Академический Документы

Профессиональный Документы

Культура Документы

GCS Product Overview - Basyx VAV

Загружено:

GlobalContSolutionsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GCS Product Overview - Basyx VAV

Загружено:

GlobalContSolutionsАвторское право:

Доступные форматы

GCS Global Control Solutions

Product Data

Basyx VAV

Product Overview

The Basyx VAV assembly provides direct digital control of pressure-

independent variable air volume boxes. The VAV unit is a fully assembled

controller/actuator combination, and includes a differential pressure sensor for

accurate monitoring and control of air flow at very low volumes. The unit

controls through a sophisticated PID algorithm which constantly resets air flow

requirements by space temperature, thus eliminating constant damper hunting

typical of temperature only control units.

The Basyx VAV controller contains four (4) relay outputs for binary control of

fan or heating stages, and one (1) 0-10vdc output for control of modulating

reheat valves. In addition, an inexpensive room temperature sensor provides

space monitoring as well as setpoint adjustment and override activation. The

system may be installed as a stand-alone unit, requiring no connection with

other controllers. A Windows based Setup and Service Program allows

direct connection to the VAV through an RJ11 jack on the room sensor, which

facilitates easy setup and manual operation for air balance and system

commissioning. The VAV may also be installed as a part of a complete Basyx control and automation system with a maximum

configuration of 256 controllers. When connected within the Basyx network, all VAV controllers may be interrogated and

programmed through the standard Basyx TriComm interface software, including direct connect, modem connection or

intranet/internet interface.

The Basyx VAV system technology allows system firmware to be modified or upgraded through a flash memory configuration,

and does not require Eprom changes for system updates. Dual processors enhance the overall operation and capabilities of the

unit.

Features

• “Stand-alone” operation requires no central controller for system operation.

• Complete assembly with integral motor and pressure sensor reduces installation labor.

• Single unit provides control of cooling only, reheat, fan-powered reheat and constant volume terminal units.

• Air flow control through space temperature reset insures the proper air flow within the controlled space - Eliminates the

“hunting” of damper and associated air noise commonly found with temperature only based controls.

• On-board pressure differential sensor performs monitoring of air flows and eliminates mounting and wiring of external

devices.

• Inexpensive room temperature sensor allows setpoint adjustment and override of the system.

• Four (4) relay outputs and one (1) 0-10vdc analog output provide automatic control of staged heating and reheat valves.

• Unit will operate as a stand-alone unit, requiring no connection to other systems or controllers - Ideal for pneumatic

system replacements.

• Windows setup program allows connection directly through the room sensor, makes air balancing and system startup

easy.

• Program integrity through flash memory which retains system programming upon a loss of power.

• Flash memory allows firmware upgrades through laptop or telephone connection - No chips to change.

• May be installed as a part of an overall Basyx automation and control system, with a total system capacity of 256

controllers.

• Maximum communications bus length of 4000 feet.

• 24vac power reduces installation cost.

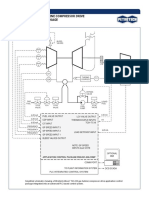

Typical Wiring Details

AUTOMATION COMPONENTS, INC.

