Академический Документы

Профессиональный Документы

Культура Документы

TARA PAA Ver 3

Загружено:

Uttam JaipuriaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TARA PAA Ver 3

Загружено:

Uttam JaipuriaАвторское право:

Доступные форматы

®

TARA PAA

PERACETIC ACID

INFORMATION BROCHURE

REDOX PHARMACHEM PVT.LTD.

PLOT #15, SECTOR 6A, IIE SIDCUL, HARIDWAR

UTTARAKHAND 249403, INDIA

Phone No. 01334-239196

FAX: 011-41551269

Email: redoxdelhi@yahoo.co.in

www.tara-paa.com

Redox

Pharmachem

PERACETIC ACID

Peracetic acid (PAA) is a liquid chemical germicide used for sterilizing or

disinfecting. Scientists have been working with this germicide since the turn of

the century. Freer and Novy reported on the germicidal action of PAA in 1902, but

PAA solution was generally unavailable due to the cost of manufacturing.

Now PAA is available to end users at a competitive price and a wide variety of

uses were introduced. In medical applications PAA has been used to sterilize

rooms, equipments, hemodialyzers, and medical, surgical and dental

instruments. PAA destroy cell membranes by disrupting sulfur and sulthydryl

bonds. PAA inactivates a catalase that breaks down Hydrogen Peroxide and

oxidizes enzymes that support biochemical transportation across cell

membranes thus causing the cell wall to rupture. PAA is known to be a protein

denaturant and destroys pyrogens.

PAA is most active against bacterial spores. In one test of 23 agents, the anti

microbial activity of PAA was efficacious against Bacillus thermoacidurant

spores, including chlorine containing compounds. PAA is most efficacious

against a wide range of bacteria, mycobacteria, viruses, yeast and fungi. PAA is

more efficacious than Hydrogen Peroxide, Formaldehyde and Gluteraldehyde.

Additional advantages are its rapid action, ability to remain effective at low

temperatures and efficacy in presence of organic material. The decomposition

products of PAA are Acetic Acid (Vinegar), Water and Oxygen

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Uses & Basic Chemistry

TARA PAA (Peroxyacetic Acid Solutions)

TARA PAA are stabilized equilibrium solution concentrates that are approved for

numerous uses, including circulation and industrial sanitizing of equipment such

as tanks, pipelines, evaporators, fillers, pasteurizers, aseptic equipment, and for

sanitizing previously cleaned food contact surface of equipment.

The equilibrium TARA PAA is a mixture of Acetic Acid and Hydrogen Peroxide.

Although the PAA is the true active ingredient, the Hydrogen Peroxide fraction aids

in stabilizing the PAA.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Applications of TARA PAA®

Peracetic Acid

A. Food Products

1. Fresh fruits and Vegetables

2. Processed Food

3. Organic Food

4. Dairy Industry

5. Meat Industry

6. Egg and Poultry

7. Starch (Medical)

8. Hotels

9. Flight Kitchen

10. Fish Farming

11. Wineries

12. Beverage

13. Breweries

B. Biocide

1. Agriculture

2. Sanitizer

3. Fogging

4. Medical Use

C. Other Uses

1. Cooling water

2. Wastewater

3. Sewage water

4. Textile Bleaching

5. Cleaning of ultra Filtration & RO. System

6. Plant & Equipment cleaning

7. Drip Irrigation tube cleaning

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Oxidation Capacity of Various Oxidizers

Oxidizer eV*

Ozone 2.07

Peracetic Acid 1.81

Chlorine Dioxide s 1.57

Sodium Hypochlorite 1.36

Hydrogen Peroxide 1.33(pH7)

*electron volts

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Germicidal Action of Peracetic Acid

