Академический Документы

Профессиональный Документы

Культура Документы

Goodwin Dual Plate Check Valves

Загружено:

Jose Antonio Ramirez AcevesИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Goodwin Dual Plate Check Valves

Загружено:

Jose Antonio Ramirez AcevesАвторское право:

Доступные форматы

TECHNICAL ADVANTAGES OF SPECIFYING AND

QUALITY ASSURED

The Goodwin Dual Plate Check Valve is designed, manufactured and tested in facilities in the UK audited to BS EN ISO 9001. Goodwins valve shop and foundry have been registered by the British Standards Institute to ISO 9000 series for some twenty two years. Approval for both companies was first obtained in 1984. The steel foundry, Goodwin Steel Castings Ltd., was the first in Europe to receive such accreditation.

RETAINERLESS DESIGN (Pat)

Goodwin was one of the first dual plate check valve manufacturers to offer a retainerless design. This original patented design has now been superseded by a technically superior solution which is available in all types of Goodwin check valve - wafer, flanged, hub-ended and buttweld end. The engineer no longer needs to worry about whether spiral wound gaskets or ring joints are compatible as the Goodwin design accommodates both USA and European sealing elements. Not only does the retainerless design provide a higher integrity pressure vessel - no screwed plugs, Goodwins design enables the valve to be disassembled very quickly without the use of force or special tools other than an Allen wrench. The Goodwin retainerless check valve design concept is such that it is impossible for the valve to become disassembled in the line and does not utilise any springs or circlips. With improved machining technology Goodwin are able to offer this superior design as standard at a price equal or less than competitors valves with retaining plugs. There is no intrusion into the gasket sealing element surface by the retaining mechanism on Goodwin check valves. (Pat) = Patented Internationally

RETAINING PLUGS

On occasion, for technical reasons, e.g. compact flange and lined valves, Goodwin cannot supply its Retainerless design. In such instances, Goodwin will provide valves with retaining plugs. Retaining plugs have been successfully utilised on check valves for some 40 years.

Cv FACTORS

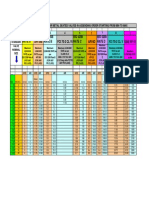

Goodwin 6" ANSI 1500 / 71/16 " API 5000 71/16 " API 5000 Major International Dual Plate Check Valve Competitor

2 1.8 1.6 1.4 Pressure Drop (bar) 1.2 1 0.8 0.6 0.4 0.2 0 0 50 100 150 200 Flow (m3/h) 250 300 350 400

From the adjacent graph it can be seen that the pressure drop in the Goodwin high pressure dual plate check valve is substantially less than that of other manufacturers. This superior performance is achieved by the use of Goodwins plates (Pat) which, through their slim design, offer less restriction to flow whilst in the fully open position. Also the plates by having a combination of rigidity in certain areas and flexibility in others make it possible to use larger throat areas in the body. This contributes to Goodwins better flow efficiencies whilst maintaining seat sealing performance. On conventional dual plate check valves there is typically a 50% reduction in valve throat area between a 150lb valve and a 1500lb valve, whereas there is only around 10% reduction on the Goodwin valve. From the FLUENT computer simulation (see page 41), it can be seen that the pressure drop is caused not only by a reduced flow area in the body but also by the plates constricting the flow path when in the open position. These constrictions are minimised in the Goodwin valve.

Diagram 1 (Feb. 1994)

USING GOODWIN DUAL PLATE CHECK VALVES

PLATE SHOCK BUMPERS

For many years Goodwin produced dual plate check valves with plate shock bumpers located at the extreme edge of the curve of the plate. Goodwins plate (Pat) now incorporates the plate bumper at the centre of mass of the plate approximately one-third the way in from the curved edge. With the plate bumper at the centre of mass, when the bumper of each plate collides, there is an equal and opposite force acting on the plates which prevents significant bending moments acting on the hinge pin of the plate. Plate bumpers are supplied as standard on all sizes, pressures and types of Goodwin Dual Plate Check Valves. It is an accepted fact that there will be occasions when the plates do not arrive fully open at the same instance. Clearance on the bumper allow and ensure the plates to hit each other rather than the stop pin. This helps prevent large forces being exerted on the stop pin which could cause damage. The stop pin has only one purpose, to stop a plate going over top dead centre when reverse flow occurs. If this did occur both plates would be on the same side of the valve leaving one port open, thereby stopping the valve performing its sole function of preventing reverse flow.

