Академический Документы

Профессиональный Документы

Культура Документы

Ceramics

Загружено:

Hitesh Bhatia0 оценок0% нашли этот документ полезным (0 голосов)

75 просмотров13 страницThe document discusses ceramic processing and properties. It states that ceramics have properties like light weight, corrosion and wear resistance, and high temperature strength but are also brittle. It describes conventional ceramic processing which involves powder preparation, consolidation, drying, sintering, and machining. Non-conventional methods like sol-gel and vapor deposition are also discussed. The document notes that ceramic properties are probabilistic due to flaws and that strength decreases with increasing size. It emphasizes designing with ceramics requires considering their brittle nature and probabilistic strength.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document discusses ceramic processing and properties. It states that ceramics have properties like light weight, corrosion and wear resistance, and high temperature strength but are also brittle. It describes conventional ceramic processing which involves powder preparation, consolidation, drying, sintering, and machining. Non-conventional methods like sol-gel and vapor deposition are also discussed. The document notes that ceramic properties are probabilistic due to flaws and that strength decreases with increasing size. It emphasizes designing with ceramics requires considering their brittle nature and probabilistic strength.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

75 просмотров13 страницCeramics

Загружено:

Hitesh BhatiaThe document discusses ceramic processing and properties. It states that ceramics have properties like light weight, corrosion and wear resistance, and high temperature strength but are also brittle. It describes conventional ceramic processing which involves powder preparation, consolidation, drying, sintering, and machining. Non-conventional methods like sol-gel and vapor deposition are also discussed. The document notes that ceramic properties are probabilistic due to flaws and that strength decreases with increasing size. It emphasizes designing with ceramics requires considering their brittle nature and probabilistic strength.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 13

Ceramic Processing

• Ceramics are light

weight, with corrosion

and wear resistance as

well as high temperature

strength

• Ceramics have high

strength but are brittle

(sensitive to flaws

• Dimensional stability and

accuracy

• Parts range from tiny to

large BUT strength varies

inversely with size

(volume or surface area)!

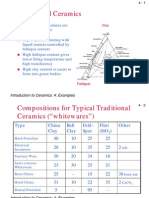

What are Ceramics

• Ceramics are compounds of

metals and non metals

• Advanced Ceramic (structural,

technical or fine): highly

engineered, high performance

predominantly non-metallic

inorganic ceramic matrial

having specific functional

properties

• Unique atomic bonding:

covalent (sharing) and ionic

(give up)

• Crystalline lattice structure:

cubic, etc. or amorphous

(glasses)

Properties of Ceramics

• Probabilistic properties due to

distributions of flaws

• ASTM standards address many

aspects of these properties

• Low fracture toughness (<10 MPa

√m)

• High strengths at small volumes

(>1 GPa)

• Low CTE (2-4 x 10-6 /°C)

• High Hardness (1 GPa)

• High Stiffness (300-600 GPa)

Processing of Ceramics

• Natural vs

Manufactured

• Conventional

(traditional) vs Non

conventional

• As-processed vs

machined

Processing of Ceramics

• Natural Ceramics -

SiO2 and SiO4 along

with hydrated

alumino silicate (e.g.

2(OH)4Al2Si2O5)

• Can be used directly,

or processed to

further refine

• Examples:

amorphous SiO2 is

glass, crystalline SiO2

is fused silica or

quartz; single crystal

Al2O3 is sapphire.

Processing of Ceramics

• Manufactured

Ceramics - SiC,

Si3N4, Al2O3, B4C,

BN, TiB2, TiO2 etc

• Usually require

decomposition and

recomposition into

powders

• Often dissociate (i.e.,

do not “melt” at high

temperatures in the

“right” environment)

Processing of Ceramics

• Conventional

Processing

- Powder Preparation

- Consolidation of

Powders: Dry

Pressing, Wet

Pressing, “Casting”

- Drying

- Green Machining

- Sintering (or hot

compaction)

- Final machining

(AWJ, diamond

grinding)

Processing of Ceramics

• Non Conventional

Processing

- Sol-gel

- Vapor Deposition

(CVD or PVD)

- Polymer Derived

- SHS (self propagating

high temperature

synthesis)

- Directed Metal

Oxidation

- Reaction Forming

Processing of Ceramics

• As fired

- At best ±3%

variability in

dimension

- Rough surfaces

- Low Straightness

/flatness

Processing of Ceramics

• Machining

- Diamond Grinding

- Lapping Honing,

Polishing

- USM (ultra sonic

machining)

