Академический Документы

Профессиональный Документы

Культура Документы

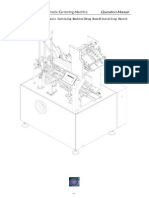

Form Fill Seal Machine

Загружено:

Frank Geng0 оценок0% нашли этот документ полезным (0 голосов)

228 просмотров19 страницA form-fill-seal machine includes parts for moving a web of packaging material through the machine according to a process path and parts for transforming the web into filled bags. The term of this patent is extended or adjusted under 35 U.S.c. 154(b) by 0 days.

Исходное описание:

Оригинальное название

6922972 Form Fill Seal Machine

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документA form-fill-seal machine includes parts for moving a web of packaging material through the machine according to a process path and parts for transforming the web into filled bags. The term of this patent is extended or adjusted under 35 U.S.c. 154(b) by 0 days.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

228 просмотров19 страницForm Fill Seal Machine

Загружено:

Frank GengA form-fill-seal machine includes parts for moving a web of packaging material through the machine according to a process path and parts for transforming the web into filled bags. The term of this patent is extended or adjusted under 35 U.S.c. 154(b) by 0 days.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 19

United States Patent

Van Rens et al.

Ga) FORME

_-SEAL MACHINE

(75) Inventors: Joseph Johan Maria Van Rens, Weer

(XL); Peter Joseph Hendriks, Weert

(NL); Wihelmus Catharina Gerardus

‘Maria Tax, Weert (NL); Peter

Hubertus Daal, Linne (NL)

CHS Weert B

(73) Assignee: 1 RV Weest (NL)

(2). Notice: Subject to any disclaimer the teem of this

patent is extended or adjusted under 35

US.C. 1540) by 0 days,

C21) Appl. Now 1O/810,685

Mar. 28, 2004

(63) Prior Publication Data

US 20060182045 AT Sep 23, 2004

Related U.S. Application Data

(62) Division of aplication No. 09985037, fled on Nov. 1

2B, now Pal No. 710875,

(30) Foreign Application Priority Data

Now 1.2000 (NL) oes

(1) Im. cu BosB 61/20

(2) US.C SH/133.4, 59/139.2; 53/550

(58) Fleld of Search 53412, 416, 451,

539550, S51, 133.4, 1394

66) References Cited

US. PATENT DOCUMENTS.

SaMS12 A 971985. Capdeboneg

ni7ags A 1198 Chroot

issisn2 A WIO8T Chait ta

10$00692297282

US 6,922,972 B2

Aug. 2, 2005

(20) Patent No.

(5) Date of Patent:

$29.38 AIST Langenberg ot

Ssro82 8 101980 Ata

‘emeoe7 A 11/1980 Ven Enden

Soatss7 A * 61991 Tilman 38303

5373933 A _ 12/1904 Plank et a

Ssoh259 A * 101905 Somer saa

Sa00.%6 A 21997 Hamid

Siei8t40 A 7997 Waders

567200 A 911997 Malin

S.%6(MS A 7/1908 Bodolay eta

674084 BL 11/2002 Simionato

Gc74SS4S B2* “62004 Schoeder et siz

FOREIGN PATENT DOCUMENTS

ep Dsr3ss6 10)108

FR 27 G18

wo SROERS 11998

Primary Esaminer-—Louis K. Huynh

‘Assistant Exainer—Hemant M Desi

(74) Auorney, Agent, or Firm—Young & Thompson

6 ABSTRACT

Form-fil-seal machine inches pats for moving 4 web of

packaging material through the machine according to 2

process path and pars for transforming the web into filled

bags, as well asa zipper strip applicator device for supplying

Zipper strip for each bug transverse to the process path, by

lise ofa Tit and a second conveyor, which inthe supply

direction ofthe ipper strip are placed one behing the other

fan are bats provided with parts or retaining the zipper sirip

‘uring supply, «blade being placed between the frst and the

second conveyor for cutting the zipper stip and the frst and

the second conveyor being provided with their own frst and

second drive

30 Claims, 10 Drawing Sheets

U.S. Patent Aug. 2, 2005 Sheet 1 of 10 US 6,922,972 B2

80

: FIG, 1

US 6,922,972 B2

Sheet 2 of 10

Aug. 2, 2005

U.S. Patent

FIG. 2

US 6,922,972 B2

Sheet 3 of 10

Aug. 2, 2005

U.S. Patent

FIG. 3

U.S. Patent Aug, 2, 2005 Sheet 4 of 10 US 6,922,972 B2

U.S. Patent Aug, 2, 2005 Sheet 5 of 10 US 6,922,972 B2

U.S. Patent Aug. 2, 2005 Sheet 6 of 10 US 6,922,972 B2

u

FIG, SA

U.S. Patent Aug, 2, 2005 Sheet 7 of 10 US 6,922,972 B2

25 250 31

SO 25c 7

a | 46 45

44

42 by

oo — Z

am |

Y

327 | 94

446

94

93

FIG, SB

US 6,922,972 B2

Sheet 8 of 10

Aug. 2, 2005

U.S. Patent

Jo) ols

vey

allo cooce ooo e000 won

v6)

¥, £6)

oo one a

v6)

it) ep £6 5 =

67

wy =) _

Ee ae

67

ve ef eo 4

ve

U.S. Patent Aug. 2, 2005 Sheet 9 of 10 US 6,922,972 B2

©) °

FIG. 7B

US 6,922,972 B2

Sheet 10 of 10

Aug. 2, 2005

U.S. Patent

US 6,922,972 B2

1

FORML-FILL-SEAL MACHINE,

(CROSS REFERENCE TO RELATED

"APPLICATIONS,

This application is a division of US, application Ser. No.

(09)985,037, filed on Nov. 1, 2001, now USS. Pat. No,

6m S875,

FIELD OP THE INVENTION

“The invention relates to a form-fil-seal machine, particu

Jaely formefilseal machine wherein a weh of bag material,

sich as foil, before transforming it into tubular shape, is

provided with so-called zipper stip, one for each bag to be

‘madefille. Said zipper strips generally consist of two strip

members situated opposite each ober and provided with

male and female pars that ean be brought into detachable

‘engagement with each other, are lakea from a stock and ate

applied transverse to the Web, either with or without a

Timited pre-weld or preaclhesion Inthe action of transverse

‘sealing the bags the zipper strip is also permanently welded

to the bag walls

BACKGROUND OF THE INVENTION

From US. Pat. No. 4,617,683 it is known to apply a

zipper strip provided with adjacent male and female parts,

‘over the full wid of a web of bag material, by engaging a

Teading area with a vacuum head and moving the head

transverse aver the upperside of the web to the atbor edge.

Subsequently the Zipper strip is welded tothe web by means

‘of a thetmal seal rod extending from above and an anvil,

Altematively the zipper sip may be provided with a heat

activated glue

From USS. Pat, No. 4,878,987 itis known to supply the

‘cooperating male and female pasts ofthe zipper stip from

both sides, ransverse tothe web, by means of pusher rolls

‘The male and female strips ae then each pushed from thei

side towards the cente, guided by transverse ducts, and then

Welded to the web.

From the international patent application WO 98103328 it

Js known to place a zipper stip transverse tothe web of bag

material by means of a vaeuum band positioned above the

‘web and weld the ssp tothe bag. atrial

‘Applying the zipper strips requires a high control of the

‘orientation and the exact lecation ofthe steps, a8 imperfee

tions in it may hinder the further process and may result ia

malfunctioning

OBIECT OF THE INVENTION

I isan object of the invention to provide a form-fll-sal

‘machine ofthe type mentioned in the preamble with whieh

avery high degree of contol ean be achieved in placing the

Pippo strips.

Iisa further object of the invention to provide a form=

fill-seal machine of the type mentioned inthe preamble, with

‘which a high processing speed can be walised of high

scctraey,

SUMMARY OF THE INVENTION

From one aspect the invention to that end provides a

formil-scal machine comprising means for moving a web

‘of packaging material through the machine according to a

process path aod means for transforming the wel ito fled

bags, furthermore comprising a zipper strip applicator

device having means for supplying a zipper strip for eae

%

o

2

bag transverse (0 the process path, whicl supply means

‘comprise 3 first and a second conveyor, wich in the supply

‘iretion of the zipper strip are placed one behind the ethet

land are both provided with means for retaining or engeging

the zipper strip during supply, a cutting means such a8 &

blade being placed between the first and the second con-

vveyor for etfing the zipper strip andthe frst and the second

conveyor being provided with their owa Fist and second

rive means.

