Академический Документы

Профессиональный Документы

Культура Документы

Mixing Weld and Bolt Part1

Загружено:

ihpeterИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mixing Weld and Bolt Part1

Загружено:

ihpeterАвторское право:

Доступные форматы

Design File

Mixing Welds and Bolts, Part 1

Practical Ideas for the Design Professional by Duane K. Miller, Sc.D., P.E.

Introduction

There are a variety of circumstances in which the engineer nut, calibrated wrench, twist-off-type tension-control bolts,

may need to assess the strength of a connection that is and direct-tension-indicators. Slip-critical joints have bolts

composed of both welds and mechanical fasteners. Today, installed just as they would be in a pretensioned joint, but

mechanical fasteners are typically bolts, but older structures also have “faying surfaces that have been prepared to pro-

may include rivets. Such situations may be encountered vide a calculable resistance against slip.” (p. xi).

during the course of rehabilitation, repair or strengthening

projects. For new construction, bolts and welds may be In simple terms, in snug-tightened joints and pretensioned

combined in connections where the materials being joined joints, the bolts act as pins. Slip-critical joints work by fric-

are initially secured with bolts, and then welded to gain the tion: the pretension forces create clamping forces and the

full connection strength. As will be seen, calculating the total friction between the faying surfaces work together to resist

capacity of the connection is not as simple as totaling the slippage of the joint.

arithmetical sum of the individual components (welds, bolts,

and rivets). Such an assumption is unconservative, and the ASTM A325 bolts have a minimum tensile strength of 105–120

consequences could be disastrous. ksi (725–830 MPa) depending upon the bolt diameter, while

A490 bolts must fall between 150 and 170 ksi (1035–1175

Part 1 of this two-part edition of “Design File” will deal with MPa) tensile strength. Riveted joints behave more like snug-

snug-tightened and pretensioned mechanical fasteners tightened joints, but the “pins” in this case are the rivets, and

combined with welds. Part 2 will address combining welds are typically about half the strength of A325 bolts.

with slip-critical, high-strength bolted connections.

When a mechanically fastened joint is loaded in shear, one

Some Background of two types of behavior is possible. The joint may have

the bolts or rivets bear against the sides of the holes in the

on Bolted Connections connected material, concurrently putting the bolt or rivet

Bolted joints are described in the AISC Specification for into shear. The second possible behavior is that friction,

Structural Joints Using ASTM A325 or A490 Bolts (June introduced by the clamping forces provided by the preten-

23, 2000) as either snug-tightened, pretensioned, or slip- sioned fastener, resists the shear loading. No slippage is

critical (p. 23). A snug-tightened joint has the condition of expected in this joint, but the possibility exists nonetheless.

“tightness that is attained with a few impacts of an impact

wrench or the full effort of an ironworker using an ordinary Snug-tight joints are acceptable for many applications

spud wrench to bring the plies into firm contact.”(p. xi). A since minor slippage may not adversely affect the perfor-

pretensioned joint is one in which the bolts have been mance of the connection. When there is significant load

installed in a manner so that the bolts are under significant reversal, pretensioned joints may be required. When joints

tensile load with the plates under compressive load (p. x). are subject to fatigue loads with reversal of direction, slip-

Four acceptable methods are listed in Section 8.2: turn-of- critical joints are required.

Welding Innovation Vol. XVIII, No. 2, 2001

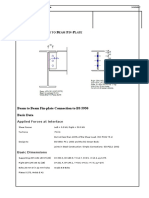

Figure 1.

Thus, an existing bolted connection may have been used, shall be provided to carry the entire load in the

designed and built to any of these criteria. Riveted joints connection. However, connections that are welded to

would be considered the snug-tight type. one member and riveted or bolted to the other member

are permitted. High-strength bolts properly installed as

Adding Welds to a slip-critical-type connection prior to welding may be

considered as sharing the stress with the welds.”