Temperature of 5°C 10°C 20°C 40°C

Action

Concentration 0.01 0.025 0.01 0.025 0.01 0.025 0.01 0.025

of 100% PAA

Gram-Positive Bacteria

Staph. Aureus 5 3 3 2 2 1 1 0.5

Strept. Faecalis 3 3 3 2 2 1 1 0.5

Gram-Negative Bacteria

Enterobacter

1 1 1 1 1 1 1 0.5

Aerogenes

Ps. Aeruginoda 3 1 2 1 1 0.5 1 0.5

Samonella Types 3 2 3 2 2 2 1 1

Yeasts

Sacch. Cerevisiae 20 10 10 5 3 1 1 0.5

Cand. Mycoderma 120 40 90 40 40 10 3 1

Molds

Penicillum

>120 90 >120 90 20 10 3 1

Camerunense

Asp. Niger >240 >240 >240 >240 90 60 10 5

Mucor Spec. >240 >240 >240 >240 20 5 3 1

Sporulators

Bac. Cereus >60 >60 >60 >60 >60 60 40 10

Bac. Subtilis >60 40 >60 >60 >60 60 40 10

Bac. Mesentericus >60 40 >60 40 10 5 10 1

Thermophile

>60 40 40 40 20 5 5 2

Sporulators

Clostridium Perfringens >60 10 >60 10 20 5 2 1

7 8

Kill times in minutes (suspension Method) with colony counts of 10 – 10 per ml of inoculum.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Comparison Chart for various Sanitizer/Disinfectant/Biocide

Optimum Use Effect of Effect of Germicidal Activity Activity Activity

pH Range Dilution Hard Organics Activity against against against

for Concentr Water in Water Gram Gram Spores

Sanitizati ation on Positive Negative

on in ppm Sanitizati Bacteria Bacterial

on

Moderate

HYPOCHLORITE 5-7 200 Inactivated High

tolerance

Reduced

Activity

activity; Moderate,

reduced

more less effective

IODOPHORS 1-5 25 More

stable than than

sanitizer

hypochlorit hypochlorites

required

es

Activity Moderately

QUATS 8 - 11 200 Varied

reduced Stable

Activity

reduced

ACID Low

1-3 200 more Very Good

SANITIZERS reactivity

sanitizer

required

2% for

Activity

ALDEHYDES 6-8 Sterilizatio No effect High

reduced

n

Loss of

ALCOHOLS 5-8 70% No effect Moderate

activity

Moderate Moderately

PHENOLICS 10.5 - 11.5 200 - 400 Very good

tolerance stable

Reacts High, better

limited and than

PAA 2 - 8.5 150 - 200

effect looses hypochlorit

activity e

High, better

CHLORINE Little

2-5 5 - 15 No effect than

DIOXIDE influence

hypochlorite

Highly Effective, Moderately Effective,Slightly effective, Ineffective

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

COOLING WATER;

PAA solutions find particular advantageous use in cooling water systems because it is a very

powerful oxidizer (second only to ozone). PAA is lipid soluble making it an effective on-line

and off-line cleaner.

Higher doses can be used to remove slime mass accumulation. It does not create halogenated

by-products or THM's, does NOT react with ammonia and many other nitrogen-based

chemistries, and does not contribute to the conductivity or TDS of the blow-down or bleed off

stream. PAA consumes alkalinity, allowing higher cycles of concentration compared to

hypochlorite.

For most surface discharges, quenching is not required. PAA is compatible with organic

scale and corrosion inhibitors.

The threshold level for most algae and slime forming organisms is 1-2 ppm active PAA.

Effective pH ranges are as high as 9.5, but the optimum pH is below 8.6. Typical micro results

for various organisms exposed to PAA solution are following.

SANITATION:

When used as the primary sanitizer in processing facilities, the PAA formula does not

contribute to wastewater TDS or total salt levels, and does not interfere with most wastewater

chemical treatment programs or systems. There are no known microbial mutation or resistance

response to PAA. It can be used at concentrations up to 200 ppm active PAA without requiring

a water rinse. Normal use rates are 80 ppm with contact times of 1 minute to achieve a

99.999% microbial kill. TARA PAA used as a continuous conveyor sanitizer (with direct food

contact) for meat, poultry, seafood, and fruit and vegetable plants in accordance with 21 CFR

173.315 and 21 CFR 173370

AGRICULTURE:

PAA solution are finding specialty use as a fungicide for daffodil and flower bulbs, a

biodispersant and slime inhibitor for flume systems, and as a drip irrigation line cleaner and

algaecide. When used as a drip line cleaner, the PAA breaks down in soil within minutes,

releases (adds) active oxygen, and does not contributes a salt or conductivity (EC) loading in

the root zone. At levels above 10 ppm, the products will dissolve calcium and add mild acidity

to the soil. When compared to Chlorine, PAA will NOT depress crop yields

WASTEWATER:

