Академический Документы

Профессиональный Документы

Культура Документы

Simple Light Sensitive Switch

Загружено:

Bharath KumarИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Simple Light Sensitive Switch

Загружено:

Bharath KumarАвторское право:

Доступные форматы

QUASAR ELECTRONICS KIT No 1072 SIMPLE LIGHT SENSITIVE SWITCH FOR 220V LIGHT BULBS

General Description There are cases that a light bulb is needed to turn on whenever no other source of light is available within a room. Similarly, it is also needed to turn off as soon as there is adequate light available. This light sensitive switch is capable of switching a light bulb in this manner. Such a switch may be fitted in the childrens room. Young children always need to have some sort of light available in their room. It is often the case that the child is left to sleep through the afternoon hours just to wake up in the evening and find that it is left alone in the darkness. It obviously gets scared and cries. Kit 1072 can take care of this. It can be insta lled in the childs room and turn a small light on as soon as darkness falls. The child will never wake up and find himself in the darkness again. There are also times that someone stays late in the study room. The work is so exciting that darkness falls o utside the house and no one takes notice. The light available within the study room becomes inadequate, the eyes get tired and hurt. Yet it is only when someone else walks into the room and turns the lights on that the low light level is actually appreciated. Kit 1072 can take care of this too. It can be installed in the study room and turn the lights on so as to keep the illumination level steady. No matter how exciting the work is, the reader will not have to hurt his eyes again.

Technical Specifications - Characteristics - Power supply voltage :..........220 VAC, - Load power :..........................150 W (without a heatsink), - Ability to adjust the level of light available (high, medium, or low light level) - Use of both positive and negative half-periods of the 220V supply, thus offering full power capability.

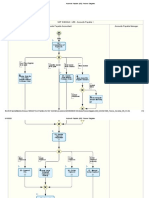

How it Works Fig. 1 shows the circuits schematic diagram. It is clear that it consists of a very simple design. R1, P1 and LDR1 form a voltage divider. This divider sets the operating point of the gate of TRIAC TRi1. TRIAC TRi1 is the actual 220 V switch of the load. There is also a DIAC connected in between them. This is D1. Its threshold voltage sets the point at which the TRIAC gate is fired. The resistance of photoresistor LDR1, falls to a low value whenever light falls on its surface. As a consequence, capacitor C1 cannot get charged adequately so as to attain a voltage high enough to trigger the DIAC. The TRIAC is therefore not fired whenever there is an adequate light level around LDR1. This light level is set by adjusting trimmer P1. On the other hand, the resistance of photoresistor LDR1 rises to a high value as soon as there is little light falling on it. In this case, capacitor C1 is charged properly and attains a voltage high enough to trigger the DIAC. This, in turn, fires the gate of TRi1 and the load (most probably a 220V light bulb) is thus turned on. Trimmer P1 adjusts the light level at

which this switching action takes place.

Construction First of all let us consider a few basics in building electronic circuits on a printed circuit board. The board is made of a thin insulating material clad with a thin layer of conductive copper that is shaped in such a way as to form the necessary conductors between the various components of the circuit. The use of a properly designed printed circuit board is very desirable as it speeds construction up considerably and reduces the possibility of making errors. Quasar Electronics Kit boards also come pre-drilled and with the outline of the components and their identification printed on the component side to make construction easier. To protect the board during storage from oxidation and assure it gets to you in perfect condition the copper is tinned during manufacturing and covered with a special varnish that protects it from getting oxidised and makes soldering easier. Soldering the components to the board is the only way to build your circuit and from the way you do it depends greatly your success or failure. This work is not very difficult and if you stick to a few rules you should have no problems. The soldering iron that you use must be light and its power should not exceed the 25 Watts. The tip should be fine and must be kept clean at all times. For this purpose come very handy specially made sponges that are kept wet and from time to time you can wipe the hot tip on them to remove all the residues that tend to accumulate on it.

DO NOT file or sandpaper a dirty or worn out tip. If the tip cannot be cleaned, replace it. There are many different types of solder in the market and you should choose a good quality one that contains the necessary flux in its core, to assure a perfect joint every time.

DO NOT use soldering flux apart from that which is already included in your solder. Too much flux can cause many problems and is one of the main causes of circuit malfunction. If nevertheless you have to use extra flux, as it is the case when you have to tin copper wires, clean it very thoroughly after you finish your work. In order to solder a component correctly you should do the following: Clean the component leads with a small piece of emery paper. - Bend them at the correct distance from the component body and insert the component in its place on the board. You may find sometimes a component with heavier gauge leads than usual, that are too thick to enter in the holes of the p.c. board. In this case use a mini drill to enlarge the holes slightly. Do not make the holes too large as this is going to make soldering difficult afterwards. Take the hot iron and place its tip on the component lead while holding the end of the solder wire at the point where the lead emerges from the board. The iron tip must touch the lead slightly above the p.c. board. When the solder starts to melt and flow wait till it covers evenly the area around the hole and the flux boils and gets out from underneath the solder. The whole operation should not take more than 5 seconds. Remove the iron and let the solder to cool naturally without blowing on it or moving the component. If everything was done properly the surface of the

