Академический Документы

Профессиональный Документы

Культура Документы

Potting Resin T905BN-4

Загружено:

Mitesh PhalakИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Potting Resin T905BN-4

Загружено:

Mitesh PhalakАвторское право:

Доступные форматы

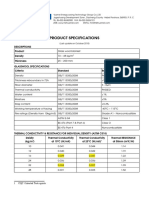

EPO-TEK® T905BN-4

Technical Data Sheet

For Reference Only

Thermally Conductive Epoxy

Number of Components: Two Minimum Bond Line Cure Schedule*:

Mix Ratio By Weight: 100:25 80ºC 1 Hour

Specific Gravity: 23ºC 1 Day

Part A 1.63

Part B 1.16

Pot Life: 1 Hour

Shelf Life: One year at room temperature

Note: Container(s) should be kept closed when not in use. For filled systems, mix contents of each container (A & B) thoroughly before mixing the

two together. *Please see Applications Note available on our website.

Product Description:

®

EPO-TEK T905BN-4 is a two component, room temperature cure, thermally conductive epoxy for general adhesive bonding,

sealing, potting and encapsulation applications

®

EPO-TEK T905BN-4 Advantages & Application Notes:

A moderate viscosity resin with flowing properties enables potting of cavities, packages and housings.

Contains a coarse grade of filler, which needs to be taken into account in all bonding, sealing and potting applications. Contact

techserv@epotek.com to review your choice.

Pure white color after cure allows for easy inspection by operators on common electronic packaging surfaces.

Versatility in cure: 23ºC and 100ºC ambient, box oven or tunnel oven processes.

Suggested Applications:

o Hybrids: thermally conductive adhesive bonding ceramics and metals

o Electronics:

General PCB level potting and adhesive applications. Bonding metal and composite heat sinks to PCBs or

SMDs.

Transformers: potting of Cu coils, magnets, inductors and other SMDs into their respective casing.

o Medical Devices

Heat sinking of x-ray and ultrasound circuits via adhesive and potting processes.

Typical Properties: (To be used as a guide only, not as a specification. Data below is not guaranteed. Different batches, conditions and

applications yield differing results; Cure condition: 80°C/1 Hour; * denotes test on lot acceptance basis)

Physical Properties:

*Color: Part A: White Part B: Light Mauve Die Shear Strength @ 23°C: ≥ 5 Kg / 1,700 psi

*Consistency: Granular paste Degradation Temp. (TGA): 350°C

*Viscosity (@ 20 RPM/23°C): 12,000 – 18,000 cPs Weight Loss:

Thixotropic Index: 2.58 @ 200°C: 0.18%

*Glass Transition Temp.(Tg): ≥ 50°C (Dynamic Cure @ 250°C: 0.64%

20—200°C /ISO 25 Min; Ramp -40—200°C @ 20°C/Min) @ 300°C: 1.44%

Coefficient of Thermal Expansion (CTE): Operating Temp:

Below Tg: 24 x 10-6 in/in/°C Continuous: - 55°C to 200°C

Above Tg: 120 x 10-6 in/in/°C Intermittent: - 55°C to 300°C

Shore D Hardness: 79 Storage Modulus @ 23°C: 1,152,068 psi

Lap Shear Strength @ 23°C: 1,412psi *Particle Size: ≤ 300 Microns

Thermal Properties:

Thermal Conductivity: 1.78 W/mK

Electrical Properties:

Dielectric Constant (1KHz): 3.82 Volume Resistivity @ 23°C: ≥ 4 x 1014 Ohm-cm

Dissipation Factor (1KHz): 0.012

EPOXY TECHNOLOGY, INC.

14 Fortune Drive, Billerica, MA 01821-3972 Phone: 978.667.3805 Fax: 978.663.9782

www.EPOTEK.com

Epoxies and Adhesives for Demanding Applications™

This information is based on data and tests believed to be accurate. Epoxy Technology, Inc. makes no warranties

(expressed or implied) as to its accuracy and assumes no liability in connection with any use of this product.