BUTT SPLICES - DO NOT USE WIRE NUTS

ACI/10K-CP-D4

2 PAIR, 18G, SHIELDED CABLE

RED GREEN

FROM PREVIOUS CONTROLLER ON DAISY CHAIN

BLACK WHITE

INSTALL SENSOR UPSTREAM

TO NEXT CONTROLLER ON DAISY CHAIN IN ENTERING DUCTWORK

VARIABLE AIR VOLUME BOX VAV100 CONTROLLER

ENTERING AIR TEMPERATURE SENSOR

SEE BELOW FOR

REF

RS485 COMM BUS

CONNECTION OF

BLACK

-

VELOCITY TUBING

RED

+

TWIST SHIELD WIRES

- 3

TOGETHER - DO NOT

AO2

BLACK

-

CONNECT TO BOARD

AO2

RED

+

RS232 SERVICE PORT

ANALOG INPUTS

+28

GREEN

-

2

GND GND

WHITE

+

GREEN BLACK

-

1 PAIR, 18G, SHIELDED CABLE TB1

1

RED RED

+

IN

RED H

OUT

BLACK

-

AO1

BLACK C

+

FDBK

-

1

3

WHITE

C

2

4

BLUE

HEATING RELAY OUTPUTS

DIGITAL INPUTS SP ADJ

BROWN

NO

-

BLUE GREEN F

C

3

GREEN BLUE

NO

- 1

WHITE

C

2

WHITE

NO

- 2

COM CCW CW

C

1

1 2 3

COM CCW

RED GREEN

NO

FAN/ELECTRIC CONTROL SECTION

DAMPER

WHITE BLACK 3 PAIR, 18G, SHIELDED CABLE

24VAC

L2

CW

BLACK RED

L1

RED

WHITE

BLACK

BLACK

3 PAIR, 18G, SHIELDED CABLE

RED

FACTORY WIRED

ON VAV100 ASSEMBLY WHITE SPACE TEMPERATURE SENSOR JUMPERS MUST BE SET

GREEN FOR SEPARATE INPUT -

BLUE JUMP LOWER 2 PINS OF

BROWN EACH VERTICAL SET

SHORT SENSOR

SEPARATE INPUT

+ - SET O/R

2 PAIR, 18G, SHIELDED CABLE

BLACK

RED

BLUE OVERRIDE BUTTON

BROWN

WHITE

GREEN

RJ11

1 2 3 4 5 6

GREEN

RED

BLACK

ACI/10K-CP-RSO-RJ6

AUTOMATION COMPONENTS, INC.

SENSOR

SETPOINT ADJUSTMENT SLIDEBAR

Specifications

Communication: EIA RS-485 at 57.6K baud on 18AWG shielded, plenum rated cable

(recommended Belden 6300FE or equivalent)

Power Requirements: Voltage: 24VAC (-10% / 5%), 50/60/Hz

Current: 3.2VA maximum

Recommend 5VA transformer sizing for AC power

Analog Inputs: (3) 10K ohm thermistor 10,000 ohm type II.

Digital Inputs: (2) Dry contacts >/= 50ms timing

Analog Outputs: (1) 0-10VDC >/= 1K ohm drive impedance

Digital Outputs: (4) Dry contacts: SPST pilot duty rated 1 amp at 24VAC/24VDC

Environmental Limits: Temperature: 32oF to 125oF.

Humidity (non-condensing): 95%

UL Listing: ANSI/UL 916

Dimensions: 9.0"W x 5.0"H x 2.5"D

Shipping Weight: Approx. 1.95 lbs.

Although accurate at the time of publication, data is subject to change without notice

Вам также может понравиться

- Electrical Safety Management Procedure May 2013Документ35 страницElectrical Safety Management Procedure May 2013Roni Enjelani100% (2)

- Pioneer VSX C300Документ67 страницPioneer VSX C300tvtechsОценок пока нет

- Partlist Keeway TX 200 TX 200 Key137Документ90 страницPartlist Keeway TX 200 TX 200 Key137AzekkunОценок пока нет

- Esq Elec 12S Ecomaster Comfort Nodo PasajerosДокумент1 страницаEsq Elec 12S Ecomaster Comfort Nodo PasajerosAnderson SalazarОценок пока нет

- C6-C64 PLC Interface ManualДокумент342 страницыC6-C64 PLC Interface Manualsunhuynh100% (1)

- Sample Shutdown Schedule For Heat Exchanger Cleaning and InspectionДокумент2 страницыSample Shutdown Schedule For Heat Exchanger Cleaning and InspectionSobu George75% (4)

- Instrument Technical Room: PDC PDC 1600 800Документ1 страницаInstrument Technical Room: PDC PDC 1600 800ENGОценок пока нет

- Scada 1Документ17 страницScada 1Elxan HacinskiОценок пока нет

- Bendix - AD-IP Sevice Data (SD-08-2414)Документ28 страницBendix - AD-IP Sevice Data (SD-08-2414)Eduardo SanchezОценок пока нет

- LV Side Total: 8 Smart Meters MV Side Total: 8 Smart Meters: EthernetДокумент1 страницаLV Side Total: 8 Smart Meters MV Side Total: 8 Smart Meters: EthernetMusembiОценок пока нет

- Boiler NetworkДокумент78 страницBoiler NetworkAnonymous ZnuMEWN1Оценок пока нет

- CNG RegulatorДокумент9 страницCNG Regulatorsayem biswasОценок пока нет

- Pioneer VSX 518 K S Rrv3707 SMДокумент94 страницыPioneer VSX 518 K S Rrv3707 SMJose FernandezОценок пока нет

- ION Air Compressor (2023.2)Документ11 страницION Air Compressor (2023.2)maderainsancitaОценок пока нет

- Aeris Corporate Overview Brochure 2018Документ3 страницыAeris Corporate Overview Brochure 2018Roger ChetcutiОценок пока нет