Mechanically Fastened Joints

While a weld may be composed of metal that is capable of The first three sentences of this provision address the

demonstrating an elongation of 20% or more in an all-weld- topic discussed here. The fourth sentence will be

metal tensile specimen, the same metal in a restrained addressed in part 2.

joint may be incapable of delivering any significant defor-

mation prior to fracture, due to the interaction of triaxial When the mechanical fasteners are of the bearing type and

stresses. In other words, welded connections are rigid. a weld is added, the capacity of the bolt is essentially

Welded connections are stiff. Unlike snug-tightened bolted ignored. The weld must be designed to transfer all the load,

joints that may slip as they are loaded, welds are not according to this provision. This is, in essence, the same as

expected to stretch and distribute the applied load to any the requirement of AISC LRFD-1999, provision J1.9.

great extent. In most cases, welds and bearing-type However, the Canadian standard CAN/CSA-S16.1-M94 also

mechanical fasteners will not deform equally. The load is permits the use of the capacity of the mechanical fastener or

transferred through the stiffer part, and therefore the weld the bolts alone when this is higher than the capacity of the

will carry virtually all the load, sharing little with the bolts. welds. All three standards are in agreement on this issue:

And that’s why caution needs to be taken when welds and the capacities of the bearing-type mechanical fasteners and

bolts and rivets are combined. the welds cannot be added together.

AWS D1.1, paragraph 2.6.3, goes on to discuss an accept-

Code Provisions able situation in the third sentence. Bolts and welds can

The issue of mixing mechanical fasteners and welds is be combined in the situation where a connection consists

addressed in the AWS D1.1:2000 Structural Welding of two separate components, as illustrated in Figure 1. On

Code—Steel. Provision 2.6.3 states: the left is a welded connection, and on the right, a bolted

one. This is acceptable. Each part of the overall connec-

“Welds with Rivets or Bolts. Rivets or bolts used in tion behaves independently, and thus, the Code provides

bearing type connections shall not be considered as an exception to the principles as contained in the first part

sharing the load in combination with welds. Welds, if of 2.6.3.

Welding Innovation Vol. XVIII, No. 2, 2001

The previous provisions are applicable for new construc-

tion. For existing structures, D1.1 paragraph 8.3.7, goes

on to say:

“Use of Existing Fasteners. When design calculations

show rivets or bolts will be overstressed by the new

total load, only existing dead load shall be assigned to

them. If rivets or bolts are overstressed by dead load

alone or are subject to cyclic loading, then sufficient

base metal and welding shall be added to support the

total load.”

The first sentence permits sharing of loads between

mechanical fasteners and welds if the structure is pre- Figure 2a.

loaded (i.e., any slip has already occurred), but only the

dead load can be assigned to the mechanical fastener.

Welds must be used to take up all the applied or live load.

No such sharing of loads is permitted when the mechanical

fasteners are already overloaded. When cyclic loading is

involved, no load sharing is permitted.

An Illustration

Consider a lap joint originally connected with snug-tight

bolts, as shown in Figure 2a. Additional capacity is being

added to the structure, and the connection and the

attached members must be increased to provide twice as

much strength. Figure 2b illustrates the basic plan to

strengthen the members. What should be done to the

connection?

Since the new steel is going to be joined to the old with fil- Figure 2b.

let welds, the engineer decides to add some fillet welds to

the connection. Since the bolts are still in place, the initial

thought is to add only the welds required to transfer the

additional capacity of the new steel, expecting 50% of the

Conclusion

load to go through the bolts, and 50% through the new In summary, the answer to the question “Is this accept-

welds. Will this be acceptable? able?” depends on the loading conditions. In the first case

where no dead load was assumed, the answer is “no.”

Let’s first assume there is no dead load currently applied to Under the specific conditions of the second scenario, the

the connection. In this case, D1.1 paragraph 2.6.3 applies. answer is “yes.” It cannot be concluded that the answer will

In this bearing type connection, the welds and bolts cannot always be “yes” simply because dead load is applied. The

be “considered as sharing the load.” Thus, the specified level of dead load, the adequacy of the existing mechanical

weld size must be large enough to carry the entire dead connection, and the nature of final loading (whether static

and live load. The capacity of the bolts cannot be consid- or cyclic) could change the answer.

ered in this example.