Rev. II

12/2008

Вам также может понравиться

- Epo-Tek 353ND: Technical Data SheetДокумент2 страницыEpo-Tek 353ND: Technical Data SheetJamesОценок пока нет

- 353ND TДокумент1 страница353ND TCothuru Santosh KumarОценок пока нет

- H70SДокумент1 страницаH70SJustin SantiagoОценок пока нет

- N20EДокумент2 страницыN20EmachoborbalaОценок пока нет

- H70EДокумент2 страницыH70ENaveenОценок пока нет

- 730 110Документ2 страницы730 110Luca de LeonardisОценок пока нет

- Epo-Tek 301: Technical Data SheetДокумент1 страницаEpo-Tek 301: Technical Data SheetAnonymous 3hUDn2Оценок пока нет

- Epotek AP-100Документ1 страницаEpotek AP-100mynОценок пока нет

- Colpoly 736 WAT TDSДокумент2 страницыColpoly 736 WAT TDSKristjan PosavecОценок пока нет

- Zalac 002Документ4 страницыZalac 002Stevie Herman TDОценок пока нет

- 3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926Документ7 страниц3M™ Scotch-Weld™ Epoxy Adhesive 2214 Hi-Temp New Formula - 20230926bnzelectricianshopОценок пока нет

- peekДокумент23 страницыpeekwamikshahidrizviОценок пока нет

- Turbo-Coat Acrylic Conformal Coating: Product# 2108Документ5 страницTurbo-Coat Acrylic Conformal Coating: Product# 2108Compras MareinsaОценок пока нет

- Loctite EA E-30CL™: Technical Data SheetДокумент3 страницыLoctite EA E-30CL™: Technical Data SheetAbhishek Kumar SinghОценок пока нет

- TDS 3M Scotch-Weld Epoxy Adhesive DP125 Translucent - 30000622Документ11 страницTDS 3M Scotch-Weld Epoxy Adhesive DP125 Translucent - 30000622Akbar Perwira UtamaОценок пока нет

- PottingДокумент4 страницыPottingdaniazgonzalez26Оценок пока нет

- Ep 280 WHG PDS EngДокумент5 страницEp 280 WHG PDS EngMajdi ShannibОценок пока нет

- Anabond 652c Heat Sink Compound Thermally ConductiveДокумент2 страницыAnabond 652c Heat Sink Compound Thermally ConductiveRohit MahaleОценок пока нет

- 3M TC-2707-TDSДокумент4 страницы3M TC-2707-TDSJavierОценок пока нет

- Loctite 384Документ2 страницыLoctite 384A DamiánОценок пока нет

- Transformer OilsДокумент2 страницыTransformer OilsAbegail BernabeОценок пока нет

- Solder PasteДокумент2 страницыSolder PasteEdgar DauzonОценок пока нет

- ResinTek RTS 075FR-1Документ2 страницыResinTek RTS 075FR-1vishal089Оценок пока нет

- TDS - Ew 6325H - enДокумент2 страницыTDS - Ew 6325H - enAnthony GalindoОценок пока нет

- Ep3hts TCДокумент2 страницыEp3hts TCClausio MeloОценок пока нет

- Epofine 221 - Finehard 964 - Accelerator 070Документ4 страницыEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuОценок пока нет

- 4x-Datasheet BONDiT B-481Документ4 страницы4x-Datasheet BONDiT B-481Marco BrolloОценок пока нет

- LOCTITE 315 en - GLДокумент2 страницыLOCTITE 315 en - GLinigo.bretonОценок пока нет

- Colpoly 7331 LV TDSДокумент2 страницыColpoly 7331 LV TDSKristjan PosavecОценок пока нет

- Freecorev - Micro - 10 - English ARtecoДокумент5 страницFreecorev - Micro - 10 - English ARtecoManh Nguyen TheОценок пока нет

- TD Propan Epoxy Cast Ec 973 2K 1Документ2 страницыTD Propan Epoxy Cast Ec 973 2K 1Yogi PranataОценок пока нет

- Epofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregДокумент5 страницEpofine 6071A80/ Finecure 197/ Finecure 190/ Finehard 986/ Accelerator 062 Toughened PrepregKarishma PrabhuОценок пока нет

- Tds - Epotec THW 4504Документ3 страницыTds - Epotec THW 4504Dr. Chem100% (2)

- Loctite 3478 enДокумент2 страницыLoctite 3478 enMohsin ModiОценок пока нет

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundДокумент3 страницыXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhОценок пока нет

- Changing The Dielectric Dissipation Factor of Transformer Fluid Based On Synthetic Ester in The Condition of A Concentrated Heat FluxДокумент4 страницыChanging The Dielectric Dissipation Factor of Transformer Fluid Based On Synthetic Ester in The Condition of A Concentrated Heat Fluxkong shiaw huiОценок пока нет

- PB Electr Conductive Adhesives e PDFДокумент4 страницыPB Electr Conductive Adhesives e PDFMhand OughanemОценок пока нет

- My T Bond Fast and Clear Epoxy TDSДокумент2 страницыMy T Bond Fast and Clear Epoxy TDSChetan MahajanОценок пока нет

