Академический Документы

Профессиональный Документы

Культура Документы

5r55e Valve Body Sonnax

Загружено:

joshetoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

5r55e Valve Body Sonnax

Загружено:

joshetoАвторское право:

Доступные форматы

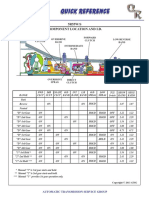

Instruction Data Sheet

4R44E/55E, 5R44E/55E

PART NUMBER 37947-EZ

37947-EZ Kit Instructions Baseline Rebuilding Kit

37947-EZ

1 Increased Ratio Boost Assembly 1 Elevated PR Spring 1 Forward Engagement Control Valve with Teflon Seal 1 Forward Engagement O-Ringed End Plug with Spring 6 Valve Bore O-Ringed End Plugs 1 Lube Orifice Disc 4 Torlon Checkballs 2 L Retaining Pins 1 High-Domed EPC Relief Tee Lube/TCC Modification Parts & Info. Extra O-Rings

Prior to installing this kit it is highly recommended that you inspect the valve body for wear beyond the scope of this kit. In the event of excessive wear in these critical locations, this kit should be used in conjunction with the appropriate Sonnax valve kit. Inspection and testing procedures can be found on pages 106-109 of Sonnax Transmission Specialties Volume 6 or online at www.sonnax.com.

2006 Sonnax Industries, Inc.

37947-EZ 02-08-07

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Guide

Figure 1 Clean and seal (optional) Bore wear causes: Delayed engagements Poor converter charge

Use high-dome relief tee with OE spring

Install aluminum lube orifice

Bore wear and loose plug cause poor line rise

This spring is often discarded to speed up forward engagement This plug is designed to be loose fitting

Clean and seal (optional)

Forward modulator OE spring

1

Optional: Install new PR spring (See Bore #2 notes on page 3)

Valve with Teflon Seal

2

Spring O-Ringed End Plug

Optional: Install new boost assembly (See Bore #2 notes on page 3)

3

Parts circled are addressed in this kit.

If OE relief here, do NOT install Sonnax spring (.700" long x .360" OD) or end plug

Circled numbers indicate bore number.

02-8-07

37947-EZ 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Steps

Bore number refers to an OE exploded view.

Bore 1: Optional The spring can be removed for quicker forward engagement. With this kit, we suggest the spring be left in, unless delayed forward is a complaint. To prevent having to pull the valve body to remove the U retainer, the plug can be retained by a .125" spring roll pin, drilled from the bottom up. The end plug is loose by design to allow for exhaust. Bore 2: Optional installation of elevated boost assembly and Sonnax PR spring. To restore OEM line pressure, reuse the OEM spring and boost assembly. For firmer forward and reverse engagment, and slightly firmer upshifts, install the Sonnax elevated PR spring. Reuse the OEM boost assembly. For firmer engagements and firm up- and downshifting, install the Sonnax elevated PR spring and Sonnax elevated boost assembly. REMINDER: These elevated versions should not be used if using the 37947-11K in conjunction with this kit. Bore 3: Remove end plug by prying up on both legs of the retainer at the same time. Remove the large forward modulator valve and its spring. If you position the manual valve furthest into the bore, air pressure can be used to blow the modulator valve out. If there is any visible wear or ridge in the bore, buff this area with Scotchbrite placed on a twisted wire and inserted into drill. Seal L pin circuit: Optional, but suggested If time does not allow, skip both sealant processes, as cure time is required. Using brake cleaner or No. 24163 Permatex, Klean and Prime or similar fluid, clean the middle plug/L pin area from both sides and through the open bore. Air dry, then drip small amount of Loctite 609, 3M No. 08732, Permatex sleeve retainer or similar product into the L pin opening. This must have a cure time to hold properly. Epoxy is not suggested, as it is permanent. Loctite can be heated to allow removal. The intent is to reduce leakage between the EPC booster valve and plug Install the Teflon seal onto the Sonnax valve. Invert the valve and bore size the Teflon seal. After sizing the seal, install OE forward modulator spring into the end of the Sonnax valve. Install valve using same process as OEM. Note: If the OEM end plug has a relief valve in it, do NOT install the Sonnax end plug or the spring. If the OEM end plug was solid, replace with the Sonnax end plug. The installation of the Sonnax spring (.700" long x .360" OD) is optional. Installation of the spring will result in shorter intermediate servo and direct clutch apply (firmer 1-2 and 2-3 shifts on a 4R44/55E; firmer 2-3 and 3-4 shifts on a 5R44/55E). To install the Sonnax end plug and spring, insert the spring into the end plug cavity. Install one large o-ring on the end plug. Install the end plug with the OEM retainer. Some OEM units had a similar end plug and lighter-weight spring in this location. This may be reused to restore OEM shifts.