- AWJ (abrasive water

jet)

- LBM (last beam

machining)

- EDM (electro

discharge machining)

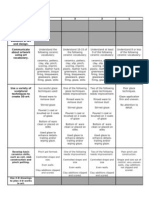

Designing with Ceramics

• Brittle Materials

Design

- Probabilistic methods

- Strength statistics

- Stress raisers

- Reliability

- Volume/area effects

Вам также может понравиться

- The Potter's Craft: A Practical Guide for the Studio and WorkshopОт EverandThe Potter's Craft: A Practical Guide for the Studio and WorkshopОценок пока нет

- Muy Buenos 3110Документ17 страницMuy Buenos 3110Jesus MorenoОценок пока нет

- Mason High - Ceramics 2 - Centerpiece Lesson PlanДокумент4 страницыMason High - Ceramics 2 - Centerpiece Lesson Planapi-267189611Оценок пока нет

- Ceramic SpectrumДокумент5 страницCeramic SpectrumMaria Auxiliadora RodriguezОценок пока нет

- STA Decorating SlipДокумент2 страницыSTA Decorating SlipmohanОценок пока нет

- Crepulje Za PecenjeДокумент4 страницыCrepulje Za PecenjeJanković DušanОценок пока нет

- Advanced Ceramics SyllabusДокумент4 страницыAdvanced Ceramics Syllabusapi-285550989Оценок пока нет

- Ceramics DefinitionsДокумент2 страницыCeramics DefinitionsNiranjanОценок пока нет

- FritДокумент4 страницыFritaymanfawzyОценок пока нет

- Ceramic: For Other Uses, See - A Ceramic Is An, NonmetallicДокумент7 страницCeramic: For Other Uses, See - A Ceramic Is An, Nonmetallicletter_ashish4444Оценок пока нет

- Introduction To CeramicsДокумент29 страницIntroduction To CeramicsShrikrishna BirajdarОценок пока нет

- ESmalte Rojos PDFДокумент7 страницESmalte Rojos PDFtengocorazon100% (1)

- Ceramic FritsДокумент6 страницCeramic FritsMohammad YoussefiОценок пока нет

- Testing The Thermal Properties of Advanced Ceramics: Standard Guide ForДокумент16 страницTesting The Thermal Properties of Advanced Ceramics: Standard Guide ForSakarin Waiyakul100% (1)

- Ceramic Material Part 1 by Pak RahmanДокумент42 страницыCeramic Material Part 1 by Pak RahmannisannisaОценок пока нет

- Esmaltes Varios en Inglés FABIДокумент8 страницEsmaltes Varios en Inglés FABIclaul66100% (1)

- 08 Chapter 4Документ8 страниц08 Chapter 4Ali AliОценок пока нет

- Esposito, Ralph Bulgarian Pottery ProjectДокумент14 страницEsposito, Ralph Bulgarian Pottery Projectceeresk12100% (2)

- Ceramic Sculpture GordonДокумент4 страницыCeramic Sculpture GordonHugo De Oliveira AssisОценок пока нет

- Roger GrahamДокумент3 страницыRoger GrahamStefan Van CleemputОценок пока нет

- Pigments and Engobes For Crystalline Glazes: KnowledgeДокумент2 страницыPigments and Engobes For Crystalline Glazes: KnowledgeJesus MorenoОценок пока нет

- CeramicsДокумент6 страницCeramicsSarah AadОценок пока нет

- Mixing Slip, Plaster Mold Fabrication, Slip-CastingДокумент4 страницыMixing Slip, Plaster Mold Fabrication, Slip-CastingLauraОценок пока нет

- 15 RakuglazesДокумент9 страниц15 Rakuglazespotteryart54Оценок пока нет

- Firing Temperatures: & Cone EquivalentsДокумент2 страницыFiring Temperatures: & Cone EquivalentsIcy45Оценок пока нет

- Ceramic Pigments and GlassesДокумент19 страницCeramic Pigments and GlassesalbaqueОценок пока нет

- 43vocabulary Basic CeramicsДокумент6 страниц43vocabulary Basic CeramicsReshmi VarmaОценок пока нет

- Chinese Ceramics Final DraftДокумент60 страницChinese Ceramics Final DraftEliezer HabaОценок пока нет

