Академический Документы

Профессиональный Документы

Культура Документы

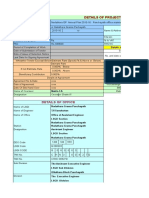

Metal Works

Загружено:

Pearl Marie HonorioИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Metal Works

Загружено:

Pearl Marie HonorioАвторское право:

Доступные форматы

Metalworks Lesson 1: Types of Metals A. Ferrous metals- Metals which contain iron. 1.

Pure iron- Silvery white in color, very soft and ductile. 2. Wrought iron- Commonly used for ornamental purposes. 3. Cast iron- Produced when melted iron ore is combined with carbon from the coal or coke used to heat it.. 4. White cast iron- Most commonly used in the production of machine parts. 5. Malleable cast iron- Very ductile that it can be stretched, bent or distorted without breaking 6. Gray cast iron- This kind of iron is used for casting. 7. Steel- An alloy containing great percentage of carbon. To produce different properties for various uses, other elements such as phosphorous, manganese, nickel and sulfur. B. Non-ferrous metals- Metals which do not contain iron. 1. Gold- most widely used for jewelry and gold plating. 2. Silver- Considered the best conductor of heat and electricity. 3. Aluminum- Commonly used for kitchen utensils 4. Copper- Commonly used as electrical wires. 5. Nickel- Hard, malleable and ductile. 6. Tin- Mostly used for coating other metals and made into food containers. 7. Lead- Has a very low melting point and very fusible. 8. Chromium- Very resistant to corrosion often alloyed with steel to produce building materials. 9. Platinum- An expensive white metal used for chemical and scientific apparatus and in jewelry 10. Tungsten- A grayish-black metal used as filaments for incandescent bulbs. 11. Monel metal- An alloy of nickel, copper and small amount of iron which is made into propeller of ships. 12. Muntz metal- Consists of 60% copper, 40% zinc makes up a very hard brass. Lesson 2: Properties of Metals 1. Malleability-Quality of being hammered and flattened into thin sheets without breaking. 2. Ductility-Allows a metal to be drawn into fine wires without breaking. 3. Hardness- Enables a metal to resist force without changing its shape. 4. Brittleness- Makes a metal break easily. 5. Elasticity-Enables a metal to return to its original shape after bending and pulling it out of shape. 6. Fusibility- Melts a metal easily and is usually combined with other metals to make an alloy. 7. Machinability-Refers to the extent to which a metal can be shaped, chipped or smoothened by a machine. 8. Permeability- The measure of the ease with which magnetic flux can be established in a metal. 9. Luster-The quality and intensity of light reflected from the surface of material. Lesson 3: Basic Tools and Equipments in Metalworks and their Uses Some of the commonly used tools in metalworks are the following: 1. Standard steel rule- One of the most used tools for measuring lengths, widths and thickness. 2. Bevel protractor- Used to measure angles from 0-180 degrees as well as to straighten edges with its steel rule. 3. Try square- An l-shaped tool used for testing squareness of corners and flatness of surfaces. 4. Divider- A two-legged pointed instrument used for drawing arcs and circles and for transferring measurements.

5. Calipers a. inside caliper- measures inside dimensions. b. outside caliper- measures outside dimensions. c. hermaphrodite caliper- scribes arcs in layout work. 6. Micrometer- Measures very small dimensions such as the diameter of a single hair strand. 7. Scribers- Pen-like tools with a sharp point and made of hard steel used to draw straight lines. 8. Layout punch- A prick punch, similar to a center punch except that its point is ground to an angle of 30-90 degrees; marks lay-out lines permanently. 9. Center punch- Looks like a prick punch, except that its point is ground to 90 degrees; marks center holes accurately. 10. Bench vise- Holds small objects securely when chipping, polishing, sawing, reaming, tapping or drilling. 11. Hammer-A handtool for pounding. Also a powerful tool used to drive and pull out nails. a. ballpeen hammer b. cross peen hammer c. claw hammer 12. Screwdrivers- Drives in and remove screws. 13. Wrench- Rotates or drives nuts, bolts, and screws. 14. Pliers- Used for gripping, bending, and holding small parts. 15. File- A tool made of hard steel used for hand cutting metal sheets and removing portions from a metal stock. 16. Hacksaw- Cuts metal and other materials. 17. Scraper- Removes small amount of metals to produce an accurate surface. 18. Chisel- Cuts and chips metals to clean out corners, correct errors and cut grooves. 19. Snips- A scissor-like tool used use to cut very thin sheet metals. 20. Hand drill- Drills small holes on metals, wood or plastic. 21. Twist drill- Bores small holes on different metals. 22. Reamer- Smoothens the surface of a hole made by a drill to finish it to a standard size. 23. Mallet- A wooden hammer used to drive tools. 24. Drill press- A machine used for drilling holes in metals.

