Академический Документы

Профессиональный Документы

Культура Документы

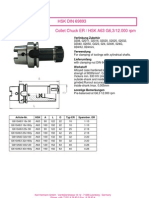

Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7Xd

Загружено:

alphatoolsИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ice-Carb High Performance Internal Coolant Drills For Drilling Depths Up To 7Xd

Загружено:

alphatoolsАвторское право:

Доступные форматы

50 36 12,5 63666 M14 X 1.5 .

4921 14

50 36 12,8 63667 M14 X 1.25 .5039 14

50 36 13 63668 9/16-18 M14 X 1 .5118 14

50 36 13,5 63669 5/8-11 .5315 14

50 36 13,8 63670 .5433 14

57 36 14 63671 M16 .5512 14

57 36 14,5 63672 5/8-18 M16 X 1.5 .5709 16

57 36 14,8 63673 .5827 16

57 36 15 63674 M16 X 1 .5906 16

57 36 15,5 63675 M18 .6102 16

57 36 15,8 63676 .6220 16

57 36 16 63677 .6299 16

66 36

66 36

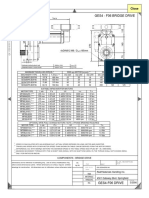

Series 140M Speed and Feed Recommendations

ICe-Carb High Performance

66 36 3 – 5 mm >

66 36 (.118 – .197 in.) (.20

66 36 material hardness speed

66

66

36

36

Internal Coolant Drills for

classification

low carbon steel

Bhn

≤ 170

Rc

≤5

sfm

450

m / min

135 .10 – .15

Drilling Depths up to 7xD

1018 (.004 – .006) (.

66 36 alloyed steel ≤ 270 ≤ 28 300 90 .075 – .12

76 36 4140 (.003 – .005) (.

76 36 high strength steel ≤ 400 ≤ 43 190 60 .05 – .10

76 36 4340, 300M (.002 – .004) (.

76 36 • Drilling Depths up

tool steel to 7xD: ≤Eliminates

170 the

≤ 5need for 230

pecking in most

70 .05 – .10

76 36 applications

H-13 (.002 – .004) (.

cast iron 150-200 1-15 400 120 .12 – .20

76 36 (.005 – .008) (.

• Internal Coolant for achieving higher cutting parameters and greater chip

76 36 200-300 15-30 245 75 .10 – .18

control

76 36 (.004 – .007) (.

76 36 300-400 30-45 190 60 .075 – .15

• 140 degree Self-Centering Point Angle (.003 – .006) (.

76 36

stainless steel ≤ 225 ≤ 20 140 45 .050 – .075 .

76 36 • Unique geometry

316, 17-4PH, features that enhance coolant flow and chip removal (.002 – .003)

15-5PH (.

76 36 stainless steel ≤ 170 ≤5 180 55 .075 – .10

87 40 • Corner protection

304, 410, 420 added for increased tool life (.003 – .004) (.

87 40 titanium ≤ 380 ≤ 40 100 30 .050 – .075

87 40 • Ti-NAMITE®-A

6Al4V (AITiN) coated for higher thermal stability and greater wear

(.002 – .003) (.

87 40 resistance

high temp in deep hole drilling

alloys ≤ 400 ≤ 43 50 15 .025 – .050 .

Inconel 718 (.001 – .002) (.

87 40

• Excellent resultsservice

Resharpening in: available upon request.

87 40

— Stainless Steel

87 40

87 40

— Alloyed Steel

87 40 — Cast Iron

87 40 — Low Carbon Steel

95 40 — Tool Steel

95 40 — Inconel

95 40 — Titanium

95 40

95 40

95 40 Series 140M Drill Tolerances - mm

95 40

95 40 Diameter Tolerance

d1 d1 (m7) d2 (h6)

95 40

≤ 3 +0,002 / +0,012 +0,0000 / -0,008

95 40 > 3-6 +0,004 / +0,016 +0,0000 / -0,008

106 45 > 6 - 10 +0,006 / +0,021 +0,0000 / -0,009

>10 - 18 +0,007 / +0,025 +0,0000 / -0,011

36 SGS HIGH PERFORMANCE

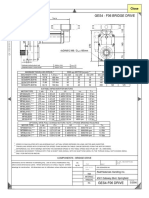

ICe-Carb Series 140M IC Internal Coolant Through Drills 7x Diameter

Metric

Ti-NAMITE-A

d1 Cutting (AlTiN) Tap Size Tap Size Decimal d2 Shank l1 Overall l2 Flute l4 Shank

Diameter mm EDP No. Reference Only Reference Only Equivalent Diameter mm Length mm Length mm Length mm