‘The division into two conveyors makes it possible 10

Aivide functions as well, and namely a supply function for

the first conveyor anda positioning function forthe second

conveyor, the zipper strip each time being held over his

length by the first andior second conveyor

Preferably the machine is provided with control means for

te first and second deive means and the bad, the control

means being adjusted to consocutively operate the frst drive

‘means to transfer a predetermined length of zipper stip 10

the second conveyor, fo subsequently operate the blade and

thea operate the second conveyor for positioning the cut-lt

Zipper sirp portion transverse to the Web.

Preferably the contol means are adjusted to et both

‘conveyors move atthe same speed during the supply of the

length of zipper stp.

Tis preferred here thatthe retaining means of the firs and

the second conveyors as well are controled by the contol

ans, preferably for continously activating them, They

ay be designed as vacuum band means—kcwn per se—

In view of elliciney of the suction and ereating as few as

possible process discupting air flows, it i advantageous

‘when the machine is provided with means for adjusting the

‘active length of the vacuum means forthe second conveyor,

Preferably the control means ae then provided with means

or comparing an entered zipper stip length and the position

in transverse direction tothe web and the acjusted length of|

the vacuum means, and of means for releasing the drive of

the machine based on the outcome of said comparison.

‘When the leagth ofthe vacuum means does not correspond

to the one necessary forthe process in question the machine

will not be released,

The means for adjusting the ative length ofthe vacuum

neans preferably comprise tube to be comnected to a

‘vacuum source, Which tube in its circumference is provided

‘With series of apertures of different length extending in tube

Girection, andl which is rotatable in an adjustable manner to

Jet a selected series of apertures form the connection

between the apertures in the vacuum band and the tube

is further preferred that at leat the second conveyor is

placed below the web.

‘This improves the stability of the zipper strip.

‘The controllability ofthe zipper strip is further improved

‘when the machine is furthermore provided with means for

guiding the zipper strip on the first and/or second conveyor,

‘hich guiding means are preterably formed by a rigid

guiding scip, which is positioned to extend between the

‘male and female parts of the zipper strip. In this way the

Zipper stip is guided in sideward dieection, so that itis

prevented that it would want to runoff from the conveyors

4a cesut of is aatural inclination o Warp ia the main plane

Preferably the guiding strip is interrupt, aod itis par-

ticularly formed by a series of teeth, so that fictional forces,

that may counteract a smooth supply ofthe zipper strip, are

limited to a minimum. The guidance is improved when the

teeth have inelined side edges andior rounded tips

‘As a result of the interrupted guidance, in particular the

teeth, the negative effeets of the undulation in the zipper

US 6,922,972 B2

7

‘trip, which undulation i the result of the rolled-up posto

in which the zipper strip material is supplied, is further

reduced, because of reduction of the friction and the guid-

ance in the vertical plane, Asa result the grip of the ettining

‘means, parculaly the vacuum means is improved

Preferably the guiding strip is positioned to—eonsidered

in process path—engage the upstream side of the zipper

stip, between the sip members having the male and female

pars.

Ina further development the zipper stip applicator device

is also provided with an anvil strip for use inthe pre-sealing

‘of the zipper stip t0 the web, which anvil strip then is

preferably situated at the—considered in process path—

‘downstream side of the second conveyor, The applicator

device here also provides a counter force during the pre

sealing

Ina further development the zipper stip applicatar device

Js supported on an auxiliary frame, whic itself is supported

in 2 main frame of the machine, the auxiliary frame wih

respect 1o the main frame being moveable between a

felricied operative position and an extended adjustment

Position, The iit insertion ofthe zipper strip ean then ake

place in an easly accessible manner. is preferred here that

2 calibration is provided on the second conveyor, extending

along he retaining means, preferably starting at the location

ofthe blade.

‘When the machin is further provided with control means

that have been provided with means for noticing the opers~

tive position of the auxiliary frame and with means for

releasing the drive of the machine based on that observation,

itis ensured that only in ease of @ coreet postion of the

auxiliary frame and thus of the applicator deviee the

‘machine can stat ean

‘From a further aspect the invention provides a formsill-

seal machine comprising means for moving a web of pack

aging material through the machine according to a process

path and means for tansforming the web into filled bags,

further comprising « zipper stip applicator device having

‘means for Supplying a zipper strip for each bag transverse to

the process path, which ripper strip applicator device is

supported on an auxiliary frame, which ilsef is supported in

‘A'main frame of the machine, the auxiliary frame with

respect 10 the main frame being moveable between a

retracted operative position and an extended adjusiment

position

From another aspect the invention provides a formsil-

seal machine ofthe type described in the preamble, further

provided with control means having means for noticing the

Position of a longitudinal edge of the woh with respect to &

fixed reference in the machine. This also provides a cond

tion for futher optimizing the accuracy ofthe placement of|

the zipper strip. It may also be possible in this way t0

influence the position in transverse direction ofthe web With

respect tothe form shoul.

