Академический Документы

Профессиональный Документы

Культура Документы

A Six Band HF Antenna

Загружено:

Tariq RahimИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Six Band HF Antenna

Загружено:

Tariq RahimАвторское право:

Доступные форматы

A Six Band HF/VHF Dipole Antenna for Portable Operation

By Gary L. Auchard WB0MNA January 15, 2004 With the advent of popular low power HF/VHF all mode portable radios like the Yaesu FT-817, Icom IC-703, SGC SG-2020 and other similar models, the opportunities for operating from remote locations has risen dramatically. Any radio system is only as good as its antenna system, and when packing equipment into remote locations weight and size become important issues. This article describes a multiband dipole style antenna that can be made to operate on any of six bands and be assembled/disassembled in only a few minutes, while taking up only a small amount of space in your portable radio kit. The bands it will cover are 6, 10, 12, 15, 17 and 20 meters. The formula for the antenna design is taken directly from the ARRL Antenna Handbook and follows the theory of operation for a half wave dipole. To minimize weight and bulk, the traps needed to make a single antenna work over a broad range of frequencies have been eliminated. In their place, I have made adjustable links in the radiating element to allow for setting the antenna to a particular band. This eliminates the need for resoldering or cutting new lengths of wire to make the antenna resonant on a different band at a later time. Another consideration of the design was overall cost and ease of acquiring building materials. Everything needed to build this antenna can be found in a well-stocked junk box, purchased at a hardware store, Radio Shack or your favorite ham dealer. The antenna consists of a center insulator, 12 in-line insulators/links, hardware, #18 AWG multi stranded wire and RG-58 Coaxial cable. The connectors used on the coaxial cable will be determined by what your operation is set up for. I choose a 25-foot piece of RG-58 coaxial cable with male BNC connectors on each end. The coaxial cable came from an old computer networking kit that was no longer used. A simple BNC to PL-259 adaptor on one end allows me to use either the rear or front antenna connector on my Yaesu FT-817 radio. The other end of the coaxial cable with the BNC connector on it connects to the center insulator of the antenna via a female chassis mount BNC connector built into the insulator. This arrangement allows for breaking down the antenna system to its smallest form for packing and storage. The lengths of wire chosen in this design are set for the SSB portions of the bands. In most cases the antenna is broad banded enough to allow for operation across the full band with an SWR of 1.5 1 or less without any adjustment. Any finer tuning of SWR can be accomplished by the use of an antenna tuner, but the antenna design was meant to work without the need for a tuner. If you want to operate in the CW portions of the 15 and 20 meter bands, you can hang a short piece of wire on the ends of those band segments to

lower the resonant frequency, or make a piece long enough to lower the resonant point for a specific band in place of the length selected for the SSB portion. This antenna design is not really meant for permanent installation where it could be exposed to ice and other harsh weather elements for a long period of time. It can be made to operate in that manner by substuting copper clad steel wire for the radiating element, stainless steel hardware and RTV sealant in several places to keep water out. The copper clad steel wire was not chosen for this portable system due to its difficulty in packing into a small space, and the stainless steel hardware was not chosen due to cost.

Building the antenna

To build this antenna, start by cutting two each of the #18 AWG wire into the following lengths: 48 40 12 16 19 41

Then trim off inch of insulation on each end of the wires. Solder a 22-18 AWG, 8-10 stud ring terminal on one end of each wire. Slip 2 pieces of 1/8 inch heat shrink tubing 1 inch long on to each wire. Slide one piece of tubing up to the edge of the plastic part of the ring terminal, then slightly heat the end closest to the plastic just enough to allow it to slide inside of the plastic on the ring terminal. Let the tubing cool for a second or two before trying to slide it inside the plastic. Be careful not to melt the plastic on the ring terminal. Once that is in place, heat the rest of that piece of tubing until it forms around the wire tightly. Next, slip the second piece over the first piece and do the same thing. The heat shrink tubing was added to minimize the flexing on the ring terminal and prevent breakage of the wire at the terminal ends due to normal use. You can pull the plastic off of the ring terminals with a pair of needle nose pliers. Use a 3/32 inch drill bit to enlarge the inside dimensions of the plastic so it will fit over the wire. Remember to slip the plastic over the wire before you solder the ring terminal. Once the ring terminal is cool you can slip the plastic back on it and then move the heat shrink tubing up an in place. Once you have a ring terminal and the heat shrink tubing on one end of each wire, select the 48 inch pieces of wire and slip a single 1/8 inch by inch long piece of heat shrink tubing onto each wire. Slide the tubing up near the ring terminal end leaving approximately inch spacing from the other tubing and heat it until it tightens on the wire. The purpose of this piece of tubing is for identifying each length of wire during

