Академический Документы

Профессиональный Документы

Культура Документы

AK-47 Souptonuts 5

Загружено:

tshirley47Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AK-47 Souptonuts 5

Загружено:

tshirley47Авторское право:

Доступные форматы

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.

com

Page 1 of 7

Please make certain to visit our new Showcase of Sponsors!

More!

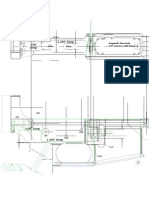

Article by Rob Summerhill (RapidRob) Adobe PDF Downloadable Version of Article The project is now close to completion. What needs to be done is to hand fit the bolt carrier assembly into the receiver and mount the barrel. A finish will be added to the rifle to protect the receiver and match the mounted parts. I will be using DuraCoat flat black. Mounting the bolt carrier is the most time consuming portion of this build. All of the flats for sale are made in such a way that there will be extra steel to remove from the two upper rails of the receiver. The front support pin and the condition of your parts kits will determine the receivers finished width. A new Romanian bolt carrier will have no wear, while a Yugo under folder dark bore may have had thousands of rounds fired through it in its past life. This step must be done right or you will not be happy with your rifle, or worse it will not function properly.

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 2 of 7

At this point you need to note the factory indentations in the bent top rails. The placement of these slight cut outs is very important for the normal operation of your rifle. 99.9% of all the flats will need to be widened in order to allow a smooth movement of the bolt carrier. First off, the rear cut out of the receiver is used to install/remove the bolt carrier from the receiver for normal maintenance.

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 3 of 7

Do not remove more than is necessary to install the bolt carrier. Remove too much and the carrier will jump out of the rails when fired. OOW receivers are known to do this. The forward edge of this opening must have a tapered angle to it to help guide the bolt carrier forward into the receiver. Note that there is a second opening cut forward of the rear opening, this opening is for the bolt head. This opening must be wide enough to allow the bolt head free passage into the receiver. As you move forward on the receiver you will note that the two top rails are not equal in the shape or length of the cuts made by the factory. These cuts will help guide the bolt as it strips a round from a magazine and starts to move the round into the chamber. These cuts give the bolt and bolt carrier wiggle room for any slight misalignment.

Use what ever means you have to mark the placement of these openings on your receiver. Using a caliper, or a good steel rule, measure the cut in the bolt carrier to obtain the minimum width the two top rails need to be. Transpose those measurements to the two top rails and mark /scribe onto the surface to help guide your cut. A milling machine would be ideal for this task; however most will have to use a Dremel tool with a good thin cut off wheel. Make sure your cut is straight and both rails are parallel to one another. Its easier to remove metal than to add metal. Take your time with these cuts. When you have made the two rail cuts, test fit the bolt carrier. The thickness of the cut off wheel will give you the clearance the carrier will need to move freely back and forth. Once you have done this, remove any burrs or sharp edges on the two top rails. Now make the cuts for the other openings as mentioned earlier. Once you have done this step you can mount the barrel. Mounting the barrel can be very easy or very hard depending on the condition of your front trunnion and breech end of the barrel. Some barrel pins have gouged the top of the breech badly. Use emery cloth to smooth the breech ring of the barrel to allow smooth movement into the front trunnion. Do not remove any more metal that you absolutely have

