Академический Документы

Профессиональный Документы

Культура Документы

President CEO

Загружено:

api-768789540 оценок0% нашли этот документ полезным (0 голосов)

15 просмотров3 страницыPresident CEO with 21 years experience looking for a Senior Executive position.

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

TXT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPresident CEO with 21 years experience looking for a Senior Executive position.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате TXT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

15 просмотров3 страницыPresident CEO

Загружено:

api-76878954President CEO with 21 years experience looking for a Senior Executive position.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате TXT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

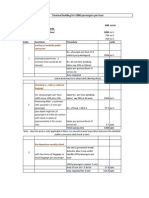

KEN BROWN MBA, CPM

3509 S. Fisher Ct. (509) 942-8242

Kennewick, WA 99337 kb4d9a06@westpost.net

President/CEO who improves small and mid cap firms that design and build custom

equipment and instrumentation by restructuring, identifying market opportunities

, controlling costs and taking them profitably to the next level. Extensive expe

rience serving industrial, government and scientific customers. Broad market kno

wledge including nuclear (NQA-1), food, material handling, scientific research,

heat treating and industrial gases. Strong knowledge of percent complete and boo

k-ship accounting.

PROFESSIONAL SKILLS

? Operations ? P&L Management

? Industrial & Government Customer Management ? Cost Control and Audit experienc

e

? Strategic Planning ? Turnaround & Financial Management

? Continuous Improvement Methodology ? NQA-1 Quality experience

? Merger and Acquisition ? Lean Manufacturing, Six Sigma, 5S

? Business Development & Product Management ? Global Technology Sales and Market

ing

? Supply Chain Management ? Staff Development

EDUCATION / LANGUAGE SKILLS

CPM (Certified Purchasing Manager) - APICS

MBA - Grand Valley State University

BS Chemistry - Bucknell University

At one time was fluent in Spanish

PROFESSIONAL EXPERIENCE

Mid Columbia Engineering, Inc. (MCE) ? Richland, WA March 2009 ? Present

President & CEO ? Custom Equipment Fabricator for the Nuclear Industry $17 milli

on

? Performed due diligence for NuVision?s acquisition of MCE, a government nuclea

r equipment fabricator.

? Established a culture of profitably delivering on time and on budget and meeti

ng the NQA-1 quality requirements of our customers.

? Implemented accounting and contract procedures to ensure accurate estimation a

nd costing of jobs and compliance with government FAR regulations.

? Created initiatives to selectively identify and win targeted business.

? Upgraded and organized the plant facility (5S) and improved project management

skills.

Smart Machine Technologies, Inc. ? Martinsville, VA Nov. 2006 to Oct. 2008

President ? Equipment Fabricator for the Food & Material Handling Industry $14 m

illion

? Increased Revenue from $8.6 to $13.7 million by securing new OEM?s and streaml

ining production.

? Increased Gross Margin from 15% to 20% and Operating Income from 2% to 11%.

? Funded $750,000 of capital investments (3% of sales) solely through cash flow.

? Implemented a transformation from an owner/operator culture with neglected fac

ilities and stagnant sales to a professional, profitable and growing concern thr

ough aggressive recruiting, goal setting, metrics management, capital investment

, employee communications, quality and sales efforts.

? Nominated for Virginia Small Business of the Year in 2007 and received ?excell

ent? appraisal rating.

? Built a team by recruiting 8 key staff/office positions and 25 additional shop

workers.

? Reduced the time from order to shipment by 7 days by performing a value stream

analysis at no cost.

? Implemented programs in 5S, non conformance reporting, document control and on

time shipments.

? Restructured shop scheduling resulting in less overtime and increased on time

shipments.

? Left company when owner brought in his son as president.

Innovative Coachworks Inc. ? Huntsville, AL Feb. 2006 to Oct. 2006

Chief Operating Officer ? Turnaround of Ambulance Remanufacturer $3 million

? Led a job shop re-manufacturer of ambulances out of bankruptcy and turned the

business around.

? Increased shipments by 33% and increase Gross Margin from 21% to 44% by reloca

ting the plant, implementing cellular manufacturing and reducing inventory.

? Implemented cash flow forecasting, budgeting, product pricing and break even a

nalysis.

? Company was closed due to owner?s personal issues.

Advanced Profit Technologies of TN, LLC. ? Knoxville, TN Jan. 2004 to Feb 2006

Franchise Owner ? Consultant for Underperforming Manufacturers

? Consultant performing in-depth analysis and restructuring of the operations, f

inance and organization of underperforming manufacturing companies.