INDEPENDENT PLATE CLOSING ACTION

The independent spring action optimises the equal closing rates of each plate especially when friction coefficients are uneven due to one plate resting upon another. The springs have been designed to ensure stresses are kept to a level so that the spring should have a theoretical infinite life. Spring designs utilised in Goodwin valves have undergone accelerated laboratory testing and are proven to be capable of operating without failure over 2,000,000 cycles.

SEAT LIFE

Increased seat life is obtained by eliminating the problem of the plates dragging on the seat when opening. Due to the clearance between the plate hinge and the hinge pin, the heel of the plate lifts with the initial flow as the foot of the spring acts beyond the centre of pressure of the plate. As the flow then increases through the valve the plates open without the heels of the plate scuffing the body seat.

SEAT LEAKAGE - METAL TO METAL SEATS

The dual plate check valve is tested to API 598 which has a metal to metal seat permitted seal leakage of 3 cc/inch of bore/min. This small but significant amount arises because it is more difficult to obtain a perfect seal on a D shaped seat compared to a circular seat. The Goodwin plates (Pat) have been specifically designed to overcome this problem and to be better at sealing than earlier designs, such that near zero leakage can be economically achieved on metal to metal seats. This is particularly useful on high temperature gas applications and cryogenic applications where it is not possible to use resilient seats. In contrast to other dual plate check valves the seat sealing characteristics of the Goodwin valve are enhanced as line pressure increases unlike competitors valves which can significantly deteriorate in higher pressure classes. This characteristic enables Goodwin to provide dual plate check valves with substantially lower leakage rates than specified in API 598.

Вам также может понравиться

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Riso Ammonia Transport Safety ReportДокумент160 страницRiso Ammonia Transport Safety ReportAlexandros GiannikosОценок пока нет

- Road Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОт EverandRoad Map Update for Carbon Capture, Utilization, and Storage Demonstration and Deployment in the People’s Republic of ChinaОценок пока нет

- 2014q A AmmoniaДокумент18 страниц2014q A AmmoniachunkyОценок пока нет

- Various Departments of SML ISUZU1Документ19 страницVarious Departments of SML ISUZU1AKash SharmaОценок пока нет

- 05 V PattabathulaДокумент16 страниц05 V Pattabathulapcorreia_81Оценок пока нет

- Hazardous Area Classification of Gas InstallationsДокумент3 страницыHazardous Area Classification of Gas InstallationspomaukОценок пока нет

- Velan High Pressure Steam Trapping Brochure PDFДокумент8 страницVelan High Pressure Steam Trapping Brochure PDFSH1961Оценок пока нет

- Stolt Tank Containers B.V. General Terms & ConditionsДокумент12 страницStolt Tank Containers B.V. General Terms & ConditionsPeterWangОценок пока нет

- Butterfly Valve Info PDFДокумент14 страницButterfly Valve Info PDFCS100% (1)

- Valves remain key to LNG plant operationsДокумент2 страницыValves remain key to LNG plant operationsgembirasekaliОценок пока нет

- Valve Leakage Class CompДокумент1 страницаValve Leakage Class CompSantoshi PriyaОценок пока нет

- 6 Kvat Commodity CodeДокумент11 страниц6 Kvat Commodity CodeAnu VenkateshОценок пока нет

- How To Seek The Commodity CodesДокумент15 страницHow To Seek The Commodity CodesMahmoud A. SalemОценок пока нет

- Cryogenic - Catalog eДокумент56 страницCryogenic - Catalog eĐặng Đình SỹОценок пока нет

- Ansi Vs API PumpsДокумент4 страницыAnsi Vs API PumpsarcanicrahulОценок пока нет

- DBB CatalogueДокумент28 страницDBB CatalogueHeri SetyantoОценок пока нет

- Applications Guideline-Flashing (Water)Документ2 страницыApplications Guideline-Flashing (Water)strahor7492Оценок пока нет

- BS en 876-1995 PDFДокумент12 страницBS en 876-1995 PDFMalik khurram shahzadОценок пока нет

- Sodium Hypochlorite - Storage: Please Consult Our Safety Data SheetДокумент4 страницыSodium Hypochlorite - Storage: Please Consult Our Safety Data SheetIoana PopescuОценок пока нет

- Mercury RemovalДокумент15 страницMercury RemovalannaОценок пока нет

- NYP BM0075 Financial Analysis ProjectДокумент10 страницNYP BM0075 Financial Analysis ProjectKeo NgОценок пока нет

- Piping Study - HomeДокумент5 страницPiping Study - HomeshantilalОценок пока нет

