Академический Документы

Профессиональный Документы

Культура Документы

Programming of Pic

Загружено:

aishuksirajИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Programming of Pic

Загружено:

aishuksirajАвторское право:

Доступные форматы

M PIC16F87X

EEPROM Memory Programming Specification

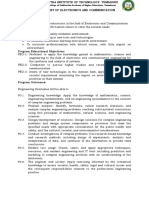

This document includes the programming Pin Diagram

specifications for the following devices: PDIP, SOIC

• PIC16F870 • PIC16F874 MCLR/VPP 1 28 RB7

RA0/AN0 2 27 RB6

• PIC16F871 • PIC16F876

PIC16F876/873/872/870

RA1/AN1 3 26 RB5

RA2/AN2/VREF 4 25 RB4

• PIC16F872 • PIC16F877 RA3/AN3/VREF 5 24 RB3

• PIC16F873 RA4/T0CKI 6 23 RB2

RA5/AN4/SS 7 22 RB1

VSS 8 21 RB0/INT

OSC1/CLKIN 9 20 VDD

1.0 PROGRAMMING THE OSC2/CLKOUT 10 19 VSS

RC0/T1OSO/T1CKI 11 18 RC7/RX/DT

PIC16F87X RC1/T1OSI/CCP2 12 17 RC6/TX/CK

RC2/CCP1 13 16 RC5/SDO

The PIC16F87X is programmed using a serial method. RC3/SCK/SCL 14 15 RC4/SDI/SDA

The Serial mode will allow the PIC16F87X to be pro-

grammed while in the user’s system. This allows for

MCLR/VPP 1 40 RB7

increased design flexibility. This programming specifi- RA0/AN0 2 39 RB6

cation applies to PIC16F87X devices in all packages. RA1/AN1 3 38 RB5

RA2/AN2/VREF 4 37 RB4

1.1 Programming Algorithm RA3/AN3/VREF 5 36 RB3

RA4/T0CKI 6 35 RB2

Requirements

PIC16F877/874/871

RA5/AN4/SS 7 34 RB1

RE0/RD/AN5 8 33 RB0/INT

The programming algorithm used depends on the RE1/WR/AN6 VDD

9 32

operating voltage (VDD) of the PIC16F87X device. RE2/CS/AN7 10 31 VSS

Algorithm 1 is designed for a VDD range of VDD 11 30 RD7/PSP7

2.2V ≤ VDD < 5.5V. Algorithm 2 is for a range of VSS 12 29 RD6/PSP6

4.5V ≤ VDD ≤ 5.5V. Either algorithm can be used with OSC1/CLKIN 13 28 RD5/PSP5

OSC2/CLKOUT 14 27 RD4/PSP4

the two available programming entry methods. The first RC0/T1OSO/T1CKI RC7/RX/DT

15 26

method follows the normal Microchip Programming RC1/T1OSI/CCP2 16 25 RC6/TX/CK

mode entry of applying a VPP voltage of 13V ± .5V. The RC2/CCP1 17 24 RC5/SDO

second method, called Low Voltage ICSPTM or LVP for RC3/SCK/SCL 18 23 RC4/SDI/SDA

RD0/PSP0 19 22 RD3/PSP3

short, applies VDD to MCLR and uses the I/O pin RB3

RD1/PSP1 20 21 RD2/PSP2

to enter Programming mode. When RB3 is driven to

VDD from ground, the PIC16F87X device enters

Programming mode.

1.2 Programming Mode

The Programming mode for the PIC16F87X allows pro-

gramming of user program memory, data memory, spe-

cial locations used for ID, and the configuration word.

2002 Microchip Technology Inc. DS39025F-page 1

PIC16F87X

PIN DESCRIPTIONS (DURING PROGRAMMING): PIC16F87X

During Programming

Pin Name

Function Pin Type Pin Description

RB3 PGM I Low voltage ICSP programming input if LVP

configuration bit equals 1

RB6 CLOCK I Clock input

RB7 DATA I/O Data input/output

MCLR VTEST MODE P* Program Mode Select

VDD VDD P Power Supply

VSS VSS P Ground

Legend: I = Input, O = Output, P = Power

* In the PIC16F87X, the programming high voltage is internally generated. To activate the Programming mode, high

voltage needs to be applied to the MCLR input. Since the MCLR is used for a level source, this means that MCLR

does not draw any significant current.

DS39025F-page 2 2002 Microchip Technology Inc.

PIC16F87X

2.0 PROGRAM MODE ENTRY The contents of data EEPROM memory have the capa-

bility to be embedded into the HEX file.

2.1 User Program Memory Map The programmer should be able to read data EEPROM

information from a HEX file and conversely (as an

The user memory space extends from 0x0000 to

option), write data EEPROM contents to a HEX file,

0x1FFF (8K). In Programming mode, the program

along with program memory information and configura-

memory space extends from 0x0000 to 0x3FFF, with

tion bit information.

the first half (0x0000-0x1FFF) being user program

memory and the second half (0x2000-0x3FFF) being The 256 data memory locations are logically mapped

configuration memory. The PC will increment from starting at address 0x2100. The format for data mem-

0x0000 to 0x1FFF and wrap to 0x0000, 0x2000 to ory storage is one data byte per address location, LSB

0x3FFF and wrap around to 0x2000 (not to 0x0000). aligned.

Once in configuration memory, the highest bit of the PC

stays a ‘1’, thus always pointing to the configuration 2.3 ID Locations

memory. The only way to point to user program mem-

A user may store identification information (ID) in four

ory is to reset the part and re-enter Program/Verify

ID locations. The ID locations are mapped in [0x2000 :

mode, as described in Section 2.4.

0x2003]. It is recommended that the user use only the

In the configuration memory space, 0x2000-0x200F four Least Significant bits of each ID location. In some

are physically implemented. However, only locations devices, the ID locations read out in an unscrambled

0x2000 through 0x2007 are available. Other locations fashion after code protection is enabled. For these

are reserved. Locations beyond 0x200F will physically devices, it is recommended that ID location is written as

access user memory (see Figure 2-1). “11 1111 1000 bbbb” where ‘bbbb’ is ID information.

In other devices, the ID locations read out normally,

2.2 Data EEPROM Memory

even after code protection. To understand how the

The EEPROM data memory space is a separate block devices behave, refer to Table 5-1.

of high endurance memory that the user accesses To understand the scrambling mechanism after code

using a special sequence of instructions. The amount protection, refer to Section 4.0.

of data EEPROM memory depends on the device and

is shown below in number of bytes.