- Pioneer - VSX 918v K - 818v KДокумент146 страницPioneer - VSX 918v K - 818v KfaroltekОценок пока нет

- Saudi Arabian Oil Company: 14.0 Coating/PaintingДокумент1 страницаSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RОценок пока нет

- 67-21-00 ClassC With Pictures CAP 21Документ66 страниц67-21-00 ClassC With Pictures CAP 21Northmoor EngenhariaОценок пока нет

- Dimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Документ1 страницаDimensi Panel Cad 2010 Mit Rev 04 SD Mit Fabs Ccep El Hvac 004Wijaya GultomОценок пока нет

- Anhydrous Ammonia Unloading Station & Storage/Vaporizer SystemДокумент2 страницыAnhydrous Ammonia Unloading Station & Storage/Vaporizer SystemWalter Rigamonti100% (1)

- 4021586-01 OemДокумент1 страница4021586-01 OemSuryadiОценок пока нет

- Evel Ommand With OmpressorДокумент4 страницыEvel Ommand With Ompressortesslik SlavaОценок пока нет

- New NGP Presentations - Sleeper OptionsДокумент19 страницNew NGP Presentations - Sleeper OptionsEduardo ColinОценок пока нет

- Leaflet Eair VSD ENДокумент8 страницLeaflet Eair VSD ENTiago PaivaОценок пока нет

- Main Control Room Engineering Room Fire StationДокумент1 страницаMain Control Room Engineering Room Fire StationENGОценок пока нет

- Co2 CylindersДокумент14 страницCo2 CylindersMohamed AmrОценок пока нет

- M4E-PR-FRM-PWD-00555-B-Form 2 - Scope of Work Appendix 5Документ15 страницM4E-PR-FRM-PWD-00555-B-Form 2 - Scope of Work Appendix 5Chakib AutomationОценок пока нет

- Total Lighting Control: Catalog Number: RPSEN-ATRДокумент2 страницыTotal Lighting Control: Catalog Number: RPSEN-ATRmotaОценок пока нет

- 1842 LAYOUTS OF AC & REPORT CompressedДокумент12 страниц1842 LAYOUTS OF AC & REPORT CompressedNurein SayedОценок пока нет

- Wing-Air Curtain - Catalogue PDFДокумент8 страницWing-Air Curtain - Catalogue PDFvishal vananiОценок пока нет

- Walker 2050 WindДокумент2 страницыWalker 2050 WindPeter PiskoraОценок пока нет

- P 200 Series+CinДокумент2 страницыP 200 Series+CinjovicatrpcevicОценок пока нет

- Mechanical Legend: Circuit Setter DetailДокумент1 страницаMechanical Legend: Circuit Setter DetailKoJoeОценок пока нет

- Pib2000 225 D4Документ7 страницPib2000 225 D4CarlosОценок пока нет

- GeneralAire 1099 Installation Manual PDFДокумент4 страницыGeneralAire 1099 Installation Manual PDFFusion EdgeОценок пока нет

- HCD4500Документ2 страницыHCD4500Walter naspiranОценок пока нет

- VSX 919 VKДокумент146 страницVSX 919 VKmaibac3300Оценок пока нет

- Conference RoomДокумент6 страницConference RoomFidel José Regúnega ArdissoneОценок пока нет

- Andrew TafoyaДокумент14 страницAndrew TafoyaDivyanshu KumarОценок пока нет

- Thayer S52C BrochureДокумент4 страницыThayer S52C BrochuretactiqueelecОценок пока нет

- 257 - AHU Connection Kits For DX Systems FlyerДокумент6 страниц257 - AHU Connection Kits For DX Systems FlyerTrirong KampoolОценок пока нет

- VSX 518 KДокумент94 страницыVSX 518 KSai R-JAgОценок пока нет

- Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810Документ1 страницаControl Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810ErmiasОценок пока нет

- Attendant Handset Locking StrapДокумент1 страницаAttendant Handset Locking Strapnestor ivan jerez francoОценок пока нет

- Dak Drinh HPP Control and Monitoring System ArchitectureДокумент1 страницаDak Drinh HPP Control and Monitoring System ArchitectureNông Dân Anh HùngОценок пока нет

- Blower Data Sheet-Aeration TankДокумент1 страницаBlower Data Sheet-Aeration TankMohammed Abdul MoiedОценок пока нет