37947-EZ 02-08-07 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Guide

Figure 2

Optional/Suggested: Clean and fill both L-pin cavities with sealant/Loctite and allow to cure.

No identifying band .306" OD

New end plugs with o-rings

5 6 7

2 ID bands 1.583" long Remove valve from Bore 13. Insert rod into 13 to drive out #7 valve.

8

SSB 1 ID band .314" OD Loose plug no 4th

9

SSD Bore wear = no TCC or slippage O-Ring Plug with o-ring

10

TCC

TCC

Parts circled are addressed in this kit.

L-pin locations Sonnax spring is supplied in case OE is damaged.

Circled numbers indicate bore number.

02-08-07

37947-EZ 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Steps

Bore 5: Seal L pin circuit: Optional, but suggested Without removing the L pin, use cleaner as referenced in Bore 3 instructions to clean, then seal the plug. The L pin cavity can be filled level full. Allow cure time. If the large .564" end plug is loose, run a tubing cutter around the spools to seal it. Bore 6: Install the longest plug with bracket groove. This uses two small o-rings. Dont forget the U retainer that holds the plug into the casting. Bore 7: Remove the plug between the EPC solenoid and 2-3, 3-4 shift valve. The plug may not come out after removing the U retainer from Bore 7. A rod (.125" OD) can be inserted into Bore 13 to drive out the plug in Bore 7. After the plug is removed, push the shift valve to the bottom of the bore and retain it with a screwdriver. Install the small OE valve into the Sonnax o-ring plug. Pre-lube two medium o-rings. A mixture of 50/50 STP and ATF works well for o-ring lube. Use a screwdriver to twist and insert into position. The widest U retainer in this body is inserted over the casting bridge and into the groove of the plug. Bore 8: Inspection: Make sure the L pin and long spacer are installed properly. Remove the solenoid. Measurement from the end of the casting to end of the spacer should be 1.720". Bore 9: A new converter regulator valve plug with one large o-ring is supplied. Removal: Pull out the L pin near the solenoid. The OE plug can be difficult to remove. Try this first: With a strong needle-nose pliers, turn the plug and hit it with the tip of your pliers. Continue this until the spring drives out the plug. Install with needle nose pliers holding the nub. Twist insert until the o-ring is inboard of the L pin. If the OE plug will not come out, you must also remove the inner L pin retainer. You will then have to drill an access hole to drive out the valves (see Figure 3). A new spring is supplied for inner coast clutch valve if damaged.

Figure 3

For Bore 9 valve removal drill .110" hole, entering at bolt and exiting into spring pocket of Bore 9. This allows rod to drive out the valve.

37947-EZ 02-08-07 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Guide

Figure 4

Parts circled are addressed in this kit.

Circled numbers indicate bore number. This spring can be removed through slot next to filter.

16

SSA

15 14

New end plugs with o-ring

13

A rod can be inserted into #13 to push out valve #7

12

SSC

* Remove spring

11

Valve sticks, affects TCC Easy to lose. Bend into an arch to avoid valve misplacement. No need to remove valves. Pull small spring out from filter side.

Thermal element. No external flow until converter oil reaches 150 degrees F.

