Академический Документы

Профессиональный Документы

Культура Документы

EP - Operating Manual

Загружено:

chillermfgИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

EP - Operating Manual

Загружено:

chillermfgАвторское право:

Доступные форматы

O P E R A T I N G M A N U A L

1 - 8 0 0 - 3 3 4 - C O O L ( 2 6 6 5 ) W W W . C H I L L E R M F G . C O M

S E R I A L #

M O D E L #

1-800-334-COOL (2665) Page 1 of 38 www.chillermfg.com

CONTENTS:

1. Warranty

2. Line Set Caution

3. Warning

4. Part Number Explanation

5. Warranty Checklist

6. Installation Procedures

7. Start Up Checklist

8. Line Set Installation

9. Electrical

10. Wiring Diagram

a) 208-240/1/60 EP2301

b) 208-240/1/60 EP2301C

c) 208-240/3/60 EP2303

d) 208-240/3/60 EP2303C

e) 460/3/60 EP4603

f) 460/3/60 EP4603C

11. Control Wire Connections Condensing Unit

12. Control Wire Connections Indoor

13. Control Wire Connections Air Handler

14. Chilled Water Piping

15. Controller Operation

a) Operation

b) Temperature Controls

c) Faults

d) Status

e) Air Handler Controls

16. Controller Screen Map

17. Converting 240 Volts to 208 Volts

18. Cold Weather Antifreeze Selection Guide

19. Maintenance

20. Troubleshooting

21. Dimensions

1-800-334-COOL (2665) Page 2 of 38 www.chillermfg.com

*

*

*

*if applicable

CHILLER MAUFACTURIG

WARRATY POLICY

Chiller Manufacturing Inc warrants all new equipment to be free from defects PARTS AD

CRAFTMASHIP for a period of one (1) year from the date of purchase. Labor charges are not included in

warranty and are the responsibility of the purchaser or end user(s).

This warranty extends to the original purchaser of Chiller Mfg. products and to those persons who under

applicable state law are entitled to rely hereon as third party beneficiaries, but in no event shall Chiller Mfg. be

held liable for property damage or damage to the chiller by such third party beneficiary if said applicable

state law contemplates such liability but permits its exclusion.

All new replacement parts for equipment manufactured by Chiller Mfg. for which the one (1) year warranty

period has expired or for all new repair or replacement parts for equipment, the warranty period is limited to ninety

(90) days from the date of sale. The warranty period on each new replacement part furnished by Chiller Mfg. in

fulfillment of the warranty on all new replacement parts shall be for the unexpired portion of the original warranty

period on the part replaced.

Chiller Mfg. liability does not include furnishing or paying for any labor such as that required to service,

remove, or install, to diagnose troubles, to adjust, remove, or replace defective equipment or part, nor does it include

any responsibility for transportation or insurance or other related expense which is involved therein.

Chiller Mfg. will apply a thirty five percent (35%) restocking fee for any equipment returned within sixty

(60) days. Equipment being returned must be in perfect condition, not installed, and Glycol must be present in

system with return. After sixty (60) days Chiller Mfg. will not accept any returns of Equipment because of purchaser

negligence to order correctly or purchaser negligence to acquire correct sizing data. Credit will only be issued when

Chiller Mfg. has determined that equipment or parts being returned has been used under normal operating

conditions. Credit will be issued sixty (60) to ninety (90) after equipment or part has been reviewed by Chiller Mfg.

The use of automotive antifreeze may VOID warranty.

The warranty of Chiller Mfg is conditioned upon installation and use of its equipment and parts under

normal operating conditions. The warranty is void on equipment and parts: that have been subjected to misuse,

accident or negligent damage, operated under loads, pressures, electrical connections, plumbing, or conditions other

than those specified by Chiller Mfg. Warranty is void if damaged by fire, flood, vandalism, or such other causes

beyond the control of Chiller Mfg, altered or repaired in any way that affects the reliability or detracts from its

performance, which have had the Serial Data Plate altered, effaced, or removed.

No defective equipment or part may be returned to Chiller Mfg. for repair or replacement without prior

written authorization from Chiller Mfg. Any charges for unauthorized repairs will not be accepted or paid for by

Chiller Mfg.

Chiller Mfg. is not responsible for any injury, property damage, or other consequential or incidental

damages arising directly or indirectly from the purchase or use of its products or from any defect in material

or workmanship.

Chiller Mfg. makes no other express or implied warranty, statutory or otherwise, concerning the

equipment, parts, or service, including, without limitation, a warranty of fitness for a particular purpose, a

warranty of merchantability, or any other implied warranties which may arise from course of dealing or

usage of trade. The warranties given here are expressly in lieu of all other warranties, express or implied.