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 4 of 7

too. Removing too much metal will make your rifle unsafe to shoot! Any gouge marks that are below level with the radius of the breech ring is not a problem. Ok, how to mount the barrel? The easy way is to freeze the barrel. Yes FREEZE the barrel. I placed the barrel in our freezer and let it cool down for 24 hours. In the mean time I have cleaned the front trunnion of any grease, removed burrs in the barrel pin hole and double check the rivets for tightness to the receivers. You can mount the barrel by several means. You can tap the barrel in, hydraulic press it in or use a long pipe clamp and coins. Make sure you have all of the tools ready to go before you pull the barrel out of the freezer. I use Never Seize to lube the barrel breech before installation. Youll have about ten minutes to mount the barrel into the receiver before it heats up and is harder to move in the front trunnion. The barrels rear sight base ears will be used to help you guide the barrel into the trunnion. I place the muzzle on a block of hard lead and start the barrel into the front trunnion with taps from a one pound bronze hammer striking the rear of the front trunnion around the breech and the extension on the left side of the trunnion. Once the barrel starts to move into the trunnion, make sure the barrel is not twisted or at an angle to the receiver. I now switch to a brass or aluminum drift punch and continue to drive the trunnion onto the barrel. The barrel will slip in with out a whole lot of trouble. Dont be shy with the hammer blows. Once you have matched up the hole for the barrel pin with the trunnion hole, stop and do this check. Hold the rifle up and check your sight alignment. Is the rear sight aligned with the gas port? The front sight? If so continue on and drive the barrel pin back into the front trunnion. If not, pad a vice and twist the barrel using a large crescent wrench on the rear sight base or the front trunnion, which ever is easier for you to do. Next, lube the barrel pin and drive it in from the left to the right as viewed from the rear of the rifle. Double check that the sights are still aligned. Now mount all parts and test for functioning. The hammer and trigger pins should pass through the parts and receivers holes and be flush or a little past flush with the right side of the receiver. Make sure that the safety sear catches the hammer if the trigger is held back and the bolt assembly cycled. Failure of the sear to catch will result with the rifle firing with an unlocked bolt.

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 5 of 7

Mount the magazine and verify that it will lock up with little or no sideways play. Did it move upward enough? If not, slightly trim the lower right rail. A small amount will be all that is needed to remove from this rail. Once done the rifle should be ready to test fire. If you can, run home made dummy rounds through the rifle. Did the ejector work? Is the ejector too wide? If so note the shape of the ejector and trim the edge back just a bit. Do not remove too much or the rifle will not function and jamb when fired. Youll be able to cycle the bolt carrier and see the ejector pass through the bolt face.

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 6 of 7

The ejector must strike the rim of the fired case. Before you test fire the rifle, make sure the top cover is a tight fit. If too long trim the front edge just a bit. Make sure the bore is clean and all cutting debris is removed from the receiver before test firing the rifle. Load one round only into the magazine and cycle the bolt letting the spring close the bolt. Hold the rifle away from your face. Shooting glasses are a must. Fire the rifle. The case should be ejected and the bolt should go forward again and lock on an empty chamber. If it did not, and you are using a normal type magazine, you will need to trim the top rails just a bit. Use a Dremel tool or Swiss needle files for this trimming. Retrieve the fired case and look closely at the shoulder area of the fired case. Compare this fired case to a live round. Is the shoulder the same? If it looks as if the shoulder has moved forward, do not fire the rifle again. The head space is way off and could damage the rifle or you. If your parts came as a kit, the bolt and front trunnion should be matched. Never mix parts unless you feel you can head space the rifle safely. If all is well, you now have your own home made AK rifle! All that is left to do is to place a finish on the rifle. To place a good hard coating on the rifle, I will be applying DuraCoat. This product comes in many colors and is easy to do if you follow the instructions to the T . The rifles parts surfaces should be roughed up first with sand paper or glass bead blasting. The most important step is to clean the rifles parts. Brake cleaner followed by acetone works very