All of the above apply to mechanical fasteners of the pin

Next, let’s assume a dead load is applied. Further, let’s type. Part 2 will deal with high strength, slip-critical bolted

assume that the existing connection is adequate to transfer connections in combination with welds. The technical

the existing dead load. D1.1 paragraph 8.3.7 applies in this aspects of the content of part 2 are currently being evaluat-

case and the new welds are only required to carry the ed by technical committees. The work of the committees

increased dead load and the total live load. The existing may not be complete in time for the next issue of Welding

dead load can be assigned to the existing mechanical Innovation. Part 2 will be forthcoming just as soon as all

fasteners. the technical information is available.

Welding Innovation Vol. XVIII, No. 2, 2001

Вам также может понравиться

- Mixing Weld and Bolt Part2Документ4 страницыMixing Weld and Bolt Part2ihpeterОценок пока нет

- Bantog - Finals HW 1Документ4 страницыBantog - Finals HW 1Penuel G. BantogОценок пока нет

- Bolted Connections (Prying Force)Документ16 страницBolted Connections (Prying Force)Ivan Hadzi BoskovicОценок пока нет

- Steelwise PDFДокумент3 страницыSteelwise PDFYan Naung KoОценок пока нет

- Course Name: CE 3130: Steel Structures DesignДокумент25 страницCourse Name: CE 3130: Steel Structures Designcarlomonsalve1Оценок пока нет

- Modulo 4 CM 19 09 2020Документ25 страницModulo 4 CM 19 09 2020carlomonsalve1Оценок пока нет

- Design of BoltsДокумент18 страницDesign of BoltsFunny & InformativeОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoОценок пока нет

- Joining Steel MembersДокумент1 страницаJoining Steel MemberstierradiegoyahooesОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoОценок пока нет

- Course Content A) Bolted ConnectionsДокумент18 страницCourse Content A) Bolted Connectionsram894uОценок пока нет

- Bolts and NutsДокумент2 страницыBolts and NutsBalaji SampathОценок пока нет

- Introduction To ConnectionsДокумент57 страницIntroduction To ConnectionsFrancisco EsparzaОценок пока нет

- Design of BoltsДокумент19 страницDesign of Boltsmoganna73Оценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoОценок пока нет

- Wisdom:: WeldingДокумент5 страницWisdom:: WeldingSathish KumarОценок пока нет

- Connections-I Bolted ConnectionsДокумент21 страницаConnections-I Bolted ConnectionsA.k.MandalОценок пока нет

- Dec11 Si PDFДокумент2 страницыDec11 Si PDFspaceheaterОценок пока нет

- Si 12 2011 PDFДокумент2 страницыSi 12 2011 PDFHectorОценок пока нет

- Mat Chapter 31Документ27 страницMat Chapter 31hemant_durgawaleОценок пока нет

- Felxural Strength of A Box Section PDFДокумент2 страницыFelxural Strength of A Box Section PDFaams_sОценок пока нет

- Fasteners: The ESG ReportДокумент4 страницыFasteners: The ESG ReportAnton SurviyantoОценок пока нет

- What Is Snug-Tightened PDFДокумент2 страницыWhat Is Snug-Tightened PDFMartín50% (2)

- Welds - Static and Fatigue Strength - IiДокумент27 страницWelds - Static and Fatigue Strength - IiOuseppachan Ambooken100% (1)

- Seminar On Shear ConnectorsДокумент37 страницSeminar On Shear Connectorssanjaymits20% (1)

- Finale SteelДокумент3 страницыFinale SteelLady MhaeDianne MalonОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoОценок пока нет

- SteelwiseДокумент3 страницыSteelwiseAnonymous 7MdZQn1Оценок пока нет

- Con 1302Документ12 страницCon 1302Sanket Arun More100% (1)

- Tack Weld, Soldadura ApuntaladorДокумент5 страницTack Weld, Soldadura ApuntaladorLora BoydОценок пока нет

- CH 7 Simple Beam End Connections-9-13Документ60 страницCH 7 Simple Beam End Connections-9-13JakesОценок пока нет