Chiller Mfg. neither assumes, nor authorizes any person to assume for it, any other warranty or liability in

connection with the manufacture, use, or sale of its equipment or parts.

For warranty service, contact the Distributor from whom the Chiller Mfg. equipment or part was purchased.

If the Distributor cannot be reached, Contact Chiller Mfg. at 1-800-334-2665

1-800-334-COOL (2665) Page 3 of 38 www.chillermfg.com

C A U T I O N

D O N O T L O O P L I N E S E T S V E R T I C A L L Y

I M P O R T A N T N O T I C E : L I N E S E T C O I L S H O U L D A L W A Y S B E I N A

H O R I Z O N T A L P O S I T I O N A N D N E V E R V E R T I C A L . L I N E S E T C A N C R E A T E A N

O I L T R A P I N A V E R T I C A L P O S I T I O N .

H O R I Z O N T A L

C O R R E C T

V E R T I C A L

N O T C O R R E C T

1-800-334-COOL (2665) Page 4 of 38 www.chillermfg.com

WARNING WARNING WARNING WARNING

CHILLER IS SET TO COOL TO A MINIMUM OF 50 DEGREES F. IF A

LOWER OUTPUT TEMPERATURE IS DESIRED, A GLYCOL MIXTURE

MUST BE USED. PROPYLENE GLYCOL ACTS, NOT ONLY AS A FREEZE

INHIBITOR, BUT ALSO AS A LUBRICANT FOR THE WATER PUMP

AND VALVES AND IS SUGGESTED FOR USE WITH ANY OF OUR

WATER CHILLER SYSTEMS.

DO NOT USE AUTOMOTIVE TYPE GLYCOL! DO NOT USE AUTOMOTIVE TYPE GLYCOL! DO NOT USE AUTOMOTIVE TYPE GLYCOL! DO NOT USE AUTOMOTIVE TYPE GLYCOL!

CAUTION CAUTION CAUTION CAUTION

THE INITIAL FILL OF WATER INTO THE CHILLER UNIT SHOULD BE

DONE THROUGH THE PLUMBED WATER INLET ASSEMBLY WITH THE

CHILLER POWER OFF THIS ALLOWS WATER TO FILL THE PUMP HEAD

BEFORE BEING ENERGIZED AND POSSIBLY DAMAGING THE WATER

PUMP. AFTER INITIAL FILL TIME WITH THE MIDGET TWIST BLACK

THERMOSTAT PLUG(S) DISCONNECTED, TURN ON UNIT POWER AND

TOGGLE SWITCHES TO FINISH CIRCULATING WATER THROUGH THE

SYSTEM. AFTER APPROXIMATELY 10 MINUTES, TURN OFF CHILLER

DISCONNECT AND PLUG IN THERMOSTAT PLUG(S). EXPOSE CHILLER

TO HEAT LOAD AND TURN ON CHILLER DISCONNECT.

DO NOT USE DE DO NOT USE DE DO NOT USE DE DO NOT USE DE- -- -IONIZED OR DISTILLED WATER IN IONIZED OR DISTILLED WATER IN IONIZED OR DISTILLED WATER IN IONIZED OR DISTILLED WATER IN

CHILLER SYSTEM. THIS WILL VOID WARRANTY. CHILLER SYSTEM. THIS WILL VOID WARRANTY. CHILLER SYSTEM. THIS WILL VOID WARRANTY. CHILLER SYSTEM. THIS WILL VOID WARRANTY.

1-800-334-COOL (2665) Page 5 of 38 www.chillermfg.com

Polar Series Part Numbers

E P - 4 -

VINTAGE

EXAMPLE (A..Z)

DESIGNATES ELECTRICAL VOLTAGE

2 22 2 = 230/1/60 (Use Control Panel EP2301)

3 33 3 = 230/3/60 (Use Control Panel EP2303)

4 44 4 = 460/3/60 (Use Control Panel EP4603)

DESIGNATES WATER PUMP HORSEPOWER

15 15 15 15 = 1.5 HP

20 20 20 20 = 2.0 HP

25 25 25 25 = 2.5 HP

30 30 30 30 = 3.0 HP

REFRIGERANT

4 44 4 = 410a

DESIGNATES ELECTRICAL DIAGRAM

S SS S = Standard (Use Control Panel EPXXXX)

C CC C = 6 Independent Dedicated Relays ( Use Control Panel EPXXXXC)

E EE E = Expandable

F FF F = Fixed

T TT T = Tank (120 Gallon)

S = S = S = S = Tank (90 Gallon)