- Japanese Teabowl RubricДокумент2 страницыJapanese Teabowl Rubricapi-95763097Оценок пока нет

- Firing Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2Документ5 страницFiring Without Signup and A Kiln Chart May Be Turned Off! Plan To Unload Your Kiln by 2stueferОценок пока нет

- Clay On The Wall - An Introduction To Hanging Ceramic Wall Pieces - Ceramic Arts DailyДокумент7 страницClay On The Wall - An Introduction To Hanging Ceramic Wall Pieces - Ceramic Arts DailylavinjaneОценок пока нет

- Ceramic Glazes and Underglazes: Getting The Most Out ofДокумент16 страницCeramic Glazes and Underglazes: Getting The Most Out ofLuis F AmatoОценок пока нет

- Ceramic Raw Material PreparationДокумент3 страницыCeramic Raw Material PreparationHarish Kuppusamy100% (1)

- Absorcion Agilent ManualДокумент64 страницыAbsorcion Agilent ManualRuben MartinezОценок пока нет

- CeramicColor PDFДокумент12 страницCeramicColor PDFSiddharthapachisiaОценок пока нет

- CeramicДокумент12 страницCeramicGtucentre GlobalstudiesОценок пока нет

- 0 York Dec15cmДокумент4 страницы0 York Dec15cmapi-24483605Оценок пока нет

- Slips and GlazesДокумент3 страницыSlips and GlazesKelley_Eggert_800Оценок пока нет

- PotteryДокумент12 страницPotterybaby_dygqu90100% (1)

- Charu Ceramics Industry LTDДокумент8 страницCharu Ceramics Industry LTDZareen Rashid ChoudhuryОценок пока нет

- Pyrotek - SIVEX - Ceramic FoamДокумент2 страницыPyrotek - SIVEX - Ceramic FoamajoilhamОценок пока нет

- Como Construir HornosДокумент8 страницComo Construir Hornosfrencho rmzОценок пока нет

- Year 9 Powerpoint For Weebly of Ceramic Artists To InspireДокумент35 страницYear 9 Powerpoint For Weebly of Ceramic Artists To InspirePrerak BothraОценок пока нет

- Introduction To ClayДокумент15 страницIntroduction To Clayapi-240152469100% (1)

- Porcelain Stoneware CLEOPATRAДокумент81 страницаPorcelain Stoneware CLEOPATRAmagedshokryОценок пока нет

- Utilization of Broken Glass Into Ceramics: QuartzДокумент7 страницUtilization of Broken Glass Into Ceramics: QuartzJane Michelle EmanОценок пока нет

- Electric Kiln Firing TechДокумент13 страницElectric Kiln Firing TechStefan Van CleemputОценок пока нет

- The Upside - Down Bowl: by Martina LantinДокумент4 страницыThe Upside - Down Bowl: by Martina LantinParaSemore Vivendo100% (1)

- Make Pottery: How ToДокумент22 страницыMake Pottery: How ToCrislОценок пока нет

- Effect of Soaking On Phase Composition and Topography and Surface MicrostructureДокумент9 страницEffect of Soaking On Phase Composition and Topography and Surface MicrostructureRafaelОценок пока нет

- Curvature Evolution in Porcelain Tile During FiringДокумент12 страницCurvature Evolution in Porcelain Tile During Firingمحمد رمضانОценок пока нет

- Stoneware MaturityДокумент3 страницыStoneware MaturityLОценок пока нет

- Beginner's Guide For Ceramic Pottery: March 2018Документ13 страницBeginner's Guide For Ceramic Pottery: March 2018dk25711Оценок пока нет

- Basic Material and Processes II Ass-2Документ21 страницаBasic Material and Processes II Ass-2tanveer100% (1)

- Porous Ceramics CA2014Документ3 страницыPorous Ceramics CA2014Ahmad AnwarОценок пока нет

- Everyday Electronics 1974 01Документ5 страницEveryday Electronics 1974 01marcosscarato0% (1)

- Ceramic Materials UTS IДокумент24 страницыCeramic Materials UTS IMaryan Arfa YhudaОценок пока нет

- ExEx 2 Al Extrusion Alloys 1Документ43 страницыExEx 2 Al Extrusion Alloys 1David Enoc NietoОценок пока нет