3 63575 .1181 6 75 37,5 36

3,1 63576 .1220 6 75 37,5 36

3,2 63577 M3.5 X.35 .1260 6 75 37,5 36

3,3 63578 M4 .1299 6 75 37,5 36

3,4 63579 #8-32 .1339 6 75 37,5 36

3,5 63580 #8-36 M4 X .5 .1378 6 75 37,5 36

3,6 63581 M4 X .35 .1417 6 75 37,5 36

3,7 63582 M4.5 .1457 6 75 37,5 36

3,8 63583 #10-24 .1496 6 75 37,5 36

3,9 63584 .1535 6 75 37,5 36

4 63585 M4.5 X .5 .1575 6 75 37,5 36

4,1 63586 #10-32 .1614 6 75 37,5 36

4,2 63587 M5 / M5 X .75 .1654 6 75 37,5 36

4,3 63588 .1693 6 85 45 36

4,4 63589 #12-24 .1732 6 85 45 36

4,5 63590 M5 X .5 .1772 6 85 45 36

4,6 63591 #12-28 .1811 6 85 45 36

4,7 63592 .1850 6 85 45 36

4,8 63593 .1890 6 90 50 36

4,9 63594 .1929 6 90 50 36

5 63595 M6 .1969 6 90 50 36

5,1 63596 1/4-20 .2008 6 90 50 36

5,2 63597 M6 X .75 .2047 6 90 50 36

5,3 63598 .2087 6 90 50 36

5,4 63599 .2126 6 97 57 36

5,5 63600 1/4-28 M6 X .5 .2165 6 97 57 36

5,6 63601 .2205 6 97 57 36

5,7 63602 .2244 6 97 57 36

5,8 63603 .2283 6 97 57 36

5,9 63604 .2323 6 97 57 36

6 63605 M7 .2362 6 97 57 36

6,1 63606 .2402 8 106 66 36

6,2 63607 M7 X .75 .2441 8 106 66 36

6,3 63608 .2480 8 106 66 36

6,4 63609 .2520 8 106 66 36

6,5 63610 .2559 8 106 66 36

6,6 63611 5/16-18 .2598 8 106 66 36

6,7 63612 .2638 8 106 66 36

6,8 63613 M8 .2677 8 106 66 36

6,9 63614 5/16-24 .2717 8 116 76 36

7 63615 M8 X 1 .2756 8 116 76 36

7,1 63616 .2795 8 116 76 36

7,2 63617 M8 X .75 .2835 8 116 76 36

7,3 63618 .2874 8 116 76 36

7,4 63619 .2913 8 116 76 36

7,5 63620 M8 X .5 .2953 8 116 76 36

7,6 63621 .2992 8 116 76 36

7,7 63622 .3031 8 116 76 36

7,8 63623 M9 .3071 8 116 76 36

7,9 63624 .3110 8 116 76 36

8 63625 3/8-16 M9 X 1 .3150 8 116 76 36

8,1 63626 .3189 10 131 87 40

8,2 63627 .3228 10 131 87 40

8,3 63628 .3268 10 131 87 40

8,4 63629 .3307 10 131 87 40

8,5 on page 38

continued 63630 3/8-24 M10 .3346 10 131 87 40

8,6 63631 .3386 10 131 87 40

8,7 63632 .3425 10 131 87 40

8,8 63633 M10 X 1.25 .3465 10 131 87 40

8,9 63634 .3504 10 131 87 40

9 63635 M10 X 1 .3543 10 131 87 40

9,1 63636 WWW.SGSTOOL.COM .3583 10 139 95 40 37

5,4 63599 .2126 stainless6steel 97≤ 225 ≤57

20 14036 45 .050 – .

.3110 8 5,5116 76

63600 36 1/4-28 M6 X .5 .2165 316, 17-4PH, 6 15-5PH 97 57 36 (.002 – .

.3150 8 116 76 36 18036 55

5,6 63601 .2205 stainless6steel 97≤ 170 ≤

575 .075 –

.3189 10 131 87 40

5,7 63602 .2244 304, 410,6 420 97 57 36 (.003 – .

.3228 10 131 87 40 titanium ≤ 380 ≤ 40 100 30 .050 – .

5,8 63603 .2283 6Al4V 6 97 57 36 (.002 – .

.3268 10 131 87 40

.3307 10 5,9131 63604

87 40 .2323 high temp 6 alloys 97≤ 400 ≤57

43 50 36 15 .025 – .

.3346 10 6131 63605

87 40 M7 .2362 Inconel 718 6 97 57 36 (.001 – .

.3386 10 6,1131 63606

87 40 .2402 Resharpening 8 service available

106 upon request.

66 36

.3425 10 6,2131 63607

87 40 M7 X .75 .2441 8 106 66 36

25 .3465 10 6,3131 63608

87 40 .2480 8 106 66 36

.3504 10 6,4131 63609

87 40 .2520 8 106 66 36

1 .3543 10 6,5131 63610

87 40 .2559 8 106 66 36

.3583 10 6,6139 63611

95 40 5/16-18 .2598 8 106 66 36

75 .3622 10 6,7139 95

63612 40 .2638 8 106 66 36

.3661 10 6,8139 95

63613 40 M8 .2677 8 106 66 36

.3701 10 6,9139 95

63614 40 5/16-24 .2717 8 116 76 36

X .5 .3740 10 7139 95

63615 40 M8 X 1 .2756 8 116 76 36

.3780 10 7,1139 95

63616 40 .2795 8 Series 140M 116 Drill Tolerances

76 - mm 36

.3819 10 7,2139 95

63617 40 M8 X .75 .2835 8 116 76 36

.3858 10 139 95 40 Diameter Tolerance

7,3 63618 .2874 8 d1 116d1 (m7) 76 36

d2 (h6)

.3898 10 139 95 40

7,4 63619 .2913 ≤8 3 116 / +0,012 76 +0,0000 / 36

+0,002 -0,008

.3937 10 139 95 40 >8 3 - 6 +0,004

7,5 63620 M8 X .5 .2953 116 / +0,016 76 +0,0000 / 36 -0,008

.3976 12 155 106 45 >8 6 - 10 +0,006

7,6 63621 .2992 116 / +0,021 76 +0,0000 / 36 -0,009

>10 - 18 +0,007 / +0,025

7,7 63622 .3031 8 116 76 +0,0000 / 36-0,011

7,8 63623 M9 .3071 8 116 76 36

ICe-Carb Series 140M IC Internal Coolant Through Drills 7x Diameter

Metric

7,9 63624 .3110 8 116 76 36

8 63625 3/8-16 M9 X 1 .3150 8 116 76 36

8,1 63626

Ti-NAMITE-A .3189 10 131 87 40

d1 Cutting

8,2 (AlTiN)

63627 Tap Size Tap Size Decimal

.3228 d2 10

Shank l1 Overall

131 l2 Flute

87 l4 Shank

40

Diameter

8,3 mm EDP No.