Device # of Bytes

PIC16F870 64

PIC16F871 64

PIC16F872 64

PIC16F873 128

PIC16F874 128

PIC16F876 256

PIC16F877 256

2002 Microchip Technology Inc. DS39025F-page 3

PIC16F87X

TABLE 2-1: PROGRAM MEMORY MAPPING

2K words 4K words 8K words

2000h ID Location 0h Implemented Implemented Implemented

1FFh

3FFh

2001h ID Location Implemented Implemented Implemented

400h

7FFh

2002h ID Location Implemented Implemented

800h

BFFh

2003h ID Location Implemented Implemented

C00h

FFFh

2004h Reserved Reserved Implemented

1000h

2005h Reserved Reserved Implemented

2006h Device ID Implemented

2007h Configuration Word Implemented

1FFFh

2008h

Reserved Reserved Reserved

2100h

Reserved Reserved Reserved

3FFFh

DS39025F-page 4 2002 Microchip Technology Inc.

PIC16F87X

2.4 Program/Verify Mode 2.4.2 SERIAL PROGRAM/VERIFY

OPERATION

The Program/Verify mode is entered by holding pins

RB6 and RB7 low, while raising MCLR pin from VIL to The RB6 pin is used as a clock input pin, and the RB7

VIHH (high voltage). In this mode, the state of the RB3 pin is used for entering command bits and data

pin does not effect programming. Low voltage ICSP input/output during serial operation. To input a com-

Programming mode is entered by raising RB3 from VIL mand, the clock pin (RB6) is cycled six times. Each

to VDD and then applying VDD to MCLR. Once in this command bit is latched on the falling edge of the clock,

mode, the user program memory and the configuration with the Least Significant bit (LSb) of the command

memory can be accessed and programmed in serial being input first. The data on pin RB7 is required to

fashion. The mode of operation is serial, and the mem- have a minimum setup and hold time (see AC/DC

ory that is accessed is the user program memory. RB6 specifications), with respect to the falling edge of the

and RB7 are Schmitt Trigger Inputs in this mode. clock. Commands that have data associated with them

(read and load) are specified to have a minimum delay

Note: The OSC must not have 72 osc clocks

of 1 µs between the command and the data. After this

while the device MCLR is between VIL and

delay, the clock pin is cycled 16 times with the first cycle

VIHH.

being a START bit and the last cycle being a STOP bit.

The sequence that enters the device into the Program- Data is also input and output LSb first.

ming/Verify mode places all other logic into the RESET

Therefore, during a read operation, the LSb will be

state (the MCLR pin was initially at VIL). This means

transmitted onto pin RB7 on the rising edge of the sec-

that all I/O are in the RESET state (high impedance

ond cycle, and during a load operation, the LSb will be

inputs).

latched on the falling edge of the second cycle. A min-

The normal sequence for programming is to use the imum 1 µs delay is also specified between consecutive

load data command to set a value to be written at the commands.

selected address. Issue the begin programming com-

All commands are transmitted LSb first. Data words are

mand followed by read data command to verify, and

also transmitted LSb first. The data is transmitted on

then increment the address.

the rising edge and latched on the falling edge of the

A device RESET will clear the PC and set the address clock. To allow for decoding of commands and reversal

to 0. The “increment address” command will increment of data pin configuration, a time separation of at least

the PC. The “load configuration” command will set the 1 µs is required between a command and a data word

PC to 0x2000. The available commands are shown in (or another command).

Table 2-2.

The commands that are available are:

2.4.1 LOW VOLTAGE ICSP 2.4.2.1 Load Configuration

PROGRAMMING MODE

After receiving this command, the program counter

Low voltage ICSP Programming mode allows a (PC) will be set to 0x2000. By then applying 16 cycles

PIC16F87X device to be programmed using VDD only. to the clock pin, the chip will load 14-bits in a “data

However, when this mode is enabled by a configuration word,” as described above, to be programmed into the

bit (LVP), the PIC16F87X device dedicates RB3 to configuration memory. A description of the memory

control entry/exit into Programming mode. mapping schemes of the program memory for normal

When LVP bit is set to ‘1’, the low voltage ICSP pro- operation and Configuration mode operation is shown

gramming entry is enabled. Since the LVP configura- in Figure 2-1. After the configuration memory is

tion bit allows low voltage ICSP programming entry in entered, the only way to get back to the user program

its erased state, an erased device will have the LVP bit memory is to exit the Program/Verify Test mode by

enabled at the factory. While LVP is ‘1’, RB3 is dedi- taking MCLR low (VIL).

cated to low voltage ICSP programming. Bring RB3 to

2.4.2.2 Load Data for Program Memory

VDD and then MCLR to VDD to enter programming

mode. All other specifications for high voltage ICSP™ After receiving this command, the chip will load in a

apply. 14-bit “data word” when 16 cycles are applied, as

described previously. A timing diagram for the load data

To disable low voltage ICSP mode, the LVP bit must be

command is shown in Figure 6-1.

programmed to ‘0’. This must be done while entered

with High Voltage Entry mode (LVP bit = 1). RB3 is now

a general purpose I/O pin.

2002 Microchip Technology Inc. DS39025F-page 5

PIC16F87X

2.4.2.3 Load Data for Data Memory 2.4.2.6 Increment Address

After receiving this command, the chip will load in a The PC is incremented when this command is

14-bit “data word” when 16 cycles are applied. How- received. A timing diagram of this command is shown

ever, the data memory is only 8-bits wide, and thus, in Figure 6-3.

only the first 8-bits of data after the START bit will be

programmed into the data memory. It is still necessary 2.4.2.7 Begin Erase/Program Cycle

to cycle the clock the full 16 cycles in order to allow the A load command must be given before every begin

internal circuitry to reset properly. The data memory programming command. Programming of the appro-

contains up to 256 bytes. If the device is code pro- priate memory (test program memory, user program

tected, the data is read as all zeros. memory or data memory) will begin after this command

is received and decoded. An internal timing mechanism

2.4.2.4 Read Data from Program Memory executes an erase before write. The user must allow for

After receiving this command, the chip will transmit both erase and programming cycle times for program-

data bits out of the program memory (user or configu- ming to complete. No “end programming” command is

ration) currently accessed, starting with the second ris- required.

ing edge of the clock input. The RB7 pin will go into

Output mode on the second rising clock edge, and it 2.4.2.8 Begin Programming

will revert back to Input mode (hi-impedance) after the Note: The Begin Program operation must take

16th rising edge. A timing diagram of this command is place at 4.5 to 5.5 VDD range.

shown in Figure 6-2.

