Академический Документы

Профессиональный Документы

Культура Документы

SI-R917B-ENG v1 m56577569830657326

Загружено:

Laurentiu GamanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SI-R917B-ENG v1 m56577569830657326

Загружено:

Laurentiu GamanАвторское право:

Доступные форматы

General Safety Information Cassette sprocket / multiple freewheel tooth combination Installation of the freewheel Connect the cable

Cassette sprocket / multiple freewheel tooth combination Installation of the freewheel Connect the cable to the rear derailleur Note: Be sure that the cable is

and, after taking up the initial slack in securely in the groove.

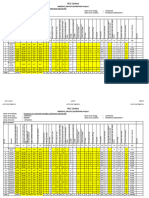

Model number Gears Group name Tooth combination the cable, re-secure to the front

Tightening torque:

WARNING CS-HG50-8I 8 an 11, 13, 15, 17, 20, 23, 26, 30T To install 30 N·m {260 in. lbs.}

derailleur as shown in the illustration.

• Check that the wheels are fastened securely before riding the bicycle. If the wheels are loose in any way, they CS-HG40-8I 8 ao 11, 13, 15, 17, 20, 23, 26, 34T Tightening torque:

may come off the bicycle and serious injury may result. 5 - 7 N·m {44 - 60 in. lbs.} Pull

MF-HG40-7 7 az 14, 16, 18, 20, 22, 24, 34T Freewheel removal tool

• Use neutral detergent to clean the chain. Do not use alkali-based or acid based detergent such as rust cleaners To disassemble TL-FW30

as it may result in damage and/or failure of the chain. MF-HG37 7 ax 14, 16, 18, 20, 22, 24, 28T

• Use the reinforced connecting pin only for connecting the narrow type of chain. MF-TZ07 7 dy 14, 16, 18, 20, 22, 24, 28T Groove

• There are two different types of reinforced connecting pins available. Be sure to check the table below before

MF-TZ06 6 bx 14, 16, 18, 21, 24, 28T

selecting which pin to use. If connecting pins other than reinforced connecting pins are used, or if a reinforced

connecting pin or tool MF-HG22 6 Y 14, 16, 18, 21, 24, 28T 3. Low adjustment Largest

sprocket

which is not suitable for Reinforced While turning the front chainwheel, operate the

Chain Chain tool

connecting pin

the type of chain is used, lever to shift to the lowest gear. Guide pulley

sufficient connection force 9-speed super narrow chain Turn the low adjustment screw so that the guide

such as Silver TL-CN31/TL-CN22

may not be obtained, pulley moves to a position directly in line with the

which could cause the

CN-7701 / CN-HG93 6.5mm Replacement of the freewheel body largest sprocket. 1 2

chain to break or fall off. 8- / 7- / 6-speed narrow

TL-CN31/TL-CN22 and After removing the hub axle, remove

chain such as Black

TL-CN30/TL-CN21

FH-CT91 2 1 Low

CN-HG50 / CN-IG51 7.1mm the freewheel body fixing bolt adjustment screw

Freewheel body Freewheel body fixing bolt

(inside the freewheel body), and

• If it is necessary to adjust the length of the chain due to a change in Reinforced then replace the freewheel body. Disassembly

the number of sprocket teeth, make the cut at some other place than End Pin Link Pin Connecting Pin

the place where the chain has been joined using a reinforced C

E

Installation of the sprockets Note: 4. How to use the B-tension adjustment screw Largest

sprocket Smallest sprocket

Do not attempt to disassemble Mount the chain on the smallest chainring and the

RA-A

connecting pin or an end pin. The chain will be damaged if it is cut at a 2

DU the freewheel body, because it largest sprocket, and turn the crank arm backward. 2

place where it has been joined with a reinforced connecting pin or an For each sprocket, the surface that has may result in a malfunction. Assembly

Then turn the B-tension adjustment screw to adjust the

end pin. the group mark should face outward The groove is wide ac -14T

▲ mark Freewheel body washer

and be positioned so that the triangle at one place only. guide pulley as close to the sprocket as possible but

• Check that the tension of the chain is correct and that the chain is not damaged. If the tension is too weak or the

(▲) mark on each sprocket and the A A Tightening torque: 10 mm Allen key (TL-WR37) not so close that it touches. Next, set the chain to the

chain is damaged, the chain should be replaced. If this is not done, the chain may break and cause serious injury. 35 - 50 N·m {305 - 434 in. lbs.}

part (where the groove width is wide) of smallest sprocket and repeat the above to make sure