PAA has, nonetheless, been used successfully as an additive for sludge debulking, algae

control, chemical enhancement for sulfide removal and prevention, as a supplement to UV

disinfection, and odor eliminator. PAA use costs are lower than Chlorine for treating raw and

physio-chemically treated effluents. For biologically treated effluents, use cost are higher (but

with similar efficacy results), yet PAA does not create THM precursors or most of the DBP's

(disinfection by-products) associated with the use of Chlorine. When neutralization is required,

Sulfite reduction may be used (the same as for Chlorine).

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

TARA PAA ® Solution for Various Uses

S.no. Application Concentration Required Temperature Exposure Note

in ppm TARA PAA Time

®

for 100

Ltrs

solution

1 Foot Dip 500 895 ml Normal Clean the

Boots with Soft

Bruch

2 Washing 25 45 ml Normal 60 Second Dry the

Fruits & Veg. vegetable &

Fruit before

use. No

washing with

fresh water

required.

3 Washing 80-200 143 ml to Normal 60 Second Allow it to drip

Meat 357 ml 230 ppm –FMC

4 Hatching Egg 80 - 200 143 ml to 43°C 60 second Allow it to Dry.

+ Shell Egg 357 ml Active against

for food as per gillus

fumigates 280

ppm

5 Fogging 150 - 750 268 ml to Normal Allow it for 2

1340 ml hrs. 3 Ltr solu

for every 100

cu.mtr.

6 Utensils & 75 135 ml Normal 60 second Apply Physical

Tableware cleaning &

used in eating washing prior

Drinking & to use.

Food

Preparation

7 Non Food 135 – 1775 240 ml to

Contact- Hard 3000 ml

Surface –

Disinfectant

8 Disinfectant 80 - 320 143 – 570 10

for Animal & ml minutes

Poultry

Premises,

Trucks &

Crates.

9 Antimicrobial 1120 - 1700 2000 to 40 - 60°C 15 second

rinse of Pre- 3000 ml

cleaned

Container

(Returnable &

Non

Returnable)

10 Algae control 3-6 6-10 ml Normal

and Bio Film

removal in

Cooling

Tower

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Frequently Asked Technical/Application Questions

TARA PAA-15 is an equilibrium mixture of 15% peracetic acid (PAA) and 22%

hydrogen peroxide. TARA PAA - 5 is an equilibrium mixture of 5.6% peracetic acid

(PAA) and 26.5% hydrogen peroxide.

GENERAL PRODUCT INFORMATION:

What are the uses of TARA PAA products?

TARA PAA products are registered for the following uses:

• Institutional / Industrial Sanitizer and Disinfectant for previously cleaned Hard, Non-

Porous Food Contact in Dairies, Wineries, Food and Beverage Plants, Poultry Egg

Facilities, and Animal Housing.

• Hard, Non-Porous Surface Disinfecting in Hospital, Schools, Industrial Facilities,

Office Buildings, Veterinary Clinics.

• Bacteria, Fungi and Slime Control in Cooling Water and Evaporative Cooling

System, Reverse Osmosis and Ultra Filtration Systems.

Why is TARA PAA-5 available in two different concentrations?

The products have almost identical label uses and can be used interchangeably.

TARA PAA-5 is preferred from a worker exposure issue whereas TARA PAA-15 is more

concentrated and more economic to ship in large volumes.

Do TARA PAA-15 products have an odor?

TARA PAA has a pungent odor of vinegar. The odor is much less intense for TARA

PAA-15.

DO TARA PAA products produce halogenated or toxic by-products?

Absolutely not. In the environment, TARA PAA products degrade to Carbon-dioxide,

Oxygen contribute no additional conductivity to the system.

Why are the storage containers vented?

TARA PAA products have a shelf life of over one year when stored in their original

container. The gradual loss of activity is accompanied by the generation of Oxygen gas

that would build up in the headspace and pressurize the container if it was not vented

to the atmosphere.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Are TARA PAA products degraded by ultra violet light?

