Академический Документы

Профессиональный Документы

Культура Документы

MV Transformer Testing (7200DB1001

Загружено:

sulthanabdulИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MV Transformer Testing (7200DB1001

Загружено:

sulthanabdulАвторское право:

Доступные форматы

7200DB1001

Data Bulletin 11/2010

Replaces 7200PD9206, 03/1992

Medium Voltage Transformer Testing

Class 7200, 7300, 7400

Retain for future use.

Introduction Transformer testing has evolved over the years to help determine the

electrical, thermal, and mechanical suitability of transformers for operation

on modern electrical systems. The types of tests and the procedures for

conducting them have been defined by the IEEE Transformers Committee

and are published in IEEE Standard C57.12.90 for liquid-filled transformers

and IEEE Standard C57.12.91 for dry-type transformers.

This data bulletin provides general information on the various tests available

and on the tests that Schneider Electric routinely performs on all medium

voltage transformers. For a more detailed description of the tests and

detailed test procedures, please see the IEEE Standards referenced below.

Standards IEEE C57.12.00—IEEE Standard General Requirements for

Liquid-Immersed Distribution, Power, and Regulating Transformers

IEEE C57.12.01—IEEE Standard General Requirements for Dry-Type

Distribution and Power Transformers Including Those with Solid-Cast

and/or Resin Encapsulated Windings

IEEE C57.12.90—IEEE Standard Test Code for Liquid-Immersed

Distribution, Power, and Regulating Transformers

IEEE C57.12.91—IEEE Standard Test Code for Dry-Type Distribution and

Power Transformers

Kinds of Tests The following definitions for the kinds of tests to be performed are from the

IEEE Standards.

Routine Tests: Routine tests made for quality control by the manufacturer

on every transformer manufactured or representative samples, or on parts

or materials as required, to verify during production that the product meets

the design specifications.

Design Tests: Design tests made to determine the adequacy of the design of a

particular type, style, or model of transformer or its component parts to meet its

assigned ratings and to operate satisfactorily under normal service conditions

or under special conditions, if specified, and to demonstrate compliance with

appropriate standards. Design tests are made only on representative apparatus

to substantiate the ratings assigned to all other apparatus of basically the same

design. These tests are not intended to be used as a part of normal production.

Test data from previous similar designs may be used for current designs, where

appropriate. Once made, the tests need not be repeated unless the design is

changed so as to modify performance.

Conformance Tests: Conformance tests that are specifically made to

demonstrate conformity with applicable standards.

Other Tests: Other tests so identified in individual product standards that

may be specified by the purchaser in addition to design and routine tests

and may depend on the size, voltage, and type of transformer involved

(Examples: insulation power factor, audible sound).

© 1992–2010 Schneider Electric All Rights Reserved

Medium Voltage Transformer Testing 7200DB1001

Data Bulletin 11/2010

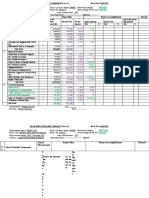

Table 1: Routine, Design, and Other Tests

Routine Tests Design Tests Other Tests

Turns Ratio Temperature Rise Zero Sequence Impedance

Polarity and Phase Relation Audible Sound Level Radio Influence Voltage

Resistance Short Circuit

No-Load Loss Insulation Power Factor 1

Excitation Current Insulation Resistance

Impedance Gas Analysis

Load Loss

Quality Control Impulse

Applied Potential

Induced Potential

Partial Discharge (cast only)

Leak (liquid-filled only)

Regulation 2

Efficiency 2

1 Routine for liquid-filled, substation transformers.

2 Calculated from test results.

Type and Purpose of Test Turns Ratio: The turns ratio test determines the ratio of turns in the primary

winding to that in all other windings of the transformer, so that when rated

voltage is applied to one winding of the transformer, all other winding

voltages will be correct within one half of one percent of the rated nameplate

voltages. The only deviation allowed by the standards is when the volts per

turn exceed the one half of one percent of the rated voltage. The turns ratio

test is performed on all taps of every winding.

