Академический Документы

Профессиональный Документы

Культура Документы

AOSCE15300

Загружено:

bmshefferИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AOSCE15300

Загружено:

bmshefferАвторское право:

Доступные форматы

Commercial Electric Water Heaters

GOLD SERIES -

COMMERCIAL ELECTRIC WATER HEATERS MODELS

Designed for use as a recovery heater having its own storage tank. Note: Not recommended

for sanitizing water applications. DRE-52, 80, 120

FEATURES

Meets the standby loss requirements of the U. S. Department of Energy and current edition

of AHRAE/IESNA 90.1.

GOLD ELEMENTS - DRE models ship with the Goldenrod 24K gold plated elements (see

element availability chart on back). Patented Goldenrod elements provide long life and superior

scaling resistance. Low watt density means lower surface temperature to minimize scale buildup

and more surface to heat water. Goldenrod elements carry a one-year warranty against failure

due to lime scale build-up.

GLASS-LINED TANK - Three sizes: 50, 80 and 119 gallon capacity. Tank interior is coated

with glass specially developed by A. O. Smith for water heater use. Tanks rated at 150 psi

(1034 kPa) working pressure (ASME 150 psi). Foam insulation reduces costly heat loss.

FUSING - Protects all elements, thermostats, and internal wiring circuits against excess current

flow. Meets National Electrical Code requirements that non-ASME tanks must have internal

fusing when current draw exceeds 48 amps. Available as an option on Canadian built heaters.

STANDARD VOLTAGES - 208, 240 and 480V single-phase and three-phase delta. Convertible

from three-phase to single -phase (in field) and vice versa. 277V single-phase also available.

TERMINAL BLOCK - Factory installed. Just bring the service to the heater and connect to block.

CONTROLS - One temperature control (adjustable through a range of 120° to 180°F) and

manual reset high temperature cut-off per element. Thermostat step control may be achieved

by varying settings on individual temperature controls. Located behind hinged control

compartment door for quick, easy access.

OTHER STANDARD FEATURES -

Surface mounted thermostats Simplified circuitry, color coded for ease of service Two

anode rods for maximum corrosion protection Cabinet has bonderized undercoat with baked

enamel finish Bottom inlet and top outlet openings Brass drain valve CSA Certified

and ASME rated T&P relief valve Single panel control box. THREE YEAR LIMITED TANK

ANSI / NSF-5

WARRANTY - For complete warranty information, consult written warranty or contact A. O. Smith.

OPTIONS -

UL and cUL listed conversion kits to adjust voltage and kW requirements in the field before

and after installation ASME 150 psi tank construction International voltages - 220, 380,

400, 415, 575, and 600 volts, three phase available with Y connected elements MANIFOLD

KITS - for multiple tank installations. Two heaters -part # 9003429205, three heaters- part #

9003430205 and four heaters- part # 9003431205

Page 1 of 2

September 2010R AOSCE15300

226267 AOSCE15300 1 6/25/10 3:13:06 PM

Commercial Electric Water Heaters

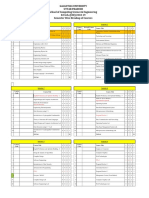

RECOVERY RATE IN GALLONS PER HOUR AT TEMPERATURE RISE OF

Standard BTU/ 3O°F 40°F 5O°F 60°F 70°F 8O°F 9O°F 100°F 110°F 120°F 130°F 140°F

kW Input Hour 17°C 22°C 28°C 33°C 39°C 45°C 50°C 56°C 61°C 67°C 72°C 78°C

6 20,478 82 62 49 41 35 31 27 25 22 21 19 18

310 233 166 155 133 116 103 93 85 78 72 66

9 30,717 123 92 74 62 53 46 41 37 34 31 28 26

465 349 279 233 199 174 155 140 127 116 107 100

12 40,956 164 123 98 82 70 61 55 49 45 41 38 35

620 465 372 310 266 233 207 186 169 155 143 133

13.5 46,075 184 138 111 92 79 69 62 55 50 46 43 40

698 523 419 349 299 262 233 209 190 174 161 150

15 51,195 205 154 123 102 88 77 68 61 56 51 47 44

775 582 465 388 332 291 258 233 211 194 149 166

18 61,434 246 184 148 123 105 92 82 74 67 62 57 53

930 698 558 465 399 349 310 279 254 233 215 199

24 81,912 328 246 197 164 140 123 109 98 90 82 76 70

1241 930 744 620 532 465 414 372 338 310 286 266

27 92,151 369 276 221 185 158 138 123 111 101 92 85 79

1396 1047 938 609 509 523 465 410 391 340 322 299

30 102,390 410 307 246 205 176 154 137 123 112 102 95 88

1551 1163 930 775 665 582 517 465 423 388 358 332

36 122,868 492 369 295 246 211 184 164 148 134 123 113 105

1861 1396 1117 930 798 698 620 556 508 465 429 399

40.5 138,226 554 418 332 277 237 208 185 166 151 138 128 119

2094 1570 1256 1047 897 785 698 628 634 582 537 498

45 153,585 615 461 369 307 263 230 205 184 168 154 142 132

2326 1745 1398 1163 997 872 755 698 634 582 537 498

54 184,302 738 554 443 359 316 277 246 221 201 185 170 158

2791 2094 1675 1396 1196 1047 930 837 761 696 644 598

Figured at 1 kW (3413 BTU) = 4.1 Gallons at 100°F temperature rise.