Unlike Sodium Hypochlorite bleach and other halogenated products, TARA PAA does not

lose activity on exposure to UV light. However, containers should be shielded

from direct sunlight to avoid build-up of heat. A cool, dry, well ventilated

environment is recommended for storage of TARA PAA products.

What materials are incompatible with TARA PAA products?

Avoid contacting TARA PAA products with strong alkalis, oxidizable organics,

heavy metals, leather, paper and wood.

What containers should be used to store TARA PAA products?

Storage in the original high density polyethylene container is recommended. When

transfers are necessary, the transfer containers should be made of the same material or

high quality stainless steel. Do not contact with any other metal (e.g. brass, copper,

galvanized, aluminum, mild steel) as these are readily corroded and the metal ions

released can cause accelerated decomposition of TARA PAA products.

What kind of personal protective equipment do I need to wear when handling TARA PAA

products?

Chemically resistance gloves such as neoprene or vinyl. Goggles, safety glasses or

face shield will protect from accidental splashing. Most common accidents or

problems are eye protection issues. Always protect your eyes!

What is the impact of TARA PAA products on the environment?

TARA PAA products are environmentally responsible. The short half-life means that

PAA is not persistent and rarely needs to be neutralized prior to discharge. No

additional conductivity is introduced to the receiving waters. The results of a large

aquatic toxic toxicity study demonstrate TARA PAA is far less toxic to marine and

fresh water organisms than alternative disinfection chemistries. If spilled or applied to

soil, PAA decays in a few minutes with no lasting impact on the soil quality. The

ultimate end result is Carbon, Oxygen, and Water.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

APPLICATION INFORMATION:

How are TARA PAA products fed?

Diaphragm-pumps with Teflon diaphragms and polypropylene, Teflon or Kynar materials

and degassing heads are recommended for feeding TARA PAA products. Only use

gaskets and ‘O’ lings made of gore-tex, Teflon or EPDM. Piping materials for the

concentrated product should be Teflon or Teflon-lined. Always pump the products from

the top of the container using a dip tube or foot valve. If using totes, never draw products

from the drain valve as this could lead to unwanted siphoning or excessive products loss

if leakage occurs. TARA PAA products can also be conveniently metered using

injectors or eductors made of compatible material of construction. Peristaltic pumps are

not recommended because of frequent squeeze tube failure with most elastomers.

We receive many questions about using polyethylene tubing and its potential use.

We do not recommend PE tubing, as it will crack, split or fail within a few month of use.

Where should TARA PAA products be introduced to the system?

TARA PAA products may be fed to either the system water or the make-up water at an

area of good mixing to promote rapid dispersion. The products may be introduced

continuously or intermittently depending upon the needs of the end user.

How does the compatibility of TARA PAA products with scale and corrosion inhibitors

compare with that of halogenated products?

TARA PAA products are far less reactive to common Phosphonate and polymeric

scale and corrosion inhibitors than halogen chemicals. TARA PAA products have no

impact on toytriazole and are actually stabilized to chemical degradation by a variety

of arclate and maleate polymer scale and corrosion inhibitors.

How effective are TARA PAA products?

A vast amount of efficacy data, has proven PAA to be a broad spectrum

microbiocide.

Are TARA PAA products suitable for slime control and biofilm removal?

Most certainly. The organic nature of the Peracetic acid molecule allows it to

penetrate the polysaccharide slime layers harboring bacteria to destroy them.

Additionally, the effervescing action of oxygen bubbles released from Hydrogen

Peroxide (scrubbing bubbles) helps to dislodge troublesome slimes from surfaces.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Can I use an approved non-oxidizing biocide in conjunction with TARA PAA products?

This is not recommended for economical reasons. TARA PAA products were

developed to be stand-alone bio-control agents. Some other companies advocate using

non-oxidizing biocides in conjunction with TARA PAA type products, but the

economic benefits are questionable.

Do TARA PAA products remain effective in the presence of ammonia, organic nitrogen

and sulfides?

Unlike chlorinated chemicals, PAA does not react with ammonia and is not

compromised by organic nitrogen. The high amounts of Hydrogen Peroxide in TARA

PAA products rapidly oxidize sulfides to sulfur or sulfate depending upon system pH.