Polarity and Phase Relation: Polarity and phase relation tests are

important when transformers are to be paralleled. Paralleled transformers

must have the same polarity and phase relation to avoid short circuits. For

single phase transformers, the polarity test determines whether the primary

and secondary windings are connected for additive or subtractive polarity.

For three-phase transformers, the phase relation test determines if the

angular displacement and relative phase sequence of the vectors

representing the transformer windings are correct.

Resistance: The DC winding resistance is used to calculate the I2R

component of load losses. It is also used to calculate winding temperature

during the temperature test.

No-Load Loss: The no-load losses or excitation losses consist of the iron

loss of the core, the dielectric loss in the insulation, and the winding loss due

to the circulation of the exciting current. Normally, the dielectric loss and

winding loss are negligible when compared to the iron loss. No-load losses,

as the name implies, are losses generated in the transformer with no load

on the secondary terminals. No-load loss tests are measured at 100% of

rated voltage.

Excitation Current: This test determines the current required to maintain

the magnetic excitation of the core. It is expressed in per unit or percent of

the rated transformer winding current. Excitation current is measured at

100% of rated voltage.

2 © 1992–2010 Schneider Electric All Rights Reserved

7200DB1001 Medium Voltage Transformer Testing

11/2010 Data Bulletin

Impedance: The impedance is normally expressed in terms of percent of

rated voltage. The impedance voltage is that voltage required to circulate

rated current in one winding with the other winding shorted. Due to

manufacturing and material tolerances, the impedance will vary from the

design and guaranteed value. For this reason, the IEEE Standards have

established impedance tolerances of ± 7.5% for two-winding transformers,

and ± 10% for three-winding transformers.

Load Loss: This test measures the losses in the transformer when it is

operating at full load. Load loss is the sum of the I2R losses in the windings,

`stray losses due to stray fluxes in the windings, tank, enclosure, assembly

parts, etc., and the eddy losses due to circulating currents. The I2R loss

component is by far the largest component of the load loss.

Table 2: Basic Impulse Levels— Quality Control Impulse: This test is not a routine test for all transformers;

Distribution Class however the test is performed on every Schneider Electric transformer to

verify the Basic Impulse Level (BIL) rating of the transformer. The test

Dry-Type Liquid -Filled consists of one reduced and one full wave. The wave shape and voltage

Voltage Transformers Transformers

level is determined by the voltage class of the transformer and the BIL

Class Full Chopped Full Chopped specified for that voltage class. When an ANSI impulse test is specified, two

Wave Wave Wave Wave chopped waves will be applied to the transformer terminals in addition to the

1.2 10 10 30 36

reduced and full waves. A full wave represents a disturbance that occurs

some distance from the transformer and travels along the transmission line

2.5 20 20 45 54

to the transformer. The chopped wave represents a traveling wave created

5 30 30 60 69

by a disturbance that occurs some distance from the transformer that

8.7 45 45 75 88

flashes to ground near the transformer terminals. For distribution class

15 60 60 95 110 transformers with low voltages less than the 5 kV class, the impulse tests

25 110 110 125 145 are normally performed only on the high voltage terminals.

34.5 150 150 150 175

Applied Potential: This test is sometimes referred to as the high-pot or

46 — — 250 290

low frequency test. The purpose of this test is to verify the adequacy of the

insulation between the winding being tested to all other windings and to

ground. The test is made at 60 Hz for one minute.

Induced Potential: This test is made to verify the adequacy of the

turn-to-turn insulation, layer-to-layer insulation, and phase-to-phase

insulation. The test is made at twice the rated voltage, with a 400 Hz source,

and is applied for 7200 cycles.

Partial Discharge: This test is a routine test for all cast coil transformers.

The purpose of the test is to very that the casting process has not left any

voids (air pockets) in the windings.

Leak: All liquid-filled transformers are tested under pressure during the final

assembly and preparation for shipment. Any reduction in pressure or visible

sign of liquid seepage will be repaired before shipment.

Regulation and Efficiency: Regulation is the change, or drop, in secondary

voltage as the load is increased on the transformer and is expressed as a

percentage of the rated secondary voltage. Efficiency is the ratio of output

watts to the input watts and is expressed as a percentage. Regulation and

efficiency are calculated values from impedance and loss testing.