• Obtain and read the service instructions carefully prior to installing the parts. Loose, worn, or damaged parts may 1 2

the freewheel body are aligned. that the pulley does not touch the sprocket.

cause injury to the rider. 1 B-tension

We strongly recommend only using genuine Shimano replacement parts. adjustment screw

• Read these Technical Service Instructions carefully, and keep them in a safe place for later reference. 1

Mounting the shifting lever

Note 11T

• If gear shifting operations do not feel smooth, wash the derailleur and lubricate all moving parts. ab

S

H

IM

A NO

HYP

ER

G

L I

m

DE

4 0 0 kg /c

• If the amount of looseness in the links is so great that adjustment is not possible, you should replace the

- C

J AP

CK

LO

AN

9 U

25 .S

derailleur.

. PA

T 4268

• You should periodically clean the derailleur and lubricate all moving parts (mechanism and pulleys). RD-TX70 / 50 / 30

• If gear shifting adjustment cannot be carried out, check the degree of parallelism at the rear end of the bicycle. The 6 sprockets are secured by Sprocket spacers Lock ring 5. SIS Adjustment

Also check if the cable is lubricated and if the outer casing is too long or too short. means of rivets. (1.0mm) Operate the shifting lever several times to move the chain to the 2nd sprocket. Then, while

• If you hear abnormal noise as a result of looseness in a pulley, you should replace the pulley. pressing the lever just enough to take up the play in the lever, turn the crank arm.

• If the wheel becomes stiff and difficult to turn, you should lubricate it with grease.

• Do not apply any lubricant to the inside of the hub, otherwise the grease will come out. • For installation of the sprockets, use the special tool Lock ring

• You should periodically wash the sprockets in a neutral detergent and then lubricate them again. In addition, (TL-HG16) to tighten the lock ring. Tightening torque: When shifting When no sound at

Tool (TL-SR20)

cleaning the chain with neutral detergent and lubricating it can be a effective way of extending the useful life of 6 - 8 N·m {53 - 69 in. lbs.} to 3rd all is heard

the sprockets and the chain. Tightening torque:

• If the chain keeps coming off the sprockets during use, replace the sprockets and the chain. 30 - 50 N·m {261 - 434 in. lbs.}

• Always be sure to use the sprocket set bearing the same group marks. Never use in Group marks TL-HG16 5 mm allen key

combination with a sprocket bearing a different group mark. • To replace the sprockets, use the special tool Outer casing

• Use a frame with internal cable routing is strongly discouraged as it has tendencies to impair ag - 18T

(TL-HG16) and TL-SR20 to remove the lock ring. adjustment barrel

ag -15

the SIS shifting function due to its high cable resistance. T

ag

-1

3T

• Use an outer casing which still has some length to spare even when the handlebars are Disassembly

turned all the way to both sides. Furthermore, check that the shifting lever does not touch

the bicycle frame when the handlebars are turned all the way.

Adjustment Outer casing

SH

IM

• Grease the inner cable and the inside of the outer casing before use to ensure that they

AN

HYPERGL I DE - C

O

adjustment barrel

slide properly. Tighten the outer casing adjustment Loosen the outer casing adjustment

• For smooth operation, use the specified outer casing and the bottom bracket cable guide. 1. Top adjustment Outer line of

smallest sprocket barrel until the chain returns to the 2nd barrel until the chain touches the 3rd

• The SC-C050 speedmeter, SC-C051 odometer and SC-C052 clock and stopwatch are available as separate Turn the top adjustment screw to sprocket. (clockwise) sprocket and makes noise.

1 2

adjust so that the guide pulley is in

items. Please ask your bicycle dealer for further details. Installation of the rear derailleur line with the outer line of the

(counter clockwise)

• Operation of the levers related to gear shifting should be made only when the front chainwheel is turning.

• Parts are not guaranteed against natural wear or deterioration resulting from normal use. When installing, be careful that deformation is not smallest sprocket when looking

<RD-MR40, RD-TX70 / 50 / 30>

• For maximum performance we highly recommend Shimano lubricants and maintenance products. caused by the B-tension adjustment screw coming from the rear. 1 2 Best setting

After this, install the chain. Guide pulley

• For any questions regarding methods of installation, adjustment, maintenance or operation, please contact a into contact with the dropout tab. Direct-mount type Top adjustment The best setting is when the shifting lever is operated just enough

professional bicycle dealer. screw to take up the play and the chain touches the 3rd sprocket and

5 mm Allen key makes noise.