W WW W = Without Tank

DESIGNATES TONNAGE

(# of Modules)

5 55 5 (1) 5 Ton Refrigeration Module

10 10 10 10 (2) 5 Ton Refrigeration Modules

15 15 15 15 (3) 5 Ton Refrigeration Modules

20 20 20 20 (4) 5 Ton Refrigeration Modules

P PP P = Polar Model Series

E EE E = ETL Approved

1-800-334-COOL (2665) Page 6 of 38 www.chillermfg.com

POLAR Series - Indoor Unit Standard Features

Touchscreen PLC

Controller

Programmed for

Energy Effciency

Brazed Plate Heat Exchanger

Best performance and energy effciency

Heat Exchanger available

24v Signal

Wire Plugs,

Pre-wired for

expansion

Adjustable Pressure

Bypass Valve

Stainless Steel

Water Pump

High Performance Noryl Impeller

with Energy Effcient TEFC* Motor

*Totally Enclosed Fan Cooled

Intake

Water

Strainer

with Mesh

Screen

Filter

Fluid Flow Switch

Safety Level Switch

Fully Tig Welded, Anodized

Aluminum Frame

Water Level

Sight Glass

Fully Insulated, accessible

120 Gallon Poly Tank

Typical Electric Panel

Non-Ferrous Plumbing

Tank Overfow

ETL / UL 1995 STD

1-800-334-COOL (2665) Page 7 of 38 www.chillermfg.com

WARRANTY CHECKLIST

TRANE condensing units carry one year parts warranty and a five year pro-rated

compressor warranty.

Chiller Factory Warranty Policy is one year parts, from date of invoice.

Warranty parts are replaced on an exchange basis. If the customer has an open

account with the factory, parts may be placed on account with credit issued upon

the return of the warranty part. If the customer does not have an open account with

the factory, parts will be shipped C.O.D. with full refund issued upon receipt of

warranty part. All warranty parts are tested before credit or refund is issued.

Factory will not be responsible for any charges from any other company without

prior authorization accompanied by a factory purchase order.

There is to be no variation of this policy without prior written authorization from

factory.

Minimum pipe size of 1 1/4 for header system must be used.

A bypass valve or pressure release valve is installed between the water outlet and

the tank. A BALL VALVE MUST BE OPEN ENOUGH TO SUPPORT THE

CHILLERS MINIMUM FLOW RATE IN THE EVENT THAT THE SUPPLY

THROUGH THE CUSTOMERS PROCESS IS INTERUPTED. UNDER O

CIRCUMSTANCES SHOULD THIS BYPASS VALVE BE CLOSED!

Refrigerant connections must be leak tested with provided bubble leak testing

solution. Provided oil shall be used when these connections are made. A BACK

UP WRECH MUST BE USED!

If the chiller is to cool 50 degrees F or lower, a mixture of propylene glycol must

be used.

Chiller is to be installed on a separate disconnect than the condenser unit (s).

1-800-334-COOL (2665) Page 8 of 38 www.chillermfg.com

INSTALLATION PROCEDURES

1. Uncrate and check packing slip.

2. Check all items for damage and possible freight claims. Freight claims are the

responsibility of the purchaser.

3. Place Polar unit at desired indoor location. Condensing unit(s) should be placed

outdoors within 25 feet of Polar unit. Additional tubing may be added to

enclosed line set if necessary.

4. Locate condensing unit(s) outdoors with a minimum clearance of 24 from

other equipment, walls, shrubbery, etc

5. When mounting and locating all equipment, conform to all local and state

codes.

1-800-334-COOL (2665) Page 9 of 38 www.chillermfg.com

1-800-334-COOL (2665) Page 10 of 38 www.chillermfg.com

LINE-SET INSTALLATION INSTRUCTIONS

1. Apply refrigerant oil to the entire surface of diaphragm, o-ring, and threaded area of

male coupling assembly. The amount of lubricant must be applied liberally to cover

all designated surfaces sufficiently.

2. Ensure that the coupling halves are held in proper alignment with each other prior to

starting the threads of the female coupling nut onto the male half. The coupling end

faces should be parallel with each other and visually in line with each other, this

allows the female coupling nut to be easily threaded on by hand for the initial 2-3

rotations of the union nut. These initial rotations bring the diaphragm in contact and a

sharp increase in torque will be felt when they come into contact.

IF THE UT WILL OT START BY HAD, - ADJUST THE POSITIO OF THE LIE SET

TO ESURE PROPER COUPLIG ALIGMET AD ELIMIATE/MIIMIZE

ALL SIDE-LOAD FORCE O THE COUPLIG DURIG ASSEMBLY.