02-08-07

37947-EZ 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBER 37947-EZ

Installation Steps

Bore 11: Removal: The smallest spring in this bore should be removed and discarded. Valves do NOT require removal. Spring can be caught and turned out of the slot next to the filter hole. Removal will shorten TCC apply time and reduce slip. Inspection: The L pin falls out easily. It must hold the barbell-shaped valve. If out of place, the overdrive servo will not apply. Bore plugs 13, 14 & 15: There are three end plugs that seal shift solenoid oil. The two smallest end plugs in the kit require four small o-rings. The larger end plug is .630" OD, which requires two large o-rings. Miscellaneous Valve Body Rebuilding Info: To remove plugs once Loctite, Permatex, 3M, etc., has been used: Heat the area until the sealant melts, then air dry. Flat stone the valve body surface and clean well to remove surface imprints. Sonnax Spring Identification Chart

Bore Valve Springs

Pressure Regulator Outer Coast Clutch Bottom Bore Outboard Forward Modulator

O.D

.748" .220" .360"

Wire Dia.

.055" .022" .038"

Free Coils Color length

1.1" .875" .700" 5 10 4.5 Plain Plain Plain

2 9 3

OEM Spring Identification Chart

Bore Valve Springs

Forward Control Pressure Regulator Outer Pressure Regulator Inner Forward Modulator EPC Boost Reverse Modulator Outer Reverse Modulator Inner 2-3/3-4 Shift 1-2/2-3 Shift Solenoid Regulator TCC Regulator, Inner TCC Regulator, Outer Coast Clutch Bottom Bore TCC Modulator Thermal Outer, Big Thermal Middle Inner Limit (smallest) 3-4/4-5 Shift Throttle Downshift Manual Low Kickdown Steel EPC Relief Tee Plastic TCC Relief Tee

O.D

.338" .745" .412" .236" .293" .210" .210" .275" .284" .218" .187" .285" .222" .238" .575" .264" .200" .280" .263" .320" .262" .292" .292"

Wire Dia.

.032" .055" .032" .026" .040" .018" .018" .030" .033" .030" .028" .040" .023" .023" .042" .026" .018" .032" .028" .032" .028" 0.04" 0.04"

Free length

.665" - .775" 1.065" 1.135" 0.738" 1.210" 1.080" 1.080" 1.052" 0.730" 0.830" 0.720" 0.787" 0.840" 1.230" 1.045" 1.232" 0.840" 1.162" 0.700" 0.985" 0.670" 0.982" 0.982"

Coils

6.5 4 9.5 14 12 10.5 10.5 13 7 8.5 12 9.5 9.5 11.5 4.5 13.5 12 12 6.5 7.5 7 13.5 13.5

Color

White Plain Or Lt. Purple Lt. Green White Orange Plain Plain Plain Lt. Purple Yellow White Orange Red White Or Yellow White Lt. Green Blue Plain Orange Yellow Orange Plain Plain

1 2 2 3 3 5 5 6 7 8 9 9 9 10 11 11 11 12 13 14 15 N/A N/A

37947-EZ 02-08-07 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

PART NUMBERS 37947-EZ

Plate Identification & Modifications

5R plate: shown. 4R plate: feed hole is aligned.

Plate Identification & Modification: To reduce TCC slip and code 741: Drill the TCC exhaust hole to .110". Predrill the neighboring hole to 1/16". Plug and peen with 1/16" pin supplied.

TCC Modifications

OD servo apply. Drill to .072" for firmer 4th.

Drill to .110"

Remove the smallest spring from Bore 11. This spring is pulled out from the lower side through the slot next to the filter inlet. The direct clutch/servo release and EPC solenoid feed holes have been identified. They DO NOT have to be altered, unless you want to increase flow. Having too large a hole at EPC feed could flood the solenoid. Too large at direct/servo release can result in firm 2-3 or flare 2-3 on a 4R. Drill pressure regulator balance orifice to .055". (Drill is supplied.) To prevent flashing, start the drill on one side, then finish from the opposite. Its always best to taper the orifice holes when done with a larger drill. Drill line pressure circuit to converter feed orifice in the plate to 1/16" or .062". Late-model 5R55E units are already this size. (Drill is supplied.) For firmer 4th in 4R or firmer 5th and 2nd in a 5R unit: Drill the OD servo apply to .072". Later 5R55E units are already this size. 4R and 5R plate identification: Plate pictured is a 5R55E plate with an EPC relief spring hole. If the plate was a 4R, the hole pictured would be lowered to the circle indicated.