What is the half life of PAA in water?

This is highly dependent on the water quality of the system. In ordinary tap water of

moderate hardness and low chemical demand, the half-life of PAA has been measured

to be between 8-30 hours. For re-circulating cooling water with elevated cycles of

concentrations and higher pH values, half-lives of between 5-10 hours have been

measured. PAA is highly unstable in seawater and has a half-life of 12-30 minutes.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

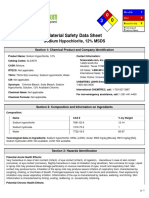

TARA PAA TECHNICAL DATA SHEET

Peroxyacetic acid

•Peracetic acid

•Ethaneperoxoic acid

•Acetyl hydroperoxide

Formula CH3COOOH

Description Colorless liquid with a strong, pungent,

acrid odor.

Uses Bactericide & fungicide, especially in

Food processing, reagent in making

caprolactam, synthetic glycerol.

Registry Numbers and Inventories.

CAS 79-21-0

EC (EINECS/ELINCS) 201-186-8

EC Index Number 607-094-00-8

EC Class Flammable; Oxidising; Harmful;

Corrosive; Dangerous for the

Environment

RTECS SD8750000

RTECS class Agricultural Chemical and Pesticide;

Tumorigen; Primary Irritant

UN (DOT) 2131

Merck 127293

Beilstein/gmelin 1098464

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Beilstein Reference 4-02-00-00390

EGA OPP 63201

Swiss Giftlistef G-2709

Canada DSL/NDSL DSL

US TSCA Listed

Australia AICS Listed

Japan ENCS (MITI) Listed

Properties :

Formula C2H403

Formula mass 76.05

Melting point, °C 0.1

Boiling point, °C 105

Vapor pressure, mmHg 7.9(25°C)

Density 1.1037 g/cm3 (20°C)

Solubility in water Very soluble

Viscosity 3.280 cp @ 78°F

Refractive index 1.3994 (15°C)

pKa/pKb 8.20 (pKa)

Heat of vaporization 44,25kJ/mol

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Hazards and Protection.

Storage Store in a cool, dry, well-ventilated location. Separate from acids,

alkalies, organic materials, heavy metals. Normally kept refrigerated outside or

detached storage is preferred.

Handling All chemicals should be considered hazardous. Avoid direct Physical

contact. Use appropriate, approved safety equipment. Untrained individuals

should not handle this chemical or its Container. Handling should occur in a

chemical fume hood.

Protection Full protective clothing (goggles, rubber gloves, etc)

Respirators Self-contained breathing apparatus.

Caution Peracetic acid is a strong oxidizer. Fire or other violent

reaction may occurs upon contact with combustible organic material. Avoid

breathing vapors. Do not touch the spilled material; shut off all ignition sources

and stop the leak if this can be done without risk. The spilled material should be

absorbed with a noncombustible absorbent such as vermiculite.

Small spills Sweep up and place in a metal container for immediate disposal. Do

not use spark-generating metals or organic materials for sweeping up or handling

spilled material. Dispose of the absorbed Peroxyacetic acid solution, in small

quantities at a time, by placing it on the ground in a remote outdoor area and

igniting with a long torch. Empty containers should be washed with a 10% Sodium

Hydroxide solution.

Stability Thermally unstable. After 30 days the specific Peracetic acid in 20gl

(with wetting agent), and Peracetic acid Spirit show a loss of Peracetic acid of

25,35,22% respectively with storage at 2-5 degrees.

Decomposition Decomposes violently @ 110° C peracetic acid diluted with 60%

acetic acid when heated to decomposition it emits acrid smoke and irritating

fumes.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196 FAX : 011-41551269 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Fire

Flash Point, °C 40.5

Autoignition, °C 200

Fire fighting : If fire occurs in the vicinity of this compound, water should be

used to keep containers cool. Cleanup salvage operations should not be attempted

until all of the Peroxyacetic acid solution has cooled completely. Keep

unnecessary people away; wear self-contained breathing apparatus and full

protective clothing. Fight fires from an explosion-resistant location. In advanced or

massive fires, area should be evacuated. For small fires: use Dry Chemical,

Carbondioxide, Water Spray, or Foam. For large fires: flood area with water.