63628 Reference Only Reference Only Equivalent

.3268 Diameter

10 mm Length 131 mm Length 87 mm Length 40 mm

10,2

8,4 63647

63629 M12 .4016

.3307 12

10 155

131 106

87 45

40

10,3

8,5 63648

63630 3/8-24 M10 .4055

.3346 12

10 155

131 106

87 45

40

10,4

8,6 63649

63631 .4094

.3386 12

10 155

131 106

87 45

40

10,5

8,7 63650

63632 M12 X 1.5 .4134

.3425 12

10 155

131 106

87 45

40

10,6

8,8 63651

63633 M10 X 1.25 .4173

.3465 12

10 155

131 106

87 45

40

10,7

8,9 63652

63634 1/2-13 .4213

.3504 12

10 155

131 106

87 45

40

10,8

9 63653

63635 M12

M10X 1.25

X1 .4252

.3543 12

10 155

131 106

87 45

40

10,9

9,1 63654

63636 .4291

.3583 12

10 155

139 106

95 45

40

11

9,2 63655

63637 M12 X .75

M10 1 .4331

.3622 12

10 155

139 106

95 45

40

11,1

9,3 63656

63638 7/16-14 .4370

.3661 12

10 163

139 114

95 45

40

11,2

9,4 63657

63639 .4409

.3701 12

10 163

139 114

95 45

40

11,3

9,5 63658

63640 M11 / M10 X .5 .4449

.3740 12

10 163

139 114

95 45

40

11,4

9,6 63659

63641 .4488

.3780 12

10 163

139 114

95 45

40

ICe-Carb Series 140M IC Internal Coolant Through Drills 7x Diameter

11,5

9,7 63660

63642 1/2-20 M12 X .5 .4528

.3819 12

10 163

139 114

95 45

40

11,6

9,8 63661

63643 .4567

.3858 12

10 163

139 114

95 45

40

11,7

9,9 63662

63644

Ti-NAMITE-A 7/16-20 .4606

.3898 12

10 163

139 114

95 45

40

d1 Cutting

11,8

10 (AlTiN)

63663

63645 Tap Size Tap Size Decimal

.4646

.3937 d2 12

Shank

10 l1 Overall

163

139 l2 114

Flute

95 l4 Shank

45

40

Diameter

10,1 mm

11,9 EDP No.

63664

63646 Reference Only Reference Only Equivalent

.4685

.3976 Diameter

12 mm Length 155 mm Length

163 106mm Length

114 45 mm

12

10,2 63665

63647 M14

M12 .4724

.4016 12 163

155 114

106 45

12,5

10,3 63666

63648 M14 X 1.5 .4921

.4055 14

12 182

155 133

106 45

12,8

10,4 63667

63649 M14 X 1.25 .5039

.4094 14

12 182

155 133

106 45

13

10,5 63668

63650 9/16-18 M14XX1.5

M12 1 .5118

.4134 14

12 182

155 133

106 45

13,5

10,6 63669

63651 5/8-11 .5315

.4173 14

12 182

155 133

106 45

13,8

10,7 63670

63652 1/2-13 .5433

.4213 14

12 182

155 133

106 45

14

10,8 63671

63653 M12M16

X 1.25 .5512

.4252 14

12 182

155 133

106 45

14,5

10,9 63672

63654 5/8-18 M16 X 1.5 .5709

.4291 16

12 204

155 152

106 48

45

14,8

11 63673

63655 M12 X 1 .5827

.4331 16

12 204

155 152

106 48

45

15 on page 39

11,1

continued 63674

63656 M16 X 1 .5906

.4370 16

12 204

163 152

114 48

45

15,5

11,2 63675

63657 M18 .6102

.4409 16

12 204

163 152

114 48

45

15,8

11,3 63676

63658 .6220

.4449 16

12 204

163 152

114 48

45

16

11,4 63677

63659 .6299

.4488 16

12 204

163 152

114 48

45

11,5 63660 1/2-20 M12 X .5 .4528 12 163 114 45

11,6 63661 .4567 12 163

drill diameter 114 45

Series

11,7 140M Speed 63662and Feed Recommendations .4606

3

(.118

– 5 mm

– .197 in.)

12>5 – 8 mm 163 >8 – 12 mm114

(.203

>12 – 16 45mm

11,8 63663 .4646 12 – .316 in.) 163 (.328 – .500 in.)

114 (.512 – .64045 in.)

material

11,9 63664 hardness speed

.4685 12 feed / revolution

163 114 45

classification Bhn Rc sfm m / min

12 63665 M14 .4724

.10 – .15

12 .15 – .25

163 .25 – .40

114 45

.40 – .50

low carbon steel ≤ 170 ≤5 450 135

1018 12,5 63666 M14 X 1.5 .4921– .006)

(.004 14(.006 – .010) 182 (.010 – .016) 133 (.016 –45 .020)

alloyed12,8

steel 63667≤ 270 ≤ 28 300 M14 X 1.25

90 .5039

.075 – .12 14 .12 – .20 182 .20 – .30133 .30 –45 .40

4140 13 63668 9/16-18 M14 X 1 .5118– .005)

(.003 14(.005 – .008) 182 (.008 – .012) 133 (.012 –45 .016)

high strength

13,5 steel 63669≤ 400 ≤5/8-11

43 190 60 .05 – .10

.5315 14 .10 – .15 182 .15 – .23133 .23 –45 .30

4340, 300M

13,8 63670 (.002

.5433– .004) 14(.004 – .006) 182 (.006 – .009) 133 (.009 –45 .012)

tool steel ≤ 170 ≤5 230 70 .05 – .10 .10 – .18 .18 – .25 .25 – .33

14 63671 M16 .5512 14 182 133 45

H-13 (.002 – .004) (.004 – .007) (.007 – .010) (.010 – .013)

14,5

cast iron 63672

150-200 5/8-18

1-15 400 M16 X1201.5 .5709

.12 – .20 16 .20 – .33 204 .33 – .50152 .50 –48 .65

14,8 63673 .5827

(.005 – .008) 16 (.008 – .013) 204 152

(.013 – .020) (.020 –48 .026)

15 63674

200-300 15-30 245 M16 X75 1 .5906

.10 – .18 16 .18 – .28 204 .28 – .43152 .43 –48 .55

15,5 63675 M18 (.004

.6102– .007) 16(.007 – .011) 204 (.011 – .017) 152 (.017 –48 .022)