- Colpoly 7167 8A TDSДокумент2 страницыColpoly 7167 8A TDSKristjan PosavecОценок пока нет

- NC-558 TDS enДокумент2 страницыNC-558 TDS enniteshacharya100% (1)

- High Performance Electrical Double Layer CapacitorДокумент8 страницHigh Performance Electrical Double Layer Capacitorkn65238859Оценок пока нет

- Thermaguard TIC 400 TDSДокумент4 страницыThermaguard TIC 400 TDSJIMMY JAMESОценок пока нет

- Huamei Spec Sheets - 2018Документ1 страницаHuamei Spec Sheets - 2018Phan LongОценок пока нет

- K300 TDSДокумент2 страницыK300 TDSM. Kürşad ArslanОценок пока нет

- Colpoly 739 S TDSДокумент2 страницыColpoly 739 S TDSKristjan PosavecОценок пока нет

- Epofine 184-Finehard 907 - Acc 062Документ4 страницыEpofine 184-Finehard 907 - Acc 062Karishma PrabhuОценок пока нет

- LOCTITEДокумент2 страницыLOCTITEHrОценок пока нет

- Ultradur B2520Документ2 страницыUltradur B2520Phung LucОценок пока нет

- 044HTGДокумент2 страницы044HTGSophia RoseОценок пока нет

- Technical Data Sheet for Epotec YDPN 631 Epoxy Phenol Novolac ResinДокумент2 страницыTechnical Data Sheet for Epotec YDPN 631 Epoxy Phenol Novolac Resintrường phạmОценок пока нет

- Duplocoll: Double-Sided Adhesive Tape With Polyester Film and Pure Acrylic AdhesiveДокумент3 страницыDuplocoll: Double-Sided Adhesive Tape With Polyester Film and Pure Acrylic AdhesiveПавел СкударновОценок пока нет

- Epikote 828Документ2 страницыEpikote 828Lê TiếnОценок пока нет

- POM_KEPITAL_F30-03_EnДокумент2 страницыPOM_KEPITAL_F30-03_EnAthonioMourinhoОценок пока нет

- Astar 02Документ5 страницAstar 02HAKANОценок пока нет

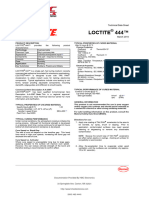

- HMC Loctite 444Документ2 страницыHMC Loctite 444sengottОценок пока нет

- F F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Документ4 страницыF F O P L: Epofine - 740 / Finehard - 918 / Accelerator - 062Karishma Prabhu100% (1)

- Ultradur® B 6550 LN en SI - Product DatasheetДокумент2 страницыUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoОценок пока нет

- Loctite EA E-30CL™: Product Description Typical Curing PerformanceДокумент3 страницыLoctite EA E-30CL™: Product Description Typical Curing PerformanceTim HortonОценок пока нет

- FR6082 DatasheetДокумент3 страницыFR6082 DatasheetEric Baltus100% (1)

- Steel Grades Material and Chemical Composition InformationДокумент2 страницыSteel Grades Material and Chemical Composition InformationMitesh PhalakОценок пока нет

- Installation Guide for Boosting Your Vehicle with HydroxyДокумент4 страницыInstallation Guide for Boosting Your Vehicle with HydroxyMitesh PhalakОценок пока нет

- Plan Virtual InkДокумент24 страницыPlan Virtual InkMitesh PhalakОценок пока нет

- Hybrid Power Management-Based Vehicle Architecture LEW18704-1Документ17 страницHybrid Power Management-Based Vehicle Architecture LEW18704-1Mitesh PhalakОценок пока нет

- Green Report - 16 May 2011Документ5 страницGreen Report - 16 May 2011Mitesh PhalakОценок пока нет

- R&D On Innovative Solar Cells Koichi SAKUTA PV in AISTДокумент24 страницыR&D On Innovative Solar Cells Koichi SAKUTA PV in AISTMitesh PhalakОценок пока нет

- Powador Megawatt-Station: High-tech 3-inverter station for 1 MW outputДокумент2 страницыPowador Megawatt-Station: High-tech 3-inverter station for 1 MW outputMitesh PhalakОценок пока нет

- CORM 2009 - IESNA Standards On LED and SSL LM79LM80 and Future Standards CORM 2009 Y OhnoДокумент28 страницCORM 2009 - IESNA Standards On LED and SSL LM79LM80 and Future Standards CORM 2009 Y Ohnoberker_yurtsevenОценок пока нет

- Torsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0Документ21 страницаTorsional Vibration Monitoring System - AWM M30-B2, DWG 1142957-2.0cengiz kutukcu100% (1)