1-800-334-COOL (2665) Page 11 of 38 www.chillermfg.com

3. Using appropriate size wrenches, reference table below, for the female coupling body

and female union nut, tighten the female union nut while preventing rotation of the

female body with respect to the female half. The nut should be tightened until a

definite increase in resistance, metal to metal contact occurs, is felt (at this point, the

nut will have covered most of the threads on the male body). It is important to ensure

the male and female coupling bodies DO NOT ROTATE during any portion of the

wrench installation.

4. Using a permanent marker or scribe, mark a line lengthwise from the female coupling

union nut to either the bulkhead or female coupling body. Then tighten an additional

turn/rotation (90degrees); refer to the marking on the union nut to confirm the

turn/rotation has occurred. This final turn/rotation is necessary to ensure the

formation of the leak-proof seal, between the male and female couplings.

5. After line sets are tightened, use a couple drops of bubble leak to test your fittings

both the Chiller and the condensing unit. If bubbles are not prevalent continue. If

bubbles are produced tighten fittings, with a back up wrench, in small increments

until the bubbles cease. If tightening of fitting is no longer an option consult the

factory.

6. Repeat steps 1 thru 5 for all connections.

Coupling Size Torque Values

-Copper-06 10-12 Ft/Lbs

-Copper-10 35-45 Ft/Lbs

-Copper-11 35-45 Ft/Lbs

-Copper-12 50-65 Ft/Lbs

1-800-334-COOL (2665) Page 12 of 38 www.chillermfg.com

ELECTRICAL

WARIG: WHE ISTALLIG OR SERVICIG THIS EQUIPMET.

ALWAYS EXERCISE BASIC SAFETY PRECAUTIOS TO AVOID THE

POSSIBILITY OF ELECTRIC SHOCK.

ALL COECTIOS TO THIS CHILLER UIT SHALL BE COMPLIET

WITH EC CODE. Connections shall be made from a fused disconnect or equivalent.

Main power wire installation hole NOT provided. Drill hole where necessary. IT IS

ISTALLERS RESPOSIBILITY TO REMOVE ALL METAL

CHIPS/SHAVIGS AD PROTECT COMPOETS FROM SUCH. DAMAGE

OR ELECTRICAL HAZARD COULD OCCUR IF CHIPS/SHAVIGS FALL

ITO COMPOETS. Fuses shall be provided in the field and rated at 125% of the

full load amperes as marked on the ID LABEL of the chiller unit. Field wiring to the

chiller control box shall be #12 AWG or larger. (FOLLOW NEC CODE)

1. Polar unit is to be mounted inside, electric brought to the system switch box

located on the control end of the Polar unit.

2. Condensing unit is to be located outdoors with the proper service connected.

Consult the condensing unit information plate for proper voltage and amperage.

3. The Polar unit has a 24 volt AC control circuit transformer. This is wired via din

rail to the small receptacle on the front panel of the Polar unit.

4. Locate disconnects wherever needed. Conform to all local and state codes.

5. If multiple outdoor units are being installed, run separate electrical services to

each condenser. NOTE: Always check condensing unit nameplate for electrical

ratings.

6. Wire Polar unit per wiring diagram displayed in control box.

7. When connecting thermostat wires to Polar unit, always connect the stages as

labeled on front of chiller. Stage A to condenser A, Stage B to condenser B etc

8. When connecting Air Handlers to Chiller Control Cabinet, use the wiring chart

located in the control box.

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP

DOES NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 13 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B2A

208-240/1/60

Incoming Line

Voltage

L2

DIST

FSPD

B2A

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-460

207 240 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

208-240/1/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP2301 5

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

3

A

F

U

S

E

24 VAC DIST

(18-19)

Wiring Diagram 1 208-240/1/60 (EP2301)

Example: EP- * * * S * - * 2 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP DOES

NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 14 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B

208-240/1/60

Incoming Line

Voltage

L2

DIST

FSPD

B

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-240

208 240 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

C1

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

C2

Q9

Q10

Q11

Q12

Q13

Q14

Q15

Q16

Horner

DQM602

Relay

SmartStick

HEX ID:

4B

HI:4

Low:B

NETWORK

V- cL SH cH V+

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

Connection for Air Handlers

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

208-230/1/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP2301C 6

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

3

A

F

U

S

E

24 VAC DIST

(18-19)

Wiring Diagram 2 208-240/1/60 (EP2301C)

Example: EP- * * * C * - * 2 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP DOES

NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 15 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B2A

208-240/3/60

Incoming Line

Voltage

L2

DIST

FSPD

B2A

L3

DIST

FSPD

B2A

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-460

207 240 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

208-240/3/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP2303 5

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WHEN INSTALLING 3 PHASE

POWER

CHECK PUMP FOR PROPER

ROTATION

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

3

A

F

U

S

E

24 VAC DIST

(18-19)

