Академический Документы

Профессиональный Документы

Культура Документы

Published Flash Process Paper

Загружено:

acetapasviИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Published Flash Process Paper

Загружено:

acetapasviАвторское право:

Доступные форматы

Development of rapid heating and cooling

(flash processing) process to produce

advanced high strength steel microstructures

T. Lolla*1, G. Cola2, B. Narayanan3, B. Alexandrov1 and S. S. Babu1

Flash processing of an AISI8620 steel sheet, which involves rapid heating and cooling with an

overall process duration of ,10 s, produced a steel microstructure with a high tensile strength

and good ductility similar to that of advanced high strength steels. Flash processed steel [ultimate

tensile strength (UTS): 1694 MPa, elongation: 7?1%], showed at least 7% higher UTS and 30%

greater elongation than published results on martensitic advanced high strength steel (UTS:

1585 MPa, elongation: 5?1%). The underlying microstructure was characterised with optical,

scanning electron, transmission electron microscopy as well as hardness mapping. A complex

distribution of bainitic and martensite microstructures with carbides was observed. A mechanism

for the above microstructure evolution is proposed.

Keywords: Flash processing, Advanced high strength steels, Heat treatment, Bainite, Phase transformation, Microstructure characterisation

Introduction that there is an impetus to develop processing techniques

to produce AHSS.

There is a need for weight reduction of automotive The present paper pertains to an innovative heat

structures in order to achieve improved fuel efficiency, treatment procedure that shows a potential as an

while not compromising the safety of passengers. To alternative route for the current production of AHSS

meet these two demands, a new class of steels known as steels.10 This process has been termed as ‘flash proces-

advanced high strength steels (AHSS) was developed by sing’ for the incredibly short time (,10 s) for heating

the ultra light steel automotive body advanced vehicle and cooling of the steel sheets. Throughout the present

concept consortium.1,2 This family of steels shows good paper this term or an acronym ‘FP’ will be used to

formability while maintaining very high strength values denote steels that are processed using this method.

[engineering yield strength (YS).300 MPa and ultimate Preliminary work has shown that FP of plain carbon

tensile strength (UTS).700 MPa].3 These AHSS grades steels (.0?15C) may lead to high YS (.1200 MPa),

include dual phase, transformation induced plasticity, tensile strength (.1500 MPa) and appreciable ductility

complex phase and partially martensitic steels. All these (.7%). As a result, FP processed steels could be

steels achieve their mechanical properties by engineering classified under the category of AHSS.10

the fractions of ferrite, bainite and martensite micro- Cursory evaluation of the above claim leads to

structure as well as austenite phase. This is achieved skepticism, since it contradicts the well established

either through energy intensive thermomechanical pro- theories of phase transformation and microstructure

cessing steps and/or by expensive alloying additions (e.g. evolution in steels.11 Heating of steels to the homo-

manganese).3 genous austenite phase field and rapid quenching will

The need to focus on the area of advanced steel lead to the formation of martensite. During tensile

development is imminent. This is demonstrated by testing of this martensitic microstructure, no appreciable

research directions of many researchers throughout the plastic strain is expected. Therefore, the objective of the

world.4–7 In addition to the production of these steels, present paper is to relate the observed thermal cycle,

there exists a critical need to develop reliable and robust microstructure and the observed properties by develop-

processes for forming8 and welding9 of these steels too. ing a mechanistic understanding of the microstructure

The above examples are not a comprehensive represen- evolution.

tation of the published literature. However, it proves

Experimental

Steel composition and initial condition

1

Industrial Systems and Welding Engineering, Ohio State University, In earlier work, Cola has investigated many steels

Columbus, Ohio 43221, USA

2

SFP Works LLC, Washington, MI, USA including AISI8620 steels by FP.10 In the current paper,

3

Materials Science and Engineering, Ohio State University, Columbus, to limit the effect of the steel compositions on the

Ohio 43221, USA interpretations of the microstructure and property

*Corresponding author, email acetapasvi@gmail.com correlations, only AISI8620 grade steel sheets were

ß 2009 Institute of Materials, Minerals and Mining

Published by Maney on behalf of the Institute

Received 1 February 2009; accepted 9 March 2009

DOI 10.1179/174328409X433813 Materials Science and Technology 2009 VOL 000 NO 000 1

Lolla et al. Development of rapid heating and cooling – Flash processing

the induction heating method was used during tempera-

ture measurement experiments. In order to impose the

similar heating conditions as of that of the flame

heating, feedrates, temperature gradients and the peak

temperature were controlled to be identical. Type K

(Chromel–Alumel) thermocouples were attached to the

middle of the steel sheets. The temperature of the steel

was measured, as the sheet traverses through the heating

and cooling ports. These measurements are made with a

high speed data acquisition system capable of recording

temperature at a sampling rate of up to 5 KHz. The

measured thermal cycles were analysed to determine the

instantaneous heating and cooling rates throughout

the FP. In addition, ferrite (a) to austenite (c) trans-

formation was evaluated by analysing thermal cycle data

using single sensor differential thermal analysis

(SSDTA) technique.12 The sensitivity and accuracy of

1 Schematic illustration of experimental set-up of FP SSDTA technique, in measuring a to c transformation

technique during high heating rates (y500 K s21), has been

documented earlier13 by direct comparison with dilato-

investigated. The measured composition of the steel is metric techniques.