Tn a further development hereof the machine is also

provided with means for positioning the zipper stip appli

‘calor device in tansverse direction, in response tothe dala

from the edge noticing means. By thus watehing the position

‘of the web side and automatically corecting the postion of

the applicator, errors inthe widih-positioning of the zippee

Strip with respect to the web edge as a result of sideward

‘movement of the web is prevented. The means for postion-

ing the zipper strip applicator device in transverse direction

may be formed by a servo-driven spindle motor.

In another further development the contral means are

adapted to control the drive of in particular the second

%

o

4

conveyor in the movement of the zipper stip to be applied,

in response lo the data from the edge noticing means

From yet another aspect the invention provides a form=

filseal machine of the type deseribed in the preamble,

Turthermore provided with conigol means baving frst means

{or noticing longitudinal marks on the web and for measur

ing the web distance travelled over a certain period by the

‘web af that location, which are placed near the zipper stip

applicator device, at least for the noticing means al =

distance from it known to the contol means, the contol

‘means being adapted to contrl the drive(s) of the zipper

strip applicator device, such as the said frst and second

‘conveyor in response to the data [eom the fist means for

‘noticing Jongitudinal marks on the web and for measuring

the web distanc

From a further aspect the invention provides « form.

seal machine of the type mentioned ia the preamble, fue

thermore provided with contol means having firs means for

noticing longitudinal marks on the web and for measuring

the web position, which are placed near the zipper stip

applicator device, wherein downstream of said first means

the machine i provided with an end roll forthe web, which

js movably arranged on the machine and which ean be

adjusted in positon with respect to the web course by means

fof movement means, the control means being adapted for

‘controling the movement means of the end rll fo altering

the web length between the fist means and the transverse

sealing means, in response to the data from the frst means

{or noticing longitudinal marks oa the web and the messur-

ing ofthe Web position, The end roll may be automatically

‘moved, for instance by sling or turing away, to increase

fr reduce the web length between zipper stip applicator

sevice and transverse sealing unit/utting unit In this way

an aceurate placement of the zipper seip wit respect to the

trooer spot and the transverse scam is ensured agein and

again.

Preferably the control means are provided with means for

storage of data regarding the bag length, the distance

between the noticing means and the pre-seal unit for the

Zipper sri, the distance between the longitudinal mark and

te transverse seam of a bag made and tbe distance between

the end transverse scaling means forthe zipper strip and the

bade forthe bags.

Alternatively deseribed the application provides a form=

‘llseal machine comprising means for moving a web of

packaging material through the machine according to @

Dracess path from a web supply side and means for tans-

forming the web ino filed bags, further provided with

contol means having first means for noticing longitudinal

‘marks on the web and for measuring the web postin, the

‘conrol means being provided with means for storage of dala

regarding the bag length, the machine heing provided with

an end or turn rol for the web, which is movably arranged

fn the machine in web direction and which is adjustable in

position in web direction by means of movement means, the

‘control means being adapted for controlling the movement

peans of tbe end rol for altering the length the web bas (©

travel from the supply side 10 the forming means, in

response (o the data ftom the bag Jeng input andthe frst

‘means for noticing longitudinal marks on the web and

measuring the web position.