Wiring Diagram 3 208-240/3/60 (EP2303)

Example: EP- * * * S * - * 3 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP DOES

NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 16 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B2A

208-240/3/60

Incoming Line

Voltage

L2

DIST

FSPD

B2A

L3

DIST

FSPD

B2A

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-240

208 240 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

C1

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

C2

Q9

Q10

Q11

Q12

Q13

Q14

Q15

Q16

Horner

DQM602

Relay

SmartStick

HEX ID:

4B

HI:4

Low:B

NETWORK

V- cL SH cH V+

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

Connection for Air

Handlers

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

208-230/3/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP2303C 6

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WHEN INSTALLING 3 PHASE

POWER

CHECK PUMP FOR PROPER

ROTATION

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

3

A

F

U

S

E

24 VAC DIST

(18-19)

Wiring Diagram 4 208-240/3/60 (EP2303C)

Example: EP- * * * C * - * 3 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP

DOES NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 17 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B2A

460/3/60

Incoming Line

Voltage

L2

DIST

FSPD

B2A

L3

DIST

FSPD

B2A

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-460

460 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

460/3/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP4603 5

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WHEN INSTALLING 3 PHASE

POWER

CHECK PUMP FOR PROPER

ROTATION

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

3

A

F

U

S

E

24 VAC DIST

(18-19)

Wiring Diagram 5 460/3/60 (EP4603)

Example: EP- * * * S * - * 4 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP DOES

NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 18 of 38 www.chillermfg.com

L1 L2 L3

T1 T2 T3

PUMP

OVLOAD

AUX

NO

NO

13

33

14

34

T1 T2 T3 A2

L1 L2 L3 A1

PUMP

CONTACTOR

LC1D18BD

PUMP

DISCONNECT

SWITCH

FSLPS25

L1

DIST

FSPD

B2A

460/3/60

Incoming Line

Voltage

L2

DIST

FSPD

B2A

L3

DIST

FSPD

B2A

DC

POWER

SUPPLY

ABL8RPS2

4030

G LV C HV

+ + - -

24VAC

TRANS-

FORMER

ZET-460

460 C

24V 24V

BREAKER

NB1-D2

BREAKER

(PWRSUP)

NB1-D2

BREAKER

NB1-D2

BREAKER

(XFORM)

NB1-D3

+

2

4

V

D

C

D

I

S

T

(

1

3

-

1

4

)

-

2

4

V

D

C

D

I

S

T

(

1

5

)

C1

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

C2

Q9

Q10

Q1

Q12

Q13

Q14

Q15

Q16

Horner

DQM602

Relay

SmartStick

HEX ID:

4B

HI:4

Low:B

NETWORK

V- cL SH cH V+

I1

I2

I3

I4

I5

I6

I7

I8

H1

0V

A1

A2

A3

A4

0V

C6

R6

C5

R5

C4

R4

C3

R3

C2

R2

C1

R1

H4

H3

H2

- +

POWER NWORK

V- cL SH cH V+

Horner xLT

PLC Controller

HE-XT-102-14

1 2 3 4 5 6 7 8 9

1

0

1

1

1

2

Connection for Air Handlers

STAGE

A

PLUG

STAGE

B

PLUG

STAGE

C

PLUG

STAGE

D

PLUG

1

6

1

7

PANEL

DOOR

E-STOP

S

T

A

G

E

A

T

E

M

P

P

R

O

B

E

S

T

A

G

E

B

T

E

M

P

P

R

O

B

E

S

T

A

G

E

C

T

E

M

P

P

R

O

B

E

S

T

A

G

E

D

T

E

M

P

P

R

O

B

E

J.C. COLLINS

NASHVILLE,TN

WIRE DIAGRAM & CONNECTIONS

CONTROL VOLTAGE

Chiller Polar Model

460/3/60 ETL

SIZE FSCM NO DWG NO REV

N/A ETLPOLAR EP4603C 5

SCA

LE

N/A 11-1-10

SHE

ET

1 OF 1

L

E

V

E

L

S

W

I

T

C

H

F

L

O

W

S

W

I

T

C

H

CAUTION

USE COPPER CONDUCTORS ONLY! UNIT

TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS. FAILURE TO

DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT

WHEN INSTALLING 3 PHASE

POWER

CHECK PUMP FOR PROPER

ROTATION

WARNING

HAZARDOUS VOLTAGE !

DISCONNECT ALL ELECTRIC

POWER INCLUDING REMOTE

DISCONNECTS BEFORE

SERVICING.