Fe–021C–0?27Si–0?002S–0?009P–0?73Mn–0?48Cr–0?48Ni–

0?007Co–0?156Mo–0?178Cu (wt-%). The original steel Mechanical property measurements

was under the annealed condition and the microstruc- In order to evaluate the spatial variations of steel

ture constitution was ferrite and uniform dispersion of microstructures, two-dimensional hardness distributions

carbides. were measured in the cross-section of samples. For each

sample, .2000 indents were made on QT and FP

Flash processing set-up and heat treatments samples using an AMH43 automatic hardness testing

A schematic of the process set-up is shown in Fig. 1. The system with a load of 300 g. The measured hardness

assembly consists of a pair of rollers that transfers the distributions were analysed in a map format and using

steel sheets through a heating and cooling stage. At a frequency distribution curves to provide quantitative

controlled distance from the top pair of rollers, the measure of mechanical heterogeneity of the samples.

heating stage is placed. The heating stage is based on Tensile samples were extracted from the edge regions

either oxy propane flame or electrical induction heating. and from the middle regions. Tensile tests were

The flame heating consists of 17 flame nozzles spaced performed along the longitudinal direction of the coils.

evenly to spread the heat over the steel sheets. The above The gauge length of the test samples was 25 mm. The

set-up has also been equipped with infrared pyrometers, width of the samples at the gauge length was 6?3 mm.

instrumentation to drive the feed rollers, mechanical The tests were performed at room temperature with a

fixtures for positioning heating and cooling units, and crosshead displacement rate of 1?27 mm min21. All the

heating intensity controls. Spot temperature check using tensile testing were performed using testing machines

an Ircon infrared pyrometer showed a small variation of

available at Edison Welding Institute. Similar tests were

temperature of approximately ¡10uC from the middle

repeated in QT samples also.

to the edges of the sample. Immediately below the

heating port, a cooling trough is placed. To avoid Microstructure characterisation

inefficient heating due to the upward flow of steam, a

Standard optical microscopy was used to characterise

graphite separator film is used to separate the heating

microstructure from the FP and QT samples. In the next

and cooling ports. In this experiment, the steel sheets

step, the samples were characterised using a Quanta200

were fed through the heating and cooling system at a

scanning electron microscope (SEM), equipped with

rate of 28 cm min21 while maintaining the peak

secondary electron, backscattered and X-ray energy

temperature at 1100uC. In order to compare the flash

dispersive spectroscopy (EDS) detectors. The micro-

processed samples with a reference sample, another

AISI8620 unprocessed steel sheet was subjected to a scope was operated at an accelerating voltage of 25 kV.

quenched and tempered (QT) treatment (1000uC/ Transmission electron microscopy (TEM) samples

2 minRquenchedRtempered at 200uC/4 min). were prepared by electrolytic thinning of 3 mm discs of

90 mm thick samples. A chemical solution of 33% Nitric

Thermal cycle measurements and analyses acid, 67% Methanol was used as the electrolyte. The

Cola10 calculated thermal cycles in different regions polishing was carried out at 25 V at a current of 10–

using infrared pyrometers and imposed feedrates of steel 15 mA and the temperature of the electrolyte was

sheets. However, the detailed temporal variations of maintained at 225uC. The samples were imaged using

temperature were not measured using contact thermo- two types of transmission electron microscopes. General

couples. Such measurements are necessary to develop a microstructure and electron diffraction analyses were

mechanistic understanding of microstructure evolution performed in a Phillips CM12 transmission electron

during FP. However, the oxy propane flame heating microscope operating at 120 kV. In addition, high angle

method does not lend itself for the direct measure- annular dark field (HAADF) and bright field imaging

ment of temperature due to possible deterioration of was performed using STEM technique in a Tecnai F-20

thermocouples by the high intensity flame. Therefore, FEG/TEM operating at 200 kV.

2 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

Computational modelling

ThermoCalc14 software with TCFE5 database was used

to estimate the thermodynamic quantities and equili-

brium phase transformation temperatures. In addition,

the time temperature transformation (TTT) diagrams

for the initiation of reconstructive and displacive trans-

formations were predicted using the methodology

developed by Bhadeshia.15,16 The TTT data were then

converted into a continuous cooling transformation

(CCT) diagram using the methodology developed by

Babu and Bhadeshia.17 The source code for these calcu-

lations can be downloaded from an internet location18

and example calculations can be made using an online

calculator.19

Results and discussion

Calculated phase transformation characteristics

In order to analyse the results from the FP experiments

with reference to expected transformation behaviours,

the transformation temperatures were calculated using

the methodologies described before14–19 for the

AISI8620 steel composition. The equilibrium A1 and

A3 temperatures of this steel were calculated to be 702

and 806uC respectively. In addition, the calculated

equilibrium volume fractions of cementite (M3C) and

alloy carbides (M23C6 and MC) that can form in these

steels as a function of temperature are shown in Fig. 2a.

This result shows that as the steel heats above 810uC, it

should transform to 100% austenite.

The bainitic and martensitic start temperatures15,16 2 a calculated variation of carbide volume fraction as

were calculated to be 553 and 426uC respectively. function of temperature obtained using ThermoCalc14

Calculated TTT and CCT diagrams for the initiation and TCFE5 database and b TTT and CCT diagrams

of paraequilibrium (transformation controlled by car- showing reconstructive transformation and displacive

bon partitioning and the ratio of substitutional to iron transformation regions

atoms are configurationally frozen in place on either side

of austenite and ferrite transformation interface) recon- AISI8620 steel. Above 780uC, the heating rate starts

structive mode of austenite to allotriomorphic ferrite reducing indicating that there is a dynamic equilibrium

transformation and displacive mode of austenite to between the heat flux, the heat conduction, and

Widmanstatten and bainitic transformations are shown endothermic/exothermic effects due to phase transfor-

in Fig. 2b. Since the FP involves rapid cooling process, mations.12 In region III, the heating rate reaches zero

the assumption of paraequilibrium is indeed valid. Based when the sample reaches a peak temperature of 1100uC.

on the above results, one can expect complete transfor- As per the equilibrium thermodynamic calculations, at

mation of austenite to 100% martensite in AISI8620 this temperature, the sample should be 100% austenite.

steels at cooling rates faster than 70 K s21. These After reaching the peak temperature, the sample starts

predictive methodologies have been developed using a cooling down gradually. The total dwell time for this

wide range of steels and their TTT data presented in the slow cooling near 1100uC is measured to be 2 s. In

literature.16,20 Therefore, the predictions are expected to region IV, within 1?2 s of reaching peak temperature,

be fairly accurate for low alloy steels including AISI8620 the sample reaches the water bath and starts cooling

grades. For example, these calculations have accurately rapidly. The maximum cooling rate of 3150 K s21 is

predicted the transformation start during continuous achieved when the sample reaches a temperature of

cooling of low alloy steels.21 393uC. This temperature is much below the calculated Bs