joint must have a bright metallic finish and its edges should be smoothly ended on the component lead and the board track. If the solder looks dull, cracked, or has the shape of a blob the n you have made a dry joint and you should remove the solder (with a pump, or a solder wick) and redo it. Take care not to overheat the tracks as it is very easy to lift them from the board and break them. When you are soldering a sensitive component it is good practice to hold the lead from the component side of the board with a pair of long-nose pliers to divert any heat that could possibly damage the component. Make sure that you do not use more solder than it is necessary as you are running the risk of short-circuiting adjacent tracks on the board, especially if they are very close together. After having finished your work cut off the excess of the component leads and clean the board thoroughly with a suitable solvent to remove all flux residues tha t still remain on it. A printed circuit board is provided for this circuit. Its dimensions are 22x33 mm. This board is therefore small enough so as to be installed almost anywhere. Thus, no extra casing is required. Fig. 2 shows the component layout diagram of the circuit. Fig. 3 shows the pin connections of TRIAC, LDR and the DIAC. The components may be easily installed simply by taking the fig. 2 diagram as a guide. It is preferable to follow a specific order though. Resistor R1 is installed first in an upright position. DIAC D1 is installed next with capacitor C1, trimmer P1 and TRIAC TRi1, following in this order. The 220V power supply is connected to points 1 and 2. The load is connected to points 3 and 4. Photoresistor LDR1 must be installed in such a way so as to have the rooms light falling on it. It may be necessary to use a piece of wire in order to connect it to the board in this case. ATTENTION: THERE ARE 220 V ON ALL POINTS OF THE PRINTED CIRCUIT BOARD. SUCH VOLTAGE IS LETHAL. In the case that LDR1 is actually installed in some distance from the main board, it is important not to touch its metal part. IT IS REPEATED THAT THE 220 V VOLTAGE IS LETHAL. EVERYONE SHOULD PAY PARTICULAR ATTENTION WHEN HANDLING SUCH VOLTAGES AND NOT RISK HIS LIFE. It is good practice to run a check on the installation of all the components of the board before operating the circuit. It is better to run an early check instead of an early repair. A bulb may be connected between points 3 and 4, as soon as the circuit is checked and any mistakes found are corrected. Points 1 and 2 should be connected to the 220 V supply. There are two possible cases at this point: a) The bulb may be turned off by the circuit. In this case, photoresistor LDR1 should be CAREFULLY covered. The bulb should light up. Its intensity should be increased as long as the light incident on LDR1 is decreased. b) The bulb may be turned on by the circuit. In this case, trimmer P1 should be CAREFULLY adjusted so as to turn the bulb off. Photoresistor LDR1 should be CAREFULLY covered as soon as this happens. There should be a small amount of light incident on it. The bulb should turn on again. The less light falls on it, the brighter the bulb should be.

NOTE: The bulb connected at the output is trembling each time the amount of light incident on the photoresistor LDR1 is gradually reduced. This is something to be expected since the TRIACs gate is fired for a series of full half-periods the number of which is adjusted by the voltage at capacitor C1. It is NOT fired at an angle with respect to the beginning of each half-period.

Adjustments This kit does not need any adjustments, if you follow the building instructions. Warning Quasar Electronics kits are sold as stand alone training kits. If they are used as part of a larger assembly and any damage is caused, our company bears no responsibility. While using electrical parts, handle power supply and equipment with great care, following safety standards as described by international specs and regulations. ATTENTION: THERE ARE 220 V ON ALL POINTS OF THE PRINTED CIRCUIT BOARD. SUCH VOLTAGE IS LETHAL. In the case that LDR1 is actually installed in some distance from the main board, it is important not to touch its metal part. IT IS REPEATED THAT THE 220 V VOLTAGE IS LETHAL. EVERYONE SHOULD PAY PARTICULAR ATTENTION WHEN HANDLING SUCH VOLTAGES AND NOT RISK HIS LIFE.

If it does not work 1. The power supply should be disconnected. THERE IS EXTREME DANGER IF THIS IS NOT DONE. 2. All components should be CAREFULLY checked. Any components that are excessively hot, distorted, or look suspicious, should be checked or replaced. 3. Are any components installed the wrong way round or at the wrong place? 4. Are there any dry joints? A proper joint is spread all over the pad and is shiny. A dry joint is dull, bulky and has the shape of a ball. 5. Is there any short circuit formed between neighbouring printed circuit pads? 6. Has any solderene been used? Any solderene residues left behind should be thoroughly cleaned. If all these are checked and found to be correct, it is possible to reconnect the power supply.

If your project still fails to work, please contact us for information about our Get-You-Going service.