Push in and

tighten * Return the lever to its original position (the position where the lever is at

5 mm Allen Key the 2nd sprocket setting and it has been released) and then turn the crank

Tightening torque: arm clockwise. If the chain is touching the 3rd sprocket and making noise,

8 - 10 N·m RD-TX70 / 50 / 30 turn the outer casing adjustment barrel clockwise slightly to tighten it until

{70 - 86 in. lbs.} the noise stops and the chain runs smoothly.

For the best SIS performance, periodically lubricate all power-transmission parts.

Shoud be touching 2. Connecting and securing the

inner cable

Technical Service Instructions SI-R917B Replace the inner cable by carrying out Gear shifting operation

steps ➀ to ➂ as shown in the illustrations.

B-tension Bracket type

adjustment screw

Rear Drive System Tightening torque:

3 - 4 N·m

{26 - 34 in. lbs.} Pedaling

Bracket nut

Dropout tab becomes lighter

Frame

In order to realize the best performance, we recommend that the following combination be used. Bracket spindle tightening torque: Bracket bolt

8 - 10 N·m {70 - 86 in. lbs.} Bracket

Series Altus Tourney 40 Tourney ➀ ➁ ➂

CI-DECK ID-C050-8R ID-C050-7R ID-C050-6R

Pedaling

REVOSHIFT SB-C055A-8R SB-C055A-7R SB-C055-6R becomes heavier

Outer casing SIS SIS SIS

Rear derailleur RD-CT95 RD-TX70/50/30 RD-MR40-7 RD-TX70 / 50 / 30 Chain length Installation of the switch

Type Smart Cage Smart Cage MGS Smart Cage Add 2 links (with the chain on both the largest sprocket and the largest chainring) Largest sprocket Largest chainring

Remove the switch cap and install the

Freehub FH-CT91 –– –– switch as shown in the illustration.

Gears 8 7 6

CS-HG50-8I MF-HG40-7 MF-HG22

Cassette sprocket / Multiple freewheel Switch

CS-HG40-8I MF-TZ07 MF-TZ06 Chain

Chain CN-HG50 / CN-UG50 Inserting the inner cable

Switch cap

Insert the inner cable into the outer casing from the end with the marking on it.

Bottom bracket cable guide SM-SP18 / SM-BT18

Chain gauge Apply grease from the end with the marking in order to maintain cable

Checking the chain connection

SHIMANO JAPAN

CHAIN GAUGE

TL-CN24

operating efficiency.

1=2.38mm

TL-CN24

For IG, chains, insert the chain gauge (TL-CN24) into the inner link which is

next to the chain connecting pin to check that the inner link width is correct.

Specifications Check that the connecting pin pro-trudes past the outer link by the same Marking

This service instruction explains how to use and maintain the Shimano bicycle parts which have

amount on both sides, and that the amount of protrusion is 0.2 mm or more. 2.38mm been used on your new bicycle. For any questions regarding your bicycle or other matters which

Rear Derailleur

Connecting pin Cutting the outer casing are not related to Shimano parts, please contact the place of purchase or the bicycle

Model number RD-CT95 RD-MR40-7 RD-TX70 / 50 / 30 When cutting the outer casing, cut the opposite end to manufacturer.

Type Smart cage MGS Smart cage Inner link

the end with the marking. After cutting the outer casing,

A, B Q 0.2mm A B make the end round so that the inside of the hole has a

Total capacity 43T 40T 43T uniform diameter.

TL-CN24

1=2.38mm

CHAIN GAUGE

SHIMANO JAPAN

Largest sprocket 34T 34T 28-34T

TL-CN24

1=2.38mm

CHAIN GAUGE

SHIMANO JAPAN

Outer end cap

Smallest sprocket 11T 13T 11T Connecting pin One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003

Attach the same outer end cap to the

Front chainwheel tooth difference 20T 20T 20T cut end of the outer casing.