(553uC) and Ms (426uC) temperatures.15 As per the

Thermal cycles during FP measured thermal cycles and the calculated CCT

A typical heating and cooling thermal cycle during FP is diagram (see Fig. 2b), the austenite phase from high

shown in Fig. 3. The plot also shows the heating and temperature should transform to 100% martensite

cooling rates as a function of time. These thermal during FP. Figure 4 shows the complete thermal profile

profiles can be divided into four regions based on the of two separate FP treatment runs recorded from

temperature range. In region I, the steel temperature thermocouples attached at the centre of the sheet. This

increases gradually due to heat conduction from the hot shows the thermal cycle repeatability that can be

stage. In region II, the steel temperature increases achieved in FP.

rapidly due to its proximity to heat source. In this Alexandrov and Lippold12 have developed the

region, maximum heating rate of 410 K s21 was SSDTA software to detect transformation temperatures

observed at 780uC. This temperature is between the from measured thermal cycles, in a well described

calculated A1 and A3 transformation temperatures for (Newtonian, Gaussian or Rosenthal type) heat transfer

Materials Science and Technology 2009 VOL 000 NO 000 3

Lolla et al. Development of rapid heating and cooling – Flash processing

3 a heating/cooling rate and b temperature variation versus time in typical FP

condition. The transformation temperatures are a polynomial function that describes a well controlled

detected by looking for a departure of measured heat transfer conditions.

temperature from a reference heating (or cooling) curve Both the results show a small endothermic phenom-

due to endothermic (or exothermic) effects during phase enon around the calculated14 Curie temperature

changes. Figure 5 shows the results of the SSDTA (y750uC) of bcc ferrite and another large endothermic

analyses of thermal profiles , for the heating regime only. peak ,900uC. These large endothermic peaks are

In these analyses, the reference curves were described by interpreted as Ac1 (926 and 930uC) and Ac3 (1046 and

1052uC) temperatures by SSDTA software. The repro-

ducibility of these measurements is within the 0?4%

accuracy of the type K thermocouple. The accuracy of

these analyses is also affected by the electromagnetic

noise generated by the induction heating. It is note-

worthy that SSDTA technique estimates a higher and

non-equilibrium Ac1 and Ac3 temperatures, in compar-

ison to equilibrium A1 (702uC) and A3 (806uC) tem-

peratures. Possible mechanisms for these are discussed

later.

Hardness and tensile properties

Measured engineering tensile properties are presented in

Table 1. Table 1 also shows the tensile properties of the

FP samples tested by Cola10 and the current work. The

data show that the flash processed AISI8620 steels do

have yield and tensile strengths greater than 1300 and

4 Thermal profile of two samples showing repeatable 1500 MPa respectively. In addition, the elongation and

thermal cycles reduction in area indicate appreciable ductility in these

4 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

6 Comparison of true stress versus true strain graphs of

QT and flash processed specimen

characteristics were calculated (see Fig. 6). The strain

hardening exponent n and pre-exponent strength coeffi-

cient K for uniform plastic strain were estimated by

fitting the following equation to the plastic regime of the

true stress–strain curve.

5 Single sensor differential thermal analysis of heating s~Ken (1)

region of a sample 1 and b sample 2 showing two

The calculated K and n values (see Table 2) are similar

endothermic thermal events

values to the published grades of AHSS steels for dual

phase and complex phase steels.22 The measured UTS

samples. The ductility of 8?8–9?9% is indeed greater than and YS from the current work are overlaid in a map of

the levels reported for martensitic AHS steels.22 The current AHSS steels. This comparison confirms that the

UTS of the FP tensile specimen is comparable to that of flash processed steels (see Fig. 7) are indeed a part of

the QT sample; however, the FP samples, consistently, AHSS steel family. It is interesting to note that

show higher elongation values. both UTS and the elongation are higher than the

In order to evaluate the formability of FP steels, the reported values for AHSS based on a martensitic

ratio of YS and UTS and true stress true strain microstructure.

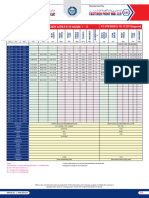

Table 1 Measured engineering tensile properties of FP (from previous and current work) and QT samples (current work).

The tests were performed according to ASTM E8 specifications*

Ultimate tensile 0.2% yield Reduction of

Sample ID strength, MPa strength, MPa area, % Elongation, % Ratio of YS to UTS Source

Ref-FP1 1685.77 1241.75 … 6.3 0.737 Ref. 10

Ref-FP2 1694.04 1314.83 … 7.3 0.776 Ref. 10

Ref-FP3 1676.12 1275.53 … 7.1 0.761 Ref. 10

Ref-FP4 1669.91 1292.77 … 6.9 0.774 Ref. 10

FP no. 1 1664.1 1442.8 39.4 8.8 0.867 Present paper

FP no. 2 1619.3 1386.9 38.0 9.9 0.856 Present paper

FP no. 3 1520.7 1300.0 38.3 9.9 0.855 Present paper

QT no. 1 1607.6 1333.8 37.4 6.8 0.829 Present paper

QT no. 2 1657.9 1464.1 49.8 10.0 0.883 Present paper

QT no. 3 1642.8 1487.6 14.8 4.3 0.905 Present paper

*Sample dimensions used in Ref. 10: width 13 mm; thickness 1?5 mm. Sample dimensions in the present work: width 6?4 mm;

thickness 1?23 mm.

Table 2 Calculated pre-exponent K and strain hardening exponent n derived by fitting equation (1) to plastic regime of

true stress–strain curve

FP no. 1 FP no. 2 FP no. 3 QT no. 1 QT no. 2 QT no. 3

K, MPa 569.6 622.1 613.7 1305.6 536.3 543.9

n 0.1542 0.1568 0.1348 0.1950 0.1342 0.1471

Materials Science and Technology 2009 VOL 000 NO 000 5

Lolla et al. Development of rapid heating and cooling – Flash processing

Microstructure of heat treated samples

In this section, the underlying microstructure in the

original steel sheets before processing and after the FP

and QT heat treatments are presented.