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

From Soup to Nuts Part V: Building an AK-47 Receiver - Surplusrifle.com

Page 7 of 7

well for this step. Use rubber gloves from now on when handling the rifle. An air brush will be needed. A HVLP sprayer can also be used. Harbor Freight has air brushes for less than 10 bucks. However you provide the air to the air brush it must be dry air. Moisture will cause lumps in the surface of the coating. Mix the epoxy coating as per instructions and apply in a thin layer. Keep the air brush moving at all times. Build up several thin coats over several hours time. The coating takes a long time to cure so there is no need to rush. Let the coating dry for at least two hours before you touch it. DuraCoat will not prevent the rifle from working normally. If you can, bake the rifle parts in an oven set to 250-300 Degs for several hours. This will speed the curing time. Other wise, let the rifle set for two weeks. Rushing to shoot the rifle sooner than that will result in a poor finish. There you have it. From soup to nuts on building you very own semi-auto AK clone. Make sure to follow all state and federal laws on compliant parts and magazine capacities. Be safe and enjoy your new rifle! Venders for AK kits, parts, and tools: AIM Surplus rifles DPH ARMS JIGS K-var AK parts Gunco.net Classifieds AK-Builder.com - Content AK47.NET AK Files GunThings.com, Military Small Arms Parts Headquarters! FNFAL, L1A1, 1919, AK, Galil Century International Arms Interordnance Lauer Weaponry (DuraCoat) Surplus Firearms Parts & Accessories Article by Rob Summerhill (RapidRob) Adobe PDF Downloadable Version of Article

http://www.surplusrifle.com/shooting2005/souptonuts5/index.asp

10/13/2005

Вам также может понравиться

- АК туториалДокумент63 страницыАК туториалLucas Gabriel100% (2)

- Soup To Nuts 4Документ17 страницSoup To Nuts 4CGROSBECK100% (2)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunОт EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunОценок пока нет

- Threading A Barrel For A Muzzle Brake or orДокумент4 страницыThreading A Barrel For A Muzzle Brake or orJohnn Schroeder100% (1)

- Practical Guide to the Operational Use of the UZI Submachine GunОт EverandPractical Guide to the Operational Use of the UZI Submachine GunОценок пока нет

- RPD Build - Red Neck EngineerДокумент6 страницRPD Build - Red Neck EngineerDale Wade67% (3)

- Sterling Build V2Документ16 страницSterling Build V2Nester Tovar100% (2)

- Grasshopper Ak-47 Jig GuncoДокумент5 страницGrasshopper Ak-47 Jig Guncoterrencebelles100% (2)

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsОт EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsРейтинг: 5 из 5 звезд5/5 (3)

- The AK Short Throw TriggerДокумент6 страницThe AK Short Throw TriggerAdam Hemsley100% (1)

- Stamped and Milled AK Receiver Identification - From UltiMAKДокумент4 страницыStamped and Milled AK Receiver Identification - From UltiMAKblowmeasshole1911100% (4)

- AK-47, AK-74 Headspace ChecksДокумент4 страницыAK-47, AK-74 Headspace ChecksNormОценок пока нет

- AK Bolt Gap SetupДокумент22 страницыAK Bolt Gap SetupAdam Hemsley100% (2)

- AK BuildДокумент185 страницAK BuildSteven W. Ninichuck100% (6)

- AK47 Parts Check ListДокумент1 страницаAK47 Parts Check ListChris Furlong100% (2)

- Build Your Own AKДокумент7 страницBuild Your Own AKKarl_Town86% (7)

- Print - How To Build An AK-47Документ8 страницPrint - How To Build An AK-47Lord Ellam100% (5)

- Build An AK 47 PDFДокумент36 страницBuild An AK 47 PDFwienslaw580480% (15)

- MAX1045 ManualДокумент13 страницMAX1045 Manualbrowar444100% (1)

- Ak47 All in OneДокумент16 страницAk47 All in OneNazar Naz100% (1)

- Lightning Link Printable Template V1.0Документ5 страницLightning Link Printable Template V1.0Luis Carlos Martinez100% (1)

- Lightning Link Plans (For The AR-15 Rifle)Документ8 страницLightning Link Plans (For The AR-15 Rifle)anthony100% (1)

- AK-47 BuildДокумент105 страницAK-47 BuildProfessor100% (1)

- AK Receiver BendingДокумент14 страницAK Receiver BendingAdam Hemsley67% (6)

- Takedown and Cleaning An AK47Документ28 страницTakedown and Cleaning An AK47Daniel Nieves100% (2)

- 50 Cal PlansДокумент24 страницы50 Cal PlansClint Muldoon100% (10)