‘Alternatively deseribed the patent application provides 3

{ormvfill-scal machine comprising means for moving a web

‘of packaging material through the machine according to a

braces path from a web supply side and means for trans-

forming the web into filled bags, further provided with

US 6,922,972 B2

5

‘control means having fist means for noticing longitudinal

‘marks on the web and for measuring the web speed, the

‘contol means being provided with means foe storage of data

Fegarding the bag length, the machine being provide with

fn end of tura roll for the web, which is movably arranged

‘on the machine in web diccction and which is adjustable in

positon in web dreetion by means of movement means, the

‘control means being adapted for controlling the movement

‘means ofthe end rll for altering the length the web has 10

travel from the supply side 10 the forming means, ia

response to the data Irom the bag length input and the first

tmetns for noticing longitudinal marks on the web and

messuring the web speed

‘From yet a further aspect the invention provides form=

fll-seal machine comprising means for moving a web of

packaging material through the machine according to @

process path from a web supply side and means for trans-

forming the web into filled bags, further comprising a zipper

Strip applicator device having means for supplying a zippes

‘tip for each bag transverse to the proeess path and having,

means for sealing a Zipper stip to the web for each bag 10

bbe made, the machine being adapted for making the bags

With contiauous web supply over the forming means, the

machine being provided with means for keeping the web

Sill at the location of the sealing means, and with means

placed dosensiream ofthe sealing means for forming a buller

‘web length prior to each Keeping sil and leasing it dring

keeping the web sil. Thus reliable, continuous weh supply

to the moulding and closing means is ensured,

It is preferred hore that tho end roll and its movement

‘means area pat of the buffer forming means so that it ean

be elective in two ways.

From another aspect the invention provides a formfill-

seal machipe comprising means for moving a web of packs

‘aging material through the machine according to 4 process

path and means for transforming the web into filled Bags,

further comprising « zipper strip applicator device having

means for supplying a zippet strip for each ag transverse 10

the process path, which supply means comprise a firs and &

second conveyer, which in supply diretion of the zipper

‘tip acc placed one behind the other and are both provided:

With meaas for cetaiaing the zipper srip during supply, a

blade being placed between the frst and second conveyor

for euting the zipper stip. Both conveyors can he driven by

‘one single drive, the iansfer to the second conveyor for

Jnstance being such that this one runs a ltl faster than the

firt conveyor, 0 that the zipper strip is stretched during

positioning,

Preferably the first and the second conveyor are posi=

tioned to suppost the zipper strip.

Preferably the retaining means are vacuum means.

From 2 further aspoct the application proves a form=

fil-seal comprising means for moving a web of packaging

‘material through the machine according to a process pall

and means for transforming the web ino filled bags, further

‘comprising a zipper stip applicator device having means for

supplying a zipper stip lor each bag transverse 10 the

process path, which supply means comprise 8 conveyor

Positioned transverse 10 the process path, which Is posi

tioned ta support the zipper stip and is provid! with means

for retaining the zipper strip during the supply and. pre~

scaling at the lower side of the web, The support of the

ripper strip improves its. stbilily during Supply and

Positioning, so that the zipper strip can be accurately

applied.

tis noted that measures discussed above, such a5 web

side watcher, the end rll and the adjustment means for the

%

o

6

sctve le xcuim band, ean be used both in

rrangement with two conveyors and in an arrangement with

‘ne continuous conveyor

From a further aspect the application provides a form-

fillseal machine comprising means for moving a web of

packaging material through the machine according to. 2

process path and means for transforming the web into filled

bags, further comprising a zipper strip applicator devi

hhaving means for supplying a zipper strip for each bag

transverse tothe process path, Which supply means comprise

4 conveyor positioned transverse to the process path, fie

thermore provided ‘with means for permanently adhering

both the strip members provided with male and female parts

respectively ofthe zipper sip, at locations that are stated

at mutual distance corresponding tothe desired Iength of

the cut-off zipper strips to the applied, the adhering means

‘comprising (wo adhering members, which engage on both

‘sides ofthe male and female parts to seal them to each other

In this way s bulge in the zipper strip ends is prevented,

which is favourable to the manageability ia the further

process. The so-called “crunching” ean now take place with

4 running Zipper stip. By adapting the contol means at the

‘wanted strip Tength and with the kaown distanee between

bade and crunch unit, as well as with known supply speed

‘ofthe zipper strip, the creect moment for erunching can be

‘ulomatically determined and a that moment the crunch uit

fan be activated

Preferably two adhering members are positioned to

enclose the male and female parts between them during

sealing

is further prefered here thatthe wo adhering members

comprise a rotatable or idle anvil and a sealing arm, par-

ticularly ultasonic sealing arm, The Trely rotatable anvil

prevents unwanted frictional forees and the arm is only in

contact with the Seip when erunching has to take place.