Initial microstructure of annealed AISI8620 steel sheets

Optical microscopy of original steel sheets showed the

presence of ferrite grains with carbides (Fig 8a). Most of

the carbides were ,1 mm and some of them were

.2 mm, suggesting a bimodal nature of carbide dis-

tribution. These carbides also appear to be aligned in

between pancaked ferrite structure suggesting that these

could have precipitated during legacy thermomechanical

processing of these sheets. Scanning electron microscopy

(see Fig. 8b) with backscattered imaging showed that

7 Overview of published tensile strength and ductility most of these carbides were associated with ferrite grain

that can be achieved for a wide range of advanced boundaries. Energy dispersive X-ray spectroscopy ana-

high strength steels22 and measured tensile strength lyses (see Fig. 8c) of these carbides show a higher ratio

and ductility of flash processed steels of Cr/Fe peak intensities compared to that of ferrite

8 a optical image microstructure of AISI8620 unprocessed sample showing extensive carbide distribution, especially

along grain boundaries, in ferrite matrix, b SEM backscattered image showing presence of carbides along grain bound-

aries in microstructure of AISI8620 unprocessed sample and c comparison of EDS signals obtained from matrix and

carbide particle observed in AISI8620 unprocessed sample (signals from particle show higher Cr/Fe ratio indicating

that particle could be chromium carbide)

6 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

9 a optical image QT AISI8620 sample showing fine microstructure consisting of martensitic and bainitic structures and

b SEM backscattered image of AISI8620 QT sample showing martensitic lath structures with prior austenite grain

boundary

matrix. Based on the above analyses and thermody- particles could be observed. By tracing the lath packet

namic calculations, the carbides are assumed to be Cr boundary (see Fig. 10b), typical prior austenite grain

rich cementite (M3C). size was estimated. This qualitatively shows that the

prior austenite grain size of FP samples ((10 mm) is

Microstructure of QT AISI8620 steel sheets much finer than that of the (20–30 mm) QT samples.

Since the QT and FP microstructures showed similar This could be attributed to the rapid heating and cooling

properties, the microstructure of the QT samples was above the Ac3 temperature. In the next step, the

characterised with optical microscopy and scanning composition of carbides was evaluated with EDS

electron microscopy. Owing to the fine nature of the analyses. The measured spectrum and the calculated

microstructure, optical microscopy (see Fig. 9a) could composition of analysed regions are presented in

not discern the martensitic and bainitic microstructures. Fig. 10c. Surprisingly, similar to the original steel

The scanning electron microscopy (see Fig. 9b) with samples before processing, these carbides were found

backscattered electron imaging revealed the martensitic to be rich in Chromium. In addition coarser and finer

lath structure with brightly imaging carbides. By tracing carbides were also observed which is similar to untreated

the lath packet boundary, typical prior austenite grain samples. Since the FP process involves rapid heating

size was estimated to be around 20–30 mm. Owing to the (.400 K s21) and cooling (.3000 K s21) rates, these

short duration of the austenitising time (2 min at carbides are interpreted as the undissolved carbides that

1000uC), extensive austenite grain growth was not were present in the original base material.

observed. A quantitative distribution of the austenite With cursory observation of optical and scanning

grain size in the overall sample was not performed due

electron micrographs, one may conclude that the FP

to the difficulty of identifying all the prior austenite

samples are predominantly martensitic. However, to

grain boundaries by this technique. A backscattered

substantiate this conclusion, detailed transmission elec-

electron diffraction technique with crystallographic

tron microscopy was performed. A low magnification

orientation analyses is required23 and is the focus of

TEM image (see Fig. 11a) shows a prior austenite/

the ongoing work.

austenite (c/c) grain boundary with presence of fine scale

The volume fraction and size of carbides in the QT

martensitic laths with high dislocation density and

samples is smaller than that of the untreated samples

(see Fig. 8b). It is possible that the microstructure may coarser bainitic ferrite with slightly reduced dislocation

contain nanometer sized carbides that formed during the density. The identification of bainitic ferrite was made

tempering (220uC for 4 min) stage. Usually the sizes of based on the size of these plates and the presence of

these carbides that form during early stages of tempering sheave-like morphology with subunits as shown by

are below the resolution of scanning electron micro- Bhadeshia.26

scopy.24–27 However, it is fair to conclude that initial In another region of the same TEM sample (see

carbides that are present in the untreated samples have Fig. 11b), three bainitic (marked as 1, 2 and 3 in the

dissolved during austenitising at 1000uC for 2 min. images) sheaves were observed. It is interesting to note

that each and every individual sheave is made up of

Microstructure of flash processed AISI8620 steel sheets many ferrite subunits with similar orientation in space.

Since the focus of this paper is related to FP, extensive Electron diffraction analyses failed to identify any

characterisation was performed on FP samples. Optical retained austenite film between these subunits.27

microscopy (see Fig. 10a) of the FP samples again Crystallographic orientation relationships between these

showed features that were difficult to distinguish. bainitic sheaves were calculated and the summary of the

However, scanning electron microscopy with backscat- results is presented in inset diffraction patterns in

tered electron imaging revealed interesting features (see Fig. 11b. The sheaves nos. 1 and 2 are indexed to be

Fig. 10b). Fine lath structures with brightly imaging in the [111] bcc zone axis with a relative misorientation

Materials Science and Technology 2009 VOL 000 NO 000 7

Lolla et al. Development of rapid heating and cooling – Flash processing

10 a optical image of flash processed AISI8620 sample showing very fine, indiscernible microstructure, b SEM backscat-

tered image of AISI8620 flash processed sample showing fine lath structures with brightly imaging particles and typi-

cal prior austenite grain boundary and c comparison of EDS signals obtained from matrix and carbide particle

observed in AISI8620 FP sample (signals from particle show higher Cr/Fe ratio indicating that particle could be chro-

mium carbide)

of only 10 degrees. Assuming that these bainitic sheaves relationship between cA and cB should be of high angle

have a Kurdjumov–Sachs/Nishiyama–Wassermann type. Copious presence of such austenite grains with