- CenpesДокумент20 страницCenpesnskumarmОценок пока нет

- Slenderness RatioДокумент6 страницSlenderness RatioDuke StonerОценок пока нет

- Liquid Jet PumpsДокумент1 страницаLiquid Jet PumpsShams TabrezОценок пока нет

- Off Brochure Petronas-Flng LR PDFДокумент8 страницOff Brochure Petronas-Flng LR PDFDak Kaiz100% (1)

- 2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankДокумент19 страниц2015 Orooji Pardis Lessons Learned From Decommissioning of A Liqud Ammonia Storage TankAdnan AliОценок пока нет

- Managing Boil Off Gas from LNG CarriersДокумент30 страницManaging Boil Off Gas from LNG CarrierskhenzyОценок пока нет

- Practical Vacuum Journal Contamination Sources RemediesДокумент4 страницыPractical Vacuum Journal Contamination Sources RemediesBenjamin BrownОценок пока нет

- Astm MaterialsДокумент13 страницAstm Materialssathish_iyengarОценок пока нет

- Commodity CodeДокумент30 страницCommodity Codesaurabh10mittalОценок пока нет

- Ebara Cryo BrochureДокумент20 страницEbara Cryo BrochuremishraenggОценок пока нет

- 4505 DiaphragmValves RWДокумент49 страниц4505 DiaphragmValves RWdbmingoОценок пока нет

- TNVat Commodity CodeДокумент53 страницыTNVat Commodity Codepsenthilkumar757867% (3)

- 10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraДокумент20 страниц10.2.2 PCS Phosphate's New 4500 STPD Sulfuric Acid Plant in AuroraCarlosОценок пока нет

- PiggingДокумент5 страницPiggingDendi AriyonoОценок пока нет

- Cryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdДокумент7 страницCryogenic Ball Valve: Lishui Oak Valve Parts Co,.LtdShams TabrezОценок пока нет

- Swagelok Flange AdaptersДокумент6 страницSwagelok Flange AdapterstotcsabОценок пока нет

- Intrastat and EC Sales List in Dynamics AX 2009Документ22 страницыIntrastat and EC Sales List in Dynamics AX 2009IzabelinStudioОценок пока нет

- Regulator Control Valves - Series 5000Документ12 страницRegulator Control Valves - Series 5000Miriam bragaОценок пока нет

- RP G103 2007Документ82 страницыRP G103 2007Robert SmallwoodОценок пока нет

- F10ca004-Gb 0597Документ8 страницF10ca004-Gb 0597gabyorОценок пока нет

- Vat Commodity Code Schedule WiseДокумент34 страницыVat Commodity Code Schedule Wiseseetharaman_63100% (2)

- Tac SprayДокумент86 страницTac SprayparthasutradharОценок пока нет

- Steam Trace Specification PDFДокумент55 страницSteam Trace Specification PDFPaulo CostaОценок пока нет

- A Guide To The Implementation of API 653Документ3 страницыA Guide To The Implementation of API 653Anbarasan PerumalОценок пока нет

- NFPA 45 (2004) Requirements That Apply NowДокумент8 страницNFPA 45 (2004) Requirements That Apply NowCarlos EduardoОценок пока нет

- DELAvAN - Spray Nozzles Brochure PDFДокумент28 страницDELAvAN - Spray Nozzles Brochure PDFAnonymous jW9BkgbQmE0% (1)

- Manage diesel safely undergroundДокумент11 страницManage diesel safely undergroundErwinApriandiОценок пока нет

- 170630-1201 MultiPoint-Flare-SS FINAL JZHCДокумент4 страницы170630-1201 MultiPoint-Flare-SS FINAL JZHCManajemen Gas UI 2018Оценок пока нет

- ISO TC 197 Hydrogen Standards UpdateДокумент14 страницISO TC 197 Hydrogen Standards Updatejkhgvdj mnhsnjkhgОценок пока нет

- Swagelok High Pressure FittingsДокумент8 страницSwagelok High Pressure FittingsSyahirul AlimОценок пока нет

- RPA Rim Seal Foam Pourer GuideДокумент3 страницыRPA Rim Seal Foam Pourer Guideadilmomin45Оценок пока нет

- "Dual Plate Check Valve PDFДокумент16 страниц"Dual Plate Check Valve PDFMohaab NasrОценок пока нет

- API 6D Pipeline Gate Valves: Slab & Expanding DesignsДокумент16 страницAPI 6D Pipeline Gate Valves: Slab & Expanding DesignsiswantmachooОценок пока нет

- Fisher Control Valve Sourcebook - Power and Severe ServiceДокумент220 страницFisher Control Valve Sourcebook - Power and Severe Servicemtrj59Оценок пока нет

