitm2006Оценок пока нет

- CFD Analysis of Ship HullДокумент48 страницCFD Analysis of Ship HullRamesh KothakondaОценок пока нет

- The Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesДокумент8 страницThe Propulsion & Manoeuvring Concept of The BCF-Super C - Class Double End FerriesLelosPinelos123Оценок пока нет

- OTC 24447 Practical Experience Gained Operating A Compact Ultradeepwater Drill ShipДокумент13 страницOTC 24447 Practical Experience Gained Operating A Compact Ultradeepwater Drill ShipEvan FNHОценок пока нет

- Progress in Ship DesignДокумент14 страницProgress in Ship DesignJuan SilvaОценок пока нет

- ShipbuildingДокумент37 страницShipbuildingSyahrul AfzalОценок пока нет

- Wartsila PP A Id Floating SolutionsДокумент6 страницWartsila PP A Id Floating SolutionsvuongОценок пока нет

- Electives Lesson 4Документ26 страницElectives Lesson 4Mixed VideosОценок пока нет

- Nuclear PropulsionДокумент107 страницNuclear PropulsionSaptarshi Basu100% (2)

- LNG Propulsion 7Документ36 страницLNG Propulsion 7xlikoОценок пока нет

- Propulsion 14000 Teu Container VesselsДокумент20 страницPropulsion 14000 Teu Container Vesselspavlo_790317697Оценок пока нет

- New Microsoft Word DocumentДокумент2 страницыNew Microsoft Word DocumentSathish KumarОценок пока нет

- Ships Repair ConversionДокумент13 страницShips Repair ConversionGouthamVenkatesh100% (1)

- General Arrangement Plan of Bulk Carrier (Seam1 CO1)Документ30 страницGeneral Arrangement Plan of Bulk Carrier (Seam1 CO1)Churchill Española100% (1)

- Air BP - Recent New Projects v3Документ15 страницAir BP - Recent New Projects v3PedroОценок пока нет

- Executive SummaryДокумент38 страницExecutive SummaryThiru Voyage InteligentsОценок пока нет

- First Voith Water JetДокумент1 страницаFirst Voith Water JetalimemetОценок пока нет

- Offshore LNG Loading Problem SolvedДокумент13 страницOffshore LNG Loading Problem SolvedpriyoОценок пока нет

- Air Lubricated and Air Cavity Ships: Development, Design, and ApplicationОт EverandAir Lubricated and Air Cavity Ships: Development, Design, and ApplicationОценок пока нет

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedОт EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedОценок пока нет

- QST30-G5: Emissions Compliance: EPA Tier 2 at 60 HZДокумент2 страницыQST30-G5: Emissions Compliance: EPA Tier 2 at 60 HZGiovanniCortesNeiraОценок пока нет

- K4M Timing BeltДокумент14 страницK4M Timing BeltCarlos XОценок пока нет

- Mitsubishi Forklift Fg50k Service ManualДокумент24 страницыMitsubishi Forklift Fg50k Service Manualchristopherwhite101288dxj100% (124)

- Case StudyДокумент2 страницыCase Studyyograj.yogesh100% (1)

- 4SPEED3honda PDFДокумент10 страниц4SPEED3honda PDFDaniel CaminatiОценок пока нет

- Cluster 206 PDFДокумент5 страницCluster 206 PDFecutronicssОценок пока нет

- 595 Obp Supplementary Parts Catalogue67Документ64 страницы595 Obp Supplementary Parts Catalogue67Workshop RSGОценок пока нет

- Vios InteriorДокумент122 страницыVios Interiorang6632Оценок пока нет

- Tourer 125 - Workshop Manual PDFДокумент293 страницыTourer 125 - Workshop Manual PDFjo100% (1)

- 1975-76 Ford Car Shop Manual Volume II EngineДокумент538 страниц1975-76 Ford Car Shop Manual Volume II Enginealie19100% (5)

- BSA Bicycle TouringДокумент18 страницBSA Bicycle Touringtspinner19Оценок пока нет

- Valve Actuators C13Документ5 страницValve Actuators C13Jose F Rivera Morales100% (3)

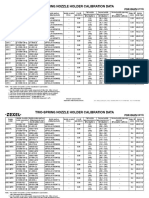

- Zexel Two Spring Nozzle Holder Calibration DataДокумент63 страницыZexel Two Spring Nozzle Holder Calibration DataИльнур Султанов100% (6)

- Despiece Susp. Post. 980e-4Документ2 страницыDespiece Susp. Post. 980e-4Andersson Campos VásquezОценок пока нет

- Technical Specifications Renault MASTER Z EДокумент1 страницаTechnical Specifications Renault MASTER Z Enawaz khanОценок пока нет

- Chapter 7 - Hybrid Cars - Introduction To Automotive EngineeringДокумент2 страницыChapter 7 - Hybrid Cars - Introduction To Automotive EngineeringDinku Seyoum ZelekeОценок пока нет

- GCC and Domestic RatesДокумент3 страницыGCC and Domestic RatesImmanuel EbenazerОценок пока нет

- Manual Pathfinder 2005Документ548 страницManual Pathfinder 2005mister147100% (1)

- CAT Product Line NewДокумент40 страницCAT Product Line NewFaisal SaleemОценок пока нет

- Lesson 4 STATION NUMBER AND ZONAL SYSTEMДокумент3 страницыLesson 4 STATION NUMBER AND ZONAL SYSTEMjeevan basnyat100% (1)

- Mitsubishi Electric Genuine SolenoidsДокумент8 страницMitsubishi Electric Genuine SolenoidsJessie BechaydaОценок пока нет

- Circuito Eléctrico Cargadora 950F CaterpillarДокумент2 страницыCircuito Eléctrico Cargadora 950F CaterpillarAlejandro Reynerio Alvarez100% (3)

- Chevrolet Competitor AnalysisДокумент3 страницыChevrolet Competitor AnalysisAtul Dureja50% (2)

- Ford Mustang Mach 1Документ4 страницыFord Mustang Mach 1Devraag C.MОценок пока нет

- Fusible JettaДокумент2 страницыFusible JettazahirronОценок пока нет

- Series: Counterbalanced Electric, Cushion TireДокумент20 страницSeries: Counterbalanced Electric, Cushion Tireleorodrigues2012100% (1)

- 205-02 Rear Drive Axle and Differential - Removal and Installation - Electronic Locking Differential ELD SolenoidДокумент4 страницы205-02 Rear Drive Axle and Differential - Removal and Installation - Electronic Locking Differential ELD SolenoidCARLOS LIMADAОценок пока нет

- 2001 RacingДокумент224 страницы2001 RacingdensrxОценок пока нет

- Engine Removal and InstallationДокумент8 страницEngine Removal and InstallationEj GonzalezОценок пока нет

- PC - Training Manual - Pt-2Документ47 страницPC - Training Manual - Pt-2Josef JoestarОценок пока нет