(KS/NW) orientation relationship,28 with the parent large angle boundaries will promote bainitic and/or

austenite (fcc) phase, one can conclude that the bainitic martensitic plates with wide varying orientations and

sheaves nos. 1 and 2 could have formed a single may improve the properties.30 It is stressed that the

austenite cA grain, within the regions that are separated above results are typical and one cannot conclude

by small angle boundaries. In contrast, the sheave no. 3 similar crystallographic conditions throughout the FP

was indexed to be close to the [011] zone axis. Using the sample. To evaluate this throughout the sample, we need

axis angle pair analyses,29 the relative orientation to do extensive backscattered electron diffraction

between no. 3 and no. 1 or between no. 3 and no. 2 analyses and correlate the orientation distribution

was found to be of high angle type. Using the same functions to the properties, which is the focus of the

assumption of KS/NW orientation relationship of ongoing work.

bainitic sheaves with austenite and symmetry relations,28 In another FP sample, HAADF STEM image showed

one can also conclude that the no. 3 sheave formed extensive carbide distributions. Some of them were

in adjacent austenite grain cB and the orientation associated with the ferrite subunit grain boundaries (see

8 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

11 Images (TEM) showing a c/c grain boundary with par-

allel laths growing out of it and b three bainitic

sheaves (1, 2, 3) in FP sample

Fig. 12a). Size of these carbides was ,100 nm.

Elongated carbides between the lath boundaries are

probably cementite. The precipitates are predominantly

darker than the matrix suggesting that their average

atomic number is lower than the iron matrix. However,

the precipitate thickness effect is convoluted with the

atomic number contrast and further work is required to

establish the chemical composition of these precipitates.

Some of the large carbides (marked by arrow) show no

correlation to the ferrite boundaries (Fig. 12b). The

EDS analyses show that these carbides were rich in

silicon and chromium (Fig 12c). The detailed analyses of

elemental distribution within these carbides can only be

attained by atom probe field ion microscopy.24,25 Owing

to the rapid rate of heating and cooling, the diffusion

controlled dissolution and/or growth is expected to be 12 a HAADF STEM image showing extensive carbides

sluggish. Therefore, these large carbides are interpreted with different size range, b HAADF STEM image show-

as the undissolved carbides from the original steel sheets ing fine carbides in between bainitic subunits and c

that existed before processing. From the above TEM measured energy dispersive X-ray spectrum obtained

analyses one can conclude that the FP microstructures from matrix and carbides showing higher Cr/Fe ratio

contain bainitic ferrite, martensitic laths as well as similar to that of carbides from unprocessed samples

uniform distribution of large and small carbides.

it is practically impossible to evaluate the microstruc-

Evaluation of mechanical heterogeneity in heat tural heterogeneity through the series of optical,

treated samples SEM and TEM techniques throughout the sample,

Although, the FP samples showed this unique hardness mapping was adopted as a measure of the

mixture of bainite, martensite and carbide microstruc- heterogeneity.17 With this method, series of hardness

ture, it is necessary to evaluate the heterogeneity of indents were made on the samples and the mechanical

these microstructures within the overall sample. Since heterogeneity31 is estimated by analysing the hardness

Materials Science and Technology 2009 VOL 000 NO 000 9

Lolla et al. Development of rapid heating and cooling – Flash processing

13 Hardness contour map of cross-section of QT sample cut into three pieces showing distribution of hardness as mea-

sured from over 2000 micro-indent points over cross-section area

14 Histogram plotted from hardness values observed in 16 Histogram plotted from hardness values observed in

cross-section of QT sample, shows large scatter peak cross-section of FP sample shows three distinct

(vQT1588%) and small scatter peak (vQT2512%) regions of different hardness range; 498¡7, 512¡11

and 534¡9 HV

distribution. The average size of the indents in the FP

sample was 42 mm which is bigger than the prior austenitised sample into the water. This is also reflected

austenite grain size and also the bainitic and martensitic in the results of the tensile tests, where QT samples

packet sizes. It is highly possible that the different showed low YS (see Fig. 6a and Table 1) and high strain

microstructure distribution may provide similar hard- hardening exponent. The hardness distribution curve

ness values. Therefore, the above measure has to be used from the QT sample is shown in Fig. 14. The above data

only as a way to evaluate the possible scatter in final were interpreted by fitting multiple peaks to the

mechanical properties.32 The mechanical heterogeneity distribution. The fitted peaks show that the QT sample

results from QT and FP samples are discussed below can be divided into two regions, i.e. large (vQT1588%)

(see Fig. 13–16). region 1 with an average hardness of 475¡47 HV with

The hardness maps from the cross-section of QT large scatter and a small (vQT2512%) region 2 with an

(Fig. 13) sample showed a large soft region (blue colour) average hardness of 483¡5 HV with small scatter.

in the edge 1 region. In addition, the hardness variations In contrast, the mechanical heterogeneity of the flash

are larger in the QT sample. This is attributed to the processed samples was less than QT samples (see

inefficient quenching during manual insertion of the Figs. 15 and 16). The image also shows that a slightly

15 Hardness contour map of cross-section of FP sample cut into three pieces showing distribution of hardness as mea-

sured from over 2000 micro-indent points over cross-section area

10 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

harder region (yellow colour) is in the middle of the FP the initial microstructure of AISI8620 steel sheets

steel sheet compared to the edge of the steel sheet. The contained only ferrite and carbide, there is a need to

reader may recall the description of the FP process set- nucleate austenite. Therefore, the rapid heating rate

up (see Fig. 1) in which the middle of the steel sheet gets should lead to an increase in Ac1 temperature above

exposed to the highest heat density, as a result of highest equilibrium value. Similar arguments can be made for an

heating rate and high peak temperature. Similar to QT increase in Ac3 temperature due to reduced dwell time

sample analyses, the calculated hardness distribution for diffusion controlled growth of austenite into a ferrite

was analysed by fitting multiple peaks to the distribu- matrix. It noteworthy that the published research34,35

tion. The fits show that the QT sample can be divided did not consider very high (.100 K s21) heating rates.

into three distinct regions, i.e. region 1 (vFP1 14%) with Therefore, we need to consider the validity of the

an average hardness of 498¡7 HV, region 2 (vFP25 continued increase in Ac1 and Ac3 temperatures far

74%) with an average hardness of 512¡11 HV and above the equilibrium Ac3 temperature.

region 3 (vFP3512%) with an average hardness of Recently, Elmer et al.38 have developed an overall