15,8 300-400

63676 30-45 190 60 .075 – .15

.6220 16 .15 – .25 204 .25 – .38152 .38 –48 .50

(.003 – .006)

16 63677 .6299 16(.006 – .010) 204 (.010 – .015) 152 (.015 – .020)

48

38 stainless steel

316, 17-4PH, 15-5PH

≤ 225

SGS HIGH

≤ 20 140

PERFORMANCE

45 .050 – .075

(.002 – .003)

.075 – .120

(.003 – .005)

.12 – .20

(.005 – .008)

.20 – .25

(.008 – .010)

ICe-Carb Series 140M IC Internal Coolant Through Drills 7x Diameter

ICe-Carb

d1 Cutting Series 140M

Ti-NAMITE-A

(AlTiN) Tap SizeIC Internal

Tap Size Coolant

Decimal Through

d2 Shank l1Drills

Overall 7x Diameter

l2 Flute l4 Shank

Diameter mm Ti-NAMITE-A

EDP No. Reference Only Reference Only Equivalent Diameter mm Length mm Length mm Length mm

d1 Cutting

10,2 (AlTiN)

63647 Tap Size Tap

M12Size Decimal

.4016 d2 12

Shank l1 Overall

155 l2 Flute

106 l4 Shank

45

Diameter

10,3 mm EDP No.

63648 Reference Only Reference Only Equivalent

.4055 Diameter

12 mm Length 155 mm Length 106 mm Length 45 mm

10,2

10,4 63647

63649 M12 .4016

.4094 12 155 106 45

ICe-Carb Series 140M IC Internal Coolant Through Drills 7x Diameter

Metric

10,3

10,5 63648

63650 M12 X 1.5 .4055

.4134 12 155 106 45

10,4

10,6 63649

63651 .4094

.4173 12 155 106 45

10,5

10,7 Ti-NAMITE-A

63650

63652 1/2-13 M12 X 1.5 .4134

.4213 12 155 106 45

d1 Cutting

10,6

10,8 (AlTiN)

63651

63653 Tap Size Tap

M12 X Size

1.25 Decimal

.4173

.4252 d2 12

Shank l1 Overall

155 l2 Flute

106 l4 Shank

45

Diameter

10,9 mm

10,7 EDP No.

63652

63654 Reference

1/2-13 Only Reference Only Equivalent

.4213

.4291 Diameter

12 mm Length 155 mm Length 106mm Length 45 mm

10,2

10,8

11 63647

63653

63655 M12M12

M12X X1.25

1 .4016

.4252

.4331 12

12 155

155 106

106 45

45

10,3

10,9

11,1 63648

63654

63656 .4055

.4291

.4370 12

12 155

163 106

114 45

45

10,4

11

11,2 63649

63655

63657 M12 X 1 .4094

.4331

.4409 12

12 155

163 106

114 45

45

10,5

11,1

11,3 63650

63656

63658 M12 X 1.5 .4134

.4370

.4449 12

12 155

163 106

114 45

45

10,6

11,2

11,4 63651

63657

63659 .4173

.4409

.4488 12

12 155

163 106

114 45

45

10,7

11,3

11,5 63652

63658

63660 1/2-13

1/2-20 M12 X .5 .4213

.4449

.4528 12

12 155

163 106

114 45

45

10,8

11,4

11,6 63653

63659

63661 M12 X 1.25 .4252

.4488

.4567 12

12 155

163 106

114 45

45

10,9

11,5

11,7 63654

63660

63662 1/2-20 M12 X .5 .4291

.4528

.4606 12

12 155

163 106

114 45

45

11

11,6

11,8 63655

63661

63663 M12 X 1 .4331

.4567

.4646 12

12 155

163 106

114 45

45

11,1

11,7

11,9 63656

63662

63664 .4370

.4606

.4685 12

12 163

163 114

114 45

45

11,2

11,8

12 63657

63663

63665 M14 .4409

.4646

.4724 12

12 163

163 114

114 45

45

11,3

11,9

12,5 63658

63664

63666 M14 X 1.5 .4449

.4685

.4921 12

14 163

182 114

133 45

45

11,4

12

12,8 63659

63665

63667 M14M14

X 1.25 .4488

.4724

.5039 12

14 163

182 114

133 45

45

11,5

12,5

13 63660

63666

63668 1/2-20

9/16-18 M12

M14XXX1.5

M14 .5

1 .4528

.4921

.5118 12

14 163

182 114

133 45

45

11,6

12,8

13,5 63661

63667

63669 5/8-11 M14 X 1.25 .4567

.5039

.5315 12

14 163

182 114

133 45

45

11,7

13

13,8 63662

63668

63670 9/16-18 M14 X 1 .4606

.5118

.5433 12

14 163

182 114

133 45

45

11,8

13,5

14 63663

63669

63671 5/8-11 M16 .4646

.5315

.5512 12

14 163

182 114

133 45

45

11,9

13,8

14,5 63664

63670

63672 5/8-18 M16 X 1.5 .4685

.5433

.5709 12

14

16 163

182

204 114

133

152 45

48

12

14

14,8 63665

63671

63673 M14

M16 .4724

.5512

.5827 12

14

16 163

182

204 114

133

152 45

48

12,5

14,5

15 63666

63672

63674 5/8-18 M14

M16XX1.5

M16 1 .4921

.5709

.5906 14

16 182

204 133

152 45

48

12,8

14,8

15,5 63667

63673

63675 M14M18

X 1.25 .5039

.5827

.6102 14

16 182

204 133

152 45

48

13

15

15,8 63668

63674

63676 9/16-18 M14

M16 X 1 .5118

.5906

.6220 14

16 182

204 133

152 45

48

13,5

15,5

16 63669

63675

63677 5/8-11 M18 .5315

.6102

.6299 14

16 182

204 133

152 45

48

13,8

15,8 63670

63676 .5433

.6220 14

16 182

204 133

152 45

48

14

16 63671

63677 M16 .5512

.6299 14

16 182

204

drill diameter 133

152 45

48

Series

14,5 140M Speed

14,8

63672and Feed

63673

Recommendations

5/8-18 M16 X 1.5 .5709

3 – 5 mm

.5827

(.118 – .197 in.)