FAILURE TO DISCONNECT

POWER BEFORE SERVICING CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH.

L1 L2 L3

T1 T2 T3

24 VAC DIST

(18-19)

3

A

F

U

S

E

Wiring Diagram 6 460/3/60 (EP4603C)

Example: EP- * * * C * - * 4 *

- See Polar Series Part Number for assistance in identifying the correct wiring diagram for your specific Chiller

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP

DOES NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 19 of 38 www.chillermfg.com

CONTROL WIRE CONNECTION(S) -

CONDENSING UNIT

ENSURE STAGE LETTER IS CONNECTED WITH MATCHING PLUG (A,B,C,D)

1. Locate 24 volt wires on the condensing unit.

a. Twist together red wire and blue wire.

b. Twist together black wire and yellow wire.

2. Use a crimp cap to make sure that you will have a good connection.

3. Crimp wires together, inspect to make sure that wires are securely

crimped together.

4. Repeat steps 1 thru 3 for each condensing unit.

1-800-334-COOL (2665) Page 20 of 38 www.chillermfg.com

CONTROL WIRE CONNECTION(S) - INDOOR

ENSURE STAGE LETTER IS CONNECTED WITH MATCHING PLUG (A,B,C,D)

1. Locate female midget plug receptacle on the side of Chiller electrical box.

2. Lift dust cap off of female midget plug.

3. Push male midget plug into female receptacle.

4. Twist bottom of male plug to lock into place. Repeat steps 1 through 4 for each

condensing unit.

1-800-334-COOL (2665) Page 21 of 38 www.chillermfg.com

CONTROL WIRE CONNECTION(S)

AIR HANDLER

(if applicable)

1-800-334-COOL (2665) Page 22 of 38 www.chillermfg.com

1-800-334-COOL (2665) Page 23 of 38 www.chillermfg.com

CONTROLLER OPERATION

Operation:

1-800-334-COOL (2665) Page 24 of 38 www.chillermfg.com

Temperature Settings:

1-800-334-COOL (2665) Page 25 of 38 www.chillermfg.com

Faults:

Emergency Stop stops

Chiller Operation Only!

EMERGENCY STOP DOES

NOT BREAK HIGH

VOLTAGE

1-800-334-COOL (2665) Page 26 of 38 www.chillermfg.com

Status:

1-800-334-COOL (2665) Page 27 of 38 www.chillermfg.com

Air Handler Controls:

(if applicable)

alternative screen:

1-800-334-COOL (2665) Page 28 of 38 www.chillermfg.com

CONTROLLER SCREEN MAP

1-800-334-COOL (2665) Page 29 of 38 www.chillermfg.com

1-800-334-COOL (2665) Page 30 of 38 www.chillermfg.com

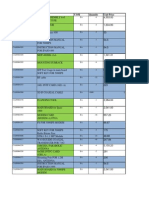

COLD WEATHER ANTIFREEZE SELECTION GUIDE

When the chiller unit sits idle overnight during cold weather, water in the heat exchanger

can freeze. To avoid freezing, a proper solution of inhibited glycol antifreeze must be

added. The following chart illustrates the number of gallons of antifreeze needed to

protect against freeze up at various temperatures.

FREEZE TEMPERATURE F % PROPYLENE GLYCOL BY VOLUME

26 10

19 20

8 30

-7 40

-28 50

-60 60

<-60 70

Propylene Glycol does not have silicates that are harmful to pump seals and gaskets at chiller

water operating temperatures compared to automotive type antifreeze. The rust inhibitors are

also specially formulated to work in cold, cooling temperatures rather than hot engine

environments.

Propylene Glycol also provides freeze protection in the event a compressor contactor welds

shut. Bad contact points, stuck coil, or lightning will permit the condenser to run and

continually drive down the water temperature.

There are high costs associated with using the wrong type of glycol for freeze protection.

Corrosion damage, system downtime, occupant discomfort, high repair costs, frequent fluid

replacement and shortened system life are all potential consequences. Propylene Glycol

should be replaced every time the system is drained and cleaned.

WARIG: THE USE OF AUTOMOTIVE TYPE ATIFREEZE WILL

VOID WARRATY. AUTOMOTIVE ATIFREEZE CA FOUL AD

CLOG THIS CHILLER SYSTEM.

1-800-334-COOL (2665) Page 31 of 38 www.chillermfg.com

MAINTENANCE

1. Clean air cooled outdoor condenser(s) 2-times/year or sooner if needed.

2. Blow off pump motor air intake openings with compressed air yearly.

3. Monthly inspection:

a. Refrigerant site glass-should be clear at full load conditions.

b. Check compressor(s) amperage.

c. Check condenser(s) for any blockage.

d. Check/Clean pump strainers.

e. Check pump seal for leakage.