From a futher aspect the invention provides 4 form:

seal machine comprising means for moving a web of pack-

aging material through the machine according to a process

path and means for transforming the web into a tubular

shape, turing it into bags, filing the bags and closing the

‘illed bags, the means for tansforming into the tubular shape

‘comprising longitudinal guides, placed at a mutual distance

corresponding to the zipper strip length, for guiding the tube

from the transformation means to the location of filling

Preferably the fling means comprise a chute, which atthe

coutside is provided with longitudinal guides, Thus it is

prevented thatthe tubular web ‘wists and the Zipper Strip

‘Would not lie correctly any more and no god! transverse seal

ould be made, Because of the longitudinal guides the

largest circumferential size ofthe chute is pot changed, but

the strips lie within suid circumferential size

[BRIEF DESCRIPTION OF THE DRAWINGS

‘The inventions willbe elucidated on the basis of a number

‘of exemplary embodiments shown inthe attached figures, in

‘which

FIG, Li sformfil-seal machine according to the inven

sion in side views

FIG. 2 is a view in perspective of the form-fil-seal

machine of FIG. 1, obliquely from its front side;

FIG. 2A is detail ofthe form-fill-seal machine of FIG.

2

FIG. 3 is a view in perspective at the rear side of the

{ormillscal machine of the FIGS. 1 and 2;

FIGS. 4A-D show a zipper strip applicator device ofthe

{ormfill-scal machines of FIGS. 1-3, in consecutive sages.

of use;

US 6,922,972 B2

1

FIGS, SA-C ate some details ofthe means for adjusting

the active leagth of the zipper strip applicator device;

FIG. 6 schematically shows a cross-section of apart ofthe

‘Zipper stip applicator deviee of the FIGS. 44-D;

FIGS. 7A and 7B show a cross-section and a top view,

respectively, of a so-called crunch unit for use in a form”

fillseal machine having. zipper stip applicator device; and

FIGS. 8A ad 8B show a schematic view in perspective of

the course ofa foil web to and about a form shoulder with

‘consecutive Hilling ube in a form-ll-seal machine: and a

cross-section of sid filling tube, respectively

DETAILED DESCRIPTION OF THE DRAWINGS

‘The formfllseal machine 1 shown in FIGS. 1-3 com=

prises « chassis or frame 2, on which various parts and

‘control means have been arranged to manufacture a series of

brags 6 filled with bull goods, sich as Foods, ut also

inedible bulk goods, from a foil web 6, that is supplied on

roll 4

(On frame 2 outiggers 3 ace provided, in which a tans-

verse axis § can be supported, On the axis $a roll of fil

web 6 has been placed,

For reasons of simplicity a number of parts in process

Вам также может понравиться

- Profil Venelteko 02 enДокумент36 страницProfil Venelteko 02 enguillermomolteniОценок пока нет

- 300 Instructions BookДокумент32 страницы300 Instructions BookceltorОценок пока нет

- fs1000 en PDFДокумент2 страницыfs1000 en PDFLukito TitoОценок пока нет

- AccelacotaBrochure2006 PDFДокумент16 страницAccelacotaBrochure2006 PDFlapandaОценок пока нет

- Tube Filling and Sealing Machine Operation ManualДокумент43 страницыTube Filling and Sealing Machine Operation ManualEdhwinn Javier Popo MorenoОценок пока нет

- Ammeraal Envolsadoras LinatexДокумент4 страницыAmmeraal Envolsadoras LinatexVictor MoralesОценок пока нет

- Vertical Form Fill SealДокумент29 страницVertical Form Fill Sealrodolfo muñoz magañaОценок пока нет

- Bouwpaco Powder Dosing & PackingДокумент33 страницыBouwpaco Powder Dosing & PackingAlexander AeromodelistaОценок пока нет

- c660b Leak and Seal Strength TesterДокумент3 страницыc660b Leak and Seal Strength TesterRizky RamadhaniОценок пока нет

- Ishida ACP-700 Series Case Packer Brochure (6200)Документ10 страницIshida ACP-700 Series Case Packer Brochure (6200)Kundan KumarОценок пока нет

- Saint Gobain Furon Microe High Purity Fluid Handling Solutions CatalogДокумент32 страницыSaint Gobain Furon Microe High Purity Fluid Handling Solutions CatalogXavierОценок пока нет

- MR - Ranjeet Kumar Kurkure Process Line With PackingДокумент12 страницMR - Ranjeet Kumar Kurkure Process Line With PackingRanjeet BhaiОценок пока нет

- Form Fill Seal BrochureДокумент12 страницForm Fill Seal BrochureMuhammad Alva Budi WardhanaОценок пока нет

- Versatility and precision with handtmann VF 600 vacuum fillerДокумент12 страницVersatility and precision with handtmann VF 600 vacuum fillermiloОценок пока нет