16>5 – 8 mm 204 >8 – 12 mm

16 – .316drill

(.203 204

152

(.328 – .500 152

in.)diameter in.)

48mm

>12 – 16

48 in.)

(.512 – .640

Series

material 15 140M Speed

classification

63674and FeedRcRecommendations

hardness speed

M16 X 1 .5906

3 – 5 mm 16>5 – 8 feed

mm / revolution

204 >8 – 12 mm 152 48mm

>12 – 16

15,5 63675Bhn sfm m / min

M18 (.118 – .197 in.)

.6102 (.203

16 – .316 in.) 204 (.328 – .500 152

in.) (.512 – .640

48 in.)

.10 – .15

low carbon steel

material

15,8 ≤ 170

63676 hardness≤ 5 450 speed 135

.6220 16 .15 – feed

.25 / revolution

204 .25 – .40152 .40 – .50

48

1018

classification Bhn Rc sfm m / min (.004 – .006) (.006 – .010) (.010 – .016) (.016 – .020)

16

alloyed steel

63677

≤ 270 ≤ 28 300 90

.6299

.075 – .12

16 .12 – .20 204 .20 – .30152 48

.30 – .40

low carbon steel ≤ 170 ≤5 450 135 .10 – .15 .15 – .25 .25 – .40 .40 – .50

4140

1018 (.003 –

(.004 – .006)

.005) (.005 –

(.006 – .010)

.008) (.008 –

(.010 – .016)

.012) (.012 –

(.016 – .020)

.016)

high strength

alloyed steel steel ≤ 270

≤ 400 ≤ 28

≤ 43 190

300 60

90 .05 ––.10

.075 .12 .10 –

.12 – .20

.15

drill diameter .15 –

.20 – .30

.23 .23 –

.30 – .40

.30

4140Series 140M Speed≤ and

4340, 300M Feed≤ 5Recommendations (.002

3 – 5–

(.003

(.118.05

–mm

.004)

.005)

– .197

(.004

(.005 – mm

>5 – 8– .006)

.008) (.006

>8 – 12

(.008 – .012)

– .009)

mm (.009

>12

(.012 – .016)

– 16

– .012)

mm

tool

highsteel

strength steel 170 ≤ 400 230

≤ 43 70 190 60 .05 – .10in.)

– .10 (.203 ––

.10

.10 .316

– .15in.)

.18 (.328.18– .500

.15 – .23in.)

– .25 (.512 – .640

.25

.23 – .30in.)

– .33

H-13

material

4340, 300M hardness speed (.002

(.002 –– .004)

.004) (.004

(.004 – .007)

– feed (.007

(.006 –

.006)/ revolution – .010)

.009) (.010

(.009 –– .013)

.012)

classification

cast iron

tool steel Bhn

150-200

≤ 170 ≤Rc5

1-15 sfm

400

230 m120

/ min

70 .12

.05 –

– .20

.10 .20

.10 –

– .33

.18 .33

.18 –– .50

.25 .50

.25 –

– .65

.33

low

H-13carbon steel ≤ 170 ≤5 450 135 (.005

(.002 – .008)

.10 – .15

.004) (.008

.15 – .013)

.25

(.004 – .007) (.013

(.007 – .020)

.25 – .40

.010) (.020

(.010 – .026)

.40 – .50

.013)

1018

cast iron 200-300

150-200 15-30

1-15 245

400 75

120 .10 –

(.004

.12 .18

– .006)

.20 .18 –

(.006

.20 .28

– .010)

.33 .28 –

(.010

.33 .43

– .016)

.50 .43 –

(.016

.50 .55

– .020)

.65

alloyed steel ≤ 270 ≤ 28 300 90 (.004

.075–

(.005 ––.008)

.007)

.12 (.007

.12 –

(.008 .011)

– .20

.013) (.011

.20 –

(.013 – .017)

.30

.020) (.017

.30 –

(.020 .022)

– .40

.026)

4140 300-400

200-300 30-45

15-30 190

245 60

75 .075

(.003 ––.005)

.10 – .15

.18 .15 –

(.005

.18 .25

– .008)

.28 .25 –

(.008

.28 .38

– .012)

.43 .38 –

(.012

.43 .50

– .016)

.55

high strength steel ≤ 400 ≤ 43 190 60 (.003

.05 –

(.004 .006)

– .10

.007) (.006 .010)

.10 –– .15

(.007 .011) (.010

.15 –

(.011 .015)

– .017)

.23 (.015

.23 –

(.017 .020)

– .30

.022)

stainless

4340, steel

300M ≤ 225

300-400 ≤ 20

30-45 140

190 45

60 .050

(.002 .075

.075––.004)

.15 .075

(.004

.15 – .120

– .006)

.25 .12

(.006

.25 – .20

– .009)

.38 .20

(.009

.38 – .25

– .012)

.50

316,steel

tool 17-4PH, 15-5PH ≤ 170 ≤5 230 70 (.002

.05 –

(.003 .003)

– .10

.006) (.003

.10 –

(.006 .005)

– .18

.010) (.005

.18 –

(.010 .008)

– .25

.015) (.008

(.015 – .010)

.25 – .33

.020)

stainless

stainless steel

H-13 steel ≤

≤ 170

225 ≤≤205 180

140 55

45 .075

(.002 –– .10

.004)

.050 – .075 .10 –

(.004

.075 .15

– .007)

.120 .15

(.007

.12 – .25

– .010)

.20 .25

(.010

.20 – .33

– .013)

.25

304,

cast 410,

316, iron 420 15-5PH

17-4PH, 150-200 1-15 400 120 (.003

.12 –

(.002 .004)