Fire potential: Flammable liquid. Dangerous fire hazard by chemical reaction with

reducing agents or exposure to heat.

Hazards Decomposes violently at 230ºF, When heated to decomposition, this

compound emits acrid smoke and fumes, runoff to sewer may create a fire or

explosion hazard. Powerful oxidizer. Isolate from other stored material,

particularly accelerators, oxidizers, and organic or flammable materials. Avoid

shock and heat.

Combustion: Fire may produce irritating, corrosive and / or toxic gases, Products

Health 3

Flammability 2

Reactivity 4

Special 0

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196, 325987 FAX : 01334-239196 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Health

Poison-Class 2

Exposure effects An increase in blood pressure, respiratory rate and pulse

has been noted in animal experiments. No data were

available to assess the teratogenic potential of this agent.

No data were available to assess the potential effects of

exposure to this agent during pregnancy or Lactation.

Ingestion Ingestion of Peracetic acid may cause gastrointestinal

tract Irritation and possible oral and esophageal burns.

Inhalation Mice exposed by inhalation developed signs of respiratory

tract irritation.

Skin Peracetic acid is highly irritating and possibly corrosive to the

skin.

Eyes Peracetic acid can cause servere eye irritation. A 10

percent solution of Peracetic acid applied to rabbit eyes

caused corneal ulceration, perforation, and symblepharon

formation.

Irritation of nasal and throat mucosa is common with exposure to vapors.

First aid:

Ingestion Seek medical assistance.

Inhalation Move victim to fresh air. Apply artificial respiration if victim is

not breathing. Administer oxygen if breathing is difficult.

Skin Remove contaminated clothing and wash exposed

area thoroughly with soap and water. A physician should

examine the area if irritation or pain persists.

Eyes Irrigate exposed eyes with copious amounts of tepid water for

at least 15 minutes. If Irritation, pain, swelling, facrimation, or

photophobia persist the patient should seen In a health care

facility.

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196, 325987 FAX : 01334-239196 EMAIL : redoxdelhi@yahoo.co.in

Redox

Pharmachem

Transport.

UN number 2131

Response guide 147

Hazard class 5.2

USCG CHRIS PAA

11.5

Revised on 100909

PLOT # 15, SECTOR 6A, SIDCUL I.I.E, HARIDWAR, UTTARAKHAND, INDIA.

PH : 01334-239196, 325987 FAX : 01334-239196 EMAIL : redoxdelhi@yahoo.co.in

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Glovebox User ManualДокумент150 страницGlovebox User ManualsingytellsОценок пока нет

- Zingiber OfficinalisДокумент5 страницZingiber OfficinalisUttam JaipuriaОценок пока нет

- The Role of Acidifiers in Poultry Nutrition PDFДокумент6 страницThe Role of Acidifiers in Poultry Nutrition PDFUttam Jaipuria100% (1)

- BREOДокумент1 страницаBREOUttam JaipuriaОценок пока нет

- OreganolДокумент4 страницыOreganolUttam JaipuriaОценок пока нет

- Livestock Devt For Sustainable Livelihood of Small FarmersДокумент20 страницLivestock Devt For Sustainable Livelihood of Small FarmersUttam JaipuriaОценок пока нет

- Loba Fine Chemical CatalogueДокумент249 страницLoba Fine Chemical CatalogueUttam JaipuriaОценок пока нет

- Msds Hempadur 4774d Part AДокумент14 страницMsds Hempadur 4774d Part AHung NGUYEN SYОценок пока нет

- Fire Extinguisher Inspection Check ListДокумент11 страницFire Extinguisher Inspection Check Listniken tri ayuningОценок пока нет

- Method Statement For Installation of Steam RoomДокумент10 страницMethod Statement For Installation of Steam RoomSanto E0% (1)

- Norwegian Oil and Gas Training Curriculum: Basic Helicopter Landing Officer (HLO) CourseДокумент21 страницаNorwegian Oil and Gas Training Curriculum: Basic Helicopter Landing Officer (HLO) CourseMohamed SOОценок пока нет