A load command must be given before every begin

2.4.2.5 Read Data from Data Memory programming command. Programming of the appro-

priate memory (test program memory, user program

After receiving this command, the chip will transmit

memory or data memory) will begin after this command

data bits out of the data memory starting with the sec-

is received and decoded. An internal timing mechanism

ond rising edge of the clock input. The RB7 pin will go

executes a write. The user must allow for program

into Output mode on the second rising edge, and it will

cycle time for programming to complete. No “end pro-

revert back to Input mode (hi-impedance) after the 16th

gramming” command is required.

rising edge. As previously stated, the data memory is

8-bits wide, and therefore, only the first 8-bits that are This command is similar to the ERASE/PROGRAM

output are actual data. CYCLE command, except that a word erase is not

done. It is recommended that a bulk erase be per-

formed before starting a series of programming only

cycles.

TABLE 2-2: COMMAND MAPPING FOR PIC16F87X

Voltage

Command Mapping (MSB … LSB) Data

Range

Load Configuration X X 0 0 0 0 0, data (14), 0 2.2V - 5.5V

Load Data for Program Memory X X 0 0 1 0 0, data (14), 0 2.2V - 5.5V

Read Data from Program Memory X X 0 1 0 0 0, data (14), 0 2.2V - 5.5V

Increment Address X X 0 1 1 0 2.2V - 5.5V

Begin Erase Programming Cycle 0 0 1 0 0 0 2.2V - 5.5V

Begin Programming Only Cycle 0 1 1 0 0 0 4.5V - 5.5V

Load Data for Data Memory X X 0 0 1 1 0, data (14), 0 2.2V - 5.5V

Read Data from Data Memory X X 0 1 0 1 0, data (14), 0 2.2V - 5.5V

Bulk Erase Setup1 0 0 0 0 0 1 4.5V - 5.5V

Bulk Erase Setup2 0 0 0 1 1 1 4.5V - 5.5V

DS39025F-page 6 2002 Microchip Technology Inc.

PIC16F87X

2.5 Erasing Program and Data 2.5.2 ERASING CODE PROTECTED

Memory MEMORY

Depending on the state of the code protection bits, pro- For the PIC16F87X devices, once code protection is

gram and data memory will be erased using different enabled, all protected program and data memory loca-

procedures. The first set of procedures is used when tions read all ’0’s and further programming is disabled.

both program and data memories are not code pro- The ID locations and configuration word read out

tected. The second set of procedures must be used unscrambled and can be reprogrammed normally. The

when either memory is code protected. A device pro- only procedure to erase a PIC16F87X device that is

grammer should determine the state of the code pro- code protected is shown in the following procedure.

tection bits and then apply the proper procedure to This method erases program memory, data memory,

erase the desired memory. configuration bits and ID locations. Since all data

within the program and data memory will be erased

2.5.1 ERASING NON-CODE PROTECTED when this procedure is executed, the security of

PROGRAM AND DATA MEMORY the data or code is not compromised.

When both program and data memories are not code 1. Execute a Load Configuration command

protected, they must be individually erased using the (000000) with a ’1’ in all locations (0x3FFF)

following procedures. The only way that both memories 2. Execute Increment Address command

are erased using a single procedure is if code protec- (000110) to set address to configuration word

tion is enabled for one of the memories. These proce- location (0x2007)

dures do not erase the configuration word or ID 3. Execute a Bulk Erase Setup1 command

locations. (000001)

Procedure to bulk erase program memory: 4. Execute a Bulk Erase Setup2 command

(000111)

1. Execute a Load Data for Program Memory com-

mand (000010) with a ’1’ in all locations 5. Execute a Begin Erase/Programming command

(0x3FFF) (001000)

2. Execute a Bulk Erase Setup1 command 6. Wait 8 ms

(000001) 7. Execute a Bulk Erase Setup1 command

3. Execute a Bulk Erase Setup2 command (000001)

(000111) 8. Execute a Bulk Erase Setup2 command

4. Execute a Begin Erase/Programming command (000111)

(001000)

5. Wait 8 ms

6. Execute a Bulk Erase Setup1 command

(000001)

7. Execute a Bulk Erase Setup2 command

(000111)

Procedure to bulk erase data memory:

1. Execute a Load Data for Data Memory com-

mand (000011) with a ’1’ in all locations

(0x3FFF)

2. Execute a Bulk Erase Setup1 command

(000001)

3. Execute a Bulk Erase Setup2 command

(000111)

4. Execute a Begin Erase/Programming command

(001000)

5. Wait 8 ms

6. Execute a Bulk Erase Setup1 command

(000001)

7. Execute a Bulk Erase Setup2 command

(000111)

2002 Microchip Technology Inc. DS39025F-page 7

PIC16F87X

FIGURE 2-1: FLOW CHART - PIC16F87X PROGRAM MEMORY (2.2V ≤ VDD < 5.5V)

START

Set VDD = VDDP

Load Data

Command

Begin

Erase/Programming

Command

Wait

tera + tprog

Increment No All Locations

Address

Done?

Command

Verify all

Locations

Report Verify No

Error Data Correct?

DONE

DS39025F-page 8 2002 Microchip Technology Inc.

PIC16F87X

FIGURE 2-2: FLOW CHART – PIC16F87X PROGRAM MEMORY (4.5V ≤ VDD ≤ 5.5V)

START

Bulk Erase

Sequence

Set VDD = VDDP

Load Data

Command

Begin

Programming Only

Command

Wait tprog

Increment No All Locations

Address

Done?

Command

Verify all

Locations

Report Verify No

Data Correct?

Error

DONE

2002 Microchip Technology Inc. DS39025F-page 9

PIC16F87X

FIGURE 2-3: FLOW CHART – PIC16F87X CONFIGURATION MEMORY (2.2V ≤ VDD < 5.5V)

START

Load

Configuration

Data

No Program ID Yes Read Data

Location? Program Cycle Command

Increment Report No

Address Programming Data Correct?

Command Failure

Yes

No Address =

0x2004?

Yes

Increment

Address

PROGRAM CYCLE Command

Load Data

Command

Increment

Address

Command

Begin

Erase/Program

Command Increment Program

Address Cycle

Command (Config. Word)

Wait

tera + tprog

Report Program No Read Data

Configuration Data Correct? Command

Word Error

Yes

DONE

DS39025F-page 10 2002 Microchip Technology Inc.

PIC16F87X

FIGURE 2-4: FLOW CHART - PIC16F87X CONFIGURATION MEMORY

START

Load

Configuration

Data

No Program ID Yes Read Data

Location? Program Cycle Command

Increment Report No

Address Programming Data Correct?

Command Failure

Yes

No Address =

0x2004?