- Chapter 34 Esip For FinalДокумент35 страницChapter 34 Esip For FinalJeaniel BorlingОценок пока нет

- Web Programming: GET / HTTP/1.1 ..Документ16 страницWeb Programming: GET / HTTP/1.1 ..Alecu IlieОценок пока нет

- Anansi and His Six Sons An African MythДокумент3 страницыAnansi and His Six Sons An African MythShar Nur JeanОценок пока нет

- T HR El 20003 ST PDFДокумент20 страницT HR El 20003 ST PDFAngling Dharma100% (1)

- The Names of Allah and Their ReflectionsДокумент98 страницThe Names of Allah and Their ReflectionsSuleyman HldОценок пока нет

- Liquid Process Piping - Part 1 General Piping Design PDFДокумент33 страницыLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaОценок пока нет

- Ddec VДокумент30 страницDdec Vllama100% (1)

- Auditing BasicsДокумент197 страницAuditing BasicsMajanja AsheryОценок пока нет

- Pavlishchuck Addison - 2000 - Electrochemical PotentialsДокумент6 страницPavlishchuck Addison - 2000 - Electrochemical PotentialscomsianОценок пока нет

- KRPL Shahjahanpur Check List For Arc Welding MachineДокумент1 страницаKRPL Shahjahanpur Check List For Arc Welding MachineA S YadavОценок пока нет

- Refrigerant Unit Lab ReportДокумент19 страницRefrigerant Unit Lab Reportakmal100% (2)

- Organic Food Business in India A Survey of CompaniДокумент19 страницOrganic Food Business in India A Survey of CompaniShravan KemturОценок пока нет

- Ias Book 2015Документ49 страницIas Book 2015Rahul SharmaОценок пока нет

- Bagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIДокумент4 страницыBagi CHAPT 7 TUGAS INGGRIS W - YAHIEN PUTRIYahien PutriОценок пока нет

- Alfa Laval Aalborg Os Tci Marine BoilerДокумент2 страницыAlfa Laval Aalborg Os Tci Marine Boilera.lobanov2020Оценок пока нет

- Lesson 7Документ6 страницLesson 7Jeya Plays YTОценок пока нет

- Alumni Homecoming ScriptДокумент2 страницыAlumni Homecoming ScriptMeliza Casipit100% (1)

- Fluid Mechanics HydraulicsДокумент420 страницFluid Mechanics Hydraulicsanonymousdi3noОценок пока нет

- History of The Hadith, Dr. Muhammad HameedullahДокумент0 страницHistory of The Hadith, Dr. Muhammad HameedullahAMEEN AKBAR100% (4)

- Dr. Alberto A. Jumao-As JRДокумент46 страницDr. Alberto A. Jumao-As JRClinton Mazo100% (1)

- Accenture MockДокумент1 страницаAccenture Mockrajyogesh487Оценок пока нет

- Technology For Duck - Fish Integrated Farming System in GoaДокумент4 страницыTechnology For Duck - Fish Integrated Farming System in GoagavinilaaОценок пока нет

- BOMA - Office Building Standard Methods of Measurement AppendixДокумент41 страницаBOMA - Office Building Standard Methods of Measurement Appendixxavest100% (7)

- A B&C - List of Residents - VKRWA 12Документ10 страницA B&C - List of Residents - VKRWA 12blr.visheshОценок пока нет

- Attitude Scale For Mental IllnessДокумент6 страницAttitude Scale For Mental IllnessSyed Faizan100% (7)

- MINDSET 1 EXERCISES TEST 1 Pendientes 1º Bach VOCABULARY AND GRAMMARДокумент7 страницMINDSET 1 EXERCISES TEST 1 Pendientes 1º Bach VOCABULARY AND GRAMMARanaОценок пока нет

- Application of SPACE MatrixДокумент11 страницApplication of SPACE Matrixdecker444975% (4)

- How To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Документ30 страницHow To Connect To iSCSI Targets On QNAP NAS Using MPIO On Windows 2008Jazz OberoiОценок пока нет

- Lesson Plan - Sight Word ObservationДокумент2 страницыLesson Plan - Sight Word Observationapi-253277023Оценок пока нет

- AA-SM-010 Stress Due To Interference Fit Bushing Installation - Rev BДокумент3 страницыAA-SM-010 Stress Due To Interference Fit Bushing Installation - Rev BMaicon PiontcoskiОценок пока нет