- A Practical Method of Design of Concrete Pedestals For Columns For Anchor Rod Tension BreakoutДокумент17 страницA Practical Method of Design of Concrete Pedestals For Columns For Anchor Rod Tension Breakoutjohn blackОценок пока нет

- Unit 3 & 4 Composite MaterialsДокумент130 страницUnit 3 & 4 Composite MaterialsTaimoor NasserОценок пока нет

- Sn027a-Design of TrussДокумент14 страницSn027a-Design of Trussdeepak_dce_meОценок пока нет

- Polar Moment of Weld GroupДокумент26 страницPolar Moment of Weld GroupTrinh Duy KhanhОценок пока нет

- Asme Sec Viii D1 Nma App y PDFДокумент15 страницAsme Sec Viii D1 Nma App y PDFADRIANОценок пока нет

- Practical Cost Saving Ideas For The Design Professionals - WeldingДокумент3 страницыPractical Cost Saving Ideas For The Design Professionals - Weldingmaxeytm_839061685Оценок пока нет

- PVP2021-62712 FinalДокумент10 страницPVP2021-62712 FinalFinn KirkemoОценок пока нет

- A - Review-Behavior - of - Reinforced - Concrete - Exterior - Beam-Column ConnectionsДокумент12 страницA - Review-Behavior - of - Reinforced - Concrete - Exterior - Beam-Column ConnectionsMekides KassayeОценок пока нет

- Splices and Other Connections in BridgesДокумент10 страницSplices and Other Connections in BridgesPankaj_Taneja_9684Оценок пока нет

- Composite Deck DesignДокумент16 страницComposite Deck DesignLatha MaОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ8 страницSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!JitendraОценок пока нет

- Steel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Документ2 страницыSteel Interchange: Modern Steel's Monthly Steel Interchange Is For You!Andres CasadoОценок пока нет

- 2 Tension MembersДокумент13 страниц2 Tension MembersAbel MulugetaОценок пока нет

- Hilti Rebar 2Документ69 страницHilti Rebar 2Jeevan ShendreОценок пока нет

- Chapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction ManualДокумент5 страницChapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction Manualedn_mj1645Оценок пока нет

- Chapter-1: 1.1 GeneralДокумент53 страницыChapter-1: 1.1 GeneralsmkdigitechОценок пока нет

- 64 - Basics of Post Installed Rebar Connections-HiltiДокумент34 страницы64 - Basics of Post Installed Rebar Connections-Hiltijrobert123321Оценок пока нет

- Si 08 2012 PDFДокумент2 страницыSi 08 2012 PDFhector diazОценок пока нет

- Welded ConnectionsДокумент10 страницWelded ConnectionsminaОценок пока нет

- Design Guidelines For Partially Composite BeamsДокумент5 страницDesign Guidelines For Partially Composite BeamsMạnh ThànhОценок пока нет

- Circular Flange Joints of Pressure VesselДокумент13 страницCircular Flange Joints of Pressure VesselKubilay AçıkgözОценок пока нет

- ASIC Steel Interchange - Shear Flow in Plastic DesignДокумент2 страницыASIC Steel Interchange - Shear Flow in Plastic DesignMikeОценок пока нет

- Cisc Vs AiscДокумент11 страницCisc Vs Aiscanon_326950184100% (1)

- Composite Deck DesignДокумент16 страницComposite Deck DesignAhmad FitrahОценок пока нет

- Steel Interchange: Drift LimitsДокумент2 страницыSteel Interchange: Drift Limitsmaxeytm_839061685Оценок пока нет

- Pages From AISC 2016Документ27 страницPages From AISC 2016Abdul basithОценок пока нет

- Hilti Design Report PDFДокумент6 страницHilti Design Report PDFihpeterОценок пока нет

- SBBДокумент3 страницыSBBihpeterОценок пока нет

- Connections UB457 191x98xconnДокумент3 страницыConnections UB457 191x98xconnihpeterОценок пока нет