Yes

Increment

Address

PROGRAM CYCLE Command

Load Data

Command

Increment

Address

Command

Begin

Program Only

Command* Increment Program

Address Cycle

Command (Config. Word)

Wait tprog

Report Program No Read Data

Configuration Data Correct? Command

Word Error

Yes

DONE

* Assumes that a bulk erase was issued before programming configuration word. If not, use the program flow from Figure 2-4.

2002 Microchip Technology Inc. DS39025F-page 11

PIC16F87X

3.0 CONFIGURATION WORD TABLE 3-1: DEVICE ID VALUE

The PIC16F87X has several configuration bits. These Device ID Value

bits can be set (reads ‘0’), or left unchanged (reads ‘1’), Device

Dev Rev

to select various device configurations.

PIC16F870 00 1101 000 x xxxx

3.1 Device ID Word PIC16F871 00 1101 001 x xxxx

The device ID word for the PIC16F87X is located at PIC16F872 00 1000 111 x xxxx

2006h. PIC16F873 00 1001 011 x xxxx

PIC16F874 00 1001 001 x xxxx

PIC16F876 00 1001 111 x xxxx

PIC16F877 00 1001 101 x xxxx

DS39025F-page 12 2002 Microchip Technology Inc.

PIC16F87X

REGISTER 3-1: CONFIG: CONFIGURATION WORD FOR PIC16F873/874/876/877

(ADDRESS 2007h)

U-0 U-0 U-0 U-0 U-0 U-0 U-0 R/P-1 U-0 R/P-1 R/P-1 R/P-1 R/P-1 R/P-1

CP1 CP0 RESV — WRT CPD LVP BODEN CP1 CP0 PWRTE WDTE F0SC1 F0SC0

bit 13 bit 0

bit 13-12 CP1:CP0: FLASH Program Memory Code Protection bits(2)

bit 5-4 4 K Devices:

11 = Code protection off

10 = 0F00h to 0FFFh code protected

01 = 0800h to 0FFFh code protected

00 = 0000h to 0FFFh code protected

8 K Devices:

11 = Code protection off

10 = 1F00h to 1FFFh code protected

01 = 1000h to 1FFFh code protected

00 = 0000h to 1FFFh code protected

bit 11 Reserved: Set to ‘1’ for normal operation

bit 10 Unimplemented: Read as ‘1’

bit 9 WRT: FLASH Program Memory Write Enable bit

1 = Unprotected program memory may be written to by EECON control

0 = Unprotected program memory may not be written to by EECON control

bit 8 CPD: Data EE Memory Code Protection bit

1 = Code protection off

0 = Data EE memory code protected

bit 7 LVP: Low Voltage ICSP Programming Enable bit

1 = RB3/PGM pin has PGM function, low voltage programming enabled

0 = RB3 is digital I/O, HV on MCLR must be used for programming

bit 6 BODEN: Brown-out Reset Enable bit(2)

1 = BOR enabled

0 = BOR disabled

bit 3 PWRTE: Power-up Timer Enable bit

1 = PWRT disabled

0 = PWRT enabled

bit 2 WDTE: Watchdog Timer Enable bit

1 = WDT enabled

0 = WDT disabled

bit 1-0 FOSC1:FOSC0: Oscillator Selection bits

11 = RC oscillator

10 = HS oscillator

01 = XT oscillator

00 = LP oscillator

Note 1: Enabling Brown-out Reset automatically enables Power-up Timer (PWRT), regardless of the value of

bit PWRTE. Ensure the Power-up Timer is enabled any time Brown-out Reset is enabled.

2: All of the CP1:CP0 pairs have to be given the same value to enable the code protection scheme listed.

Legend:

R = Readable bit P = Programmable bit U = Unimplemented bit, read as ‘0’

- n = Value when device is unprogrammed u = Unchanged from programmed state

2002 Microchip Technology Inc. DS39025F-page 13

PIC16F87X

REGISTER 3-2: CONFIG: CONFIGURATION WORD FOR PIC16F870/871/872 (ADDRESS 2007h)

U-0 U-0 U-0 U-0 U-0 U-0 U-0 R/P-1 U-0 R/P-1 R/P-1 R/P-1 R/P-1 R/P-1

CP1 CP0 RESV — WRT CPD LVP BODEN CP1 CP0 PWRTE WDTE F0SC1 F0SC0

bit 13 bit 0

bit 13-12 CP1:CP0: FLASH Program Memory Code Protection bits(2)

bit 5-4 11 = Code protection off

10 = Not supported

01 = Not supported

00 = 0000h to 07FFh code protected

bit 11 Reserved: Set to ‘1’ for normal operation

bit 10 Unimplemented: Read as ‘1’

bit 9 WRT: FLASH Program Memory Write Enable bit

1 = Unprotected program memory may be written to by EECON control

0 = Unprotected program memory may not be written to by EECON control

bit 8 CPD: Data EE Memory Code Protection bit

1 = Code protection off

0 = Data EE memory code protected

bit 7 LVP: Low Voltage ICSP Programming Enable bit

1 = RB3/PGM pin has PGM function, low voltage programming enabled

0 = RB3 is digital I/O, HV on MCLR must be used for programming

bit 6 BODEN: Brown-out Reset Enable bit(2)

1 = BOR enabled

0 = BOR disabled

bit 3 PWRTE: Power-up Timer Enable bit

1 = PWRT disabled

0 = PWRT enabled

bit 2 WDTE: Watchdog Timer Enable bit

1 = WDT enabled

0 = WDT disabled

bit 1-0 FOSC1:FOSC0: Oscillator Selection bits

11 = RC oscillator

10 = HS oscillator

01 = XT oscillator

00 = LP oscillator

Note 1: Enabling Brown-out Reset automatically enables Power-up Timer (PWRT), regardless of the value of

bit PWRTE. Ensure the Power-up Timer is enabled any time Brown-out Reset is enabled.

2: All of the CP1:CP0 pairs have to be given the same value to enable the code protection scheme listed.

Legend:

R = Readable bit P = Programmable bit U = Unimplemented bit, read as ‘0’

- n = Value when device is unprogrammed u = Unchanged from programmed state

DS39025F-page 14 2002 Microchip Technology Inc.

PIC16F87X

4.0 EMBEDDING THE CONFIGURATION WORD AND ID INFORMATION IN THE

HEX FILE

To allow portability of code, the programmer is required to read the configuration word and ID locations from the HEX

file when loading the HEX file. If configuration word information was not present in the HEX file, then a simple warning

message may be issued. Similarly, while saving a HEX file, configuration word and ID information must be included.

An option to not include this information may be provided.

