Академический Документы

Профессиональный Документы

Культура Документы

Recent Innovations in Paper Recycling Flotation)

Загружено:

kayee516Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Recent Innovations in Paper Recycling Flotation)

Загружено:

kayee516Авторское право:

Доступные форматы

Recent innovations i paper recyCling n

Peter Seifert

ABSTRACT: From mdnyprocess steps inpaper reqcling ystems, two

have been selectedfir diswsion, name& washing deinking and fitation deinking Recent innovations aTe reviewed in the context of the basic mechanisms responsiblef i r the&nctzoning of these machines. An u p h e is ab0 givenfir their application in the processing of used oficepapers.

KEywoRDs.. Concentrators, denking,fitation, fitation md-

ws i g a hn

Ink removal systems have two hearts: flotationand washing. They commonly deal with ink particles in different size categories, as illustrated in Fig. 1. Washing is effective for very small particles (10-20 microns) and below, which is a size not visible to the naked eye. Flotation addresses the next larger group of particles and, subsequently, so do cleaning and finally screening. Washing to remove small particular contaminants from recovered paper goes back to the 1950s and 1960s, where the literature describes use of deckers (l),side hill screens (Z), paper-machine-type washers (3), and screw thickeners (4). Today, a tissuemachine-style washer by Sulzer Escher Wyss is in use (5) and a new device by Black Clawson-the DNT washer (6-8). This latter unit (Fig. 2) is certainly not a paper-machine-style washer. It consists of an endless wire mesh loop,which travels at high speed around only two rolls; the slurry is injected and stays on the inside surface of this loop. A sheet is not formed because the first roll has deep grooves, causing pulp to thicken in the form of strips. These strips stay on the wire mesh, go around the second roll, separate from the wire to follow the roll surface, and are doctored off for discharge. There is no way that a sheet of paper is formed in this machine, and, even if it were, it could not be guided out of the loop. The great advantage of such a twostage washer lies in the very high percentage of feed water that is rapidly removed and the small proportion that

Vol. 77, No. 2 Tappi Journal

chines, reqcling, sepurutors, solid wastes, washm, wasbing, waste papers.

ncreased paper recycling is on parameters are truly important to obmany peoples minds and has be- tain maximum benefit. The user then come an accepted reality. Significant can make better decisions on which capacity increases have been realized equipment to employ or how to better in recycling of old corrugated contain- use machinery that he or she already ers for brown grades, mixed waste re- has. My company also is actively parcycling for multi-ply boards, and old newsprint reprocessing to make new ticipating in the evaluation and optimization of other new processes such newsprint. A new technological challenge lies as Recoupe steam explosion, oxygen in utilizing used office paper and up- bleaching of recovered paper, and aggrading it, by deinking, to tissue or glomeration technologyfor Xerox and even printing grades. Even in this field, laser-containingrecovered papers. In substantial tonnage already is being addition, we are developingnew pulpprocessed,but with significantpresort- ing technology and continuouslywork on improving cleaners for light and ing required. In this paper, I do not want to re- heavy dirt removal. These processes hash the entire deinking process phi- will be discussed at other times; space losophy and practice but, rather, simply does not allow me to cover all concentrate on a discussion of some the new technology here. Mere mensignificant, individual process steps. tion of them should help you to put My selection includes ink removal by into proper perspective the topics covwashing and by flotation.I plan to show ered in this paper. how these machinesfundion and which

Seiferf is vice president, research and product planning, for the Black Clawson Co., 605 Clark St., Middletown, OH 45042-0160.