– .20

.003) (.004 – .006)

.20 – .33

(.003 .005) (.006 – .010)

.33 – .50

(.005 .008) (.010 – .013)

.50 – .65

(.008 .010)

titanium

stainless steel ≤ 170

≤ 380 ≤≤405 100

180 30

55 .050

(.005 .075

.075––.008)

.10 .075

(.008 ––.013)

.10 – .10

.15 .10 –

(.013

.15 .15

– .020)

.25 .15 –

(.020

.25 .20

– .026)

.33

6Al4V

304, 410, 420 200-300 15-30 245 75 (.002 .003)

.10 – .18

(.003 .004) (.003 .004)

.18 – .28

(.004 .006) (.004 .006)

.28 – .43

(.006 .010) (.006 .008)

.43 – .55

(.010 .013)

high temp alloys

titanium ≤

≤ 400

380 ≤ 40

≤ 43 50

100 15

30 .025 – .007)

(.004

.050 .050

.075 .050

.075––.075

(.007 .011)

.10 .075

.10 ––.017)

(.011 .10

.15 .10 – .022)

(.017

.15 .12

.20

Inconel 718

6Al4V 300-400 30-45 190 60 (.001

.075–

(.002 ––.003)

.002)

.15 (.002 .003)

.15 – .25

(.003 .004) (.003 .004)

.25 – .38

(.004 .006) (.004 .005)

.38 – .50

(.006 .008)

Resharpening

high temp alloysservice available

≤ 400upon request.

≤ 43 50 15 (.003

.025 – .006)

.050 (.006

.050 – .010)

.075 (.010

.075––.015)

.10 (.015

.10 – .020)

.12

stainless steel

Inconel 718 ≤ 225 ≤ 20 140 45 .050 – .075

(.001 .002) .075 – .120

(.002 .003) .12 – .20

(.003 .004) .20 – .25

(.004 .005)

316, 17-4PH, 15-5PH (.002 – .003) (.003 – .005) (.005 – .008) (.008 – .010)

Resharpening service available upon request.

stainless steel ≤ 170 ≤5 180 55 .075 – .10 .10 – .15 .15 – .25 .25 – .33

304, 410, 420 (.003 – .004) (.004 – .006) (.006 – .010) (.010 – .013)

titanium ≤ 380 ≤ 40 100 30 .050 – .075 .075 – .10 .10 – .15 .15 – .20

6Al4V (.002 – .003) (.003 – .004) (.004 – .006) (.006 – .008)

high temp alloys ≤ 400 ≤ 43 50 15 .025 – .050 .050 – .075 .075 – .10 .10 – .12

Inconel 718 (.001 – .002) (.002 – .003) (.003 – .004) (.004 – .005)

Resharpening service available upon request.

Series 140M Drill Tolerances - mm

Diameter Tolerance

WWW.SGSTOOL.COM 39

Вам также может понравиться

- School: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabДокумент3 страницыSchool: Sta. Maria Integrated School Group No. Names: Energy Forms & Changes Virtual LabNanette Morado0% (1)

- COLLOIDAL GOLD RECIPE - CitrateДокумент9 страницCOLLOIDAL GOLD RECIPE - CitrateDevon Narok100% (4)

- Cast Wheel in Indian Rlys-Present StatusДокумент6 страницCast Wheel in Indian Rlys-Present StatusDevarshi GaurОценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Figs Taste Scale of Selected Varieties From Hawaiifruit-Net PDFДокумент4 страницыFigs Taste Scale of Selected Varieties From Hawaiifruit-Net PDFHanafizar Hanafi Napi AtanОценок пока нет

- Steel Grade: Material Data SheetДокумент3 страницыSteel Grade: Material Data SheetRushangОценок пока нет

- Consteel Catalogue BARS FlatДокумент2 страницыConsteel Catalogue BARS FlatWei YaoОценок пока нет

- 5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052Документ3 страницы5 MM X 20 MM Fast-Acting Glass Tube Fuses: Technical Data 2052MahfudОценок пока нет

- JIS Steel Norms For General Structural SteelДокумент3 страницыJIS Steel Norms For General Structural SteelValentin StănescuОценок пока нет

- 36smnpb14 1.0765 pr80 11l37 EngДокумент1 страница36smnpb14 1.0765 pr80 11l37 EngJason-chungОценок пока нет

- 36SMnPb14 1.0765 PR80 11L37 ENG PDFДокумент1 страница36SMnPb14 1.0765 PR80 11L37 ENG PDFDragos AndreiОценок пока нет

- Direct-Hardening: Free-Cutting Steels 35S20Документ1 страницаDirect-Hardening: Free-Cutting Steels 35S20Biaizidi Abbou SamirОценок пока нет

- 46S20PB - 46SPb20-Nr 1 0757-ENGДокумент1 страница46S20PB - 46SPb20-Nr 1 0757-ENGVipul SharmaОценок пока нет

- Consteel Catalogue PLATES ChequeredPlatesДокумент3 страницыConsteel Catalogue PLATES ChequeredPlatesrichard richОценок пока нет

- Alloy 6013 Tech Sheet 1Документ4 страницыAlloy 6013 Tech Sheet 1IlyasОценок пока нет

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfДокумент2 страницыDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoОценок пока нет

- Al Alloys Chemicals MechanicalsДокумент1 страницаAl Alloys Chemicals MechanicalsFactory FactoryОценок пока нет

- Gasnitriding - Plasmanitriding - SaltbathnitridingДокумент4 страницыGasnitriding - Plasmanitriding - SaltbathnitridingKevin ThomasОценок пока нет

- 42 CR Mo 4Документ4 страницы42 CR Mo 4Alin ChehadeОценок пока нет

- 05 Pump Sizing-ExerciseДокумент39 страниц05 Pump Sizing-ExerciserahulОценок пока нет

- 02 - ESP Performance CurvesДокумент32 страницы02 - ESP Performance CurvesrahulОценок пока нет