Specifically for the PIC16F87X, the EEPROM data memory should also be embedded in the HEX file (see

Section 2.2).

Microchip Technology Inc. feels strongly that this feature is important for the benefit of the end customer.

2002 Microchip Technology Inc. DS39025F-page 15

PIC16F87X

5.0 CHECKSUM COMPUTATION The Least Significant 16 bits of this sum are the

checksum.

Checksum is calculated by reading the contents of the

The following table describes how to calculate the

PIC16F87X memory locations and adding up the

checksum for each device. Note that the checksum cal-

opcodes, up to the maximum user addressable loca-

culation differs depending on the code protect setting.

tion, e.g., 0x1FF for the PIC16F87X. Any carry bits

Since the program memory locations read out differ-

exceeding 16-bits are neglected. Finally, the configura-

ently depending on the code protect setting, the table

tion word (appropriately masked) is added to the

describes how to manipulate the actual program mem-

checksum. Checksum computation for each member of

ory values to simulate the values that would be read

the PIC16F87X devices is shown in Table 5-1.

from a protected device. When calculating a checksum

The checksum is calculated by summing the following: by reading a device, the entire program memory can

• The contents of all program memory locations simply be read and summed. The configuration word

• The configuration word, appropriately masked and ID locations can always be read.

• Masked ID locations (when applicable) Note that some older devices have an additional value

added in the checksum. This is to maintain compatibil-

ity with older device programmer checksums.

DS39025F-page 16 2002 Microchip Technology Inc.

PIC16F87X

TABLE 5-1: CHECKSUM COMPUTATION

0x25E6 at 0

Code Blank

Device Checksum* and max

Protect Value

address

PIC16F870 OFF SUM[0x0000:0x07FFF] + CFGW & 0x3BFF 0x33FF 0xFFCD

ALL CFGW & 0x3BFF + SUM_ID 0x3FCE 0x0B9C

PIC16F871 OFF SUM[0x0000:0x07FFF] + CFGW & 0x3BFF 0x33FF 0xFFCD

ALL CFGW & 0x3BFF + SUM_ID 0x3FCE 0x0B9C

PIC16F872 OFF SUM[0x0000:0x07FFF] + CFGW & 0x3BFF 0x33FF 0xFFCD

ALL CFGW & 0x3BFF + SUM_ID 0x3FCE 0x0B9C

PIC16F873 OFF SUM[0x0000:0x0FFF] + CFGW & 0x3BFF 0x2BFF 0xF7CD

0x0F00 : 0xFFF SUM[0x0000:0x0EFF] + CFGW & 0x3BFF +SUM_ID 0x48EE 0xFAA3

0x0800 : 0xFFF SUM[0x0000:0x07FF] + CFGW & 0x3BFF + SUM_ID 0x3FDE 0xF193

ALL CFGW & 0x3BFF + SUM_ID 0x37CE 0x039C

PIC16F874 OFF SUM[0x0000:0x0FFF] + CFGW & 0x3BFF 0x2BFF 0xF7CD

0x0F00 : 0xFFF SUM[0x0000:0x0EFF] + CFGW & 0x3BFF +SUM_ID 0x48EE 0xFAA3

0x0800 : 0xFFF SUM[0x0000:0x07FF] + CFGW & 0x3BFF + SUM_ID 0x3FDE 0xF193

ALL CFGW & 0x3BFF + SUM_ID 0x37CE 0x039C

PIC16F876 OFF SUM[0x0000:0x1FFF] + CFGW & 0x3BFF 0x1BFF 0xE7CD

0x1F00 : 0x1FFF SUM[0x0000:0x1EFF] + CFGW & 0x3BFF +SUM_ID 0x28EE 0xDAA3

0x1000 : 0x1FFF SUM[0x0000:0x0FFF] + CFGW & 0x3BFF + SUM_ID 0x27DE 0xD993

ALL CFGW & 0x3BFF + SUM_ID 0x27CE 0xF39C

PIC16F877 OFF SUM[0x0000:0x1FFF] + CFGW & 0x3BFF 0x1BFF 0xE7CD

0x1F00 : 0x1FFF SUM[0x0000:0x1EFF] + CFGW & 0x3BFF +SUM_ID 0x28EE 0xDAA3

0x1000 : 0x1FFF SUM[0x0000:0x0FFF] + CFGW & 0x3BFF + SUM_ID 0x27DE 0xD993

ALL CFGW & 0x3BFF + SUM_ID 0x27CE 0xF39C

Legend: CFGW = Configuration Word

SUM[a:b] = [Sum of locations a to b inclusive]

SUM_ID = ID locations masked by 0xF then made into a 16-bit value with ID0 as the most significant nibble.

For example, ID0 = 0x1, ID1 = 0x2, ID3 = 0x3, ID4 = 0x4, then SUM_ID = 0x1234

*Checksum = [Sum of all the individual expressions] MODULO [0xFFFF]

+ = Addition

& = Bitwise AND

2002 Microchip Technology Inc. DS39025F-page 17

PIC16F87X

6.0 PROGRAM/VERIFY MODE ELECTRICAL CHARACTERISTICS

TABLE 6-1: TIMING REQUIREMENTS FOR PROGRAM/VERIFY MODE

Standard Operating Conditions (unless otherwise stated)

AC/DC CHARACTERISTICS Operating Temperature: 0°C ≤ TA ≤ +70°C

Operating Voltage: 2.2V ≤ VDD ≤ 5.5V

Characteristics Sym Min Typ Max Units Conditions/Comments

General

VDD level for Algorithm 1 VDD 2.2 5.5 V Limited command set

(See Table 2-2)

VDD level for Algorithm 2 VDD 4.5 5.5 V All commands available

High voltage on MCLR for

high voltage programming entry VIHH VDD + 3.5 13.5 V

Voltage on MCLR for VIH 2.2 5.5 V

low voltage ICSP programming entry

MCLR rise time (VSS to VHH) for Test tVHHR 1.0 µs

mode entry

(RB6, RB7) input high level VIH1 0.8 VDD V Schmitt Trigger input

(RB6, RB7) input low level VIL1 0.2 VDD V Schmitt Trigger input

RB<7:6> setup time before MCLR ↑ tset0 100 ns

RB<7:6> hold time after MCLR ↑ thld0 5 µs

RB3 setup time before MCLR ↑ tset2 100 ns

Serial Program/Verify

Data in setup time before clock ↓ tset1 100 ns

Data in hold time after clock ↓ thld1 100 ns

Data input not driven to next clock input tdly1 1.0 µs

(delay required between command/data or

command/command)

Delay between clock ↓ to clock ↑ of next tdly2 1.0 µs

command or data

Clock ↑ to data out valid (during read data) tdly3 80 ns

Erase cycle time tera 2 4 ms

Programming cycle time tprog 2 4 ms

DS39025F-page 18 2002 Microchip Technology Inc.