149

1. Efficient removal of contaminants by particle size and conventional stock preparation process steps

2. Schematic of the Black Clawson DNT washer with pulp mat on inside surface of wire mesh IOOD

" Screening Cleaning Flotation Washing Filtrate

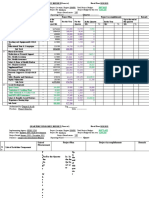

stays with the pulp. The discharge consistency ranges from 10% to 14%.Another factor responsible for the high washing efficiency is that the pulp strips are very thin. One measure of washing efficiency is the brightness gain of the pulp as small, invisible ink and dirt particles are removed; these particles normally would render the pulp gray. Naturally, some cellulose fines also are washed out, and often we try to minimize that loss. Figure 3 shows an example of ink removal from a pulp furnish containing flexo printed newsprint and magazine paper, a mix that does not respond well to deink flotation. Different deinking methods are used. Clearly, the DNT washer has the best brightness gain and also the best balance of brightness gain versus yield. Similarly,ash-i.e., inorganicfillers, clay, and coating particles-is removed, another measure of washing efficiency.Figure 4 shows an example of such results in a ledger processing tissue system. Just about 100 DNT washers are now operating.

3. Effect of different deinking treatments on brightness using a mix of 70% flexo printed

newsprint and 30% magazine paper. Starting brightness is 39 GE.

Flotation

Hydradenser Inclined screw Thickener 1.5 68

DNT washer 0.8 76

t4

t8

t12

t16

t20

BRIGHTNESSINCREASE

4. Ledger deinking, development of pulp brightness, and ash content in various process steps

BRIGHTNESS, GE

ASH, %

0

60 65 70 75 I

9 1

Flotation

Ink removal by flotation also started in the 1950swhen this technology was transferred to paper recycling from the mining industry. Since then, many solutions have been found to blow air bubbles into the pulp slurry to catch

Clarification

Dilution

Press

8

Micar disperser

0

Flotation

8

Fine cleaner

8

DNT washer

8

Post bleaching

150

February 1994 Tappi Journal

5. Schematic of the Black Clawson/llM flotator featuring very high rates of air introduction

6. Typical efficiency of flotator treatment for removal of contaminant particles by size for various applications

.

8

0

E 0

gH4aI

50

Visible

E a

TAPPI

100

200

300

Drain

Turbine

PARTICLE SIZE, prn

Accepts

I I

the hydrophobic ink particles (sometimes also stickies and clay) and carry them to the surface for removal as foam (9). Obviously,the more air introduced, the greater the ink removal, but there is a problem, namely turbulence and subsequent remixing of the ink contaminants. The common solutionto the problem is to use very little air (20% volumetricallyper stage, based on flow rate) and repeat the treatment in successive stages. Sometimes as many as six stages are used, rendering airaddition of 120% based on flow rate (IO, 11). Reference 10 includes an example for multistage treatment, an early design by my company,with cells stacked on top of each another. The concept recently has been revisited by others. Now we have licensed a new and different flotation cell developed in Japan. This design (12) has overcome the old barriers and operateswith only one large stage; it permits addition of huge quantities of air,6-10 times the volumetricpulp flow rate (600-1000%), without detrimental levels of turbulence. Figure 5 is a picture of the cell showing inlet and outlets for slurry, air manifold and mixers, and the foam discharge. The new flotator cell is operating commercially, treating a mix of news and magazine recovered paper in Japan and in North America. The brightness gain is on the order of 10-14 points

GE,very high by any standard (13). In another installation, the cell processes 100%old newsprint (not flexo printed), achievinga brightness gain of 8 points GE, almost double conventional cell 1 performance ( 3). The latter normally requires the presence of magazine papers to achieve acceptable brightness gains. More recently, a unit also has started on ledger-to-tissuedeinkingwith similarly good results, which are included in Fig. 6. When we brought a mobile pilot flotation unit into a paper mill, it was connected to treat the rejects from a primary conventionalflotation cell. No further chemicalswere added. S q r i s ingly, the fibers recovered from the new flotator had a higher brightness than the accepts of the conventional primary cell in operation in the mill. We attribute the overall good performance of this new flotation cell to the unique combination of high quantities of air,good mixing of the air, and suppression of detrimental turbulence.