- 5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332Документ2 страницы5 MM X 20 MM Time-Delay Glass Tube Fuses: Technical Data 4332LXCОценок пока нет

- Consteel Catalogue CHANNELS ParallelFlangePFCДокумент2 страницыConsteel Catalogue CHANNELS ParallelFlangePFCazharigunawan.gam10092023Оценок пока нет

- 34crnimo6: Steel GradeДокумент6 страниц34crnimo6: Steel GradeBiju KОценок пока нет

- Gearless MGI27SДокумент3 страницыGearless MGI27SMk KuraОценок пока нет

- 5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeДокумент2 страницы5 X 20mm Fuses: S500 Series, Fast-Acting, Glass TubeMemona FayyazОценок пока нет

- Copper Bussman FusesДокумент9 страницCopper Bussman FusesKhaled BellegdyОценок пока нет

- Nama Barang, Toko, No TelponДокумент9 страницNama Barang, Toko, No Telpontutun financeОценок пока нет

- Table J.2.1 Filler Strengths Table J.2.2 Tensile Strengths For 5183, 5356, and 5556 StudsДокумент1 страницаTable J.2.1 Filler Strengths Table J.2.2 Tensile Strengths For 5183, 5356, and 5556 StudsAbdullah NajjarОценок пока нет

- Steel Grade: Material Data SheetДокумент3 страницыSteel Grade: Material Data SheetBouremana AnèsОценок пока нет

- Steel Grade: Material Data SheetДокумент3 страницыSteel Grade: Material Data Sheetdinesh kumarОценок пока нет

- 42 CR Mo 4Документ3 страницы42 CR Mo 4lucasОценок пока нет

- Alloy Machining: NickelДокумент2 страницыAlloy Machining: Nickeljoko setiawanОценок пока нет

- S355J2Документ5 страницS355J2jon perez diezОценок пока нет

- MURAFLEX 2020 Low RizeДокумент4 страницыMURAFLEX 2020 Low RizeanisyariskiОценок пока нет

- Steel Grade: Material Data SheetДокумент3 страницыSteel Grade: Material Data Sheetprabhu vijayanОценок пока нет

- Eton S A0001030147 1Документ2 страницыEton S A0001030147 1Nacho AlvarezОценок пока нет

- Astm A789Документ15 страницAstm A789Huan Dinh QuangОценок пока нет

- REDA (Data)Документ20 страницREDA (Data)saeedОценок пока нет

- Stainless Steel AISI 630-17-4PHДокумент1 страницаStainless Steel AISI 630-17-4PHwillyОценок пока нет

- Propiedades Mecanicas Del B7Документ1 страницаPropiedades Mecanicas Del B7alejandrorhino2 rhinoОценок пока нет

- Electrode Booklet F Web 85Документ1 страницаElectrode Booklet F Web 85satnamОценок пока нет

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFДокумент2 страницы304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalОценок пока нет

- Info EN755 9Документ19 страницInfo EN755 9Don JonesОценок пока нет

- General Linear Tolerances: Nominal Dimension Overall Dimensions Over Over UptoДокумент9 страницGeneral Linear Tolerances: Nominal Dimension Overall Dimensions Over Over Uptosidharth saraswatОценок пока нет

- 42CrMo4QT-Pulley Shaft MaterialДокумент1 страница42CrMo4QT-Pulley Shaft MaterialanishgirmeОценок пока нет

- 42crmo4: Steel GradeДокумент5 страниц42crmo4: Steel GradeMahmoud KchaouОценок пока нет

- Principal Application Fields Heat Treatable Steel - Steel For Cold ExtrusionДокумент1 страницаPrincipal Application Fields Heat Treatable Steel - Steel For Cold ExtrusionBhuvnesh VermaОценок пока нет

- LabofinitosДокумент4 страницыLabofinitosSergio Fernandez quispeОценок пока нет

- Ges4 - f06 Drive-Imperial 0Документ1 страницаGes4 - f06 Drive-Imperial 0KracinОценок пока нет

- Ges4 - f06 Drive-Imperial 0Документ1 страницаGes4 - f06 Drive-Imperial 0KracinОценок пока нет

- Ges4 - f06 Drive-Imperial 0Документ1 страницаGes4 - f06 Drive-Imperial 0KracinОценок пока нет

- Ges4 - f06 Drive-Imperial 0Документ1 страницаGes4 - f06 Drive-Imperial 0KracinОценок пока нет

- SD II PDF - OCRДокумент18 страницSD II PDF - OCRSuraj KumarОценок пока нет

- Din 17455-85 General Purpose Welded Circular Stainless Steel TubesДокумент13 страницDin 17455-85 General Purpose Welded Circular Stainless Steel TubestanyaОценок пока нет

- Steel Grade: Material Data SheetДокумент2 страницыSteel Grade: Material Data SheetLanceal TanОценок пока нет

- ShaftDesigner Report. AlignmentДокумент49 страницShaftDesigner Report. AlignmentMonglen Z. CasiñoОценок пока нет

- JMS Mochia Fab Aug-19Документ14 страницJMS Mochia Fab Aug-19SAMEERОценок пока нет

- Alvenius Comparativo de Diametros Nominais e ExternosДокумент1 страницаAlvenius Comparativo de Diametros Nominais e ExternosAna Carolina AlvesОценок пока нет

- Tubos Comparativo de Diametros Nominais e ExternosДокумент1 страницаTubos Comparativo de Diametros Nominais e ExternosFábio Da Silva AlanoОценок пока нет

- Comparativo de Diametros Nominais e ExternosДокумент1 страницаComparativo de Diametros Nominais e ExternosSidney CesarОценок пока нет

- Bearings For Screw DrivesДокумент10 страницBearings For Screw DrivesTravis DavisОценок пока нет

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsОт EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsРейтинг: 5 из 5 звезд5/5 (1)