Drill to 116". Then insert 116" aluminum plug and peen to close off hole.

EPC solenoid feed must not be smaller than 116". Direct clutch and servo release .046" OE.

Drill PR balance to .055".

EPC relief hole: The hole identified near the servo cover area is where the Sonnax domed relief will rest. The OE spring will be reused in the valve body casting. The TCC relief and the EPC relief springs are interchangeable. If no hole exists here, the plate is designed for an OE relief valve in the No. 3 bore end plug. That OE valve number is 3L5Z-7M203-JA. You cannot use that end plug relief if the plate has a hole, as pictured here. Delayed forward, reverse and low line pressure result.

Line pressure to converter release. Drill to 116". If hole is present, must use supplied high domed tee and (OE) EPC relief spring. If no hole here, must have OE relief in end plug at Bore 3.

Combining Modifications: Do not combine aftermarket parts or procedures with this kit. Do not drill line to lube through the casting at the pressure regulator valve. Do not use a stronger pressure regulator spring or shim than the ones supplied here. Do not remove springs or block reverse engagement control valve.

Figure 5

02-08-07

37947-EZ 2006

800-843-2600 802-463-9722 F: 802-463-4059 www.sonnax.com info@sonnax.com

Вам также может понравиться

- 4r44e 5r55e Zip BookletДокумент8 страниц4r44e 5r55e Zip BookletDaniel BernardОценок пока нет

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsОт EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsРейтинг: 5 из 5 звезд5/5 (5)

- 48 Re 03 05Документ2 страницы48 Re 03 05eurospeed2Оценок пока нет

- Chrysler Manual V3.1Документ22 страницыChrysler Manual V3.1smilley32100% (5)

- 4R44E 5R55E Vac LocationsДокумент2 страницы4R44E 5R55E Vac LocationsPedroMecanico100% (1)

- 5R55S Cooler Thermal Bypass FixДокумент4 страницы5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- Atsg 2005 BulletinДокумент46 страницAtsg 2005 Bulletinlolop434350% (4)

- 5r55 OverheatingДокумент46 страниц5r55 OverheatingAhmed Ali100% (2)

- Zf6 6r60 Zip BookletДокумент8 страницZf6 6r60 Zip BookletAlitar Hersongolls100% (1)

- Cuerpos de Válvulas Catálogo PDFДокумент68 страницCuerpos de Válvulas Catálogo PDFTransmisiones Automáticas Chepe83% (6)

- Ford Fnr5 TCC SlipДокумент2 страницыFord Fnr5 TCC SlipAlex Maceira Graterol100% (2)

- A604 A606 42rle PDFДокумент2 страницыA604 A606 42rle PDFGuilherme Zoboli100% (2)

- 4R44E 5R55E Vac LocationsДокумент2 страницы4R44E 5R55E Vac LocationsHumberto Lojan100% (1)

- 5R55N / 5R55S / 5R55W: Ganzeboom Transmission Parts & Torque ConvertersДокумент2 страницы5R55N / 5R55S / 5R55W: Ganzeboom Transmission Parts & Torque ConvertersDejan Lenarcic100% (1)

- Ford 5R55 W/S 153: SOLENOID TEST: (Engine Off)Документ2 страницыFord 5R55 W/S 153: SOLENOID TEST: (Engine Off)Lojan Coronel José HumbertoОценок пока нет

- Sonnax 45RFE, 545RFE, 68RFE Solenoid Identification & Connector Pin OutДокумент4 страницыSonnax 45RFE, 545RFE, 68RFE Solenoid Identification & Connector Pin OutJean Jose Morillo AñezОценок пока нет

- Technical Service Information: Ford E4OdДокумент10 страницTechnical Service Information: Ford E4OdJOSE GARVCVIAОценок пока нет

- 6R60Документ1 страница6R60PedroMecanico50% (2)

- 01m Erro 1 E2Документ7 страниц01m Erro 1 E2choco84Оценок пока нет

- 45RFEДокумент2 страницы45RFEherusamx100% (2)