PIC16F87X

FIGURE 6-1: LOAD DATA COMMAND MCLR = VIHH (PROGRAM/VERIFY)

VIHH

MCLR 1 µs min.

tset0 1 2 3 4 5 6 1 2 3 4 5 15 16

tdly2

RB6

(Clock)

thld0

RB7 0 1 0 0 X X strt_bit stp_bit

(Data)

tset1 tdly1 tset1

} thld1 1 µs min. thld1

}

}

}

100 ns min. 100 ns min.

RESET Program/Verify Test Mode

FIGURE 6-2: READ DATA COMMAND MCLR = VIHH (PROGRAM/VERIFY)

VIHH

MCLR

tdly2

tset0

thld0 1 µs min.

1 2 3 4 5 6 1 2 3 4 5 15 16

RB6

(Clock)

tdly3

RB7 0 1 0

0 X X stp_bit

(Data) strt_bit

tset1 tdly1

thld1

1 µs min.

}

}

100 ns min. RB7

RB7 = input RB7 = output input

RESET Program/Verify Test Mode

FIGURE 6-3: INCREMENT ADDRESS COMMAND MCLR = VIHH (PROGRAM/VERIFY)

VIHH

MCLR

tdly2

Next Command

1 µs min.

1 2 3 4 5 6 1 2

RB6

(Clock)

RB7 0

0 1 1 X X X 0

(Data)

tset1 tdly1

thld1 1 µs min.

}

}

100 ns min.

RESET Program/Verify Test Mode

2002 Microchip Technology Inc. DS39025F-page 19

PIC16F87X

FIGURE 6-4: LOAD DATA COMMAND MCLR = VDD (PROGRAM/VERIFY)

VIH

MCLR 1 µs min.

tset0 1 2 3 4 5 6 1 2 3 4 5 15 16

tdly2

RB6

(Clock)

thld0

RB7 0 1 0 0 X X strt_bit stp_bit

(Data)

tset1 tdly1 tset1

tset2 1 µs min.

thld1 thld1

}

}

}

}

100 ns min. 100 ns min.

RB3

RESET Program/Verify Test Mode

FIGURE 6-5: READ DATA COMMAND MCLR = VDD (PROGRAM/VERIFY)

VIH

MCLR

tdly2

tset0

thld0 1 µs min.

1 2 3 4 5 6 1 2 3 4 5 15 16

RB6

(Clock)

tdly3

RB7 0 1 0

0 X X stp_bit

(Data) strt_bit

tset1 tdly1

thld1

1 µs min.

}

}

tset2 RB7

100 ns min.

RB7 = input RB7 = output input

RB3

RESET Program/Verify Test Mode

FIGURE 6-6: INCREMENT ADDRESS COMMAND MCLR = VDD (PROGRAM/VERIFY)

VIH

MCLR

tdly2

Next Command

1 µs min.

1 2 3 4 5 6 1 2

RB6

(Clock)

RB7 0

0 1 1 X X X 0

(Data)

tset1 tdly1

tset2 thld1

1 µs min.

}

}

100 ns min.

RB3

RESET Program/Verify Test Mode

DS39025F-page 20 2002 Microchip Technology Inc.

Note the following details of the code protection feature on PICmicro® MCUs.

• The PICmicro family meets the specifications contained in the Microchip Data Sheet.

• Microchip believes that its family of PICmicro microcontrollers is one of the most secure products of its kind on the market today,

when used in the intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our knowl-

edge, require using the PICmicro microcontroller in a manner outside the operating specifications contained in the data sheet.

The person doing so may be engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable”.

• Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of

our product.

If you have any further questions about this matter, please contact the local sales office nearest to you.

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

and may be superseded by updates. It is your responsibility to The Microchip name and logo, the Microchip logo, FilterLab,

ensure that your application meets with your specifications. KEELOQ, microID, MPLAB, PIC, PICmicro, PICMASTER,

No representation or warranty is given and no liability is PICSTART, PRO MATE, SEEVAL and The Embedded Control

assumed by Microchip Technology Incorporated with respect Solutions Company are registered trademarks of Microchip

to the accuracy or use of such information, or infringement of Technology Incorporated in the U.S.A. and other countries.

patents or other intellectual property rights arising from such

dsPIC, ECONOMONITOR, FanSense, FlexROM, fuzzyLAB,

use or otherwise. Use of Microchip’s products as critical com-

In-Circuit Serial Programming, ICSP, ICEPIC, microPort,

ponents in life support systems is not authorized except with

Migratable Memory, MPASM, MPLIB, MPLINK, MPSIM,

express written approval by Microchip. No licenses are con-

MXDEV, PICC, PICDEM, PICDEM.net, rfPIC, Select Mode

veyed, implicitly or otherwise, under any intellectual property

and Total Endurance are trademarks of Microchip Technology

rights.

Incorporated in the U.S.A.

Serialized Quick Term Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2002, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received QS-9000 quality system

certification for its worldwide headquarters,

design and wafer fabrication facilities in

Chandler and Tempe, Arizona in July 1999. The

Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro® 8-bit MCUs, KEELOQ® code hopping

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

2002 Microchip Technology Inc. DS39025F - page 21

M

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC Japan

Microchip Technology Japan K.K.

Corporate Office Australia

Benex S-1 6F

2355 West Chandler Blvd. Microchip Technology Australia Pty Ltd

3-18-20, Shinyokohama

Chandler, AZ 85224-6199 Suite 22, 41 Rawson Street

Kohoku-Ku, Yokohama-shi

Tel: 480-792-7200 Fax: 480-792-7277 Epping 2121, NSW

Kanagawa, 222-0033, Japan

Technical Support: 480-792-7627 Australia

Web Address: http://www.microchip.com Tel: 61-2-9868-6733 Fax: 61-2-9868-6755 Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Rocky Mountain China - Beijing Korea

2355 West Chandler Blvd. Microchip Technology Consulting (Shanghai) Microchip Technology Korea

Chandler, AZ 85224-6199 Co., Ltd., Beijing Liaison Office 168-1, Youngbo Bldg. 3 Floor

Tel: 480-792-7966 Fax: 480-792-7456 Unit 915 Samsung-Dong, Kangnam-Ku

Bei Hai Wan Tai Bldg. Seoul, Korea 135-882

Atlanta No. 6 Chaoyangmen Beidajie Tel: 82-2-554-7200 Fax: 82-2-558-5934

500 Sugar Mill Road, Suite 200B Beijing, 100027, No. China Singapore

Atlanta, GA 30350 Tel: 86-10-85282100 Fax: 86-10-85282104 Microchip Technology Singapore Pte Ltd.