Temperature Rise: This test is a design test and is performed to verify that

the average winding temperatures do not exceed the guaranteed values

specified for the temperature rating of the insulation system. The tests are

made by circulating rated current in the windings until the temperature has

stabilized. The change in winding resistance from a cold start to the

resistance at the stabilized temperature is used to calculate the average

winding temperature rise.

© 1992–2010 Schneider Electric All Rights Reserved 3

Medium Voltage Transformer Testing 7200DB1001

Data Bulletin 11/2010

Audible Sound Level: This is a design test that measures the average

sound level generated by the transformer when energized at rated voltage

and no-load applied to the terminals.

Zero Sequence Impedance: This test measures the line to neutral

impedance when the transformer has a wye connected winding(s). The zero

sequence impedance is also expressed as a percentage of rated voltage.

Radio Influence Voltage (RIV): Also known as Telephone Influence Factor

(TIF). This test, which is performed on liquid-filled transformers, is similar to

the partial discharge test performed on cast coil transformers. The purpose

of this test is to determine the amount of electrical discharges that occur in

the electrical insulation as a result of high velocity ionization under the

influence of an electrical field, and to ensure the dielectric strength of the

insulation is not exceeded.

Short Circuit: This test is performed only on prototype transformers only to

verify the mechanical and thermal integrity of the core and coil assembly and

other electrical components during a through-fault on the transformer.

Because of the power required to perform this test, it has to be performed at a

high power test laboratory which has the high power equipment necessary to

perform the test.

Insulation Power Factor: The ratio of power dissipated in the insulation in

watts to the product of the effective voltage and current in volt-amperes

when tested with a sinusoidal voltage. This test is used to give an indication

of the condition (dryness) of the transformer insulation. Presently, there are

no established limits for acceptable power factor readings in the transformer

standards. Acceptable power factor readings are a matter of judgment and

experience. However, a power factor value of 1.0% or less for distribution

transformers and 0.5% or less for large power transformers are generally

used as acceptable values.

Insulation Resistance: This test is also used to give an indication of the

dryness of the transformer insulation. Although not considered a routine

test, it is often performed by manufacturers to give an indication of the

condition of the transformer insulation. The insulation resistance varies with

moisture contend, cleanliness, and temperature of all insulating parts.

Gas Analysis: This test does not measure the performance of the

transformer, but is a chemical analysis of the liquid to determine the levels

of gases being produced by the operation of the transformer. When a

transformer is operated, gases are generated from the insulation materials

in the transformer. Gas generation is a natural phenomenon within

transformers that can come from a variety of events, including electrical

disturbances, thermal events, conductor losses, and other temperature

effects. Although not common, it is possible for some transformers to

operate throughout their useful life with large quantities of combustible

gases present. Dissolved Gas Analysis (DGA) is most effective when

performed over time on a periodic basis starting when the transformer is put

into service. This becomes the baseline for future comparisons.

Schneider Electric USA, Inc. Electrical equipment should be installed, operated, serviced, and maintained only by

1010 Airpark Center Drive qualified personnel. No responsibility is assumed by Schneider Electric for any

Nashville, TN 37217 consequences arising out of the use of this material.

1-888-SquareD (1-888-778-2733)

www.schneider-electric.us

4 © 1992–2010 Schneider Electric All Rights Reserved

Вам также может понравиться

- Difference Between IEEE and IEC Standard For HV Metal Clad SwitchgearДокумент14 страницDifference Between IEEE and IEC Standard For HV Metal Clad Switchgearsameerray12Оценок пока нет

- New VarplusCan - Reactive EnergyДокумент40 страницNew VarplusCan - Reactive EnergyAlfiansyah Dharma Setia Djaketra100% (1)

- 745-b5 - 7 Modbus MultilinДокумент68 страниц745-b5 - 7 Modbus MultilinJorge William Bermudez GaviriaОценок пока нет

- The Importance of Earth Loop ImpedanceДокумент4 страницыThe Importance of Earth Loop ImpedanceKarim Amer100% (1)