- Trigger Slap and Doubling Trouble ShootingДокумент8 страницTrigger Slap and Doubling Trouble ShootingAdam Hemsley100% (2)

- Virgin Build AK-47 Yugoslavian M70AB2 Stamped Receiver Yugo M70 AB2Документ50 страницVirgin Build AK-47 Yugoslavian M70AB2 Stamped Receiver Yugo M70 AB2scout50100% (1)

- BarrelДокумент1 страницаBarrelNO2NWO100% (2)

- Blueprints To Build A Mark II Sten GunДокумент25 страницBlueprints To Build A Mark II Sten GunKawchhar AhammedОценок пока нет

- 级触发自动武器 PDFДокумент15 страниц级触发自动武器 PDFJin SongОценок пока нет

- AR15 Barrel Nut IndexingДокумент1 страницаAR15 Barrel Nut IndexingMike Nichlos100% (3)

- Blueprints PPSH41 Yugo49-57 American180 Browning1919Документ7 страницBlueprints PPSH41 Yugo49-57 American180 Browning1919Mika100% (2)

- Io Inc January 2016 News Press ReleaseДокумент4 страницыIo Inc January 2016 News Press Releaseapi-242710584Оценок пока нет

- Uzi Barrel TrunionsДокумент4 страницыUzi Barrel TrunionsNester Tovar50% (2)

- Building An AR-70 Full AutoДокумент28 страницBuilding An AR-70 Full AutoJosiah JohnsonОценок пока нет

- Uzi Receiver Blueprints AaДокумент7 страницUzi Receiver Blueprints AaMamoun Kh Omari100% (2)

- Cetme FlatДокумент15 страницCetme Flatjohnoneal0% (2)

- AK-47 Select Fire Full-Auto ConversionДокумент16 страницAK-47 Select Fire Full-Auto Conversion(Administrator)100% (10)

- Type 2 & Type 3 AK-47Документ6 страницType 2 & Type 3 AK-47scout50100% (1)

- PPs Semi-Auto FCGДокумент5 страницPPs Semi-Auto FCGangelines12375% (8)

- AKM 47 ReceiverДокумент7 страницAKM 47 ReceiverMika100% (6)

- Jaco DerringerДокумент4 страницыJaco DerringerFunkpiratОценок пока нет

- Lower Guide Drill JigДокумент5 страницLower Guide Drill Jigwiccanways100% (1)

- Polymer80: Phoenix Version - G150 80% Lower Receiver InstructionsДокумент13 страницPolymer80: Phoenix Version - G150 80% Lower Receiver InstructionsTimothy ScottОценок пока нет

- Bolt Together AR15 Lower ReceiverДокумент0 страницBolt Together AR15 Lower ReceiverLogicIndustriesLLC100% (1)

- My 3D Printed CETME and HK G3 Bending JigДокумент6 страницMy 3D Printed CETME and HK G3 Bending Jigamacman100% (2)

- Uzi Family DiagramsДокумент7 страницUzi Family DiagramsAna Carolina100% (1)

- Vepr Bullet Guide IntstallДокумент2 страницыVepr Bullet Guide IntstallTawnee Rae HallОценок пока нет

- 2008-11!23!233015 Receiver Template 7 SimplifiedДокумент1 страница2008-11!23!233015 Receiver Template 7 Simplifiedpalaciosro100% (2)

- CZ 805bren A1Документ19 страницCZ 805bren A1deckahmОценок пока нет

- Colt AR-15 Rifle Lightning LinkДокумент5 страницColt AR-15 Rifle Lightning Linkelvergonzalez1100% (2)

- TesmaДокумент123 страницыTesmaexcic2000121Оценок пока нет

- SF 3.3 Reflections On Spiritual Warfare by Dean ShermanДокумент7 страницSF 3.3 Reflections On Spiritual Warfare by Dean ShermaneltropicalОценок пока нет

- Times Leader 07-28-2013Документ83 страницыTimes Leader 07-28-2013The Times LeaderОценок пока нет