534¡9 HV. This presence of distinct and homogeneous transformation kinetic model for ferrite to austenite

mixing of soft and hard regions in the FP sample is transformation formation in 1005 steel based on

tentatively attributed to the improved mechanical synchrotron diffraction measurements during a heating

properties of the flash processed steels. cycle of a weld. The model was calibrated using the data

from low heating rates ,100 K s21. However, the

Mechanism of microstructure evolution during model calculations were extrapolated to higher heating

FP rates. The calculations suggest a superheating of 100uC

Based on the above results, one can conclude that the FP temperature or more above the equilibrium Ac3 tem-

leads to a complex microstructure that contains mar- perature for the completion of austenite formation at

tensite, bainite and carbides. In addition the above heating rates .300 K s21. This result supports the

complex microstructure also leads to a preferred notion of non-equilibrium Ac1 and Ac3 temperatures

mechanical heterogeneity that is better than the refer- during FP (heating rate .410 K s21). Moreover, the

ence QT sample. In addition, the FP steels can be SSDTA analyses of the heating curve (Fig. 5a and b)

classified under the category of AHSS based on the indicate that the Ac1 temperature is definitely above

strength observed. Furthermore, the flash processed 900uC; 925?7uC (Fig. 5a) and 929?6uC (Fig. 5b).

steels show at least 7% higher UTS and 30% higher Similarly the Ac3 temperature is calculated to be above

elongation than published martensitic advanced high 1000uC; 1045uC (Fig. 5a) and 1052uC (Fig. 5b), which is

strength steels22 (see Fig. 7). However, these results have 200uC higher than the equilibrium Ac3 temperature

to be discussed in context of the mechanism for the (806uC). Such a large increase in Ac1 and Ac3

microstructure evolution during FP. temperatures will also affect the carbide dissolution,

since the presence of austenite is necessary for the

On heating carbide dissolution initiation of dissolution. In addition, the time taken for

As per equilibrium thermodynamic calculations, the austenite grain growth will also be reduced. This is

8620 steels should be 100% austenite above 800uC. From supported by the small prior austenite grain size

the measured thermal cycle during the flash process, the (,20 mm) measured in the flash processed samples.

peak temperature was 1100uC. Therefore, the sample As a result of small dwell time above Ac3 temperature,

should have completely transformed into austenite at the carbon diffusion and redistribution within the

this temperature and all the carbides should have austenite grain is expected to be incomplete.39 Hence

dissolved. However, electron microscopy showed that the steel that is being cooled from peak temperature will

the carbides have not dissolved completely. This have inhomogeneous carbon distribution within the

discrepancy is attributed to a very short dwell time in austenite matrix, which could trigger complex decom-

the austenitising region which limits the dissolution of position of austenite into different ferrite morphologies

carbides. This hypothesis is supported by the observa- and martensite.

tion of fewer carbides in the QT samples, which were

austenitised for 2 min at 1000uC before quenching. It is On cooling austenite decomposition

well known that, extended time in the austenite phase Based on the calculated CCT diagram and cooling rate

field will promote the complete dissolution of carbides33 (.3000 K s21) during FP, the steel should have

by enhancing the substitutional element diffusion. transformed to 100% martensite. To evaluate the effect

of carbon concentration gradients within the austenite

On heating ferrite to austenite transformation on the final microstructure, the CCT diagrams for

Another possibility of such unique microstructure AISI8620 steels with different carbon concentrations

evolution can be attributed to an increase in Ac1 and ranging from 0?03 to 0?21 wt-%, with the same

Ac3 temperatures due to rapid heating rates substitutional alloying element concentrations, were

(.400 K s21) during FP. This hypothesis is in agree- calculated using the methodology described earlier.16,17

ment with neural network analysis34 and Gaussian These series of CCT diagrams are also overlaid with the

process modelling.35 The level of superheating required measured cooling curve (see Fig. 17). The comparison

to nucleate and grow the austenite phase depends on the shows that even with very low carbon content in the

alloy composition, initial microstructure and the heating austenite the microstructure should be 100% martensite.

rate. This increase in Ac1 temperature also been However, the microstructure contains bainitic ferrite,

rationalised with the need to nucleate austenite phase martensite and carbides.

from a ferritezcarbide microstructure.36 On the other This discrepancy is attributed to the inadequacies of

hand, if the initial microstructure contains retained transformation kinetic modelling methodologies. These

austenite, there is no need for nucleation barrier.37 Since models were developed using the TTT data generated by

Materials Science and Technology 2009 VOL 000 NO 000 11

Lolla et al. Development of rapid heating and cooling – Flash processing

and carbide dissolution. Owing to rapid heating rates,

the temperature at which the austenite nucleation and

growth occurs may be elevated to higher temperatures

(.900uC) (Fig. 18b). But before the complete dissolu-

tion of cementite, the cooling cycle stars. At this

juncture, the austenite is expected to have inhomoge-

neous distribution of carbon content (Fig. 18c). With

the on-set of rapid cooling, the carbon enriched regions

may transform to martensite and carbon depleted

regions may transform to bainite or low carbon

martensite. This leads to a final microstructure with

complex distribution of bainite, martensite and carbides

(Fig. 18d). This hypothetical mechanism suggests that

the initial microstructure will have a strong effect on the

final microstructure and properties achieved by FP.