- Unit-1-Protective Relaying OC and Earth Fault ProtectionДокумент127 страницUnit-1-Protective Relaying OC and Earth Fault Protectionsubbu2051100% (2)

- MVA Method Short Circuit ABCДокумент12 страницMVA Method Short Circuit ABCciksay71Оценок пока нет

- MCB Tripping CurvesДокумент10 страницMCB Tripping CurvesFredy Para DavisОценок пока нет

- Digital Circuits PDFДокумент66 страницDigital Circuits PDFSatyendra ShgalОценок пока нет

- Generator ProtectionДокумент12 страницGenerator ProtectionFarrukh IlyasОценок пока нет

- Generator ProtectionДокумент36 страницGenerator Protectiongloby_pnbОценок пока нет

- Motor Temperature Ratings: DefinitionsДокумент4 страницыMotor Temperature Ratings: DefinitionstekhakkoОценок пока нет

- White Paper 2009 System Neutral Resistance Grounding LBДокумент7 страницWhite Paper 2009 System Neutral Resistance Grounding LBLong LeoОценок пока нет

- Chapter 1 Introduction To Power System ProtectionДокумент65 страницChapter 1 Introduction To Power System Protectionjaved kazim100% (1)

- Overcurrent Protection of Transformer NEC450.3Документ12 страницOvercurrent Protection of Transformer NEC450.3simonОценок пока нет

- Service Factor Motor - ToshibaДокумент2 страницыService Factor Motor - Toshibasameerray12Оценок пока нет

- Basic Transformer Training - Chapter 3 - Federal PacificДокумент5 страницBasic Transformer Training - Chapter 3 - Federal PacificfluxОценок пока нет

- Motor Differential Protection Using Flux BalancingДокумент1 страницаMotor Differential Protection Using Flux Balancingshyam_krishnan_16Оценок пока нет

- Disconnector Contact Condition PDFДокумент130 страницDisconnector Contact Condition PDFipraoОценок пока нет

- A Review About Vector Group Connections in TransformersДокумент7 страницA Review About Vector Group Connections in TransformersMohamed Wahid100% (1)

- Insulation Resistance TestingДокумент3 страницыInsulation Resistance TestingAJB2010Оценок пока нет

- ABB 63 WPO BreakerCoordination FinalДокумент4 страницыABB 63 WPO BreakerCoordination FinalCA Cole100% (1)

- Transformer Failure AnalysisДокумент12 страницTransformer Failure AnalysisABHINAV SAURAVОценок пока нет

- Analog Circuits Versus Digital CircuitsДокумент2 страницыAnalog Circuits Versus Digital CircuitsTalha MaqsoodОценок пока нет

- Effect Residual Magnetism On The Magnetic Core of A TransformerДокумент4 страницыEffect Residual Magnetism On The Magnetic Core of A Transformerhendro suprianto nugrohoОценок пока нет

- VRLA Batteries ChargingMethodsДокумент8 страницVRLA Batteries ChargingMethodsbinodeОценок пока нет

- SP0504R01Документ8 страницSP0504R01Avoor KhanОценок пока нет

- Note Switchgear PDFДокумент36 страницNote Switchgear PDFNur FatihahОценок пока нет

- Current Transformer: Theory, Types and Testing Conducted By-Javed ShaikhДокумент11 страницCurrent Transformer: Theory, Types and Testing Conducted By-Javed Shaikhjaved shaikh chaand100% (1)

- Electromagnetic Relays - ManiДокумент17 страницElectromagnetic Relays - ManipraveenaprabhuОценок пока нет

- Physics of Contact ResistanceДокумент17 страницPhysics of Contact ResistanceSurajit DasОценок пока нет

- Saturable ReactorДокумент2 страницыSaturable ReactorGilberto ManhattanОценок пока нет

- Open Delta PT Vs Wye PT - Electric Power & Transmission & Distribution - Eng-TipsДокумент8 страницOpen Delta PT Vs Wye PT - Electric Power & Transmission & Distribution - Eng-Tipswas00266Оценок пока нет

- Definition of Basic Insulation Level BILДокумент7 страницDefinition of Basic Insulation Level BILPierre Enrique Carrasco FuentesОценок пока нет