Deinking of office waste

The deinking of office waste represents an additional challenge, namely the removal of small but visible particles of ink from xerographic and laser printed recovered papers. Apparently, these particles are sufficiently strong to survive the turbu-

lence in pulpers, pumps, and dispersers and remain in the pulp as very unsightly contaminants, not unlike spots of pepper. Combinationsof flotation and washing with other steps like centrifugal cleaning and dispersion are still the current commercial solution to this problem, and the selection of high-efficiency unit operations contributes to overall better success. Still, such dirt removal is a percentage matter, and as incoming waste varies in content and type of xerographic and laser printed materials,results also can vary. For this reason, we are active in the evaluation of other processes like Recoupe steam explosion (14) and ink agglomeration technology (15). The former relies on thickening pulp and then heating it for a short time under steam pressure to about 200C in a continuously operating pressure vessel. Discharge through a blow valve causes rapid flashing of the hot water (explosion)and a high dispersion effect, which reduces the heat softened contaminants to very small size and makes them removable by washing. In cooperation with Recoupe Technologies, Inc., we hope to offer this process to treat wastes that cannot be processed successfully and economically by conventional means. One completely different avenue is not to disperse but to agglomerate ink particles into fewer larger ones. These

Vol. 77, No. 2 Tappi Journal

15 1

larger particles may be removed by screening, flotation, or fine centrifugal cleaning. We are actively providing process equipmentand conducting pilot studies to test this technology.

Conclusions

Deinking is an important function in the recycling of a new raw materialoffice waste. Fine ink particles must be removed to raise the brightness, and larger visible ink particles from xerographic and laser printed waste require removal to improve appearance. A new two-stage washer was discussed and examples of its performance shown in terms of brightness gain and ash removal. Effectiveness of the washer must always be compared with overall yield, and examples of this also were given.

Single-stageflotationwith introduction of high quantities of air also has become a very effective tool for raising pulp brightness and for removing ink particles in the visible range. Several commercial and pilot results have been discussed that have air addition rates of 600-1000% in a single stage and produce exceptional results. Office waste contains Xerox and laser-printed papers which often produce unsightly pepper-like spots in the deinked pulp. This problem is addressed with combinations of flotation, dispersion, fine cleaning, and washing. Still, we are trying to further improve final quality by evaluating new technologies such the Recoupe steam explosion and the agglomeration technology. Ink removal is a very important part of recycling of secondary fiber for reuse in printing papers, and our

company is proud to offer contributions at the forefront of paper recycling development. m

Literature cited

1. Deinking of Waste Paper, Monograph No. 16, TAPPI, Atlanta, p. 134,1956. 2. Deinking of Waste Paper, Monograph No. 16, TAPPI, Atlanta, p. 135,1956. 3. Webster, Canadian pat. 614,901 (Feb. 21, 1961). 4. Horacek, R. G. and Matthew, J., Deinking Manual, Beloit Jones, Dalton, MA, 1978. 5. Linck, E., Mayr H., and Siewert, W. H., The Vario-Split (in German), Papiertechnische Stiftung, Munich, 1981. 6. Gilkey, M. and McCarthy, C., T M P I 1988 Pulping Conference Proceedings, TAPPI PRESS, Atlanta, p. 649. 7 . Seifert, P., TAPPI 1992 Pulping Conference Proceedings,TAPPI PRESS, Atlanta, p. 917. 8. Seifert, P., Kine, M. F., and Markham, L. D., U.S. pat. 4,722,793 (Feb. 2,1988). 9. Deinking of Waste Paper, Monograph No. 31, TAPPI, Atlanta, 1967. 10. Matzke,Das Papier 778-784(1976) (in German). 11. Cruea, R. D., et al., U.S. pat. 5,028,315 (July 2,1991). 12. Gilkey, M. and Yoshida, H., CPPA 1992 Annual Meeting Proceedings, Canadian Pulp and Paper Association, Montreal. 13. Gilkey, M., TAPPI 1991 Pulping Conference Proceedings,TAPPI PRESS, Atlanta, p. 1051. 14. Bouchette, M., U.S. pat. 5,122,228 (June 16,1992). 15. Woodward, T. W., Deinking Chemistry, Chemical Processing Aids, 1991.