17 Calculated CCT curves for AISI8620 steel austenite

Ongoing experiments are focusing on evaluating these

with same substitutional concentration (Fe–021C–0?27Si–

effects and methods to track the phase transformations

0?002S–0?009P–0?73Mn–0?48Cr–0?48Ni–0?007Co–0?156Mo–

during heating and cooling for a wide range of steels to

0?178Cu, wt-%) but with different carbon concentra-

prove or disprove this hypothesis.

tions (diagram is overlaid with measured cooling

curve during FP)

Conclusions

A rapid heating (.400 K s21) and cooling

traditional heat treatment conditions16,20 involving slow 21

(.3000 K s ) flash process has been developed that

heating and isothermal hold at austenitising temperature produces a microstructure with good combination of

exceeding 5 min and homogenous austenite. The exten- yield (1280 MPa), UTS (1600 MPa) and appreciable

sion of these models to austenite with inhomogeneous ductility of up to 9?9%. The above strength and ductility

carbon concentration may not be reliable. These levels are significantly better than martensitic based

situations are similar to the rapid heating and cooling AHSS (1400–1500 MPa UTS). Based on the above data,

conditions experienced by heat affected zone of welds. the flash processed steels can be classified as part of the

Based on the above results and discussions, a advanced high strength steel family. As the overall

hypothetical microstructure evolution during FP is processing time (,10 s) is very short, this process could

proposed (see Fig. 18). At room temperature, the initial be an alternative route for producing AHSS sheets.

microstructure contains ferrite and carbides (Fig. 18a). The underlying microstructures in flash processed

On rapid heating, the austenite nucleation is expected to samples were characterised with optical and analytical

occur at the carbide–ferrite boundaries36 and the electron microscopy. The characterisation results

austenite is expected to grow at the expense of ferrite showed that the steel contains bainite, martensite and

a unprocessed ferrite with carbides; b growth of austenite and start of carbide dissolution; c inhomogeneous carbon

distribution in austenite with reduction in carbides; d martensite with bainitic plates formed from inhomogeneous carbon

distribution in austenite

18 Schematic illustration of microstructure evolution

12 Materials Science and Technology 2009 VOL 000 NO 000

Lolla et al. Development of rapid heating and cooling – Flash processing

carbides. The hardness map analyses showed that the 15. H. K. D. H. Bhadeshia: Acta Metall., 1981, 9, 1117–

flash processed samples contain a minor fraction of 1130.

16. H. K. D. H. Bhadeshia: Met. Sci., 1982, 16, 159–165.

soft microstructure interspersed within a harder micro- 17. S. S. Babu and H. K. D. H. Bhadeshia: Mater. Sci. Technol., 1990,

structure. This unique distribution of soft and hard 10, 1005–1020.

microstructure is correlated with the improved YS, UTS 18. Materials Algorithm Project, available at: http://www.msm.cam.

and ductility. ac.uk/map/mapmain.html

Traditional phase transformation models indicated 19. http://calculations.ewi.org/VJP/MaterialsModeling.html

20. BISRA: ‘Atlas of isothermal transformation diagrams of B. S. EN

that, for the cooling rates measured in the flash process, steels’, Special report no. 56, 2nd edn, The Iron and Steel Institute,

the microstructure should be 100% martensite after London, 1956.

processing. This discrepancy is addressed with a 21. S. S. Babu, G. M. Goodwin, R.J. Rohde and B. Sielen: Weld. J.

theoritical mechanism that involves an increase in Ac1 Res. Suppl., 1998, 77, 249s–253s.

and Ac3 temperatures due to rapid heating rate, 22. J. Zrnik, I. Mamuzic and S. V. Dobatkin: Metallugija, 2006, 4,

323–331.

incomplete dissolution of carbides and decomposition

23. B. Narayanan: Ohio State University, Columbus, OH, to be

of austenite with non-uniform carbon concentration. published.

24. F. Caballero, M. Miller, C. Garcia-Mateo, C. Capdevila and S.

References Babu: Acta Mater., 2008, 56, 188–189.

25. S. S. Babu, K. Hono and T. Sakurai: Metall. Trans. A., 1994, 25A,

1. ‘Body structure materials’, Technical transfer dispatch no. 6, 499–508.

ULSAB-AVC, May 2001. 26. H. K. D. H. Bhadeshia: ‘Bainite in Steels’, 2nd edn; 2001, London,

2. Porsche Engineering Services, Inc., ULSAB-AVC engineering Institute of Materials.

report, October 2001 27. G. I. Rees and H. K. D. H. Bhadeshia: Mater. Sci. Technol., 1992,

3. R. Kuziak: ‘Advanced high strength steels for automotive industry: 8, 994–996.

a review’, Arch. Civil Mech. Eng., 2008, 8, (2), 102–177. 28. S. S. Babu and H. K. D. H. Bhadeshia: Mater. Sci. Eng. A, 1991,

4. D. V. Edmonds, K. He, F. C. Rizzo, B. C. de Cooman, D. K. A142, 209–220.

Matlock and J. G. Speer: Mater. Sci. Eng., 2006, 438–440, 25–34. 29. H. K. D. H. Bhadeshia: ‘Worked Examples in the Geometry of

5. F. G. Caballero, H. K. D. H. Bhadeshia, K. J. A. Mawella, D. G. Crystals’, 1st edn; 1987, London, Institute of Metals.

Jones and P. Brown: Mater. Sci. Technol., 2002, 18, 279–284.

30. T. Furuhara, S. Morito, T. Maki: ‘On the controlling factors of

6. T. Inoue, S. Torizuka and K. Nagai: Mater. Sci. Technol., 2001, 17,

grain sizes in martensite and bainite’, Proc. 1st Int. Symp. on ‘Steel

1329–1338.

science’, (ed. T. Furahara and K. Tsukzai), 51–56; 2007, Tokyo,

7. T. Ohmura and K. Tsuzaki: ‘A new aspect of the strengthening

The Iron and Steel Institute of Japan.

factors f Fe-C martensite through characterization of nano-

31. S. S. Babu, S. A. David, J. M. Vitek and R. W. Reed: Sci. Technol.

indentation-induced deformation behavior’, Proc. 1st Int. Symp.

Weld. Join., 2001, 6, 31–40.

on ‘Steel science’, (ed. T. Furahara and K. Tsukzai), 35–46; 2007,

32. A. A. B. Sugden and H. K. D. H. Bhadeshia: ‘Microstructure

Tokyo, The Iron and Steel Institute of Japan.

8. W. Gan, S. S. Babu, N. Kapustka and R. H. Wagoner: Metall. entropy and the scatter in toughness’, Proc. 2nd Int. Conf. on

Mater. Trans. A, 2006, 37A, 3221–3231. ‘Trends in welding research’, Gatlinburg, TN, USA, May 1989,

9. N. Kapustka, C. Conrardy, S. Babu and C. Albright: Weld. J. Res. ASM International, 745–748.

Suppl, 2008, 87, 135s–148s. 33. Z. K. Liu, L. Höglund, B. Jönsson and J. Ågren: Metall. Mater.