- Dab CatalogueДокумент382 страницыDab CatalogueFILID MADОценок пока нет

- 777D Off Highway Truck: Service Training MalagaДокумент22 страницы777D Off Highway Truck: Service Training MalagaDevid Waladan SholehanОценок пока нет

- QSB3.3 CM2250 B137 5411062Документ1 страницаQSB3.3 CM2250 B137 5411062Cristobal HenriquezОценок пока нет

- Allison 501 KB CompressorДокумент3 страницыAllison 501 KB CompressortaghiОценок пока нет

- Adf4360 7Документ29 страницAdf4360 7shhmmmОценок пока нет

- Integrated Synthesizer and VCO: Data SheetДокумент24 страницыIntegrated Synthesizer and VCO: Data SheetDUDULEОценок пока нет

- Arnel904u1 EngДокумент2 страницыArnel904u1 EngnormОценок пока нет

- Balancing Kit-HVAC4Документ8 страницBalancing Kit-HVAC4Chaminda KumaraОценок пока нет

- Refrigeration SheetsДокумент4 страницыRefrigeration Sheetsromeo pedranoОценок пока нет

- Product Catalogue & Technical Manual 2016Документ15 страницProduct Catalogue & Technical Manual 2016Munever OkićОценок пока нет

- AX4 AX2 PCSoft ENДокумент30 страницAX4 AX2 PCSoft ENHuisen zhangОценок пока нет

- Themes For Research WorksДокумент15 страницThemes For Research WorksMarinaldo RodriguesОценок пока нет

- 3311 Stamped Plan SetДокумент15 страниц3311 Stamped Plan SetDung AnhОценок пока нет

- Forest Ave Ice Creams e LayoutДокумент3 страницыForest Ave Ice Creams e LayoutengrfurhanОценок пока нет

- Service Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentДокумент116 страницService Manual For Electrical/Electronic: P.O. Box 868 - 501 Sanford Ave Mocksville, N.C. 27028 Utility EquipmentMario Garcia100% (1)

- sdv5 ManualДокумент8 страницsdv5 ManualHernan RomeroОценок пока нет

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationОт EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationОценок пока нет

- BASYX IPM Installation & Setup Manual v81Документ13 страницBASYX IPM Installation & Setup Manual v81GlobalContSolutionsОценок пока нет

- BASYX TriComm System Operation Manual v21Документ58 страницBASYX TriComm System Operation Manual v21GlobalContSolutionsОценок пока нет

- GCS Lighting Control BrochureДокумент2 страницыGCS Lighting Control BrochureGlobalContSolutionsОценок пока нет

- GCS General Control BrochureДокумент4 страницыGCS General Control BrochureGlobalContSolutionsОценок пока нет

- GCS C-Store Control BrochureДокумент4 страницыGCS C-Store Control BrochureGlobalContSolutionsОценок пока нет

- BASYX PSC Installation Manual v41Документ27 страницBASYX PSC Installation Manual v41GlobalContSolutionsОценок пока нет

- GCS Product Overview - TimeWatch TWC ConfigurationДокумент2 страницыGCS Product Overview - TimeWatch TWC ConfigurationGlobalContSolutionsОценок пока нет

- GCS Product Overview - Programming WarrantyДокумент1 страницаGCS Product Overview - Programming WarrantyGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx VVRДокумент2 страницыGCS Product Overview - Basyx VVRGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx SVCДокумент2 страницыGCS Product Overview - Basyx SVCGlobalContSolutionsОценок пока нет

- GCS Product Overview - Product WarrantyДокумент1 страницаGCS Product Overview - Product WarrantyGlobalContSolutionsОценок пока нет

- GCS Product Overview - Interface DevicesДокумент2 страницыGCS Product Overview - Interface DevicesGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx RFCДокумент2 страницыGCS Product Overview - Basyx RFCGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx RFWДокумент2 страницыGCS Product Overview - Basyx RFWGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx EMNДокумент2 страницыGCS Product Overview - Basyx EMNGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx PSCДокумент2 страницыGCS Product Overview - Basyx PSCGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx LC8-RДокумент2 страницыGCS Product Overview - Basyx LC8-RGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx IPRДокумент1 страницаGCS Product Overview - Basyx IPRGlobalContSolutionsОценок пока нет

- GCS Product Overview - Application Engineering & Panel AssemblyДокумент2 страницыGCS Product Overview - Application Engineering & Panel AssemblyGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx LC5Документ2 страницыGCS Product Overview - Basyx LC5GlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx IPMДокумент1 страницаGCS Product Overview - Basyx IPMGlobalContSolutionsОценок пока нет