Tel: 770-640-0034 Fax: 770-640-0307 200 Middle Road

China - Chengdu

Boston #07-02 Prime Centre

Microchip Technology Consulting (Shanghai)

2 Lan Drive, Suite 120 Singapore, 188980

Co., Ltd., Chengdu Liaison Office

Westford, MA 01886 Tel: 65-6334-8870 Fax: 65-6334-8850

Rm. 2401, 24th Floor,

Tel: 978-692-3848 Fax: 978-692-3821 Taiwan

Ming Xing Financial Tower

Chicago No. 88 TIDU Street Microchip Technology Taiwan

333 Pierce Road, Suite 180 Chengdu 610016, China 11F-3, No. 207

Itasca, IL 60143 Tel: 86-28-6766200 Fax: 86-28-6766599 Tung Hua North Road

Tel: 630-285-0071 Fax: 630-285-0075 Taipei, 105, Taiwan

China - Fuzhou

Dallas Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Microchip Technology Consulting (Shanghai)

4570 Westgrove Drive, Suite 160 Co., Ltd., Fuzhou Liaison Office

Addison, TX 75001 Unit 28F, World Trade Plaza

Tel: 972-818-7423 Fax: 972-818-2924 EUROPE

No. 71 Wusi Road

Detroit Fuzhou 350001, China Denmark

Tri-Atria Office Building Tel: 86-591-7503506 Fax: 86-591-7503521 Microchip Technology Nordic ApS

32255 Northwestern Highway, Suite 190 China - Shanghai Regus Business Centre

Farmington Hills, MI 48334 Microchip Technology Consulting (Shanghai) Lautrup hoj 1-3

Tel: 248-538-2250 Fax: 248-538-2260 Co., Ltd. Ballerup DK-2750 Denmark

Kokomo Room 701, Bldg. B Tel: 45 4420 9895 Fax: 45 4420 9910

2767 S. Albright Road Far East International Plaza France

Kokomo, Indiana 46902 No. 317 Xian Xia Road Microchip Technology SARL

Tel: 765-864-8360 Fax: 765-864-8387 Shanghai, 200051 Parc d’Activite du Moulin de Massy

Los Angeles Tel: 86-21-6275-5700 Fax: 86-21-6275-5060 43 Rue du Saule Trapu

18201 Von Karman, Suite 1090 China - Shenzhen Batiment A - ler Etage

Irvine, CA 92612 91300 Massy, France

Microchip Technology Consulting (Shanghai)

Tel: 949-263-1888 Fax: 949-263-1338 Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Co., Ltd., Shenzhen Liaison Office

New York Rm. 1315, 13/F, Shenzhen Kerry Centre, Germany

150 Motor Parkway, Suite 202 Renminnan Lu Microchip Technology GmbH

Hauppauge, NY 11788 Shenzhen 518001, China Gustav-Heinemann Ring 125

Tel: 631-273-5305 Fax: 631-273-5335 Tel: 86-755-2350361 Fax: 86-755-2366086 D-81739 Munich, Germany

Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

San Jose Hong Kong

Microchip Technology Inc. Microchip Technology Hongkong Ltd. Italy

2107 North First Street, Suite 590 Unit 901-6, Tower 2, Metroplaza Microchip Technology SRL

San Jose, CA 95131 223 Hing Fong Road Centro Direzionale Colleoni

Tel: 408-436-7950 Fax: 408-436-7955 Kwai Fong, N.T., Hong Kong Palazzo Taurus 1 V. Le Colleoni 1

Tel: 852-2401-1200 Fax: 852-2401-3431 20041 Agrate Brianza

Toronto

Milan, Italy

6285 Northam Drive, Suite 108 India Tel: 39-039-65791-1 Fax: 39-039-6899883

Mississauga, Ontario L4V 1X5, Canada Microchip Technology Inc.

Tel: 905-673-0699 Fax: 905-673-6509 India Liaison Office United Kingdom

Divyasree Chambers Arizona Microchip Technology Ltd.

1 Floor, Wing A (A3/A4) 505 Eskdale Road

No. 11, O’Shaugnessey Road Winnersh Triangle

Bangalore, 560 025, India Wokingham

Tel: 91-80-2290061 Fax: 91-80-2290062 Berkshire, England RG41 5TU

Tel: 44 118 921 5869 Fax: 44-118 921-5820

03/01/02

DS39025F-page 22 2002 Microchip Technology Inc.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Automatic Water Pump ControllerДокумент19 страницAutomatic Water Pump ControllerSrinivasRaoОценок пока нет

- E91 (11) C&asmДокумент12 страницE91 (11) C&asmAlekso GjakovskiОценок пока нет

- E91 IntroДокумент25 страницE91 IntroAlekso GjakovskiОценок пока нет

- Carrier Current PHDДокумент26 страницCarrier Current PHDAlekso GjakovskiОценок пока нет

- An Introduction To The Discrete Fourier Transform - Technical ArticlesДокумент13 страницAn Introduction To The Discrete Fourier Transform - Technical ArticlesAlekso GjakovskiОценок пока нет

- Understanding WiegandДокумент12 страницUnderstanding WiegandAlekso GjakovskiОценок пока нет

- HZ1050 RfidДокумент8 страницHZ1050 RfidAlekso GjakovskiОценок пока нет

- E91 (3) Assembly LanguageДокумент16 страницE91 (3) Assembly LanguageAlekso GjakovskiОценок пока нет

- Lista eДокумент7 страницLista eAlekso GjakovskiОценок пока нет

- Tron Will Execute Any Bat File Placed in This Folder. Read This For InstructionsДокумент1 страницаTron Will Execute Any Bat File Placed in This Folder. Read This For InstructionsAlekso GjakovskiОценок пока нет

- Default SettingsДокумент23 страницыDefault SettingsAlekso GjakovskiОценок пока нет

- Lista LaptopДокумент3 страницыLista LaptopAlekso GjakovskiОценок пока нет

- Lista NasДокумент12 страницLista NasAlekso GjakovskiОценок пока нет

- Udc HelpДокумент41 страницаUdc HelpAlekso GjakovskiОценок пока нет

- Lista e FilmsДокумент11 страницLista e FilmsAlekso GjakovskiОценок пока нет

- Lista ExtДокумент3 страницыLista ExtAlekso GjakovskiОценок пока нет

- Za NarackaДокумент3 страницыZa NarackaAlekso GjakovskiОценок пока нет

- Lista DДокумент5 страницLista DAlekso GjakovskiОценок пока нет

- ChristmasДокумент1 страницаChristmasAlekso GjakovskiОценок пока нет

- New Text DocumentДокумент1 страницаNew Text DocumentAlekso GjakovskiОценок пока нет