Tank Dimensions Inlet/ Approx. Ship.

Model Capacity Outlet (NPT) Wt. (Lbs.)

Number A B C

gal. litre in. cm in. cm in. cm in. cm Ib kg

DRE-52 50 189 55 3/4 142 21 3/4 55.2 27 68.6 1 1/4 3.2 265 120

DRE-80 80 300 60 1/4 153 25 1/2 64.8 31 78.7 1 1/4 3.2 280 127

DRE-120 119 450 62 1/4 158.1 29 1/2 75.0 35 88.9 1 1/4 3.2 390 177

Model Numbers Number Full Load Current In Amperes

kW Tank Capacity in Gallons Of Element Single Phase Three Phase

Input Elements Wattage

50 80 119 20 8V 2 4 0V 27 7 V 4 8 0V 20 8V 2 4 0V 4 8 0V

6 DRE-52-6 DRE-80-6 DRE-120-6 3 2,000 28.8 25.0 21.7 12.5 16.7 14.4 7.2

9 DRE-52-9 DRE-80-9 DRE-120-9 3 3,000 43.3 37.5 **32.5 18.8 25.0 21.7 10.8

12 DRE-52-12 DRE-80-12 DRE-120-12 3 4,000 57.7 50.0 43.3 25.0 33.3 28.9 14.4

13.5 DRE-52-13.5 DRE-80-13.5 DRE-120-13.5 3 4,500 64.9 56.3 **48.7 28.1 37.5 32.5 16.2

15 DRE-52-15 DRE-80-15 DRE-120-15 3 5,000 72.1 62.5 **54.2 31.3 41.6 36.1 18.0

18 DRE-52-18 DRE-80-18 DRE-120-18 3* 6,000 86.5 75.0 65.0 37.5 50.0 43.3 21.7

24 DRE-52-24 DRE-80-24 DRE-120-24 6 4,000 115.4 100.0 86.6 50.0 66.6 57.7 28.9

27 DRE-52-27 DRE-80-27 DRE-120-27 6 4,500 129.8 112.5 **97.5 56.3 74.9 65.0 32.5

30 DRE-52-30 DRE-80-30 DRE-120-30 6 5,000 144.2 125.0 **108.3 62.5 83.3 72.2 36.1

36 DRE-52-36 DRE-80-36 DRE-120-36 6 6,000 173.1 150.0 130.0 75.0 99.9 86.6 43.3

40.5 N/A DRE-80-40.5 DRE-120-40.5 9 4,500 194.7 168.8 **146.2 84.4 112.4 97.4 48.7

45 N/A DRE-80-45 DRE-120-45 9 5,000 216.3 187.5 **162.5 93.8 124.9 108.3 54.1

54 N/A DRE-80-54 DRE-120-54 9 6,000 N/A 225.0 194.9 112.5 149.9 129.9 65.0

*208 volt models may contain three (3) additional elements. ** Elements available in incoloy only.

SUGGESTED SPECIFICATION

The heater(s) shall be Gold Series Commercial Electric Model Number ______________ as manufactured by A. O. Smith. Heater(s) shall be rated at ____________

kW,_______volts, ____________ phase, 60 cycle AC, and listed by Underwriters’ Laboratories and approved to the NSF Standard 5 by UL. Tank(s) shall be ________

gallon capacity. Tanks shall be 50, 80 and 119 gallon capacity and shall have 150 psi working pressure and be equipped with extruded high density anode. All internal

surfaces of the heater(s) exposed to water shall be glass-lined with an alkaline borosilicate composition that has been fused-to-steel by firing at a temperature range

of 1400°F to 1600°F. Electric heating elements shall be low watt density Goldenrod 1” screw-in type. Each element shall be controlled by an

individually mounted thermostat and high temperature cut-off switch. All internal circuits shall be fused. The outer jacket shall be of baked enamel finish

and shall be provided with full size control compartment for performance of service and maintenance through hinged front panel and shall enclose the tank

with foam insulation. Electrical junction box with heavy duty terminal block shall be provided. The drain valve shall be located in the front for ease of

servicing. Heater tank shall have a three year limited warranty as outlined in the written warranty. Manufacturer shall supply ASME rated temperature and

pressure relief valve. Fully illustrated instruction manual to be included. Meets standby loss requirements of the U. S. Department of

. Energy and current edition of ASHRAE/IENSA 90.1.