- Odyssey Unit PlanДокумент36 страницOdyssey Unit PlanAlan Florence100% (1)

- Figure 1. The VT Fuse As Used For Antiaircraft Fire and Against Protected Enemy PersonnelДокумент6 страницFigure 1. The VT Fuse As Used For Antiaircraft Fire and Against Protected Enemy PersonneljamesfletcherОценок пока нет

- The Colditz Cock Prison Escape GliderДокумент9 страницThe Colditz Cock Prison Escape Glider18912170Оценок пока нет

- KrasnovДокумент5 страницKrasnovsmashthecommienwoОценок пока нет

- Notes On Soviet Montage Including A Short Analysis of Eisenstein's StrikeДокумент12 страницNotes On Soviet Montage Including A Short Analysis of Eisenstein's Strikestyleform100% (4)

- Stamp Magazine June 2020Документ76 страницStamp Magazine June 2020codriver69100% (1)

- Full Thrust Star Wars PDFДокумент79 страницFull Thrust Star Wars PDFDoktor Avalanche100% (1)

- FeatherweightДокумент2 страницыFeatherweightBubba GaunceОценок пока нет

- Air Force News Jul-Dec 1922Документ292 страницыAir Force News Jul-Dec 1922CAP History LibraryОценок пока нет

- Defib - Dying Light #2Документ22 страницыDefib - Dying Light #2DocAnonОценок пока нет

- USA002573-20 ICR - 2020 - WebДокумент184 страницыUSA002573-20 ICR - 2020 - Webakomp.support100% (1)

- Shinsengumi in Fact and FictionДокумент37 страницShinsengumi in Fact and FictionDasimen100% (1)

- Rizal Concept PaperДокумент4 страницыRizal Concept PaperEJMRA67% (3)

- Danial Brundige (Order #1510026)Документ130 страницDanial Brundige (Order #1510026)reaper696986% (7)

- Glazyev Sergei - The Last World War - The US To Move and LoseДокумент501 страницаGlazyev Sergei - The Last World War - The US To Move and LoseO S100% (1)

- WWI Document-Based Question (TEACHER ANSWER KEY)Документ6 страницWWI Document-Based Question (TEACHER ANSWER KEY)Macky GonzalesОценок пока нет

- SNEAK PEEK: 21st Century Mahan: Sound Military Conclusions For The Modern EraДокумент19 страницSNEAK PEEK: 21st Century Mahan: Sound Military Conclusions For The Modern EraNaval Institute Press100% (4)

- United States v. Bin Laden - Day 4 TranscriptДокумент124 страницыUnited States v. Bin Laden - Day 4 TranscriptRobert ValeОценок пока нет

- FFG Star Wars Reference PDFДокумент26 страницFFG Star Wars Reference PDFAndrew RicketОценок пока нет

- Consolidation of Nazi Power 1933-1934Документ2 страницыConsolidation of Nazi Power 1933-1934Dafydd Robert HumphreysОценок пока нет

- Bucket List EssayДокумент8 страницBucket List Essaydunqfacaf100% (2)

- Messerschmitt BF 110EДокумент16 страницMesserschmitt BF 110EHarold Clements100% (1)

- BS BuzzДокумент8 страницBS BuzzBS Central, Inc. "The Buzz"Оценок пока нет

- TM 11-5820-667-12Документ111 страницTM 11-5820-667-12alexportmanОценок пока нет

- The Old Man On The Bridge - Reading CompДокумент4 страницыThe Old Man On The Bridge - Reading CompwrayspОценок пока нет

- MilestonesДокумент6 страницMilestonesprofessionalgrieferОценок пока нет

- Women of The Weeping River Reaction PaperДокумент8 страницWomen of The Weeping River Reaction PaperLliyah Nicole M. MangawangОценок пока нет

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 4.5 из 5 звезд4.5/5 (285)

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 5 из 5 звезд5/5 (1)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!От EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Рейтинг: 4 из 5 звезд4/5 (4)