- Area-Layer-Gripping-Systems Catalogue PDFДокумент40 страницArea-Layer-Gripping-Systems Catalogue PDFaidixon CAD designОценок пока нет

- Packaging Machine Tablet Filler Webpage Rev01Документ1 страницаPackaging Machine Tablet Filler Webpage Rev01Mayank ShekharОценок пока нет

- SVC Series enДокумент5 страницSVC Series enJulioОценок пока нет

- Ficha Tecnica Correa Habasit Grammer (Vfha001h04) PDFДокумент4 страницыFicha Tecnica Correa Habasit Grammer (Vfha001h04) PDFdavid caraoОценок пока нет

- Optima Branch Brochure Food v2 enДокумент24 страницыOptima Branch Brochure Food v2 enjohnb2bОценок пока нет

- Honetop-Rotary Packing Machine HT-8GДокумент27 страницHonetop-Rotary Packing Machine HT-8GNathaniel FernandesОценок пока нет

- Health Monitoring of VFFS Machine PDFДокумент5 страницHealth Monitoring of VFFS Machine PDFRakesh patelОценок пока нет

- Your Packaging Specialists: C Ntour SalesДокумент52 страницыYour Packaging Specialists: C Ntour SalesAhmad عfiaОценок пока нет

- NM402 Norden Tube FillingДокумент8 страницNM402 Norden Tube FillingSaka International LtdОценок пока нет

- ETL 89403175 001200 Innoclean EN 013Документ437 страницETL 89403175 001200 Innoclean EN 013Eren akarsuОценок пока нет

- Supertech Packing Machine - FaridabadДокумент4 страницыSupertech Packing Machine - Faridabadrajesh_rbpОценок пока нет

- Modular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogДокумент2 страницыModular Labelling System, Labeling Equipment - Tronics America Series S1000 Brochure, CatalogtronicsamericaОценок пока нет

- Tube filling machines optimized for productivityДокумент8 страницTube filling machines optimized for productivitymhafizanОценок пока нет

- Netpack NP 350: Vertical Form, Fill and Seal MachineДокумент2 страницыNetpack NP 350: Vertical Form, Fill and Seal MachineJuan OrtegaОценок пока нет

- 10 Head Scale Manual PDFДокумент74 страницы10 Head Scale Manual PDFGerencia AngavilОценок пока нет

- Article Linear Weigh Filler Packaging MachineДокумент2 страницыArticle Linear Weigh Filler Packaging MachineMayank ShekharОценок пока нет

- Bosch Guide To Flow Wrapping enДокумент30 страницBosch Guide To Flow Wrapping engherla_bogdanОценок пока нет

- Semi Automatic Cartoning Machine SpecificationДокумент9 страницSemi Automatic Cartoning Machine SpecificationArkaОценок пока нет

- DQ BlisteadoraДокумент15 страницDQ Blisteadorasami2210Оценок пока нет

- Automatic Vert-Bag Packaging Machine ManualДокумент81 страницаAutomatic Vert-Bag Packaging Machine ManualLeonОценок пока нет

- VFJ-520 Automatic Vertical Packing Machine ManualДокумент39 страницVFJ-520 Automatic Vertical Packing Machine ManualIvan SaladinoОценок пока нет

- Blister Packaging Machine With Integrated CartonerДокумент20 страницBlister Packaging Machine With Integrated CartonerSatish HiremathОценок пока нет

- Impulse Sealer ManualДокумент8 страницImpulse Sealer Manualmariopilar100% (1)

- DL Texturing OBA DTY enДокумент32 страницыDL Texturing OBA DTY ensaul renteriaОценок пока нет

- Operation Manual of Powder Packing MachineДокумент7 страницOperation Manual of Powder Packing MachineProfar SAS LaboratorioОценок пока нет

- Knife BrochureДокумент2 страницыKnife BrochurechinchotarngОценок пока нет

- CB-VG52B Continuous Motion Machine (High Speed ManualДокумент8 страницCB-VG52B Continuous Motion Machine (High Speed ManualPaolo AltobelОценок пока нет

- VFFS Machine OmronДокумент35 страницVFFS Machine OmronAhmad EkoОценок пока нет

- Operation Manual: FWM1200 FWM1200AДокумент27 страницOperation Manual: FWM1200 FWM1200AnicolasОценок пока нет

- SPC - MWLV-01003 - Heedle Band Version 720 Pos.Документ17 страницSPC - MWLV-01003 - Heedle Band Version 720 Pos.Ade AdeОценок пока нет