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 3-77 Oimatsu-cho, Sakai, Osaka 590-8577, Japan

Applicable front chainwheel FC-TX70 (42-34-24T) Outer link Correct Incorrect

FC-CT92 (42-34-24T) FC-TY33A (48-38-28T) Please note: specifications are subject to change for improvement without notice. (English)

(chainring tooth configuration) FC-TX71 (48-38-28T) © Oct. 2003 by Shimano Inc. XBC SZK Printed in Singapore

Вам также может понравиться

- Automatic Transmission Service GroupДокумент48 страницAutomatic Transmission Service GroupAndrei Balla100% (3)

- Shimano AltusДокумент1 страницаShimano Altusbambangw_99Оценок пока нет

- Everdi̇gm Ehb50Документ28 страницEverdi̇gm Ehb50OrhanОценок пока нет

- Installation Reference, Volvo Penta IPS Propulsion Unit and EngineДокумент2 страницыInstallation Reference, Volvo Penta IPS Propulsion Unit and Engineakhil9182100% (1)

- 980H PDFДокумент2 страницы980H PDFIgnacio Lazo JhsúsОценок пока нет

- Man D2866-LF28 PDFДокумент153 страницыMan D2866-LF28 PDFadi100% (5)

- Om Insignia Kta-2675 9-En Eu My13 Ed0812 32 en GB OnlineДокумент321 страницаOm Insignia Kta-2675 9-En Eu My13 Ed0812 32 en GB OnlineKhalil YacОценок пока нет

- D3E8034DF5E Gearbox 09GДокумент216 страницD3E8034DF5E Gearbox 09GVasile-Cristian Rusu50% (2)

- Transmissao 938Документ58 страницTransmissao 938Jose De Moura CamaraОценок пока нет

- Hoist Drum Assy 4100XPCДокумент3 страницыHoist Drum Assy 4100XPCFrancisco GonzalezОценок пока нет

- CAT D342 Shop Armer Manual PDFДокумент18 страницCAT D342 Shop Armer Manual PDFJhony Soto LoperaОценок пока нет

- Shimano Front DerailleurДокумент1 страницаShimano Front DerailleurAndreiОценок пока нет

- Shimano SLX HG81 Cassette Service ManualДокумент1 страницаShimano SLX HG81 Cassette Service ManualJose Luis GutierrezОценок пока нет

- SI 5NB0A 001 00 Eng - v1 - m56577569830747488Документ1 страницаSI 5NB0A 001 00 Eng - v1 - m56577569830747488brassoyОценок пока нет

- LayoutMaps™ - LED Strip Light Layout 3001-1B - Waveform LightingДокумент4 страницыLayoutMaps™ - LED Strip Light Layout 3001-1B - Waveform LightingYazan ZurkiyehОценок пока нет

- Alivio Front Drive SystemДокумент1 страницаAlivio Front Drive SystemMarОценок пока нет

- SI 6M10A en v1 m56577569830604102Документ1 страницаSI 6M10A en v1 m56577569830604102xjcaiОценок пока нет

- Bike CalipersSI - 8C60H - en - v1 - m56577569830604598Документ1 страницаBike CalipersSI - 8C60H - en - v1 - m56577569830604598Stuart BaileyОценок пока нет

- Polamco Product Finder PDFДокумент1 страницаPolamco Product Finder PDFpaula09Оценок пока нет

- Televes Nova SwitchДокумент4 страницыTeleves Nova Switchnasser22Оценок пока нет

- Eng Shimano Manu 07214Документ1 страницаEng Shimano Manu 07214RodrigoMacedoОценок пока нет

- Instrument Hookup 6Документ1 страницаInstrument Hookup 6Wael ZakariaОценок пока нет

- Maa Manasa Pole ShedulesДокумент69 страницMaa Manasa Pole Shedulesmuralipower1986Оценок пока нет

- SI 6KFFB 001 ENG - v1 - m56577569830687361Документ1 страницаSI 6KFFB 001 ENG - v1 - m56577569830687361Onus Probandis HedonistaОценок пока нет

- Instrument Hookup 8Документ1 страницаInstrument Hookup 8Wael ZakariaОценок пока нет

- Min. 700 MM: Installation Instructions and Safety AdviceДокумент1 страницаMin. 700 MM: Installation Instructions and Safety AdviceregisztralljОценок пока нет

- BTI PlanosДокумент18 страницBTI PlanosHache Reyk KhanОценок пока нет

- Before Reading This User ManualДокумент2 страницыBefore Reading This User ManualfanllazaОценок пока нет

- GOOLOO GE1200 - User ManualДокумент1 страницаGOOLOO GE1200 - User ManualzoltanpolyakОценок пока нет

- BN68-13710B-01 Um QBLS03M ZC L02 220527.0Документ2 страницыBN68-13710B-01 Um QBLS03M ZC L02 220527.0joskeОценок пока нет

- XT FD & Crank InstallationДокумент1 страницаXT FD & Crank InstallationMarОценок пока нет