- DAN-EX Brochure WebДокумент12 страницDAN-EX Brochure Webzakkyf6455Оценок пока нет

- Gatevalve (Wedge Vs Parallel Slide - Flowserve)Документ5 страницGatevalve (Wedge Vs Parallel Slide - Flowserve)Shameer MajeedОценок пока нет

- Pressure Seal Valves-GateДокумент24 страницыPressure Seal Valves-GateHieu NguyenОценок пока нет

- CZ-RTC4 - Service ManualДокумент68 страницCZ-RTC4 - Service ManualAnonymous 31Airw50% (2)

- Pipe Sizes and Flow Rates for Air Flush DrillingДокумент14 страницPipe Sizes and Flow Rates for Air Flush DrillingzapspazОценок пока нет

- Factors Affecting Potential EnergyДокумент3 страницыFactors Affecting Potential EnergyArgyll PaguibitanОценок пока нет

- LLG FaultДокумент8 страницLLG Faultranjish_007Оценок пока нет

- Xref 2010Документ1 страницаXref 2010Axel Mahya AvichenaОценок пока нет

- Configuration 2-20-17 12 PDFДокумент2 страницыConfiguration 2-20-17 12 PDFbagusОценок пока нет

- Budget of Lesson Science 9Документ14 страницBudget of Lesson Science 9Hezl Valerie ArzadonОценок пока нет

- Model AR Ellipse® Annular Flow Meter PDFДокумент2 страницыModel AR Ellipse® Annular Flow Meter PDFjhorlanОценок пока нет

- Unu GTP SC 26 14Документ30 страницUnu GTP SC 26 14Ernesto RomeroОценок пока нет

- Separating Acetic Acid and Water by DistillationДокумент8 страницSeparating Acetic Acid and Water by DistillationSuzanne Clariz M. BaltazarОценок пока нет

- Fluid Flow Applications: SolutionДокумент6 страницFluid Flow Applications: Solutionmanikandaprabhu.rk14Оценок пока нет

- Hydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Документ22 страницыHydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Thulasidasan JeewaratinamОценок пока нет

- Ncert Summary Class 12th PhysicsДокумент29 страницNcert Summary Class 12th Physicsmeghraj.socialОценок пока нет

- Symmetry & Crystal StructuresДокумент37 страницSymmetry & Crystal StructuresNurnajihah Sukimi JiehaОценок пока нет

- (Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFДокумент321 страница(Geoffrey Lawrence, Kristen Lyons, Tabatha Walling (BookFi) PDFIManОценок пока нет

- 24th Annual International Pittsburgh Coal 2007 WixДокумент10 страниц24th Annual International Pittsburgh Coal 2007 WixAmauche OgeОценок пока нет

- Impulse Valve Operator Kit IV.1.09.01Документ2 страницыImpulse Valve Operator Kit IV.1.09.01eduardo gonzalezav0% (1)

- DPDC MaintenanceДокумент5 страницDPDC MaintenanceArfana Akter BanogirОценок пока нет

- Metalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UДокумент5 страницMetalux Hbled Standard Efficiency Specsheet - Hbled ld5 24se W Unv l850 Ed2 UDANIEL SALAZARОценок пока нет

- Types of Supports For Vessels - Chemical Engineering WorldДокумент10 страницTypes of Supports For Vessels - Chemical Engineering WorldAdityaОценок пока нет

- 50 Straw Bale House PlansДокумент9 страниц50 Straw Bale House Plansdarius-matuiza-81990% (1)

- AC TO AC Write UpsДокумент7 страницAC TO AC Write UpsTin PelingonОценок пока нет

- Ul 854 - 2014 PDFДокумент64 страницыUl 854 - 2014 PDFDouglasОценок пока нет

- 568100Документ2 страницы568100Talha TariqОценок пока нет

- Kvpy Pee PDFДокумент9 страницKvpy Pee PDFstudysteps.inОценок пока нет

- Transfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualДокумент32 страницыTransfer Switching Equipment 100, 200, 260, 400A: Instr Uction ManualMesseňger HệŢhốngОценок пока нет

- E PM 100Документ29 страницE PM 100masoudОценок пока нет

- How Electric Cars Work: A Guide to EV TechnologyДокумент4 страницыHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoОценок пока нет

- Siemens Actuator M3K20FXNДокумент10 страницSiemens Actuator M3K20FXNbasil christopherОценок пока нет

- Matter-Energy Transformations ExploredДокумент22 страницыMatter-Energy Transformations ExploredAmit BidlanОценок пока нет