? Worked with a metal container fabricator to improve their profitability by $40

0,000 in 6 months.

? Used a holistic Deming based continuous improvement methodology.

? Closed franchise due to personal desire to be a direct contributor not a consu

ltant.

Bull Run Metal Fabricators and Engineers ? Clinton, TN Aug. 2003 to Jan. 2004

Chief Operating Officer ? Turnaround of Nuclear Container Fabricator $5 million

? Led the turnaround effort of a nuclear container fabricator by increasing prod

uction and reducing material costs, resulting in operating profits increasing by

12 percentage points.

? Structured an acquisition of a competitor and performed the due diligence.

? Located a site and helped specify equipment for a new product line.

? Business was sold when largest customer, 70% of revenue, delayed release of th

eir orders.

American Magnetics ? Oak Ridge, TN Sept. 1996 to Nov. 2002

Executive Director ? Scientific Equipment and Instrument Manufacturer $7 million

? Increased profits by 135% for a manufacturer of superconducting magnets and in

struments.

? Created global sales/marketing plan and formed strategic alliances, which incr

eased sales by 85%.

? Started up a new instrument division by creating a business plan, identifying

market needs, defining product specifications and establishing production target

s.

? Helped implement the GE Six Sigma quality process by creating bills of materia

ls, written and visual work procedures, and tracking quality defects and their r

oot causes.

? Reduced material costs 28% by changing supply methodologies, competitively bid

ding products, revising product specifications, securing alternative vendors, an

d issuing larger purchase orders.

? Left family owned company due to limited upward mobility.

C.I. Hayes ? Cranston, RI Dec. 1993 to Aug. 1996

Global Director Sales & Marketing ? Heat Treating Furnace Manufacturer $12 Milli

on

? Increased global capital equipment sales by 17% and grew the spare parts busin

ess by 16%.

? Increased qualified leads by 300% by revamping ads, increasing trade show and

association participation and writing press releases.

? Arranged international financing and letters of credit, which represented 20%

of the company?s sales.

? Left company prior to its sale.

Abar Ipsen ? Bensalem, PA Jan. 1993 to Dec. 1993

Business Group Manager ? Atmospheric Heat Treating Furnace Division $15 million

? Recruited a team of engineering, sales, and production to re-launch a product

line in the US.

? Achieved bookings of $15 million, 40% over plan, by educating the sales depart

ment, targeting key customers and quickly securing a state of the art order from

a flagship customer.

? My position was eliminated due to decision to direct efforts from the German c

orporate office.

MG Industries ? Valley Forge, PA Aug. 1990 to June 1992

North American Director of Sales ? Industrial Gas Plant Division $25 million

? Increased annual sales from $12 to $25 million in 2 years, with a 25% net prof

it, by creating a target customer profile and a defined decision matrix for the

sales reps and application engineers.

? Broad industry exposure gained by working with over 500 plants, universities a

nd laboratories.

? Resigned due to lack of a team culture.

Praxair/Union Carbide ? Industrial Gas Division ? Chicago, IL July 1978 to June

1990

Midwest Region Sales Manager ? Industrial Gas Plants $100 million

? Managed regional sales and led the nation in new business for 4 consecutive ye

ars.

? Sold the worlds largest Membrane-Deoxo Nitrogen Plant and first Nitrogen VPSA

Plant.

? National account responsibility for Amoco and Monsanto.

? Recruited by the competition and left the company.

Sales Representative

? Known as ?The fixer? for underachieving sales territories, increased the perfo

rmance of 4 faltering territories, earning a top 10% performance rating for 6 co

nsecutive years.

? Created "Project Tulip?, a plan that thwarted 2 new competitors by re-signing

customers to long term contracts, while maintaining minimal price erosion. The

project was later implemented nationally.

? Increased sales to a distributor by 40% by teaming with the owner, working clo

sely with the sales people, and creating a stocking program, allowing them to ea

rn the "Distributor of the Year? aw

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Sec A - Group 9 - When A New Manager StumblesДокумент13 страницSec A - Group 9 - When A New Manager StumblesVijay Krishnan100% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- AS Unit 1 Revision Note Physics IAL EdexcelДокумент9 страницAS Unit 1 Revision Note Physics IAL EdexcelMahbub Khan100% (1)

- Episode 6: Deductive and Inductive Methods of Teaching: My Learning Episode OverviewДокумент10 страницEpisode 6: Deductive and Inductive Methods of Teaching: My Learning Episode OverviewJustine Elle Vijar85% (13)