1-800-334-COOL (2665) Page 32 of 38 www.chillermfg.com

TROUBLESHOOTING

WARIG: WHE SERVICIG THIS EQUIPMET. ALWAYS EXERCISE

BASIC SAFETY PRECAUTIOS TO AVOID THE POSSIBILITY OF

ELECTRIC SHOCK.

1. Indoor pump will not run.

a. Check voltage connection to switch box located on indoor unit. Voltage

should be as per nameplate.

b. Check that switch is in the on position.

c. Check voltage at pump connection. Voltage should be as per nameplate.

d. Feel pump motor, if motor is hot to the touch. Pump is off on internal

overload. Allow pump to cool then restart. Check the amperage

immediately.

e. Check pump for blockage in impeller.

2. Indoor pump will start but shuts down after a few minutes.

a. Check for sufficient water in reservoir.

b. Check for proper voltage to pump.

c. Check wire connections at pump.

d. Check intake of pump for obstruction in impeller.

3. Indoor pump will run, but no water is circulating.

a. Check for sufficient water in reservoir.

b. Check that all valves in chiller header loops are open.

c. Check that all air is bled from any piping that is located above indoor

cabinet on non-tank madels.

4. Indoor pump unit will run but digital controller is not on.

a. Check voltage feed to controller. See wiring diagram on controller or

panel diagram.

b. Check fuses.

5. Indoor unit operates properly but outdoor condensing unit(s) will not run.

a. Check that unit is wired correctly.

b. Check main line voltage to unit. Voltage should be as per nameplate.

1-800-334-COOL (2665) Page 33 of 38 www.chillermfg.com

c. Check that temperature controller on indoor unit is set below temperature

of circulating water.

d. Check low voltage signal at the outdoor condensing unit. Control voltage

should be 24vac across the two control wires coming from the indoor unit

to the outdoor unit(s).

e. By breaking and making the 24vac control circuit, you should be able to

hear the compressor relay open and close. A snap will be heard at the

condensing unit when the compressor relay closes. Unit(s) should start.

f. On chiller with two or more outdoor units(s), the temperature control is

staged. There is a 5F differential between each stage.

g. Check refrigerant PSI. Ensure condenser is not off due to internal PSI

switch.

6. Outdoor compressor relay is closed but unit will not run.

a. Check main line voltage.

b. Check voltage at compressor connections.

c. Check compressor body. If you cannot hold your hand on the compressor

body because of heat, internal overloads may have tripped open. You must

allow compressor time to cool down and reset.

d. Perform a circuit test through compressor to verify if windings are open.

7. Outdoor compressor has tripped on internal overloads.

a. Allow time to reset.

b. Check all wire connections

c. Check compressor amperage draw.

d. Check voltage to compressor while unit is running.

e. Check that condenser fan is coming on.

f. Check that condenser is clean and not blocked.

g. Check that hot discharge air from another source is not being drawn into

condenser intake.

h. Check that unit is properly sized.

8. Outdoor main line voltage is correct to unit, 24vac control voltage is correct to unit,

compressor relay will not close.

a. Check that all wire connections are made.

1-800-334-COOL (2665) Page 34 of 38 www.chillermfg.com

b. Check that all refrigerant line connections are tightened properly. See

installation manual under Refrigeration Line Set.

c. Check that refrigeration service valves located on condensing unit are

open. See instructions with outdoor unit.

d. Check for any crimps in refrigeration line set.

e. Check refrigerant charge. Low-pressure control will open at 8psi and close

at 30 psi of suction pressure.

9. Pump is running but controller goes blank.

a. Check voltage to controller.

b. Check fuses.

1-800-334-COOL (2665) Page 35 of 38 www.chillermfg.com

1

0

/

1

0

N

E

1-800-334-COOL (2665) Page 36 of 38 www.chillermfg.com

1

0

/

1

0

N

E

1-800-334-COOL (2665) Page 37 of 38 www.chillermfg.com

Chiller South

568 Brick Church Park Dr.

Nashville, TN 37207

T 615.262.0307

F 615.262.0308

Chiller North

133 Harrison Ave

Jeffersonville, IN 47130

T 812.288.8413

F 812.285.5508

1.800.334.COOL (2665)

Thank you

for choosing Chiller Mfg.