- 20180923Документ13 страниц20180923ihpeterОценок пока нет

- Connections UB457 191x98xconnДокумент3 страницыConnections UB457 191x98xconnihpeterОценок пока нет

- Anchor Bolt CheckДокумент1 страницаAnchor Bolt CheckihpeterОценок пока нет

- 11Документ3 страницы11ihpeterОценок пока нет

- Anchor Bolt CheckДокумент1 страницаAnchor Bolt CheckihpeterОценок пока нет

- Expo Favoriteroom 5Документ1 страницаExpo Favoriteroom 5ihpeterОценок пока нет

- UB457 End PlateДокумент4 страницыUB457 End PlateihpeterОценок пока нет

- Portal Output 20180718 R2Документ60 страницPortal Output 20180718 R2ihpeterОценок пока нет

- 20170303Документ4 страницы20170303ihpeterОценок пока нет

- 1 Input Data: Profis Anchor 2.6.1Документ6 страниц1 Input Data: Profis Anchor 2.6.1ihpeterОценок пока нет

- Conn DetailДокумент1 страницаConn DetailihpeterОценок пока нет

- Conn ForcesДокумент2 страницыConn ForcesihpeterОценок пока нет

- Circular Skylight Splice DetailДокумент1 страницаCircular Skylight Splice DetailihpeterОценок пока нет

- Reaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZДокумент1 страницаReaction Summary: Horizontal Vertical Horizontal Moment Node L/C FX FY FZ MX MY MZihpeterОценок пока нет

- 1 Input Data: Profis Anchor 2.6.4Документ6 страниц1 Input Data: Profis Anchor 2.6.4ihpeterОценок пока нет

- UB 356 171 45 B B F - P: X X EAM TO EAM IN LateДокумент6 страницUB 356 171 45 B B F - P: X X EAM TO EAM IN LateihpeterОценок пока нет

- RRДокумент6 страницRRihpeterОценок пока нет

- 1 Input Data: Profis Anchor 2.6.4Документ6 страниц1 Input Data: Profis Anchor 2.6.4ihpeterОценок пока нет

- SHS120 Post FixingДокумент6 страницSHS120 Post FixingihpeterОценок пока нет

- UB 457 152 52 B B F - P: X X EAM TO EAM IN LateДокумент6 страницUB 457 152 52 B B F - P: X X EAM TO EAM IN LateihpeterОценок пока нет

- SHS120 Post FixingДокумент6 страницSHS120 Post FixingihpeterОценок пока нет

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateДокумент7 страницUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterОценок пока нет

- AДокумент7 страницAihpeterОценок пока нет

- UB 254 146 31 B B F - P: X X EAM TO EAM IN LateДокумент7 страницUB 254 146 31 B B F - P: X X EAM TO EAM IN LateihpeterОценок пока нет

- AДокумент7 страницAihpeterОценок пока нет

- AДокумент9 страницAihpeterОценок пока нет

- AДокумент2 страницыAihpeterОценок пока нет

- Tutorial Answers Only 2002Документ7 страницTutorial Answers Only 2002Ahmed MoustafaОценок пока нет

- Mazda Bt50 WL C & We C Wiring Diagram f198!30!05l10Документ1 страницаMazda Bt50 WL C & We C Wiring Diagram f198!30!05l10staff0550% (1)

- Novec 1230 DesignДокумент8 страницNovec 1230 Designnandeesh100% (1)

- HENNLICH Telescopic Loading SpoutsДокумент34 страницыHENNLICH Telescopic Loading SpoutsTomas masquimillanОценок пока нет

- Grading 101Документ2 страницыGrading 101api-546896509Оценок пока нет

- MagnumДокумент16 страницMagnumgacm98100% (1)

- Fiber Optic Cable Splicing Procedure PDFДокумент2 страницыFiber Optic Cable Splicing Procedure PDFJim33% (3)

- 2014 Batch (Sem 1 16-17)Документ25 страниц2014 Batch (Sem 1 16-17)Bharath ThokalaОценок пока нет

- Writing Process Poster and ChecklistДокумент4 страницыWriting Process Poster and ChecklistNur FarahinОценок пока нет