Lesson 4: Safety Precautions in Metalworks Metalworks require the use of sharp, pointed and electrically powered tools and equipments. Hence, utmost care must be observed to prevent accidents specially inside the work place where presence of oil and other foreign matters may cause serious injury. 1. Ask permission from your teacher before touching or operating machines. Do not use a machine with which you are not familiar. 2. Handtools such as scribers, screwdrivers, files, dividers should be kept in a tool cabinet when not in use, never in your pocket. 3. Use only tools in good working condition. Damaged tools should be repaired or replaced. 4. Make sure your hands are dry and you are not standing on wet floor before touching any electric machine. 5. Wear protective clothing and gadgets such as cap for your hair and goggles or eye shield when chipping, grinding, buffing, or pouring hot metals. 6. Remove all jewelry before starting to work. Avoid long sleeve clothes when working. 7. Keep flammable materials away from the working area. 8. Pick up immediately tools and materials dropped on the floor to prevent accidents. 9. Report accidents to your teacher immediately, no matter how minor these are. 10. Avoid playing and teasing inside the shop.

Вам также может понравиться

- Introduction To CarpentryДокумент57 страницIntroduction To CarpentryJonnah Sarmiento100% (1)

- Materials ManualДокумент720 страницMaterials Manualsukanta420100% (1)

- Jewelry Making for Beginners: 32 Projects with MetalsОт EverandJewelry Making for Beginners: 32 Projects with MetalsРейтинг: 4 из 5 звезд4/5 (2)

- Module in Industrial Arts 1Документ76 страницModule in Industrial Arts 1Kevin Nichols Abacan100% (1)

- The Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home BlacksmithОт EverandThe Home Blacksmith: Tools, Techniques, and 40 Practical Projects for the Home BlacksmithОценок пока нет

- Sheet Metal ShopДокумент43 страницыSheet Metal ShopBhaskar KandpalОценок пока нет

- Surface Repair Using Form-and-Pump Techniques: Field Guide To Concrete Repair Application ProceduresДокумент8 страницSurface Repair Using Form-and-Pump Techniques: Field Guide To Concrete Repair Application ProcedurescustomerxОценок пока нет

- I. Objectives: II. Subject MatterДокумент4 страницыI. Objectives: II. Subject MatterWilson Agustin100% (1)

- Basics of SolderingДокумент4 страницыBasics of SolderingNAIR KRISHNA RAVEENDRAN100% (2)

- Department of Education: Use of Basic Hand Tools and EquipmentДокумент11 страницDepartment of Education: Use of Basic Hand Tools and EquipmentJay BustamanteОценок пока нет

- Introduction To Smaw Classification of ToolsДокумент31 страницаIntroduction To Smaw Classification of ToolsJensly Tias100% (1)

- Metal WorksДокумент16 страницMetal WorksMAXINE DELA ROSAОценок пока нет

- BIS 455 - Portland Slag Cement SpecificationДокумент14 страницBIS 455 - Portland Slag Cement Specificationvikramgoenka100% (1)

- Woven Fabrics AtiqДокумент291 страницаWoven Fabrics AtiqMohammed Atiqul Hoque ChowdhuryОценок пока нет

- Welding Technology: By: Engr. Elmer B. Dollera, MSMEДокумент31 страницаWelding Technology: By: Engr. Elmer B. Dollera, MSMEReuven SioseОценок пока нет

- Tle 7 and 8 Smaw Week1Документ6 страницTle 7 and 8 Smaw Week1Mary Angeline MabulayОценок пока нет

- Use Basic Hand Tools and Equipment: Effective Alternative Secondary Education (Ease) ProgramДокумент18 страницUse Basic Hand Tools and Equipment: Effective Alternative Secondary Education (Ease) ProgramJoseph Caloscos100% (5)

- Sheet Metal ShopДокумент35 страницSheet Metal ShopAshish SinghОценок пока нет

- Tvl-Ia-Smaw: Quarter 1 - Module 1B: Prepare Tools, Materials, and Equipment For WeldingДокумент25 страницTvl-Ia-Smaw: Quarter 1 - Module 1B: Prepare Tools, Materials, and Equipment For WeldingLoli Gonzales ArtiagaОценок пока нет

- Sheet 20metal 20shop 131017100652 Phpapp01Документ37 страницSheet 20metal 20shop 131017100652 Phpapp01eafz111Оценок пока нет

- DR Kumar Neeraj Jha July15 PDFДокумент73 страницыDR Kumar Neeraj Jha July15 PDFShalom ArayaОценок пока нет