- GR-SXM58 GR-SXM48 GR-FXM38 GR-SX24 GR-FX14: Compact Vhs CamcorderДокумент2 страницыGR-SXM58 GR-SXM48 GR-FXM38 GR-SX24 GR-FX14: Compact Vhs CamcorderMaryОценок пока нет

- ISD700 Directional/Fixed Antenna (Passive) : Installation GuideДокумент2 страницыISD700 Directional/Fixed Antenna (Passive) : Installation GuideravikkotaОценок пока нет

- C-Leg Prosthetic System. Instructions For Use (Qualified Personnel)Документ28 страницC-Leg Prosthetic System. Instructions For Use (Qualified Personnel)Nada GhammemОценок пока нет

- TwoStep Linkage SSP9028 v10Документ1 страницаTwoStep Linkage SSP9028 v10David BriggsОценок пока нет

- Si 6uafa 003 EngДокумент1 страницаSi 6uafa 003 EngRodrigoMacedoОценок пока нет

- Yamaha RX V365 Owners ManualДокумент1 страницаYamaha RX V365 Owners ManualandreiОценок пока нет

- Nexus 7 Installation Service ManualДокумент2 страницыNexus 7 Installation Service ManualsolerviОценок пока нет

- Si 7C26C 000 EngДокумент1 страницаSi 7C26C 000 EngsolerviОценок пока нет

- M5N Civ SHP 125 601 BD 4311 2 - R0Документ1 страницаM5N Civ SHP 125 601 BD 4311 2 - R0Tarek AbulailОценок пока нет

- As Built - CP Drawing For Well Head AreaДокумент1 страницаAs Built - CP Drawing For Well Head AreaMohammed HijaziОценок пока нет

- M5N Civ SHP 125 601 BD 4310 2 - R0Документ1 страницаM5N Civ SHP 125 601 BD 4310 2 - R0Tarek AbulailОценок пока нет

- Released: Iso View Back SCALE 1:30Документ6 страницReleased: Iso View Back SCALE 1:30Mohammed Saleem Syed KhaderОценок пока нет

- ESM-9944-N / ESM-9945-N Cooking Controllers: Electr Cal W R Ngs Panel Mount NGДокумент2 страницыESM-9944-N / ESM-9945-N Cooking Controllers: Electr Cal W R Ngs Panel Mount NGCristian SerbanoiuОценок пока нет

- 9 13 Notes:: Construction IssueДокумент1 страница9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайОценок пока нет

- Shimano Resetting Disc Brake PistonsДокумент1 страницаShimano Resetting Disc Brake PistonsJose Luis GutierrezОценок пока нет

- Si 6ngfa 004 EngДокумент1 страницаSi 6ngfa 004 EnglgsmartОценок пока нет

- Restrictive LayoutДокумент7 страницRestrictive LayoutMamelucoОценок пока нет

- 2007 Transit (2006) InstallДокумент14 страниц2007 Transit (2006) InstallMarcosОценок пока нет

- M5N Civ SHP 125 601 BD 4307 2 - R0Документ1 страницаM5N Civ SHP 125 601 BD 4307 2 - R0Tarek AbulailОценок пока нет

- Ultrix Quick Start Guide (2101DR-002)Документ1 страницаUltrix Quick Start Guide (2101DR-002)Habtamu TadesseОценок пока нет

- SW Fender PDFДокумент4 страницыSW Fender PDFJeff TrinidadОценок пока нет

- Locking ConnectorsДокумент2 страницыLocking ConnectorsDieabsolute NullimBettОценок пока нет

- InstallДокумент2 страницыInstallpqcrackerОценок пока нет

- DR1000 Installation Instruction Rev JДокумент4 страницыDR1000 Installation Instruction Rev JLupita ArriagaОценок пока нет

- M5N Civ SHP 125 601 BD 4308 2 - R0Документ1 страницаM5N Civ SHP 125 601 BD 4308 2 - R0Tarek AbulailОценок пока нет

- Equipment Grounding ConductorДокумент1 страницаEquipment Grounding Conductoramelna enterpriОценок пока нет

- TH L32B6 ManualДокумент2 страницыTH L32B6 ManualmegmanojsterОценок пока нет

- Drawing Limit - N 19736.000: J94-C04-003-TP001Документ1 страницаDrawing Limit - N 19736.000: J94-C04-003-TP001illiasuddinОценок пока нет

- Greenlee Cable Pulling09Документ1 страницаGreenlee Cable Pulling09Anonymous 1LgoS05gvlОценок пока нет