Electronic Diagram

Parts List All components including printed circuit board, assembly instructions including schematics and detailed parts list are supplied when you purchase the kit. Ordering For pricing info and online ordering please visit: http://www.quasarelectronics.com/1072.htm For further info please contact us by e-mail: mailto: sales@QuasarElectronics.com

COPYRIGHT 2003 Quasar Electronics Limited. All rights reserved. Reproduction of this document in whole or in part in any form or medium without express written permission of Quasar Electronics Limited is prohibited. E&OE

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Java ProgrammingДокумент134 страницыJava ProgrammingArt LookОценок пока нет

- Loading The Dataset: 'Churn - Modelling - CSV'Документ6 страницLoading The Dataset: 'Churn - Modelling - CSV'Divyani ChavanОценок пока нет

- Getting Ready For NZ Ifrs 16 Leases: Checklist - Utilising External Experts To Assist in The Adoption of NZ Ifrs 16Документ1 страницаGetting Ready For NZ Ifrs 16 Leases: Checklist - Utilising External Experts To Assist in The Adoption of NZ Ifrs 16Usman FiazОценок пока нет

- Introduction To Internet: Definition, History of Internet, Functions, Different ServicesДокумент20 страницIntroduction To Internet: Definition, History of Internet, Functions, Different ServicesMoonlight LotusОценок пока нет

- Problem Solving in OperationДокумент3 страницыProblem Solving in OperationMohammad RakibОценок пока нет

- Iedscout: Versatile Software Tool For Working With Iec 61850 DevicesДокумент12 страницIedscout: Versatile Software Tool For Working With Iec 61850 DeviceshmhaidarОценок пока нет

- Emptech Activity 1Документ6 страницEmptech Activity 1Ashley AgramonОценок пока нет

- Appendix B: Technical InformationДокумент11 страницAppendix B: Technical InformationOnTa OnTa60% (5)

- Technology and Tourism by Anil SangwanДокумент62 страницыTechnology and Tourism by Anil SangwanAkhil V. MadhuОценок пока нет

- SketchBook User ManualДокумент57 страницSketchBook User ManualJCM100% (1)

- Dresner Data Preparation Market Study 2021Документ101 страницаDresner Data Preparation Market Study 2021Carlos Alonso FernandezОценок пока нет

- VoyeurismДокумент9 страницVoyeurismsaurabhosaurus100% (1)

- IELTS Technology VocabularyДокумент4 страницыIELTS Technology Vocabularymanju sisodiyaОценок пока нет

- SAC Training 01Документ11 страницSAC Training 01Harshal RathodОценок пока нет

- SHA MAN 0052 Ver4 WebДокумент96 страницSHA MAN 0052 Ver4 WebGreed CssОценок пока нет

- SVCN CSE AI With IP InternshipДокумент72 страницыSVCN CSE AI With IP Internshipkvpravee28nОценок пока нет

- Pandapower PDFДокумент167 страницPandapower PDFAlen TatalovićОценок пока нет

- HP Pavilion 14 - x360 Touchscreen 2-In-1 Laptop - 12th Gen Intel Core I5-1235u - 1080p - Windows 11 - CostcoДокумент4 страницыHP Pavilion 14 - x360 Touchscreen 2-In-1 Laptop - 12th Gen Intel Core I5-1235u - 1080p - Windows 11 - CostcoTanish JainОценок пока нет

- Tda 7293Документ16 страницTda 7293AntónioRodriguesОценок пока нет

- Operating SystemsДокумент18 страницOperating SystemsMr. Rahul Kumar VermaОценок пока нет

- Design of Innovative Ship Concepts UsingДокумент22 страницыDesign of Innovative Ship Concepts UsingN KoteeswarОценок пока нет

- Hamidavi Et Al 2020 - Towards Intelligent Structural Design of Buildings AДокумент15 страницHamidavi Et Al 2020 - Towards Intelligent Structural Design of Buildings ARober Waldir Quispe UlloaОценок пока нет

- Accounts Payable (J60) - Process DiagramsДокумент16 страницAccounts Payable (J60) - Process Diagramsgobasha100% (1)

- Advanced Computer Architectures: 17CS72 (As Per CBCS Scheme)Документ31 страницаAdvanced Computer Architectures: 17CS72 (As Per CBCS Scheme)Aasim InamdarОценок пока нет

- 3d Object RepresentationsДокумент9 страниц3d Object RepresentationsJishnu JayakumarОценок пока нет

- Write About Global Catalog. How To View Replication Properties For AD PropertiesДокумент19 страницWrite About Global Catalog. How To View Replication Properties For AD PropertiesChandan KumarОценок пока нет

- Theories and Principles of Public Administration-Module-IVДокумент12 страницTheories and Principles of Public Administration-Module-IVAnagha AnuОценок пока нет

- HP Client Management Interface Technical WhitepaperДокумент39 страницHP Client Management Interface Technical Whitepaperpottytoddy1422Оценок пока нет

- Victor Chironda CV 2019Документ4 страницыVictor Chironda CV 2019Alex LebedevОценок пока нет

- MP Unit-3Документ24 страницыMP Unit-3SARTHAK PANWARОценок пока нет