- Ground-Fault ProtectionДокумент50 страницGround-Fault Protectionsimon_o_connor_5100% (1)

- 3 - Transformer FaultДокумент4 страницы3 - Transformer FaultJoseph FaresОценок пока нет

- Medium Voltage Motor StartingДокумент3 страницыMedium Voltage Motor StartingharmlesdragonОценок пока нет

- Sampled Values Configuration ExampleДокумент14 страницSampled Values Configuration ExampleVishwanath Todurkar100% (1)

- ONLOAD 2007 enДокумент46 страницONLOAD 2007 enpokojang100% (1)

- Transformer ProtectionДокумент23 страницыTransformer ProtectionARVIND50% (2)

- Circuit BreakerДокумент70 страницCircuit BreakerBADAL CHOUDHARYОценок пока нет

- On-Site Testing of Power Transformers TDS 146 - 201602Документ10 страницOn-Site Testing of Power Transformers TDS 146 - 201602Agatsi WulansatyaОценок пока нет

- Lecture Note MechatronicДокумент50 страницLecture Note MechatronicMdnor Rahim100% (2)

- VLF-12011CMF Manual Complete - 2k19Документ40 страницVLF-12011CMF Manual Complete - 2k19Selk CLОценок пока нет

- Breaker Failure Protection: PSRC - K2 WGДокумент32 страницыBreaker Failure Protection: PSRC - K2 WG1453hОценок пока нет

- Unbalanced Fault Analysis Lec 8Документ20 страницUnbalanced Fault Analysis Lec 8Bante TadeleОценок пока нет

- Low Resistance Measurement Guide PDFДокумент34 страницыLow Resistance Measurement Guide PDFbill1022Оценок пока нет

- Current-Limiting Inductors Used inДокумент7 страницCurrent-Limiting Inductors Used inkgskgmОценок пока нет

- Upptcl Training (Ee)Документ27 страницUpptcl Training (Ee)AakashОценок пока нет

- Ergon Energy: Specialist Plant ServicesДокумент4 страницыErgon Energy: Specialist Plant ServicesMohan Raj100% (1)

- Various Types of Closing Mechanism May Be FittedДокумент2 страницыVarious Types of Closing Mechanism May Be FittedshahedОценок пока нет

- Baker 2012Документ8 страницBaker 2012JONATHAN MORALESОценок пока нет

- IEEE Recommended Practice For Testing Insulation ResistanceДокумент1 страницаIEEE Recommended Practice For Testing Insulation Resistancealvin meОценок пока нет

- (09-0a) Transformer Testing Systems - v1.9Документ8 страниц(09-0a) Transformer Testing Systems - v1.9SrinivasanОценок пока нет

- Secondary Substation Transformers Test Application Data Standard TestsДокумент2 страницыSecondary Substation Transformers Test Application Data Standard TestsMarcelo Rueda MartínezОценок пока нет

- Power Transformer Web1Документ2 страницыPower Transformer Web1kalatzoiОценок пока нет

- Full Bridge Phase Shift ConverterДокумент21 страницаFull Bridge Phase Shift ConverterMukul ChoudhuryОценок пока нет

- Leadership PresentationДокумент10 страницLeadership Presentationapi-404415990Оценок пока нет

- TDS Shell Spirax s6 Gxme 75w-80Документ2 страницыTDS Shell Spirax s6 Gxme 75w-80rstec pyОценок пока нет

- Post Traumatic Stress DisorderДокумент2 страницыPost Traumatic Stress Disorderapi-188978784100% (1)

- Indiana Administrative CodeДокумент176 страницIndiana Administrative CodeMd Mamunur RashidОценок пока нет

- AcquaculturaДокумент145 страницAcquaculturamidi64100% (1)

- Quarterly Progress Report FormatДокумент7 страницQuarterly Progress Report FormatDegnesh AssefaОценок пока нет

- Citizen's 8651 Manual PDFДокумент16 страницCitizen's 8651 Manual PDFtfriebusОценок пока нет

- Aircaft Avionics SystemДокумент21 страницаAircaft Avionics SystemPavan KumarОценок пока нет