- Thermal SprayДокумент42 страницыThermal Spraykac147100% (1)

- Bench Worh ConДокумент53 страницыBench Worh Conaragawyohannes3Оценок пока нет

- Metal AlloysДокумент6 страницMetal AlloysMarinilla Dela TorreОценок пока нет

- Chapter 4 Metal Craft IiaДокумент3 страницыChapter 4 Metal Craft IianicoleОценок пока нет

- Rohit WeldingДокумент13 страницRohit WeldingSachin KhadkaОценок пока нет

- Trabajo MetalesДокумент5 страницTrabajo MetalesJuan MadronaОценок пока нет

- Intro Sheet Metal FabricationДокумент13 страницIntro Sheet Metal FabricationIKОценок пока нет

- How Are Metal Extracted From Ores 1Документ11 страницHow Are Metal Extracted From Ores 1vimal_730389669Оценок пока нет

- Engg Chem - Matoy RussellДокумент1 страницаEngg Chem - Matoy RussellGoldèn DawnОценок пока нет

- SWEPДокумент11 страницSWEPRizzleОценок пока нет

- Imp ReviewerДокумент12 страницImp ReviewerJohn Jeric de LunaОценок пока нет

- 1 Welding Research TankДокумент5 страниц1 Welding Research TankRen ConcepcionОценок пока нет

- Metal PropertiesДокумент17 страницMetal PropertiesAzzah NazОценок пока нет

- CHAPTER 7.fabrication&weldingДокумент8 страницCHAPTER 7.fabrication&weldingIsrael PopeОценок пока нет

- PROPERTIES AND USES OF METALS Group2E MATДокумент26 страницPROPERTIES AND USES OF METALS Group2E MATNormandy AlcantaraОценок пока нет

- SCC - Electonics - Q4M2Weeks3-4 - PASSED NO AKДокумент18 страницSCC - Electonics - Q4M2Weeks3-4 - PASSED NO AKLyle Isaac L. IllagaОценок пока нет

- Lesson 3 in CarpentryДокумент8 страницLesson 3 in CarpentryLeo Nino DulceОценок пока нет

- Electrical ToolsДокумент4 страницыElectrical ToolsCris Anne AlvarezОценок пока нет

- Exp 1Документ4 страницыExp 1Priyank GoswamiОценок пока нет

- Smaw Week 3 4Документ24 страницыSmaw Week 3 4Joseph Bautista100% (1)

- Metal WorkingДокумент45 страницMetal WorkingLilith StarkОценок пока нет

- Sheet Metal 3&4Документ29 страницSheet Metal 3&4Muhd Shabeeb AОценок пока нет

- Fitting ShopДокумент26 страницFitting ShopBiladenОценок пока нет

- Ballpeenhammer FДокумент15 страницBallpeenhammer FnickoleОценок пока нет

- Final DemoДокумент20 страницFinal DemoMarivel De Jesus CaingletОценок пока нет

- 8 Different Types of Metal Cutting Tools and Their UsesДокумент31 страница8 Different Types of Metal Cutting Tools and Their UsesAlexander MwauraОценок пока нет

- Marc Kevin B. GonzalesДокумент4 страницыMarc Kevin B. GonzalesBenjie flor CalayegОценок пока нет

- Ia Q0 Las 1 Smaw 7 8 FinalДокумент11 страницIa Q0 Las 1 Smaw 7 8 Finalruelquirino29Оценок пока нет

- Chap 2 Part 2Документ5 страницChap 2 Part 2Kristine Joy Dawa IyoОценок пока нет

- Industrial Production Engineering - 1-1Документ71 страницаIndustrial Production Engineering - 1-1Freby Tony EОценок пока нет

- Workshop Practice DE-42 Mechatronics: SyndicateДокумент5 страницWorkshop Practice DE-42 Mechatronics: SyndicateibrahimОценок пока нет

- Exp 1Документ4 страницыExp 1ᴀᴍᴀɴОценок пока нет

- State University of Performing & Visual Arts: Module Title Market SourcingДокумент33 страницыState University of Performing & Visual Arts: Module Title Market SourcingSagar SinghОценок пока нет

- MS-II Lab ManualДокумент18 страницMS-II Lab ManualdibyenindusОценок пока нет

- Construction Materials and Testing: "Metals"Документ6 страницConstruction Materials and Testing: "Metals"Aira Joy AnyayahanОценок пока нет

- Lesson Plan - Electrical Tools and EquipmentДокумент2 страницыLesson Plan - Electrical Tools and Equipmentwels berdОценок пока нет

- Midterm Unit 6 HandtoolsДокумент10 страницMidterm Unit 6 HandtoolsAliceОценок пока нет