For Technical Information and Automated Fax Service, call 800-527-1953. A. O. Smith Corporation reserves the right to make prod uct changes or improvements without prior notice.

September 2010R Page 2 of 2

www.hotwater.com AOSCE15300

226267 AOSCE15300 2 6/25/10 3:13:07 PM

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- CA21159 MG 8 Digital BookletДокумент5 страницCA21159 MG 8 Digital BookletcantaloupemusicОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- CHAPTER IV The PSYCHOLOGY of YOGA Yoga, One Among The Six Orthodox Schools of Indian ... (PDFDrive)Документ64 страницыCHAPTER IV The PSYCHOLOGY of YOGA Yoga, One Among The Six Orthodox Schools of Indian ... (PDFDrive)kriti madhokОценок пока нет

- Unit 1 Module 3 Rep in PlantsДокумент26 страницUnit 1 Module 3 Rep in Plantstamesh jodhanОценок пока нет

- A Comparative Study of Public Private Life Insurance Companies in IndiaДокумент5 страницA Comparative Study of Public Private Life Insurance Companies in IndiaAkansha GoyalОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Chapter 1 - Main Hydrological ConceptsДокумент16 страницChapter 1 - Main Hydrological ConceptsWhy Merah0% (1)

- Conducting Focus GroupsДокумент4 страницыConducting Focus GroupsOxfam100% (1)

- Practice - Test 2Документ5 страницPractice - Test 2Nguyễn QanhОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- State Space ModelsДокумент19 страницState Space Modelswat2013rahulОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Li JinglinДокумент3 страницыLi JinglincorneliuskooОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- FMEA Minus The PainДокумент7 страницFMEA Minus The PainMUNISОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Cobol v1Документ334 страницыCobol v1Nagaraju BОценок пока нет

- Galgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesДокумент2 страницыGalgotias University Uttar Pradesh School of Computing Science & Engineering B.Tech. (CSE) 2018-19 Semester Wise Breakup of CoursesRohit Singh BhatiОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 220245-MSBTE-22412-Java (Unit 1)Документ40 страниц220245-MSBTE-22412-Java (Unit 1)Nomaan ShaikhОценок пока нет

- Derma Notes 22pages. DR - Vishwa Medical CoachingДокумент23 страницыDerma Notes 22pages. DR - Vishwa Medical CoachingΝίκος ΣυρίγοςОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Literature Review of Retailing Sector and BusineДокумент21 страницаA Literature Review of Retailing Sector and BusineSid MichaelОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Toolbox TalkДокумент14 страницToolbox Talkcall_mustafas2361Оценок пока нет

- Arithmetic QuestionsДокумент2 страницыArithmetic QuestionsAmir KhanОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Origin ManualДокумент186 страницOrigin ManualmariaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- IM1 Calculus 2 Revised 2024 PUPSMBДокумент14 страницIM1 Calculus 2 Revised 2024 PUPSMBEunice AlonzoОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- BiografijaДокумент36 страницBiografijaStjepan ŠkalicОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Saiva Dharma ShastrasДокумент379 страницSaiva Dharma ShastrasfunnybizОценок пока нет

- Sla At&tДокумент2 страницыSla At&tCésar Lainez Lozada TorattoОценок пока нет

- Test Physics Chapter# 12,13,14 (2 Year) NameДокумент1 страницаTest Physics Chapter# 12,13,14 (2 Year) NameStay FocusedОценок пока нет

- Jonathan Livingston Seagull - Richard Bach - (SAW000) PDFДокумент39 страницJonathan Livingston Seagull - Richard Bach - (SAW000) PDFAdrià SonetОценок пока нет

- DJ Crypto ResumeДокумент1 страницаDJ Crypto ResumeNitin MahawarОценок пока нет

- Math F112Документ3 страницыMath F112ritik12041998Оценок пока нет

- Lesson 1 3 Transes in Reading in Philippine HistoryДокумент17 страницLesson 1 3 Transes in Reading in Philippine HistoryNAPHTALI WILLIAMS GOОценок пока нет

- Generation III Sonic Feeder Control System Manual 20576Документ32 страницыGeneration III Sonic Feeder Control System Manual 20576julianmataОценок пока нет

- 18 Composition Rules For Photos That ShineДокумент20 страниц18 Composition Rules For Photos That Shinemahfuzkhan100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Is 2 - 2000 Rules For Rounded Off For Numericals PDFДокумент18 страницIs 2 - 2000 Rules For Rounded Off For Numericals PDFbala subramanyamОценок пока нет