final antenna assembly without the need for a ruler. This tubing mark will identify the two 48 inch pieces of wire as being the first section installed on each side of the center insulator. On the next section of wires you will install two inch pieces of tubing to denote these pieces as being the second section installed and so on. After you have performed the marking step, slip two more pieces of 1/8 inch by 1-inch heat shrink tubing on the first two pieces of wire. Solder another ring terminal on the free end of the wire and repeat the process of shrinking the two pieces of tubing on that end of the wire near the terminal. The next steps will be to repeat the same process performed on the first two pieces of wire until all of the antenna sections are finished with a ring terminal on each end, heat shrink tubing and marking rings on each piece. Build and mark the wires in the order they are listed above, top to bottom. This will complete the wire portion of the radiating element construction. Dont forget to add 2 marking rings to each piece in the second set, then 3 in the third set and so on before you solder the last ring terminal on each wire segment. The next step will be to construct the in-line insulators. The material used here can be varied based upon what your have handy or can find in the hardware store. I used a piece of inch thick Plexiglas I had in my junk box. Marked out 12 pieces with the dimensions of inch by 2 inches, then carefully cut them on a band saw. Next drill a 11/64 inch hole in each piece 3/8 inch in from both ends. The hole needs to be large enough to accommodate an 8-32 x inch machine screw. Place a machine screw in each hole followed by a #8 flat washer on the opposite side of the plastic from the head of the screw, followed by an 8-32 hex nut. Place 2 more #8 flat washers followed by an 8-32 type A wing nut on each screw. Cut 10 two inch pieces of the #18 AWG wire, strip off inch of insulation from each end and solder a ring terminal to each end. These short pieces of wire will go on the two machine screws of each insulator. They are used to short or open the connection across each in-line insulator. On two of the insulators only install 1 machine screw. The remaining hole will be used to accommodate a piece of #14 AWG solid wire formed into a loop so a rope can be attached to support the ends of the antenna when fully assembled. This completes construction of the in-line and end insulators. The center insulator is made from the same inch thick Plexiglas or whatever suitable material you have. I made my center insulator in a triangle shape with the sides being about 3 inches long. Slightly round off each point of the triangle, then drill a hole on two of the points large enough to accommodate an 8-32 x inch machine screw followed by a #8 flat washer on the side of the plastic opposite the head of the screw, followed by an 8-32 hex nut, two more #8 flat washers and a 8-32 type A wing nut. A third hole inch in diameter can be drilled evenly spaced between these first two holes. This hole will serve as an attachment point for a rope to elevate the antenna from the center insulator if desired.

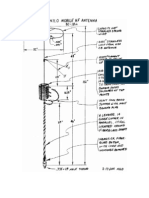

How you attach the coaxial cable will vary based on what you are comfortable with. If you want to permanently attach the coaxial cable to the center insulator, drill a 5/16-inch hole in the third point of the triangle inch in from the tip. Thread the coaxial cable through the hole about 6 inches, loop back in a U shape and place a tie-wrap around the coaxial cable leaving enough slack for the cable to flex. Carefully split the coaxial cable shield and center conductors apart about 4 inches. Attach the shield to one of the machine screws and the center wire to the other machine screw by soldering a ring terminal on the shield and center wire so they will securely attach over the machine screws. The method I used for attaching the coaxial cable to the center insulator required more work and time. Its only advantage is to break the antenna down to a slightly smaller package for transportation. For further clarification on any step, view the attached pictures. The final step is to assemble the pieces and test the antenna.