- GCS Product Overview - Basyx 100Документ2 страницыGCS Product Overview - Basyx 100GlobalContSolutionsОценок пока нет

- GCS Product Overview - Accessory DevicesДокумент1 страницаGCS Product Overview - Accessory DevicesGlobalContSolutionsОценок пока нет

- GCS Product Overview - TimeWatch TWCДокумент2 страницыGCS Product Overview - TimeWatch TWCGlobalContSolutionsОценок пока нет

- Pre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsДокумент15 страницPre-Insertion Resistor and Grading Capacitor in Multi Break Circuit Breaker - Electrical ConceptsSheraz KhanОценок пока нет

- General Information (Brake, Hydraulic Fan System)Документ5 страницGeneral Information (Brake, Hydraulic Fan System)EVER DAVID SAAVEDRA HUAYHUA0% (1)

- HPR-2Документ12 страницHPR-2v2nssysy6fОценок пока нет

- QC Welding Inspector Interview Questions - Wisdom Jobs India7Документ1 страницаQC Welding Inspector Interview Questions - Wisdom Jobs India7kokaanilkumarОценок пока нет

- Relief ValveДокумент16 страницRelief ValveArmando RiveraОценок пока нет

- CM1N5192en 2018-02-28: Building TechnologyДокумент12 страницCM1N5192en 2018-02-28: Building TechnologyAllamine OUMARОценок пока нет

- Datasheet - HK Mb90m408apf 4289720Документ64 страницыDatasheet - HK Mb90m408apf 4289720Sebastian CorreaОценок пока нет

- Fresadora B40pte B40e 2 PDFДокумент70 страницFresadora B40pte B40e 2 PDFRaul Alanoca ColqueОценок пока нет

- Installation Instruction: NTL600EДокумент3 страницыInstallation Instruction: NTL600EPayphone.comОценок пока нет

- A320 - SRM - 01-Aug-2019 - TASK 55-44-00-300-003 - Partial Replacement of Rudder Tip StructureДокумент6 страницA320 - SRM - 01-Aug-2019 - TASK 55-44-00-300-003 - Partial Replacement of Rudder Tip Structurejr primeОценок пока нет

- Anil Bhat 125Документ125 страницAnil Bhat 125harsh yadavОценок пока нет

- Invertec 135S, 150S & 170SДокумент7 страницInvertec 135S, 150S & 170SDiegoОценок пока нет

- Impact Panel Printer For Industrial Use: CharacteristicsДокумент3 страницыImpact Panel Printer For Industrial Use: CharacteristicsWALTER DANIEL GUTIERREZ VEREAUОценок пока нет

- Inversor PV1800 VHM (220V) SPECSДокумент4 страницыInversor PV1800 VHM (220V) SPECSwilliam andres pena castanoОценок пока нет

- Catalog 301: Condensed Catalog of Sporlan Products March 2011Документ64 страницыCatalog 301: Condensed Catalog of Sporlan Products March 2011AbdulSattarОценок пока нет

- TMB Switchgear ProductsДокумент3 страницыTMB Switchgear Productskazem shakeriОценок пока нет

- CC CCCC: Y Y Y YyДокумент24 страницыCC CCCC: Y Y Y YyRavi KantОценок пока нет

- SENCORE Understand ESR in CapacitorsДокумент4 страницыSENCORE Understand ESR in CapacitorsmashjlОценок пока нет

- F200aet 2006Документ88 страницF200aet 2006Ray Cepeda MenaОценок пока нет

- Aeron Systems: Inertial Sensors and Navigation SystemsДокумент7 страницAeron Systems: Inertial Sensors and Navigation SystemsBhagavad GitaОценок пока нет

- PIC16F18855 ModДокумент662 страницыPIC16F18855 Modwhynot05Оценок пока нет

- CCS-DX CCS Delegate UnitДокумент2 страницыCCS-DX CCS Delegate UnitvtcuongОценок пока нет

- Hydraulic Transmission Jacks: Operating Instructions & Parts ManualДокумент8 страницHydraulic Transmission Jacks: Operating Instructions & Parts Manualamare addisОценок пока нет

- HQ 170aДокумент82 страницыHQ 170aTony WellsОценок пока нет

- MS 415 PDFДокумент7 страницMS 415 PDFerode els erodeОценок пока нет

- ST352 Sales Presentation 1-6-2005Документ26 страницST352 Sales Presentation 1-6-2005Jesus David Perez OrdóñezОценок пока нет