- Yarega FeltetДокумент1 страницаYarega Feltetapi-3698374Оценок пока нет

- 118 WJДокумент3 страницы118 WJAmin HunzaiОценок пока нет

- Volt - and Ammeters W. Switch Data Sheet 4921210077 UK PDFДокумент3 страницыVolt - and Ammeters W. Switch Data Sheet 4921210077 UK PDFEdwin QuispeОценок пока нет

- Megum /thixon /robond Rubber-to-Substrate Bonding Agents: Solutions From Dow Automotive SystemsДокумент8 страницMegum /thixon /robond Rubber-to-Substrate Bonding Agents: Solutions From Dow Automotive SystemsAdriana Soto ArzolayОценок пока нет

- Lecture 5 Wiring Materials PDFДокумент11 страницLecture 5 Wiring Materials PDFAnonymous 3Ra3zVuMDОценок пока нет

- Vacancies 20th of MarchДокумент89 страницVacancies 20th of MarchCosmin-AlinBerendeОценок пока нет

- 2008 Owners Manual Subaru ForesterДокумент371 страница2008 Owners Manual Subaru ForesterLiviu ToaderОценок пока нет

- 95CBM020Документ6 страниц95CBM020Saša OljačaОценок пока нет

- EL 403-Power SystemДокумент54 страницыEL 403-Power SystemkaruppusamymariОценок пока нет

- Buckling Analysis of Tractor - 489Документ5 страницBuckling Analysis of Tractor - 489eshuОценок пока нет

- EGK Butterfly Valve VE200+VE201Документ2 страницыEGK Butterfly Valve VE200+VE201Sai PrasathОценок пока нет

- Zytech Solar Modules CatalogueДокумент9 страницZytech Solar Modules CatalogueEnrique ZuecoОценок пока нет

- Compost BrochureДокумент2 страницыCompost BrochureKristen MeidtОценок пока нет

- RC Example-Problems Canete PDFДокумент45 страницRC Example-Problems Canete PDFRhonoelle Reevenujlah100% (1)

- Dazon 250 HandbuchДокумент16 страницDazon 250 Handbuchapi-26422514Оценок пока нет

- Embraer Towing and Brake Riding OverviewДокумент20 страницEmbraer Towing and Brake Riding Overviewrelaxation02Оценок пока нет

- Appendix C Architectural Exterior Finishes RequirmentsДокумент2 страницыAppendix C Architectural Exterior Finishes RequirmentsEr Bishwonath ShahОценок пока нет

- Manuscript - Stress Corrosion Cracking of Stainless Steel Pipes For Methyl-Methacrylate Process PlantsДокумент23 страницыManuscript - Stress Corrosion Cracking of Stainless Steel Pipes For Methyl-Methacrylate Process PlantsadammplouhОценок пока нет

- 2G Gas EngineДокумент32 страницы2G Gas EngineQaiser IqbalОценок пока нет

- Unit III Heat Exchange EquipmentДокумент17 страницUnit III Heat Exchange EquipmentaberraneОценок пока нет

- Wireless Polling Method Using RFДокумент101 страницаWireless Polling Method Using RFSravani SravzОценок пока нет

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceОт EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceРейтинг: 4 из 5 звезд4/5 (19)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!От EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Рейтинг: 4 из 5 звезд4/5 (3)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsОт EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsРейтинг: 5 из 5 звезд5/5 (1)

- Artificial Intelligence: From Medieval Robots to Neural NetworksОт EverandArtificial Intelligence: From Medieval Robots to Neural NetworksРейтинг: 4 из 5 звезд4/5 (3)

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- The Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОт EverandThe Art of Welding: Featuring Ryan Friedlinghaus of West Coast CustomsОценок пока нет

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- Design for How People Think: Using Brain Science to Build Better ProductsОт EverandDesign for How People Think: Using Brain Science to Build Better ProductsРейтинг: 4 из 5 звезд4/5 (8)

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsОт EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsРейтинг: 5 из 5 звезд5/5 (3)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableОт EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableОценок пока нет