- Design and Fabrication of Volumetric Weighing and Packing MachineДокумент3 страницыDesign and Fabrication of Volumetric Weighing and Packing MachineInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Packing MachineДокумент9 страницPacking Machinemiha3la33Оценок пока нет

- UHLMANN Blister Machine B 1240Документ3 страницыUHLMANN Blister Machine B 1240Mahendra Putrianti Sasongko0% (1)

- EPI-3522 GRAND - Abian BlisreringДокумент12 страницEPI-3522 GRAND - Abian Blisreringmohammad pirayesh100% (1)

- Operation Manual: Multihead WeigherДокумент40 страницOperation Manual: Multihead WeigherAlvaro DiazОценок пока нет

- The New: The Best Solution For The New Class of Filter BagДокумент24 страницыThe New: The Best Solution For The New Class of Filter BagThong Kin MunОценок пока нет

- Bottle Unscrambling SystemsДокумент2 страницыBottle Unscrambling SystemsAhmet MetinОценок пока нет

- 40 Sweet Sides of InterpackДокумент20 страниц40 Sweet Sides of InterpackRainierKОценок пока нет

- XWZ-120A Operation Manual: Full Automatic Cartoning MachineДокумент35 страницXWZ-120A Operation Manual: Full Automatic Cartoning MachinealexjoelОценок пока нет

- Sim Tab FeederДокумент2 страницыSim Tab FeederMusab HashmiОценок пока нет

- Ertical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingДокумент13 страницErtical Type Cosmetic Cream Ointment Sauce Filler Equipment With HeatingAbd Al-Rahmman Al-qatananiОценок пока нет

- Meech Web Cleaning Overview Brochure 2015Документ24 страницыMeech Web Cleaning Overview Brochure 2015danceОценок пока нет

- He Fam 1080 6 Brick Quotation Latest PriceДокумент10 страницHe Fam 1080 6 Brick Quotation Latest PriceSHASHANKDUBEY52Оценок пока нет

- SomatecДокумент123 страницыSomatecAdi kurniantoОценок пока нет

- Side Sealing Machine Operation GuideДокумент30 страницSide Sealing Machine Operation GuideRocio GimenezОценок пока нет

- Other People's Dirt: A Housecleaner's Curious AdventuresОт EverandOther People's Dirt: A Housecleaner's Curious AdventuresРейтинг: 3.5 из 5 звезд3.5/5 (104)

- You Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherОт EverandYou Can't Joke About That: Why Everything Is Funny, Nothing Is Sacred, and We're All in This TogetherОценок пока нет

- The Asshole Survival Guide: How to Deal with People Who Treat You Like DirtОт EverandThe Asshole Survival Guide: How to Deal with People Who Treat You Like DirtРейтинг: 4 из 5 звезд4/5 (60)

- Welcome to the United States of Anxiety: Observations from a Reforming NeuroticОт EverandWelcome to the United States of Anxiety: Observations from a Reforming NeuroticРейтинг: 3.5 из 5 звезд3.5/5 (10)

- The Importance of Being Earnest: Classic Tales EditionОт EverandThe Importance of Being Earnest: Classic Tales EditionРейтинг: 4.5 из 5 звезд4.5/5 (43)

- The House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedОт EverandThe House at Pooh Corner - Winnie-the-Pooh Book #4 - UnabridgedРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolОт EverandThe Smartest Book in the World: A Lexicon of Literacy, A Rancorous Reportage, A Concise Curriculum of CoolРейтинг: 4 из 5 звезд4/5 (14)

- Sexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesОт EverandSexual Bloopers: An Outrageous, Uncensored Collection of People's Most Embarrassing X-Rated FumblesРейтинг: 3.5 из 5 звезд3.5/5 (7)

- The Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverОт EverandThe Best Joke Book (Period): Hundreds of the Funniest, Silliest, Most Ridiculous Jokes EverРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Lessons from Tara: Life Advice from the World's Most Brilliant DogОт EverandLessons from Tara: Life Advice from the World's Most Brilliant DogРейтинг: 4.5 из 5 звезд4.5/5 (42)

- Humorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreОт EverandHumorous American Short Stories: Selections from Mark Twain, O. Henry, James Thurber, Kurt Vonnegut, Jr. and moreОценок пока нет

![The Inimitable Jeeves [Classic Tales Edition]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/711420909/198x198/ba98be6b93/1712018618?v=1)