10. G. M. Cola, Jr: ‘Properties of bainite nucleated by water quenching Trans. A., 1991, 22A, 1745–1752.

in 80 ms’, Proc. 1st Int. Symp. on ‘Steel science’, (ed. T. Furahara 34. L. Gavard, H. K. D. H. Bhadeshia, D. J. C. MacKay and S. Suzuki:

and K. Tsukzai), 187–190; 2007, Tokyo, The Iron and Steel Mater. Sci. Technol., 1996, 12, 453–463.

Institute of Japan. 35. C. A. L. Bailer-Jones, H. K. D. H. Bhadeshia and D. J. C.

11. H. K. D. H. Bhadeshia and R. Honeycombe: ‘Steels: MacKay: Mater. Sci. Technol., 1999, 15, 287–294

Microstructure and Properties’, 3rd edn; 2006, Oxford, 36. R. C. Reed, T. Akbay, Z, Shen, J. M. Robinson, J.H. Root: Mater.

Butterworth-Heinemann. Sci. Eng., 1998, 256, 152–165.

12. B. T. Alexandrov and J. C. Lippold: ‘Method and device for 37. J. R. Yang and H. K. D. H. Bhadeshia: Mater. Sci. Eng. A, 1989,

investigation of phase transformations in metals and alloys’, US A118, 155–170.

patent no. 7473028, 6 January 2009. 38. J. W. Elmer, T. A. Palmer, W. Zhang and T. DebRoy: Sci. Technol.

13. B. T. Alexandrov and J. C. Lippold: Weld. World, 2007, 51, 48–59. Weld. Join., 2008, 13, 265–277.

14. B. Sundman, B. Jansson and J. O. Anderson: Calphad, 1985, 9, 39. J. W. Elmer, T. A. Palmer, W. Zhang, S. S. Babu: Weld. J. Res.

153–190. Suppl., 2004, 83, 244s–253s.

Materials Science and Technology 2009 VOL 000 NO 000 13

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Notice: Antidumping: Carbon and Alloy Steel Wire Rod From— CanadaДокумент1 страницаNotice: Antidumping: Carbon and Alloy Steel Wire Rod From— CanadaJustia.comОценок пока нет

- Drasta C 5022: UtilisationsДокумент1 страницаDrasta C 5022: UtilisationsAnya PamungkasОценок пока нет

- Tunnel and Metro VentilationДокумент16 страницTunnel and Metro VentilationIrinaОценок пока нет

- Catastrophic Rupture of Heat Exchanger - Tesoro Anacortes RefineryДокумент160 страницCatastrophic Rupture of Heat Exchanger - Tesoro Anacortes RefineryoluninjaaОценок пока нет

- 9.7 PaintingДокумент62 страницы9.7 PaintingAnbu AlagupandianОценок пока нет

- CXT® Concrete Tie Catalog - CXT Concrete TiesДокумент12 страницCXT® Concrete Tie Catalog - CXT Concrete TiesslamdunkelevenОценок пока нет

- S2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationДокумент7 страницS2K14 SBU1 PIP DOC 1003 Pipe Class SpecificationvivekpecОценок пока нет

- 2008 March 4 Acetaldehyde From Ethylene OxidationДокумент4 страницы2008 March 4 Acetaldehyde From Ethylene OxidationameymurudkarОценок пока нет

- Galvanizing Design Manual PDFДокумент38 страницGalvanizing Design Manual PDFResita Ichsani100% (1)

- Welding ReportДокумент15 страницWelding ReportSamОценок пока нет

- Astm A-579Документ6 страницAstm A-579martinОценок пока нет

- Steel Alloy Testing OpДокумент14 страницSteel Alloy Testing OpOm PrakashОценок пока нет

- Boehler FOX CN 25 9 CuT - CeДокумент1 страницаBoehler FOX CN 25 9 CuT - CeNiranjan Fakirchand YadavОценок пока нет

- The Use of Iron & SteelДокумент7 страницThe Use of Iron & SteelMaureen AlboresОценок пока нет

- Spring Manufacturing ProcessДокумент4 страницыSpring Manufacturing ProcessUzma sijratОценок пока нет

- Fairchild Keyserts - Thread Repair InsertsДокумент12 страницFairchild Keyserts - Thread Repair InsertsgeorgeОценок пока нет

- Kanak MetalДокумент7 страницKanak MetalAakash KoradiyaОценок пока нет

- Clean Air enДокумент6 страницClean Air enHyundianto AgОценок пока нет

- EAF and Secondary Dust CharacterisationДокумент8 страницEAF and Secondary Dust CharacterisationJorge MadiasОценок пока нет

- Guy JollyДокумент24 страницыGuy JollyAndres Fitria FarrelОценок пока нет

- Hydrogen Permeation Barrier Coatings: December 2007Документ16 страницHydrogen Permeation Barrier Coatings: December 2007david fojtОценок пока нет

- F1089 1479757-1Документ3 страницыF1089 1479757-1Thaweekarn Changthong100% (1)

- Lime, Glass, Metals, Paints VarnishesДокумент76 страницLime, Glass, Metals, Paints VarnishesMonash MongerОценок пока нет

- 03 Bolt Astm A325mДокумент1 страница03 Bolt Astm A325mMUSTAFA TEMEMIОценок пока нет

- Zhongshou Metal Product AtlasДокумент7 страницZhongshou Metal Product AtlasRipul GoyalОценок пока нет

- IAB-041-02 (IW Inspection Personnel)Документ43 страницыIAB-041-02 (IW Inspection Personnel)Teddy TP100% (1)

- Defence STD 05-50 Part 29Документ14 страницDefence STD 05-50 Part 29goodguymumbaiОценок пока нет

- A Practical Treatise of Foundry Irons 1911 PDFДокумент340 страницA Practical Treatise of Foundry Irons 1911 PDFAngel AlvaroОценок пока нет

- Robo Catalog US LIT.9075Документ40 страницRobo Catalog US LIT.9075Oscar SermeñoОценок пока нет

- Fiber Glass ProtectionДокумент679 страницFiber Glass Protectionsohebam100% (1)