1-800-334-COOL (2665) Page 38 of 38 www.chillermfg.com

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- 1996 Jeep Motor ZJ Diagrama ElectricoДокумент474 страницы1996 Jeep Motor ZJ Diagrama ElectricoTRONALD2020100% (7)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Sharp Lc40le800un Lc46le810un Lc52810un Lc60le810un Led TV SM FinalДокумент96 страницSharp Lc40le800un Lc46le810un Lc52810un Lc60le810un Led TV SM Finaledsel72100% (1)

- Randall 103e7Документ24 страницыRandall 103e7CJОценок пока нет

- Uenr7788uenr7788 Sis PDFДокумент33 страницыUenr7788uenr7788 Sis PDFMarcelo Daniel Gonzalez LLanosОценок пока нет

- EHVT 69kv Class PII With FoilДокумент9 страницEHVT 69kv Class PII With FoilAntonio GresiaОценок пока нет

- MAN Injectie Electronica EDC M S 6 4 PDFДокумент63 страницыMAN Injectie Electronica EDC M S 6 4 PDFarminОценок пока нет

- Mattler Toledo Panther Technical Manual E14957000AДокумент150 страницMattler Toledo Panther Technical Manual E14957000AGuy GervaisОценок пока нет

- Dmx512-A Guide (8x10) EstaДокумент112 страницDmx512-A Guide (8x10) EstaArturo SierraОценок пока нет

- Installation Guide 854 Advanced Technology Gauge: July 2008 Part No. 4416.225 Rev. 6Документ24 страницыInstallation Guide 854 Advanced Technology Gauge: July 2008 Part No. 4416.225 Rev. 6just_hammaОценок пока нет

- 3M MV Termination KitsДокумент20 страниц3M MV Termination Kitsomh129Оценок пока нет

- CIBANO 500 Ordering Information ENUДокумент18 страницCIBANO 500 Ordering Information ENUشاہد یونسОценок пока нет

- Ring Assembly - 43 Conductor Slip PDFДокумент6 страницRing Assembly - 43 Conductor Slip PDFReyes VargasОценок пока нет

- NJ Series Motion Control Rev B PDFДокумент123 страницыNJ Series Motion Control Rev B PDFi izaguirreОценок пока нет

- FP08-620 Eng Manual FellerДокумент33 страницыFP08-620 Eng Manual FellerIvan IvanovОценок пока нет

- Siv - Microwave ProjectДокумент32 страницыSiv - Microwave ProjectFahmi AbdullaОценок пока нет

- Alesis Ra300 SchematicsДокумент27 страницAlesis Ra300 SchematicsCah NgaloefОценок пока нет

- VIMARДокумент12 страницVIMARYong Ee VonnОценок пока нет

- Yamaha R-N602 PDFДокумент109 страницYamaha R-N602 PDFboroda2410100% (3)

- Service Manual CLX-8540ND Ver1.1 111103 PDFДокумент403 страницыService Manual CLX-8540ND Ver1.1 111103 PDFRobert SaumellОценок пока нет

- ITT American Electric Contempo Post Top Series 45-46-145-146 Spec Sheet 4-80Документ8 страницITT American Electric Contempo Post Top Series 45-46-145-146 Spec Sheet 4-80Alan MastersОценок пока нет

- iKA Reocor S en 371305-D 2011-11-28 PDFДокумент8 страницiKA Reocor S en 371305-D 2011-11-28 PDFAlexОценок пока нет

- Halo24 Radar - Installation ManualДокумент28 страницHalo24 Radar - Installation ManualMuhamad FazlyОценок пока нет

- NTRC 2014Документ192 страницыNTRC 2014Marc MendozaОценок пока нет

- Nf4k8ab Manual en v1.0 01 21 05Документ75 страницNf4k8ab Manual en v1.0 01 21 05Santiago AzzolinaОценок пока нет

- Micom P591, P592, P593: Communication Interface Units For Optical/Electrical Signal Conversion P59X/En M/A11Документ82 страницыMicom P591, P592, P593: Communication Interface Units For Optical/Electrical Signal Conversion P59X/En M/A11Juan Manuel Costales ParrondoОценок пока нет

- Thinkcentre A57 9702Документ82 страницыThinkcentre A57 9702Adrian SalazarОценок пока нет

- Sony Video Camera Manual PDFДокумент118 страницSony Video Camera Manual PDFGary Hoehler100% (1)

- Golf Sportsvan AccesoriesДокумент52 страницыGolf Sportsvan AccesoriesMariano CacchiarelliОценок пока нет

- Mybox: User ManualДокумент52 страницыMybox: User ManualKhawar IqbalОценок пока нет

- Scorpio1400ADG - V21ISDN MODEM PDFДокумент98 страницScorpio1400ADG - V21ISDN MODEM PDFFahmi MohammedОценок пока нет