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesДокумент29 страницUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemОценок пока нет

- RB Boiler Product SpecsДокумент4 страницыRB Boiler Product Specsachmad_silmiОценок пока нет

- EngineCleaningAndVolcanicAsh InternДокумент69 страницEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaОценок пока нет

- PowderCoatingResins ProductGuide 0Документ20 страницPowderCoatingResins ProductGuide 0zizitroОценок пока нет

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonДокумент1 страницаVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaОценок пока нет

- TC 000104 - VSL MadhavaramДокумент1 страницаTC 000104 - VSL MadhavaramMK BALAОценок пока нет

- UK FreshTECH Jammer RecipeBook 0Документ24 страницыUK FreshTECH Jammer RecipeBook 0Temet NoscheОценок пока нет

- SRV SLB222 en - 05062020Документ2 страницыSRV SLB222 en - 05062020Nguyen ThuongОценок пока нет

- TFALL CaseStudy-Chandni+Chopra 072020+Документ5 страницTFALL CaseStudy-Chandni+Chopra 072020+Luis Gustavo Heredia VasquezОценок пока нет

- Kes MahkamahДокумент16 страницKes Mahkamahfirdaus azinunОценок пока нет

- Hydrogen Production From The Air: Nature CommunicationsДокумент9 страницHydrogen Production From The Air: Nature CommunicationsdfdffОценок пока нет

- 812571-006 RevB (GPC3000 Service)Документ270 страниц812571-006 RevB (GPC3000 Service)BPОценок пока нет

- FNCP Improper Waste DisposalДокумент2 страницыFNCP Improper Waste DisposalKathleen Daban RagudoОценок пока нет

- Traditional vs. Enterprise Risk Management - How Do They DifferДокумент4 страницыTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanОценок пока нет

- Posi LokДокумент24 страницыPosi LokMarcel Baque100% (1)

- Imagine Unit 1 P 10 11Документ1 страницаImagine Unit 1 P 10 11נויה לבדובОценок пока нет

- Recommendation On The Acquisation of VitasoyДокумент8 страницRecommendation On The Acquisation of Vitasoyapi-237162505Оценок пока нет

- CampingДокумент25 страницCampingChristine May SusanaОценок пока нет

- PSB 3441 CH 1 HallucinogensДокумент2 страницыPSB 3441 CH 1 HallucinogensAnonymous lm3GIU45Оценок пока нет

- Pentacam Four Maps RefractiveДокумент4 страницыPentacam Four Maps RefractiveSoma AlshokriОценок пока нет

- Pengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Документ10 страницPengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Haris FirdausОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- Cyber-Physical Systems: Foundations, Principles and ApplicationsОт EverandCyber-Physical Systems: Foundations, Principles and ApplicationsHoubing H. SongОценок пока нет

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОт EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОценок пока нет

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Chasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItОт EverandChasing the Demon: A Secret History of the Quest for the Sound Barrier, and the Band of American Aces Who Conquered ItРейтинг: 4 из 5 звезд4/5 (25)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersОт EverandBulk Material Handling: Practical Guidance for Mechanical EngineersРейтинг: 5 из 5 звезд5/5 (1)

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОт EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionОценок пока нет

- Laminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОт EverandLaminar Flow Forced Convection in Ducts: A Source Book for Compact Heat Exchanger Analytical DataОценок пока нет

- Airplane Flying Handbook: FAA-H-8083-3C (2024)От EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Рейтинг: 4 из 5 звезд4/5 (12)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsОт EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Safety Theory and Control Technology of High-Speed Train OperationОт EverandSafety Theory and Control Technology of High-Speed Train OperationРейтинг: 5 из 5 звезд5/5 (2)

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- Gas Turbines: A Handbook of Air, Land and Sea ApplicationsОт EverandGas Turbines: A Handbook of Air, Land and Sea ApplicationsРейтинг: 4 из 5 звезд4/5 (9)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Electrical (Generator and Electrical Plant): Modern Power Station PracticeОт EverandElectrical (Generator and Electrical Plant): Modern Power Station PracticeРейтинг: 4 из 5 звезд4/5 (9)