- DELFERДокумент81 страницаDELFERalphatoolsОценок пока нет

- Z-CARB MD SpeedFeedДокумент1 страницаZ-CARB MD SpeedFeedalphatoolsОценок пока нет

- SAITДокумент166 страницSAITalphatoolsОценок пока нет

- The Finishing Touch: Expect More From A Finishing MillДокумент4 страницыThe Finishing Touch: Expect More From A Finishing MillalphatoolsОценок пока нет

- Z-Carb Original End Mills: Revolutionizes MillingДокумент4 страницыZ-Carb Original End Mills: Revolutionizes MillingalphatoolsОценок пока нет

- Z-Carb JetStream SpeedFeedДокумент2 страницыZ-Carb JetStream SpeedFeedalphatoolsОценок пока нет

- Z-Carb Corner Radius SpeedFeedДокумент2 страницыZ-Carb Corner Radius SpeedFeedalphatoolsОценок пока нет

- Osborn EZ-Flex CatalogueДокумент1 страницаOsborn EZ-Flex CataloguealphatoolsОценок пока нет

- Turbo CarbДокумент2 страницыTurbo CarbalphatoolsОценок пока нет

- Osborn Novoflex-B CatalogueДокумент1 страницаOsborn Novoflex-B CataloguealphatoolsОценок пока нет

- VDI enДокумент110 страницVDI enalphatoolsОценок пока нет

- HPC Flyer UnzippedДокумент8 страницHPC Flyer UnzippedalphatoolsОценок пока нет

- Ti NAMITEДокумент2 страницыTi NAMITEalphatoolsОценок пока нет

- S20x2 Deckel enДокумент9 страницS20x2 Deckel enalphatools100% (1)

- DIN 69871 enДокумент69 страницDIN 69871 enalphatoolsОценок пока нет

- MAS-BT enДокумент62 страницыMAS-BT enalphatoolsОценок пока нет

- HSK DIN 69893 enДокумент29 страницHSK DIN 69893 enalphatoolsОценок пока нет

- Pull Studs enДокумент8 страницPull Studs enLLОценок пока нет

- Threading ToolsДокумент9 страницThreading ToolsalphatoolsОценок пока нет

- DIN 2080 enДокумент45 страницDIN 2080 enalphatoolsОценок пока нет

- Powerbor DrillsДокумент6 страницPowerbor DrillsalphatoolsОценок пока нет

- Listes de Produits GAURAPADДокумент1 страницаListes de Produits GAURAPADBertrand KouamОценок пока нет

- Interactive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsДокумент5 страницInteractive and Comprehensive Database For Environmental Effect Data For PharmaceuticalsRaluca RatiuОценок пока нет

- Audio AmplifierДокумент8 страницAudio AmplifierYuda Aditama100% (2)

- Gpat Reference NotesДокумент9 страницGpat Reference NotesPreethi KiranОценок пока нет

- Interventional Cardiology and SurgeryДокумент19 страницInterventional Cardiology and SurgeryDEV NANDHINI RОценок пока нет

- Sample UploadДокумент14 страницSample Uploadparsley_ly100% (6)

- Guia Laboratorio Refrigeración-2020Документ84 страницыGuia Laboratorio Refrigeración-2020soniaОценок пока нет

- Broza Saric Kundalic - Ethnobotanical Study On Medicinal +Документ16 страницBroza Saric Kundalic - Ethnobotanical Study On Medicinal +turdunfloranОценок пока нет

- All Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationДокумент7 страницAll Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationRakesh KumarОценок пока нет

- February 2023 PROGRAM OF THE MPLEДокумент8 страницFebruary 2023 PROGRAM OF THE MPLEDale Iverson LacastreОценок пока нет

- Oral PresentationДокумент4 страницыOral PresentationYaddie32Оценок пока нет

- Question Bank Chemistry (B.Tech.) : Solid StateДокумент10 страницQuestion Bank Chemistry (B.Tech.) : Solid StatenraiinОценок пока нет

- Pioneer Deh-P4850mp p4850mphДокумент76 страницPioneer Deh-P4850mp p4850mphVxr GsiОценок пока нет

- Aircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management EngineerДокумент46 страницAircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management Engineerchouchou chamaОценок пока нет

- Republic Act No. 10070Документ3 страницыRepublic Act No. 10070Ganiela MCОценок пока нет

- CSF LeaksДокумент3 страницыCSF LeaksDrTarek Mahmoud Abo KammerОценок пока нет

- 08 163 4 JPL ScheickДокумент50 страниц08 163 4 JPL ScheickSaqib Ali KhanОценок пока нет

- Nepal Health Research CouncilДокумент15 страницNepal Health Research Councilnabin hamalОценок пока нет

- Network Access Control Quiz3 PDFДокумент2 страницыNetwork Access Control Quiz3 PDFDaljeet SinghОценок пока нет

- EarthWear Clothier MaterialsДокумент1 страницаEarthWear Clothier MaterialsZhining LimОценок пока нет

- Msla Business FeesДокумент1 страницаMsla Business FeesNBC MontanaОценок пока нет

- User'S Guide: 5. SpecificationsДокумент8 страницUser'S Guide: 5. SpecificationsNguyễn Xuân VĩОценок пока нет

- Congenital Malformation of The Lung and AirwaysДокумент48 страницCongenital Malformation of The Lung and AirwaysrubyniОценок пока нет

- Governance, Business Ethics, Risk Management and Internal ControlДокумент4 страницыGovernance, Business Ethics, Risk Management and Internal ControlJosua PagcaliwaganОценок пока нет

- Peseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Документ1 страницаPeseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Kelly DIOGOОценок пока нет

- GLYSANTIN+G48+bg+IN 000000000030667689 SDS GEN US en 8-1Документ11 страницGLYSANTIN+G48+bg+IN 000000000030667689 SDS GEN US en 8-1Ali RidloОценок пока нет

- Materials Management in Hospital Industry Nandi ProjectДокумент27 страницMaterials Management in Hospital Industry Nandi Projectkumaraswamy226Оценок пока нет