- Vacumat 22 22TДокумент2 страницыVacumat 22 22TSandeep ChhonkerОценок пока нет

- FX1N PLC HW ManualДокумент90 страницFX1N PLC HW Manualaar9999Оценок пока нет

- Bidirectional DC-DC Converter With Full-Bridge / Push-Pull Circuit For Automobile Electric Power SystemsДокумент5 страницBidirectional DC-DC Converter With Full-Bridge / Push-Pull Circuit For Automobile Electric Power SystemsPaulo UchihaОценок пока нет

- Micromouse Contest Rules BDSSCДокумент5 страницMicromouse Contest Rules BDSSCK M Nasim RushoОценок пока нет

- Multiple Choice: Intermolecular ForcesДокумент4 страницыMultiple Choice: Intermolecular ForcesCardio LogyОценок пока нет

- Electromechanical Fuel Shutoff Valves M25 - M50Документ4 страницыElectromechanical Fuel Shutoff Valves M25 - M50AlejandroMuñozОценок пока нет

- CDJ 200 Service ManualДокумент80 страницCDJ 200 Service ManualbzrmiltosОценок пока нет

- Photoelectric Effect and EinsteinДокумент6 страницPhotoelectric Effect and EinsteinmylinhxoОценок пока нет

- United States Patent: Barger Et Al. (45) Date of Patent: Jun. 15, 2004Документ39 страницUnited States Patent: Barger Et Al. (45) Date of Patent: Jun. 15, 2004Gek CagatanОценок пока нет

- CV Idir Mahrouche - 3 PDFДокумент2 страницыCV Idir Mahrouche - 3 PDFIdirMahroucheОценок пока нет

- Z TXgard-IS+ Iss8 Jan 15 EngДокумент60 страницZ TXgard-IS+ Iss8 Jan 15 EngkazishahОценок пока нет

- 8086 MICROPROCESSOR LAB MANUALДокумент14 страниц8086 MICROPROCESSOR LAB MANUALhariОценок пока нет

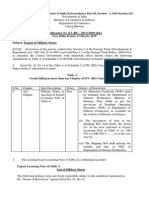

- DGFT Notification No.115 (RE-2013) /2009-2014 Dated 13th March, 2015Документ5 страницDGFT Notification No.115 (RE-2013) /2009-2014 Dated 13th March, 2015stephin k jОценок пока нет

- Breaker Pole Discrepancy FunctionДокумент10 страницBreaker Pole Discrepancy FunctionErmin FazlicОценок пока нет

- Soldadura Manual KukaДокумент78 страницSoldadura Manual KukaEduardoОценок пока нет

- HFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanДокумент97 страницHFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanAmmar AlkindyОценок пока нет

- 50 Top Design Engineering Software Tools and Apps - PannamДокумент43 страницы50 Top Design Engineering Software Tools and Apps - PannamAgniva DuttaОценок пока нет

- Lec3 Single StageДокумент24 страницыLec3 Single Stagerajeevjain09Оценок пока нет

- Telecommunication SwitchingДокумент24 страницыTelecommunication SwitchingSanjanaDeyОценок пока нет

- The Main Circuit Board of A MicrocomputerДокумент16 страницThe Main Circuit Board of A Microcomputeramandeep123Оценок пока нет

- OptiX OSN 8800 T64&T32 Product OvervieДокумент114 страницOptiX OSN 8800 T64&T32 Product OvervieYaroslavОценок пока нет

- Lecture 5Документ31 страницаLecture 5Ali MustafaОценок пока нет

- IAE 102 Information Sheet 3 SERIES AND PARALLEL CIRCUITДокумент7 страницIAE 102 Information Sheet 3 SERIES AND PARALLEL CIRCUITChristian Lumactod EmbolodeОценок пока нет

- ARC Master Controller User ManualДокумент16 страницARC Master Controller User ManualDinesh MehtaОценок пока нет

- Colpitts Oscillator Design PDFДокумент2 страницыColpitts Oscillator Design PDFShayОценок пока нет

- v22 v24 v23 - DtoДокумент70 страницv22 v24 v23 - DtoplasmapeteОценок пока нет

- Eliwell 2011 Catalogue RUS A4 High 72Документ1 страницаEliwell 2011 Catalogue RUS A4 High 72Януш ЗейдальОценок пока нет

- Fix Touchpad Issues on Acer Aspire LaptopДокумент11 страницFix Touchpad Issues on Acer Aspire LaptopYandexОценок пока нет

- Kisah Wanita SholehahДокумент2 страницыKisah Wanita SholehahimamОценок пока нет