- Workshop AssignmentДокумент9 страницWorkshop Assignmentkajalverma2301Оценок пока нет

- K To 12 Basic Education Curriculum: Shielded Metal Arc Work (SMAW)Документ18 страницK To 12 Basic Education Curriculum: Shielded Metal Arc Work (SMAW)Dy IsottoОценок пока нет

- Metal PropertiesДокумент17 страницMetal PropertiesThe Engineers EDGE, CoimbatoreОценок пока нет

- SMAW 9 - Q1 - W3 - Mod3Документ19 страницSMAW 9 - Q1 - W3 - Mod3Romeo Dela RosaОценок пока нет

- PDF Q1 Mod 1B SMAW 11 EnhancedДокумент27 страницPDF Q1 Mod 1B SMAW 11 EnhancedRosciane BallesterosОценок пока нет

- Module-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationДокумент10 страницModule-3 Aircraft Hardware Materials Systems Processes: Basic Hand Tools Used in AviationDinesh ChandranОценок пока нет

- Principles of Machine Shop Practice RST1Документ4 страницыPrinciples of Machine Shop Practice RST1Joel Kelly Cangrehilla MabaoОценок пока нет

- Workshop Report (1) 2C25 (1588)Документ8 страницWorkshop Report (1) 2C25 (1588)Thazin LinnОценок пока нет

- Sialon ENДокумент2 страницыSialon ENsusu222000Оценок пока нет

- Nortoncatalog Sharpeningstones PDFДокумент14 страницNortoncatalog Sharpeningstones PDFMarian DragosОценок пока нет

- How To Control ShrikageДокумент2 страницыHow To Control Shrikagestylish eagleОценок пока нет

- 142 Ward Avenue, Hamilton, May 29, 2012Документ88 страниц142 Ward Avenue, Hamilton, May 29, 2012miiszОценок пока нет

- Formula Costo SandblastingДокумент20 страницFormula Costo SandblastingSerch VillaОценок пока нет

- Bostik Boscoseal Puxrev 1Документ4 страницыBostik Boscoseal Puxrev 1Yayat Syam HidayatОценок пока нет

- Waterlust Alaia ManualДокумент13 страницWaterlust Alaia ManualClaudio ColettaОценок пока нет

- C 1172 - 96 - QzexnzitukveДокумент7 страницC 1172 - 96 - QzexnzitukveangeljosechuquiureОценок пока нет

- Poly Bag Costing For Apparel MerchandisingДокумент2 страницыPoly Bag Costing For Apparel MerchandisingerabbiОценок пока нет

- N322 TDS Us Okf PDFДокумент2 страницыN322 TDS Us Okf PDFLindi NewmanОценок пока нет

- Etag 002 PT 2 PDFДокумент13 страницEtag 002 PT 2 PDFRui RibeiroОценок пока нет

- BS2L99 Alloy DetailДокумент2 страницыBS2L99 Alloy Detailcharles_boyle_3Оценок пока нет

- Exothermic Welconnection Copper Strip To Ground RodДокумент8 страницExothermic Welconnection Copper Strip To Ground RodBenny HillОценок пока нет

- DSR 2016 (Vol.1) PDFДокумент234 страницыDSR 2016 (Vol.1) PDFJoe78% (54)

- Forgingforging ProcessДокумент13 страницForgingforging Processpatel ketanОценок пока нет

- ExteriorScape Product GuideДокумент28 страницExteriorScape Product GuideWorld Outdoor EmporiumОценок пока нет

- Sika MonoTop 615 PDS (CE)Документ6 страницSika MonoTop 615 PDS (CE)Virah Sammy ChandraОценок пока нет

- Welder Model QuestionДокумент4 страницыWelder Model QuestionSaheed JdtОценок пока нет

- Askeland ChapterДокумент79 страницAskeland ChapterjuegyiОценок пока нет

- Fiberglass Piping SystemДокумент13 страницFiberglass Piping Systemashish2783Оценок пока нет

- Mechanical Behavior and Dynamic Mechanical Analysis Study On Nanoclay Filled Carbon-Epoxy CompositesДокумент11 страницMechanical Behavior and Dynamic Mechanical Analysis Study On Nanoclay Filled Carbon-Epoxy CompositesKarthikeyan MurugananthanОценок пока нет

- CP CatalogДокумент273 страницыCP Catalogrocket-vtОценок пока нет

- Lube 1090Документ2 страницыLube 1090ΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣОценок пока нет

- 15-16 CPWD Panchayath Office MaintenanceДокумент153 страницы15-16 CPWD Panchayath Office MaintenanceMahin ThaliyathОценок пока нет