Developments and insights such as the ones reported here are the result of work by our entire technical development and marketing teams and significantcontributionsby other companies with whom we cooperate, such as IIM of Japan, hs Recoupe, Betz, and others. T i fact should hereby be recognized, acknowledged, and stressed beyond a mere mention in the references. Received for review Feb. 4,1993. Accepted July 15,1993. Presented at the TAPPI 1993Papermakers Conference.

152

February 1994 Tappi Journal

Вам также может понравиться

- StickiesДокумент9 страницStickiesMarceloОценок пока нет

- Century Pul112Документ48 страницCentury Pul112Shubh Prakash TiwariОценок пока нет

- Grades of PaperДокумент25 страницGrades of PaperRohit SinghОценок пока нет

- FillersДокумент15 страницFillersRamesh SaatyaОценок пока нет

- Pulp and Paper PDFДокумент12 страницPulp and Paper PDFVishnu Prakash SinghОценок пока нет

- Hasil Review Maintenance Roll Calender MHV KusterДокумент5 страницHasil Review Maintenance Roll Calender MHV KusterrajapalasaОценок пока нет

- Pulpandpaperindustry 141230140617 Conversion Gate02Документ31 страницаPulpandpaperindustry 141230140617 Conversion Gate02Salman ShahzadОценок пока нет

- t580 D 3 Sarg With Editorial Corrections IncorporatedДокумент8 страницt580 D 3 Sarg With Editorial Corrections IncorporatedRaОценок пока нет

- PaperGrades VendittiДокумент33 страницыPaperGrades VendittiArif HasanОценок пока нет

- CHEP 410 (5) Pulp and Paper IndustriesДокумент41 страницаCHEP 410 (5) Pulp and Paper IndustriesCJ SacoboОценок пока нет

- Chapter 1 Pulp PDFДокумент31 страницаChapter 1 Pulp PDFBhatu DevareОценок пока нет

- Report in Envi (Paper Industry)Документ63 страницыReport in Envi (Paper Industry)Ramces SolimanОценок пока нет

- Chapter 18 Surface TreatmentДокумент70 страницChapter 18 Surface Treatmentavandetq15Оценок пока нет

- Applications of StarchДокумент5 страницApplications of StarchvienzenyОценок пока нет

- 2004 - Treatment-Of-Pulp-And-Paper-Mill-Wastewaterâ EURO - A-ReviewДокумент22 страницы2004 - Treatment-Of-Pulp-And-Paper-Mill-Wastewaterâ EURO - A-ReviewHoang Anh VuОценок пока нет

- T200 PDFДокумент9 страницT200 PDFOllafОценок пока нет

- Fiber and Pulp Properties For Papermaking: Pekka KomulainenДокумент35 страницFiber and Pulp Properties For Papermaking: Pekka KomulainenjjccmmaaОценок пока нет

- T 826Документ6 страницT 826burucuОценок пока нет

- Tappt Method T211Документ5 страницTappt Method T211HeerHeerОценок пока нет

- Deculator Article 5 03Документ4 страницыDeculator Article 5 03tsvmpm1765100% (3)

- Pulp & PaperNew-1Документ24 страницыPulp & PaperNew-1shamsul amin100% (1)

- Wet End ChemistryДокумент36 страницWet End ChemistrySam Lua100% (1)

- Tappi T413Документ4 страницыTappi T413Hansel OmarОценок пока нет

- AKD Details StudyДокумент7 страницAKD Details Studysukallan dharОценок пока нет

- Paper and Board Manufacture and Properties WorkshopДокумент99 страницPaper and Board Manufacture and Properties WorkshopJJGОценок пока нет

- Paper Fan PumpsДокумент8 страницPaper Fan PumpsnazeerОценок пока нет

- Thickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)Документ0 страницThickness (Caliper) of Towel, Tissue, Napkin and Facial Products (Proposed New Provisional Method)andy981Оценок пока нет

- T807Документ4 страницыT807Pratik PrajapatiОценок пока нет

- Waste in Paper ProductionДокумент10 страницWaste in Paper Productiongo2_sumitОценок пока нет

