Академический Документы

Профессиональный Документы

Культура Документы

Advanced Quality Planning Status Report

Загружено:

rajivggocАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Advanced Quality Planning Status Report

Загружено:

rajivggocАвторское право:

Доступные форматы

ADVANCED QUALITY PLANNING WORKSHEET

Part Number: Part Name: Program: Customer: Production Plans: Scheduled Date for Initial Samples: Scheduled Date for First Production: Scheduled Date for Regular Production: Quality Plan Report: Original Issue Date: Revision Date(s):

Quality Planning Elements

16

15

14

13

12

11

10

Weeks Prior to Production Start

Initial Quality Assessments

Preliminary Feasibility Quality History Review Customer Complaints Warranty Info (if applicable) Prior Statistical Info All Other Indicators Process FMEA Major Characteristics (Process/Product) Gage & Test Equipment Variable Attribute

Standards Preparation

Process Flowchart including Control Points Control Plan including SPC Requirements Inspection Instruction Sheet

Prototype Build/Verification

Prototype Build with Process Potential for Feasiblity Final Feasibility & Sign-off

Processing Equipment/Verification

Order Production Tooling, Gages, & Test Equipment Process Potential Studies on Vendor's Floor Setup & Debug Production & Inspection Equipment Process Potential Studies for all Major Characs.

Evaluation Activities

Process Review/Production Sign-off Process Sheets Gage & Test Equipment Packaging Initial Sample & First Production Part Evaluation SPC Data

Adapted from the APQP Ref. Manual

http://thequalityportal.com

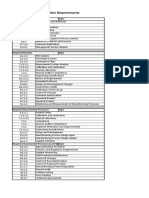

ADVANCED PRODUCT QUALITY PLANNING STATUS REPORT

Date: Supplier Name: Location: Supplier Code: RISK ASSESMENT Part Number: Part Name: Revision Level:

New:

Site

Technology

Process

Team Members

Company

Title / Position

Contact Information (tele, fax, mobile, pager, etc.)

CAPABILITY STUDIES

KPC # Date

Report the Ppk of each KPC on an on-going basis, as the process changes and new lots are manufactured

APQP ELEMENTS FMEA Feasibility Commitment 3 Preliminary Process Flow and PFMEA 4 Design Review(s) 5 Facilities & Tools 6 Gauging and Test Equipment 7 Prototype Build Control Plan 8 Design, Drawings and Specifications 9 Logistics/EDI Capability 10 Packaging Specifications 11 Manufacturing Process Flow Chart 12 Process FMEA & Control Plan Review 13 Measurement Systems Evaluation 14 Pre-Launch Control Plan GP12 15 Operator Process Instructions 16 Production Trial Run (Capacity Verified) 17 Production Control Plan 18 Production Source Approval 19 Production Part Approval (PPAP)

2 Team 20 Production 1 Design

AIAG APQP Status Element (G/Y/R or N/A)

Program Date

Supplier Date

Closed Date

Resp. Engineer Initials

Remarks or Note Assistance Required

Readiness

Additional Comments:

Вам также может понравиться

- PPAP TemplatesДокумент23 страницыPPAP Templatestejesh77100% (1)

- APQP Checklist Combined Rev 5 - 2Документ17 страницAPQP Checklist Combined Rev 5 - 2Neil SarkarОценок пока нет

- APQP Check ListДокумент17 страницAPQP Check ListmdjeckelОценок пока нет

- VCC Phased PPAP Requirements Handbook - V2Документ14 страницVCC Phased PPAP Requirements Handbook - V2medi38Оценок пока нет

- APQP ChecklistДокумент18 страницAPQP ChecklistmichaelbarkovicОценок пока нет

- Appendix 25 VDA 6 3 Process AuditДокумент12 страницAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- Cooper Industries PPAP Quick ReferenceДокумент1 страницаCooper Industries PPAP Quick ReferenceMoraru CiprianОценок пока нет

- APQP ProcedureДокумент9 страницAPQP ProcedurePk Nimiwal100% (4)

- Responsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsДокумент4 страницыResponsibility Rank of Development: D:/APQP Document/ Special Product and Process CharactesticsAL BARAKAH GRAINS100% (1)

- Manual - APQP 20121017 PDFДокумент135 страницManual - APQP 20121017 PDFBerk NoyanОценок пока нет

- APQP Training MaterialДокумент13 страницAPQP Training Materialsuresh kumar100% (1)

- Advance Product Quality Planning - MatrixДокумент6 страницAdvance Product Quality Planning - Matrixomm100% (1)

- APQP TemplateДокумент7 страницAPQP TemplateBob ZepfelОценок пока нет

- AIAG PPAP Cover SheetДокумент1 страницаAIAG PPAP Cover SheetSCHOPENHAUERОценок пока нет

- GM 1927-16 PCPA ChecksheetДокумент4 страницыGM 1927-16 PCPA Checksheetrahul100% (1)