- SuppressorsОт EverandSuppressorsEditors of RECOIL MagazineОценок пока нет

- Precision Rifle Marksmanship: The Fundamentals - A Marine Sniper's Guide to Long Range Shooting: A Marine Sniper's Guide to Long Range ShootingОт EverandPrecision Rifle Marksmanship: The Fundamentals - A Marine Sniper's Guide to Long Range Shooting: A Marine Sniper's Guide to Long Range ShootingРейтинг: 3.5 из 5 звезд3.5/5 (4)

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)От EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Рейтинг: 3.5 из 5 звезд3.5/5 (2)

- Book of Glock: A Comprehensive Guide to America's Most Popular HandgunОт EverandBook of Glock: A Comprehensive Guide to America's Most Popular HandgunРейтинг: 5 из 5 звезд5/5 (1)

- Prepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideОт EverandPrepared: The 8 Secret Skills of an Ex-IDF Special Forces Operator That Will Keep You Safe - Basic GuideРейтинг: 5 из 5 звезд5/5 (9)

- Gun Digest's Principles of Jeff Cooper Defensive Handguns eShort: Jeff Cooper’s color-code system give you the edge in defensive handgun shooting accuracy & technique. Learn essential handgun training drills, tips & safety.От EverandGun Digest's Principles of Jeff Cooper Defensive Handguns eShort: Jeff Cooper’s color-code system give you the edge in defensive handgun shooting accuracy & technique. Learn essential handgun training drills, tips & safety.Рейтинг: 4.5 из 5 звезд4.5/5 (2)

- Shooter's Bible Guide to Firearms Assembly, Disassembly, and CleaningОт EverandShooter's Bible Guide to Firearms Assembly, Disassembly, and CleaningРейтинг: 3 из 5 звезд3/5 (2)

- The Wind Book for Rifle Shooters: How to Improve Your Accuracy in Mild to Blustery ConditionsОт EverandThe Wind Book for Rifle Shooters: How to Improve Your Accuracy in Mild to Blustery ConditionsРейтинг: 5 из 5 звезд5/5 (1)

- The Duck Commander Family: How Faith, Family, and Ducks Built a DynastyОт EverandThe Duck Commander Family: How Faith, Family, and Ducks Built a DynastyРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Designing and Forming Custom Cartridges for Rifles and Handguns: Custom CartidgesОт EverandDesigning and Forming Custom Cartridges for Rifles and Handguns: Custom CartidgesОценок пока нет

- Pistol Shooting Sports: A Beginner's Guide to Practical Shooting CompetitionОт EverandPistol Shooting Sports: A Beginner's Guide to Practical Shooting CompetitionОценок пока нет

- Happy, Happy, Happy: My Life and Legacy as the Duck CommanderОт EverandHappy, Happy, Happy: My Life and Legacy as the Duck CommanderРейтинг: 5 из 5 звезд5/5 (39)

- Practical Guide to the Operational Use of the DShK & DShKM Machine GunОт EverandPractical Guide to the Operational Use of the DShK & DShKM Machine GunОценок пока нет

- The Illustrated Directory of Guns: A Collector's Guide to Over 1500 Military, Sporting, and Antique FirearmsОт EverandThe Illustrated Directory of Guns: A Collector's Guide to Over 1500 Military, Sporting, and Antique FirearmsРейтинг: 4 из 5 звезд4/5 (5)

- The Complete Guide to Gunsmithing: Gun Care and RepairОт EverandThe Complete Guide to Gunsmithing: Gun Care and RepairРейтинг: 3 из 5 звезд3/5 (6)

- AR-15 Skills & Drills: Learn to Run Your AR Like a ProОт EverandAR-15 Skills & Drills: Learn to Run Your AR Like a ProРейтинг: 5 из 5 звезд5/5 (1)

- Ray Eye's Turkey Hunting Bible: The Tips, Tactics, and Secrets of a Professional Turkey HunterОт EverandRay Eye's Turkey Hunting Bible: The Tips, Tactics, and Secrets of a Professional Turkey HunterОценок пока нет