- Metering Size PressДокумент22 страницыMetering Size PressDaud ZamanОценок пока нет

- Hy Andritz Pumps Portfolio en - PDДокумент45 страницHy Andritz Pumps Portfolio en - PDMark CentenoОценок пока нет

- Paper Is A Thin Material Produced by Pressing Together MoistДокумент10 страницPaper Is A Thin Material Produced by Pressing Together Moistvijileela8580Оценок пока нет

- Pump Learning Guide1Документ171 страницаPump Learning Guide1password2013Оценок пока нет

- t455 - Identification of Wire SideДокумент4 страницыt455 - Identification of Wire Sidetsvmpm1765Оценок пока нет

- 2009 Issue 4 IPPTA Article 05Документ4 страницы2009 Issue 4 IPPTA Article 05Lev BОценок пока нет

- Manual Paper Recycling Machine DesignДокумент6 страницManual Paper Recycling Machine DesignJashandeep SinghОценок пока нет

- Modeling of Chip Bed Packing in A Continuous Kraft Cooking Digester PDFДокумент142 страницыModeling of Chip Bed Packing in A Continuous Kraft Cooking Digester PDFHuy NguyenОценок пока нет

- Toilet Paper Factors of ProductionДокумент6 страницToilet Paper Factors of ProductionLayneGelleiMeneses-MillaminaBuenaventeОценок пока нет

- Concentrated Acid Solubility of Tio2Документ12 страницConcentrated Acid Solubility of Tio2Bogdan BulgariuОценок пока нет

- Steam and Kondensat For PapermachineДокумент33 страницыSteam and Kondensat For PapermachinesakarisoОценок пока нет

- High Yield Nucleophile Cooking of Wood ChipsДокумент109 страницHigh Yield Nucleophile Cooking of Wood ChipsHuy NguyenОценок пока нет

- Pulp and Paper Production From EFBДокумент9 страницPulp and Paper Production From EFBEddie TaiОценок пока нет

- Manual Paper Recycling MachineДокумент6 страницManual Paper Recycling MachineShubhamDabralОценок пока нет

- TOPIC 15 Paper (Note)Документ7 страницTOPIC 15 Paper (Note)Kaynine KikoОценок пока нет

- Paper TestingДокумент42 страницыPaper TestingdongnamvietОценок пока нет

- Paper Industries IntroductionДокумент49 страницPaper Industries Introductioninstengg100% (1)

- VoithDrive-624 e VP Voithdrive enДокумент6 страницVoithDrive-624 e VP Voithdrive enMarcWorldОценок пока нет

- Paper and PulpДокумент76 страницPaper and PulpDynamo GamingОценок пока нет

- Dressing For Success: Today's Paper Machine ClothingДокумент4 страницыDressing For Success: Today's Paper Machine Clothingst7167Оценок пока нет

- Paper Making ProcessДокумент13 страницPaper Making ProcessSamin MaharjanОценок пока нет

- GuidancefДокумент119 страницGuidancefarunyogОценок пока нет

- Pulp and Paper IndustryДокумент35 страницPulp and Paper IndustryKlesh Padma Bhimrao Shrirame100% (1)

- PulpДокумент382 страницыPulpBeerBie100% (1)

- Finishing EnglДокумент49 страницFinishing EnglSalim NgaosОценок пока нет

- Deinking of Waste Paper - FlotationДокумент8 страницDeinking of Waste Paper - FlotationMiko Still SpeedinОценок пока нет

- Flotation of Cleaner Rejects Removes High Density StickiesДокумент16 страницFlotation of Cleaner Rejects Removes High Density Stickiespaperravi2000Оценок пока нет

- Detrashing SystemДокумент6 страницDetrashing Systemfrancesco.migliorucciОценок пока нет

- Advanced Training Course On Deinking - Dispersion and KneadingДокумент38 страницAdvanced Training Course On Deinking - Dispersion and KneadingGuido PeraltaОценок пока нет