- User Manual - Heraeus - Heracell 150 - Rev. D - 50075549 - D - EnglischДокумент86 страницUser Manual - Heraeus - Heracell 150 - Rev. D - 50075549 - D - Englischluroguita-1100% (2)

- Stihl Ts 410 420 Owners Instruction ManualДокумент112 страницStihl Ts 410 420 Owners Instruction ManualDrakhoОценок пока нет

- c4 Raffinate 1 Etbe Ver 5 0 enДокумент8 страницc4 Raffinate 1 Etbe Ver 5 0 enLudi D. LunarОценок пока нет

- BOSH First Exam ReviewerДокумент16 страницBOSH First Exam ReviewerEDRICK PARASОценок пока нет

- 41S Fire Emergency ProceduresДокумент41 страница41S Fire Emergency ProceduresashishОценок пока нет

- DG MotorДокумент213 страницDG MotorMehedy MasudОценок пока нет

- Fire Accident ReportДокумент6 страницFire Accident ReportSakshi AgrawalОценок пока нет

- Standard Operating Procedure - OxidizersДокумент5 страницStandard Operating Procedure - OxidizersMishel Mijares100% (1)

- SLM 8-Week 4-Grade1112DRRR-2nd Quarter-Analyze The Different Causes of FiresДокумент16 страницSLM 8-Week 4-Grade1112DRRR-2nd Quarter-Analyze The Different Causes of FiresRomel BayabanОценок пока нет

- Measurement Needs 6527 Oh LeДокумент274 страницыMeasurement Needs 6527 Oh LeNikola MisicОценок пока нет

- Eclipse Combustion Veriflame Single Burner Monitoring System User ManualДокумент42 страницыEclipse Combustion Veriflame Single Burner Monitoring System User ManualAntonio nunes silvaОценок пока нет

- Specification For Fire and Gas Detection System PDFДокумент48 страницSpecification For Fire and Gas Detection System PDFgalih santoso100% (2)

- Grade VIII-Notes (Chemistry) Chapter 4-Combustion and Flame.Документ10 страницGrade VIII-Notes (Chemistry) Chapter 4-Combustion and Flame.kedar vatsОценок пока нет

- Masplene Material Safety Data Sheet PDFДокумент4 страницыMasplene Material Safety Data Sheet PDFsetyo777Оценок пока нет

- Msds (Sodium Hydrochlorite) PDFДокумент6 страницMsds (Sodium Hydrochlorite) PDFAyman Medaney100% (1)

- Sample Fire Safety RegisterДокумент19 страницSample Fire Safety RegisterJohn HegartyОценок пока нет

- MSDS Formic Acid LuxiДокумент7 страницMSDS Formic Acid LuxiMarthinus BoxyОценок пока нет

- COSTINGДокумент65 страницCOSTINGAngela LaurillaОценок пока нет

- data - Docs/nsw-Risk - Management - Guide - Small - Business - Pdf&Ei 0Dk2Tim0Jmecomcxkfqe&Usg Afqjcne - Jko92Pmixrru 2Fna4Rbdzz-TqwДокумент9 страницdata - Docs/nsw-Risk - Management - Guide - Small - Business - Pdf&Ei 0Dk2Tim0Jmecomcxkfqe&Usg Afqjcne - Jko92Pmixrru 2Fna4Rbdzz-TqwRushi NaikОценок пока нет

- ISO14520-1-2000 (Sistemas de Co2)Документ4 страницыISO14520-1-2000 (Sistemas de Co2)Ricardo CardosoОценок пока нет

- Chartek Range - UKДокумент2 страницыChartek Range - UKTung ThanhОценок пока нет

- Fire Fighting EquipmentДокумент2 страницыFire Fighting EquipmentuniversalfireprotectionОценок пока нет

- NSD Quiz in EnglishДокумент4 страницыNSD Quiz in EnglishRajesh SutharОценок пока нет

- Memorandum Ssupt Roderick Esteban B Ramirez, MDДокумент11 страницMemorandum Ssupt Roderick Esteban B Ramirez, MDJanine Blaize Oplay CaniwОценок пока нет

- AXA Affin Impairment FormДокумент2 страницыAXA Affin Impairment FormZubaidi OthmanОценок пока нет