- Cooper Industries PPAP Forms KitДокумент25 страницCooper Industries PPAP Forms KitAshutosh SinghОценок пока нет

- Procedure APQPДокумент9 страницProcedure APQPAzmul Fadhli80% (10)

- ChryslerДокумент117 страницChryslerdokser29100% (1)

- Apqp FormsДокумент32 страницыApqp FormsAnonymous A2jnZ5MNPxОценок пока нет

- IATF 16949 DocumenДокумент1 страницаIATF 16949 Documenpunitg_2Оценок пока нет

- 1 ApqpДокумент30 страниц1 ApqpVIPIN YADAVОценок пока нет

- Giriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeДокумент9 страницGiriraj Precision Screws PVT - Ltd. Quality Manual Procedure APQP (Advanced Product Quality Planning) 1. PurposeMohit KaushikОценок пока нет

- Apqp FormsДокумент25 страницApqp FormsgkspОценок пока нет

- Advanced Product Quality PlanningДокумент35 страницAdvanced Product Quality Planninggerry3854100% (2)

- APQP Supplier ProcedureДокумент20 страницAPQP Supplier ProcedurepharmatonОценок пока нет

- GS-0002D, Design FMEAДокумент26 страницGS-0002D, Design FMEAmesa142100% (1)

- APQP Manual VolvoДокумент30 страницAPQP Manual VolvoVictor Hugo50% (2)

- S ApqpДокумент15 страницS ApqpIram ChaviraОценок пока нет

- PPAPДокумент51 страницаPPAPGuru PrasadОценок пока нет

- PS - APQP Check ListДокумент17 страницPS - APQP Check ListalexrferreiraОценок пока нет

- Apqp & PpapДокумент63 страницыApqp & Ppapjd4u100% (1)

- Apqp PpapДокумент50 страницApqp PpapAlpkan YılmazОценок пока нет

- APQP ENG SiemensДокумент12 страницAPQP ENG SiemensVikash KumarОценок пока нет

- Clausul IATFДокумент8 страницClausul IATFAhmad ZainuddinОценок пока нет

- Apqp - DR SHFTДокумент60 страницApqp - DR SHFTrajesh5000100% (2)

- APQPДокумент3 страницыAPQPsam1hi5Оценок пока нет

- APQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Документ49 страницAPQP 3 - 1 Pan Brand Reporter V7c (586) Rev 19Pranjal JangidОценок пока нет

- DRBFM WorksheetДокумент1 страницаDRBFM WorksheetHareth MRAIDIОценок пока нет

- Apqp Status LogДокумент1 страницаApqp Status Logsathyabalaraman67% (3)

- QMP-10 New Product DevelopmentДокумент15 страницQMP-10 New Product Developmentom cnc100% (1)

- New Product Development Npd (新產品開發流程) 第二組Документ44 страницыNew Product Development Npd (新產品開發流程) 第二組littlekheongОценок пока нет

- Ppap-Template 4th EditionДокумент23 страницыPpap-Template 4th EditionAshutosh SinghОценок пока нет

- GP-9 Process Control Plan Audit Summary SheetДокумент5 страницGP-9 Process Control Plan Audit Summary SheetAsifОценок пока нет

- Supplier APQP ProcedureДокумент12 страницSupplier APQP ProcedureNabeel Arya ZahranОценок пока нет

- Apqp Advanced Product Quality PlanningДокумент27 страницApqp Advanced Product Quality PlanningRajesh KumarОценок пока нет

- Required Doc For IATFДокумент3 страницыRequired Doc For IATFAbhayОценок пока нет

- Ppap CriteriaДокумент1 страницаPpap CriteriaramanriОценок пока нет

- APQPДокумент25 страницAPQPHeera Singh100% (3)

- ISO 13485 Quality Management System A Complete Guide - 2021 EditionОт EverandISO 13485 Quality Management System A Complete Guide - 2021 EditionОценок пока нет

- APQPДокумент2 страницыAPQPSachin Kumbhar67% (3)

- Appendix F Apqp Form4Документ1 страницаAppendix F Apqp Form4FranciscoBizarroОценок пока нет

- Aqp Flow FmeaДокумент2 страницыAqp Flow FmeaqmsnorthОценок пока нет

- Apqp PpapДокумент50 страницApqp PpapEvandro Ribeiro50% (2)

- Phased Ps Wwith P Pap Tracking FormДокумент3 страницыPhased Ps Wwith P Pap Tracking FormKurt FinkОценок пока нет

- SAQP Elements OverviewДокумент38 страницSAQP Elements OverviewBoštjan Dokl MenihОценок пока нет

- Process Performance Qualification ProtocolДокумент7 страницProcess Performance Qualification Protocolsandeep sharmaОценок пока нет

- Run at Rate AuditДокумент12 страницRun at Rate AuditPurushothama Nanje GowdaОценок пока нет

- The Basics of PPAPДокумент29 страницThe Basics of PPAPஎன் கருத்துОценок пока нет