- Toolbars BHOs To Target by GUIDДокумент107 страницToolbars BHOs To Target by GUIDAlekso GjakovskiОценок пока нет

- What The Heck Do These Tools DoДокумент1 страницаWhat The Heck Do These Tools DoAlekso GjakovskiОценок пока нет

- LДокумент3 страницыLAlekso GjakovskiОценок пока нет

- Instructions On Loading Tron With WSUS Offline UpdatesДокумент1 страницаInstructions On Loading Tron With WSUS Offline UpdatesAlekso GjakovskiОценок пока нет

- Tron Ccleaner Cookie WhitelistДокумент1 страницаTron Ccleaner Cookie WhitelistAlekso GjakovskiОценок пока нет

- Rkill Process WhitelistДокумент2 страницыRkill Process WhitelistAlekso GjakovskiОценок пока нет

- Programs To Target by GUIDДокумент158 страницPrograms To Target by GUIDBlock FarmerОценок пока нет

- Programs To Target by NameДокумент4 страницыPrograms To Target by NameAlekso GjakovskiОценок пока нет

- How To Customize Debloat - READ THIS YOU SCRUBДокумент2 страницыHow To Customize Debloat - READ THIS YOU SCRUBŽīã ÝãďãvОценок пока нет

- Drive CleanupДокумент2 страницыDrive CleanupAlekso GjakovskiОценок пока нет

- ExplanationДокумент1 страницаExplanationAlekso GjakovskiОценок пока нет

- COA Module 4 FinalДокумент22 страницыCOA Module 4 FinalAkhil KrishnaОценок пока нет

- EnglishДокумент105 страницEnglishHector KennerleyОценок пока нет

- A 1-V 1-GSs 6-Bit Low-Power Flash ADC in 90nm CMOSДокумент4 страницыA 1-V 1-GSs 6-Bit Low-Power Flash ADC in 90nm CMOSThanos van RamОценок пока нет

- INHEP Digital Security IDS805 InstallerДокумент61 страницаINHEP Digital Security IDS805 InstallerPete GaleaОценок пока нет

- Digital Electronics QuestionsДокумент8 страницDigital Electronics QuestionsShivamahendar SunkaОценок пока нет

- 1996 OKI LCD Driver Controller DatabookДокумент232 страницы1996 OKI LCD Driver Controller DatabooksuriantoОценок пока нет

- A Constituent College of Siddhartha Academy of Higher Education, TumakuruДокумент42 страницыA Constituent College of Siddhartha Academy of Higher Education, TumakuruRoyal ClashОценок пока нет

- Microprocessor-Based System Design, Ricardo Gutierrez-Osuna, Wright State UniversityДокумент21 страницаMicroprocessor-Based System Design, Ricardo Gutierrez-Osuna, Wright State UniversityAce DanielОценок пока нет

- CS Unit 1 EoT Exam SolutionsДокумент5 страницCS Unit 1 EoT Exam SolutionsKaif AliОценок пока нет

- 6300 SP OverviewSpecsДокумент8 страниц6300 SP OverviewSpecsRicardas KragnysОценок пока нет

- VLSI Design Flow - Comprehensive OverviewДокумент112 страницVLSI Design Flow - Comprehensive OverviewSruthi SriОценок пока нет

- Aditya Engineering College (A) Digital Circuits and Logic DesignДокумент33 страницыAditya Engineering College (A) Digital Circuits and Logic DesignkalaОценок пока нет

- Xilinx Spartan-3EДокумент37 страницXilinx Spartan-3EDon Lahiru HettiarachchiОценок пока нет

- Chapter Objectives:: Ee 120 Lecture Notes Chapte R 5: Sequential Logic Circuits 5.1Документ13 страницChapter Objectives:: Ee 120 Lecture Notes Chapte R 5: Sequential Logic Circuits 5.1Christian MoyaОценок пока нет

- Digital Electronics - Principal and Application PDFДокумент723 страницыDigital Electronics - Principal and Application PDFKamal Bhattacharjee100% (2)

- Design of Logic Circuits S3 SyllabusДокумент3 страницыDesign of Logic Circuits S3 Syllabussethu0% (1)

- 3rd Int Sequential Logic PDFДокумент14 страниц3rd Int Sequential Logic PDFUtsav ParasharОценок пока нет

- Vehicle Door Latch Safety Measures Based On System DynamicsДокумент7 страницVehicle Door Latch Safety Measures Based On System DynamicsKrystof JankowskiОценок пока нет

- Btech 2Документ66 страницBtech 2Ayush VishwakarmaОценок пока нет

- Flip Flops and Application: Japan Malaysia Technical Institute (Jmti) TKEДокумент34 страницыFlip Flops and Application: Japan Malaysia Technical Institute (Jmti) TKEFadly ShafiqОценок пока нет

- Ec3352 Set1Документ2 страницыEc3352 Set1menakadevieceОценок пока нет

- TC4027BP, TC4027BF, TC4027BFN: TC4027B Dual J-K Master-Slave Flip FlopДокумент9 страницTC4027BP, TC4027BF, TC4027BFN: TC4027B Dual J-K Master-Slave Flip FlopHla Swe OoОценок пока нет

- Divide by 3 FSMДокумент14 страницDivide by 3 FSMGirish ChukkaОценок пока нет

- A New Hardware Implementation of Manchester Line Decoder: Ibrahim A. Khorwat and Nabil NaasДокумент5 страницA New Hardware Implementation of Manchester Line Decoder: Ibrahim A. Khorwat and Nabil NaasAlif Mu'tashimОценок пока нет

- Signal and Timing Parameters II: Source Synchronous Timing - Class 3Документ29 страницSignal and Timing Parameters II: Source Synchronous Timing - Class 3Naftal MassingueОценок пока нет

- ECEN 248 Lab 8 ReportДокумент7 страницECEN 248 Lab 8 ReportRebecca SontheimerОценок пока нет

- PPTДокумент20 страницPPTBinu Merrin AlexОценок пока нет

- Experiment 11 Asynchronous CountersДокумент10 страницExperiment 11 Asynchronous CountersMd. Arif Hasan MasumОценок пока нет

- Enrollment NoДокумент5 страницEnrollment Nosanjit kumarОценок пока нет