Setup and Operating

Start with the center insulator. Attach the two pieces of wire with a single marker, one on each side of the insulator by removing the wing nut and one flat washer. Place the ring terminal over the 8-32 machine screw, then reinstall the flat washer and wing nut. Tighten the wing nut snugly. On the other end of the first two wires, attach an in-line insulator in the same manner. On the opposite end of those in-line insulators attach the next two pieces of wires with the two markers on them and follow up with another in-line insulator on the outer ends. Continue this pattern until all of the wires are attached. On the end of the final set of wires, attach the insulator with only one machine screw and the piece of #14 AWG wire. The next step is to decide on the method of elevating the antenna. For optimal results the antenna should be at least one half wavelength above the ground for the lowest frequency youre going to operate on. In this case, if youre planning to operate on 20 meters, you need to be 33+ feet above the ground if possible. Placing the antenna too close to the ground will have adverse affects on its performance by changing the SWR, impedance and radiation pattern. Before you elevate the antenna, chose which band you want to operate on. If you elect to operate 6 meters for example, remove the in-line jumper wire from the first insulator out from the center insulator. Remove the jumper wire from the end closest to the outer end of the radiating element youre going to be using. Just point the jumper wire up out of the way so it cannot make contact with the machine screw you just removed it from. Now elevate the antenna to its operating position.

If you like, you can test the antenna for resonance before trying to transmit by attaching a test meter like the MFJ259 or MFJ269 to the coaxial cable. This will give you a good idea of the resonant frequency the antenna is set for, and the impedance and bandwidth of safe SWR you have available to use. As stated earlier, the antenna wire lengths are cut for the SSB portions of the band on 6, 10, 12, 15, 17 and 20 meters. The antenna can safely work across the full 6, 10, 12 and 17-meter bands with an SWR of 1.5 1 or less. On the 15 and 20 meter bands, you can attach a short piece of wire to the ends of those band segments and let it hang straight down to lower the resonant point into the CW portions of the band if desired. The alternative is to use an antenna tuner, which will add bulk and weight to your overall portable station kit. If everything looks good, attach your radio and start making contacts. While this antenna will not equal the forward gain of a tuned beam antenna, it will radiate effectively and allow your radio to operate safely and correctly for its designed load. Cutting different lengths of wire for each segment can make variations of the bands covered by this antenna. For example, you may only want to build a 10, 15, 17 and 20meter dipole antenna. In those cases a little experimentation with a MFJ259 antenna analyzer will help you find the final length for each segment. Start with the formula for calculating the length of a 1/ 2 wave antenna, which is 468 divided by the frequency in megahertz. This will result is a length measurement in feet with a center insulator in the middle of the wire. Be sure to elevate the antenna a half wavelength above the ground to avoid ground effects when testing. As a side note, it always helps to carry a few extra pieces of the hardware to replace those that somehow seem to find a new home in the grass or dirt at your operating site. This antenna will break down and comfortably fit into a 1 gallon size zip lock freezer bag with the coaxial cable and support ropes included. That makes it easy to carry in a backpack or portable operating kit and weighs about 1 pounds. Have fun with the antenna and enjoy making many fun and challenging contacts from the boonies.

Parts List

24 each 8-32 x inch machine screws. Westlake Ace Hardware - P/N 111723 24 each 8-32 Hex nuts. Westlake Ace Hardware - P/N 140018 72 each #8 Flat washers. Westlake Ace Hardware - P/N 280052 24 each 8-32 Type A wing nuts. Westlake Ace Hardware P/N 180240 46 each Ring terminals, 22-18 AWG, 8-10 Stud. Westlake Ace Hardware P/N 34539 Ring terminal alternate slightly heavier duty, 16 14 AWG, 8-10 Stud. Westlake Ace Hardware P/N 34542

Plexiglas 12x 12x . 50 75 feet of #18 AWG stranded insulated wire. 6 feet of 1/8 heat shrink tubing. 2 tie wraps. 25 50 feet of RG-58 coaxial cable. Connectors for fit your radio, most likely PL-259 with adapter. 50 feet of rope to elevate the antenna. Solder and 60 watt soldering iron.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Technician License Class Study Guide - ARRLДокумент21 страницаTechnician License Class Study Guide - ARRLpavan_jssateb100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- SGC SG-230 Smart TunerДокумент81 страницаSGC SG-230 Smart TunerRuthCdhara100% (1)

- Transmission Lines (Blake C14) : True/FalseДокумент6 страницTransmission Lines (Blake C14) : True/FalseLovely Eulin FulgarОценок пока нет