- Owner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13Документ18 страницOwner'S Manual: Explosion-Proof Motor Mf07, Mf10, Mf13mediacampaigncc24Оценок пока нет

- Reading Assignment Nuclear ChemistryДокумент2 страницыReading Assignment Nuclear Chemistryapi-249441006Оценок пока нет

- Capacity Requirement PlanningДокумент17 страницCapacity Requirement PlanningvamsibuОценок пока нет

- Quarterly Progress Report FormatДокумент7 страницQuarterly Progress Report FormatDegnesh AssefaОценок пока нет

- Seven-Year Financial Pro Jection: ProblemДокумент10 страницSeven-Year Financial Pro Jection: Problemnyashadzashe munyatiОценок пока нет

- ME-317 Internal Combustion Engines - TurbochargingДокумент21 страницаME-317 Internal Combustion Engines - TurbochargingHamzaJavedОценок пока нет

- Cheap TBE Inverter TeardownsДокумент33 страницыCheap TBE Inverter TeardownsWar Linux92% (12)

- Consent CertificateДокумент5 страницConsent Certificatedhanu2399Оценок пока нет

- Exercise 8 BeveragewareДокумент9 страницExercise 8 BeveragewareMae Cleofe G. SelisanaОценок пока нет

- Refrigerator: Service ManualДокумент119 страницRefrigerator: Service ManualMihaela CaciumarciucОценок пока нет

- Cough PDFДокумент3 страницыCough PDFKASIA SyОценок пока нет

- Open Cholecystectomy ReportДокумент7 страницOpen Cholecystectomy ReportjosephcloudОценок пока нет

- MSU-Iligan Institute of TechnologyДокумент5 страницMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDOОценок пока нет

- Gloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Документ10 страницGloria Pfoltzer Theresa Morris, an Infant, by Mother and Next Friend Christopher Morris, an Infant, by Mother and Next Friend Randy Morris, an Infant, by Mother and Next Friend v. Fairfax County Department of Human Development Susan Manzo Paulette Byrd Florence Hannigan, and Louis Villafane, 966 F.2d 1443, 4th Cir. (1992)Scribd Government DocsОценок пока нет

- For Hand Grip Strength: NormsДокумент7 страницFor Hand Grip Strength: NormsPraneethaОценок пока нет

- Snap Bore Ring PDFДокумент8 страницSnap Bore Ring PDFlaaliОценок пока нет

- Kern County Sues Governor Gavin NewsomДокумент3 страницыKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- 0010 kOBELCO SK 179-9 PDFДокумент52 страницы0010 kOBELCO SK 179-9 PDFDaman Huri100% (2)

- Poisoned NeedleДокумент147 страницPoisoned NeedleMark Cooper100% (3)

- Citizen's 8651 Manual PDFДокумент16 страницCitizen's 8651 Manual PDFtfriebusОценок пока нет

- Photoperiodism Powerpoint EduДокумент12 страницPhotoperiodism Powerpoint EduAlabi FauziatBulalaОценок пока нет

- As 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningДокумент9 страницAs 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningSAI Global - APAC14% (7)

- RestraintsДокумент48 страницRestraintsLeena Pravil100% (1)

- RISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Документ17 страницRISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Martin NiОценок пока нет

- Site Quality ManualДокумент376 страницSite Quality ManualsОценок пока нет

- Updated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetДокумент2 страницыUpdated2021.KEBOS GR11-2KVA 1800W Online Rack Mount UPS DatasheetRicardo HolleroОценок пока нет

- Hasil Pemeriksaan Laboratorium: Laboratory Test ResultДокумент1 страницаHasil Pemeriksaan Laboratorium: Laboratory Test ResultsandraОценок пока нет

- A I R P O R T S Construction Program Management 56Документ56 страницA I R P O R T S Construction Program Management 56Carl WilliamsОценок пока нет

- Wa0016Документ3 страницыWa0016Vinay DahiyaОценок пока нет

- Project PlanДокумент55 страницProject PlanAlfredo SbОценок пока нет