- H.P. Elementary Education Code Chapter - 4 - 2012 SMC by Vijay Kumar HeerДокумент7 страницH.P. Elementary Education Code Chapter - 4 - 2012 SMC by Vijay Kumar HeerVIJAY KUMAR HEERОценок пока нет

- Housing Vocabulary TermsДокумент3 страницыHousing Vocabulary TermslucasОценок пока нет

- Full Download Test Bank For Ethics Theory and Contemporary Issues 9th Edition Mackinnon PDF Full ChapterДокумент36 страницFull Download Test Bank For Ethics Theory and Contemporary Issues 9th Edition Mackinnon PDF Full Chapterpapismlepal.b8x1100% (16)

- Akshaya Tritya! One of The Ancient Festivals of IndiaДокумент9 страницAkshaya Tritya! One of The Ancient Festivals of IndiaHoracio TackanooОценок пока нет

- Laboratory Manual: Microprocessor & MicrocontrollerДокумент4 страницыLaboratory Manual: Microprocessor & Microcontrollershamsul hadiОценок пока нет

- Bibliografia Antenas y RadioДокумент3 страницыBibliografia Antenas y RadioJorge HerreraОценок пока нет

- West Visayas State University (CHECKLIST FOR FS)Документ3 страницыWest Visayas State University (CHECKLIST FOR FS)Nichole Manalo - PoticarОценок пока нет

- Piggery BookletДокумент30 страницPiggery BookletVeli Ngwenya100% (2)

- (NewResultBD - Com) Mymensingh Board JSC Scholarship Result 2019Документ80 страниц(NewResultBD - Com) Mymensingh Board JSC Scholarship Result 2019rthedthbdeth100% (1)

- CVT / TCM Calibration Data "Write" Procedure: Applied VehiclesДокумент20 страницCVT / TCM Calibration Data "Write" Procedure: Applied VehiclesАндрей ЛозовойОценок пока нет

- Article 124-133Документ14 страницArticle 124-133andresjosejrОценок пока нет

- Bus Terminal Building AreasДокумент3 страницыBus Terminal Building AreasRohit Kashyap100% (1)

- 6.marketing ManagementДокумент11 страниц6.marketing ManagementadararaОценок пока нет

- 10 Ideas For ConversationДокумент116 страниц10 Ideas For ConversationGreenLake36100% (1)

- National Highways Authority of IndiaДокумент3 страницыNational Highways Authority of IndiaRohitОценок пока нет

- Product Bulletin Fisher 8580 Rotary Valve en 123032Документ16 страницProduct Bulletin Fisher 8580 Rotary Valve en 123032Rachmat MaulanaОценок пока нет

- Mushaf Qiraat Asim - (Syukbah)Документ604 страницыMushaf Qiraat Asim - (Syukbah)amnrs88100% (1)

- Q. 15 Insurance Regulatory and Development AuthorityДокумент2 страницыQ. 15 Insurance Regulatory and Development AuthorityMAHENDRA SHIVAJI DHENAKОценок пока нет

- PHYTOCHEMICAL AND CYTOTOXICITY TESTING OF RAMANIA LEAVES (Bouea Macrophylla Griffith) ETHANOL EXTRACT TOWARD VERO CELLS USING MTT ASSAY METHODДокумент6 страницPHYTOCHEMICAL AND CYTOTOXICITY TESTING OF RAMANIA LEAVES (Bouea Macrophylla Griffith) ETHANOL EXTRACT TOWARD VERO CELLS USING MTT ASSAY METHODLaila FitriОценок пока нет

- 659.69 BM67 2018-02-06 02 Im Beu-UsaДокумент88 страниц659.69 BM67 2018-02-06 02 Im Beu-UsaIrakli JibladzeОценок пока нет

- ORtHOGRAPHIC Plan FinalДокумент8 страницORtHOGRAPHIC Plan FinalKrizzie Jade CailingОценок пока нет

- Effects of Changes in Foreign Exchange Rates Ias 21Документ11 страницEffects of Changes in Foreign Exchange Rates Ias 21cykenОценок пока нет

- Jee Mathmatic PaperДокумент16 страницJee Mathmatic PaperDeepesh KumarОценок пока нет

- SHARE SEA Outlook Book 2518 r120719 2Документ218 страницSHARE SEA Outlook Book 2518 r120719 2Raafi SeiffОценок пока нет

- Speakers Reaction PaperДокумент2 страницыSpeakers Reaction Papermaui100% (2)

- Bill Vaskis ObitДокумент1 страницаBill Vaskis ObitSarah TorribioОценок пока нет

- I Am A Filipino by Carlos RomuloДокумент7 страницI Am A Filipino by Carlos RomuloKimberly NgОценок пока нет