- BTS3900 Spare Parts Catalog (09) (XLS) - enДокумент30 страницBTS3900 Spare Parts Catalog (09) (XLS) - enZahid MehboobОценок пока нет

- Manual For Triaxial NetworksДокумент180 страницManual For Triaxial NetworksMiguel AngelОценок пока нет

- 2010 Catalogo 5968-4314ENДокумент78 страниц2010 Catalogo 5968-4314ENClenaОценок пока нет

- TC L42e5h Oi PDFДокумент172 страницыTC L42e5h Oi PDFJohn ForeroОценок пока нет

- LDF4 50aДокумент5 страницLDF4 50aDamar Lukito WahyudiОценок пока нет

- BIT2204 Introduction To Data Communication and Computer Networks PDFДокумент83 страницыBIT2204 Introduction To Data Communication and Computer Networks PDFbarton267% (3)

- L Com 14 CoaxialДокумент40 страницL Com 14 CoaxialAsadОценок пока нет

- Panamax Max 5100-EX Owner's GuideДокумент12 страницPanamax Max 5100-EX Owner's Guideshawn174100% (3)

- Instructions For Dish Network Dish Pro Plus InstallationДокумент25 страницInstructions For Dish Network Dish Pro Plus InstallationJake MastersОценок пока нет

- Digsilent Powerfactory: Technical Reference DocumentationДокумент23 страницыDigsilent Powerfactory: Technical Reference DocumentationDong BachОценок пока нет

- UNIT I Microwave Transmission LinesДокумент60 страницUNIT I Microwave Transmission Lineskasireddy saibhargaviОценок пока нет

- Transmission Lines Circuit Board Thevenin EquivalentsДокумент17 страницTransmission Lines Circuit Board Thevenin EquivalentsWaelBazziОценок пока нет

- Antena Movil HFДокумент10 страницAntena Movil HF10sd156100% (1)

- Unit 4 Communication Mediums: 4.0 Digital Data TransmissionДокумент14 страницUnit 4 Communication Mediums: 4.0 Digital Data TransmissionNilesh SawantОценок пока нет

- Multi-Turn LoopsДокумент6 страницMulti-Turn LoopsFernando PimentaОценок пока нет

- SIEMENS - IWLAN Making The Most AirДокумент8 страницSIEMENS - IWLAN Making The Most AirJorge_Andril_5370Оценок пока нет

- Simple Dipole For 2m Band v11Документ11 страницSimple Dipole For 2m Band v11fox7878Оценок пока нет

- Computer Communication Networks Lab (R4ET3005P)Документ21 страницаComputer Communication Networks Lab (R4ET3005P)Joshua DsouzaОценок пока нет

- Telecommunications & NetworksДокумент58 страницTelecommunications & NetworksMohan singhОценок пока нет

- AeroWave 100 Active Pricing R3 2 18 16Документ1 страницаAeroWave 100 Active Pricing R3 2 18 16josue jetavionicsОценок пока нет

- Determine Best-Fit Topology Transmission MediaДокумент49 страницDetermine Best-Fit Topology Transmission MediaBekaОценок пока нет

- KEI" Single Core Compacted Aluminium & Copper Conductor, XLPE Insulated, Unarmoured & Armoured Cable AL & CU / XLPE / AL Wire / PVC Conforming To IS 7098 Part-2/1985Документ2 страницыKEI" Single Core Compacted Aluminium & Copper Conductor, XLPE Insulated, Unarmoured & Armoured Cable AL & CU / XLPE / AL Wire / PVC Conforming To IS 7098 Part-2/1985Wires Cable0% (1)

- 991 Thrust Transmitter: Bently Nevada Asset Condition MonitoringДокумент12 страниц991 Thrust Transmitter: Bently Nevada Asset Condition MonitoringJosé Luis Ríos GuerraОценок пока нет

- ACS 50 User S GuideДокумент20 страницACS 50 User S GuidelupelupeОценок пока нет

- Comparison Between Network Topologies PDFДокумент2 страницыComparison Between Network Topologies PDFNikhil Gobhil100% (1)

- Broadband Drop CableДокумент28 страницBroadband Drop CableAngel LopezОценок пока нет

- SRPT 30 and SRPT 40A RPU Transmitters ManualДокумент48 страницSRPT 30 and SRPT 40A RPU Transmitters ManualMiguel Angel Cara RiosОценок пока нет