- Parts Catalogue DCD 250Документ23 страницыParts Catalogue DCD 250Quốc Viêtj HuỳnhОценок пока нет

- Manual KW810 BNWAS Iss 02Документ28 страницManual KW810 BNWAS Iss 02Fernando Rebolo100% (2)

- Quickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingДокумент2 страницыQuickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingINTERGUEST GuestОценок пока нет

- Installation, Operation, and Maintenance Manual: Model BCF Belt Drive Centrifugal Cabinet FansДокумент6 страницInstallation, Operation, and Maintenance Manual: Model BCF Belt Drive Centrifugal Cabinet FansStefy CarrascoОценок пока нет

- USER MANUAL Rev 1Документ35 страницUSER MANUAL Rev 1Rajkumar ArumugamОценок пока нет

- D-151-1225-0005G - 7 Revised Isolation PlanДокумент1 страницаD-151-1225-0005G - 7 Revised Isolation PlanTiến Dũng VũОценок пока нет

- Series 92 93 Pneumatic Actuators Operations Maintenance ManualДокумент14 страницSeries 92 93 Pneumatic Actuators Operations Maintenance ManualEdison RiosОценок пока нет

- Hanix h75c Parts CatalogДокумент20 страницHanix h75c Parts CatalogJames100% (48)

- Wheel Set: Dealer's ManualДокумент31 страницаWheel Set: Dealer's ManualHeather ColeОценок пока нет

- Hydraulic BrakesДокумент65 страницHydraulic BrakesFausto ArmijosОценок пока нет

- View All Callouts: Function Isolation ToolsДокумент37 страницView All Callouts: Function Isolation ToolsTechnicien CheikhnaОценок пока нет

- Ferramenta NaДокумент6 страницFerramenta NaLeon LellaОценок пока нет

- SM 26 PDFДокумент140 страницSM 26 PDFEnrique Arevalo LeyvaОценок пока нет

- Hensel Price List 2021Документ24 страницыHensel Price List 2021Ashish MahapatraОценок пока нет

- AMSLA426 Manual Megamouth 2019-12-11 PDFДокумент119 страницAMSLA426 Manual Megamouth 2019-12-11 PDFRoger Pozo AriasОценок пока нет

- EN Iso 965-1 AddendumДокумент2 страницыEN Iso 965-1 AddendumhoustonhimselfОценок пока нет

- Fdocuments - in Tata 207 Di LHD CatДокумент253 страницыFdocuments - in Tata 207 Di LHD CatGibj MisquittaОценок пока нет

- Automobile Engineering: Objective Questions and AnswersДокумент121 страницаAutomobile Engineering: Objective Questions and AnswersAjin Sadanandan100% (2)

- Cub Cadet Parts Manual For Model Fmz50Документ5 страницCub Cadet Parts Manual For Model Fmz50giovanni100% (50)

- 14 - Manual Motor WeichaiДокумент220 страниц14 - Manual Motor WeichaiJoão Paulo Gobbo AugustoОценок пока нет

- Sample Task List For Sap PM ModuleДокумент38 страницSample Task List For Sap PM ModuleDurga PrasadОценок пока нет

- Terrano 6.4 GX Parts Catalog 2018Документ94 страницыTerrano 6.4 GX Parts Catalog 2018Juli PОценок пока нет

- Bosch Motronic Mp3 2-Multipoint-Xu10j2cte RGX 406 Peugeot Fan ClubДокумент7 страницBosch Motronic Mp3 2-Multipoint-Xu10j2cte RGX 406 Peugeot Fan ClubMohamed TarekОценок пока нет

- Genima ED4W-YD90-Serie-Spareparts-CatalogДокумент33 страницыGenima ED4W-YD90-Serie-Spareparts-Catalogcupid75Оценок пока нет

- Motor 1Документ428 страницMotor 1Cory EnmanuelОценок пока нет

- D4B804B24F7 Brake SystemДокумент159 страницD4B804B24F7 Brake SystemDaniel CharlesОценок пока нет

- 019 - 137370 - Oms My20 Caad13 - en PDFДокумент24 страницы019 - 137370 - Oms My20 Caad13 - en PDFDarko AndreevskiОценок пока нет

- Fig. 18 Charging Pump (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Документ3 страницыFig. 18 Charging Pump (Tor-Con Type) :, JCPQD20/25N-RW11, S CPQD20/25N-RW7Walter FormigoniОценок пока нет