- Cuerpo de Válvulas Nissan RE4f04A 1992-2006Документ4 страницыCuerpo de Válvulas Nissan RE4f04A 1992-2006gtran75% (4)

- Axod PDFДокумент111 страницAxod PDFrodrigo michelОценок пока нет

- 4t40e and 4t45eДокумент18 страниц4t40e and 4t45eDinoMcLean86% (7)

- Jf404e VW PoloДокумент8 страницJf404e VW Polofulltransmission100% (2)

- pdf142 6l80e PDFДокумент5 страницpdf142 6l80e PDFLuisОценок пока нет

- Boletin de Fallas Atra 2012Документ34 страницыBoletin de Fallas Atra 2012marcelo ustarezОценок пока нет

- FNR5 Mazda 3 PDFДокумент1 страницаFNR5 Mazda 3 PDFAlberto Del Rio MejiaОценок пока нет

- Re4f03v - Re4f04v - 4f20e - Jf403eДокумент6 страницRe4f03v - Re4f04v - 4f20e - Jf403etejonmxОценок пока нет

- Code False Akpp 5r55Документ7 страницCode False Akpp 5r55VobsStrongОценок пока нет

- 09G Adjustment Notice 2 PDFДокумент1 страница09G Adjustment Notice 2 PDFossoski100% (1)

- (Ford Escape, Galaxy Mercury Mariner, Mondeo, Mazda Trubute) 2007-6 Speed FWD (Full Electronic Control)Документ3 страницы(Ford Escape, Galaxy Mercury Mariner, Mondeo, Mazda Trubute) 2007-6 Speed FWD (Full Electronic Control)SamuelОценок пока нет

- 5 R 110 WДокумент4 страницы5 R 110 WNuman2100% (1)

- Caja CVTДокумент4 страницыCaja CVTEsteban CaceresОценок пока нет

- U151E/U151F: Technical Bulletin #1575Документ3 страницыU151E/U151F: Technical Bulletin #1575oscarОценок пока нет

- Quick Reference: 5R55W/S Component Location and I.DДокумент7 страницQuick Reference: 5R55W/S Component Location and I.DAyhan Ümit100% (3)

- 4r44e 5r55e ZipДокумент1 страница4r44e 5r55e ZipAlejandro VargasОценок пока нет

- 6F35Документ5 страниц6F35Nancy Garcia100% (1)

- 16a GM 2014 6T40 6T45 6F35Документ2 страницы16a GM 2014 6T40 6T45 6F35fadrique54Оценок пока нет

- 8L90 Valvule BodyДокумент10 страниц8L90 Valvule BodyJose Andres HuertaОценок пока нет

- 2007 ATRA Seminar Manual ContentsДокумент272 страницы2007 ATRA Seminar Manual Contentschoco84Оценок пока нет

- JIAKE Transmission Parts CATALOG - JolinДокумент52 страницыJIAKE Transmission Parts CATALOG - JolinMaría Martz De GarcíaОценок пока нет

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WОт EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildОт EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildРейтинг: 5 из 5 звезд5/5 (1)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- CHEETAH E-SHIFT Pro Series Valve BodyДокумент8 страницCHEETAH E-SHIFT Pro Series Valve BodyhidraulicОценок пока нет

- Air CylinderДокумент4 страницыAir Cylindersimbua720% (1)

- Ideal Installation: I & M Mark 68G SeriesДокумент4 страницыIdeal Installation: I & M Mark 68G SeriesByron PanchiОценок пока нет

- Volvo 740 SolutionДокумент26 страницVolvo 740 SolutionPaulo MandingaОценок пока нет

- Torspec Model 100Tcd-Nema: Variable Speed DriveДокумент6 страницTorspec Model 100Tcd-Nema: Variable Speed Drivevirus40Оценок пока нет

- QuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service ManualДокумент10 страницQuickServe Online - (4310591) N14 Base Engine (STC, Celect™, Celect Plus™) Service Manualcarlosar1477Оценок пока нет

- S2000 SOS Supercharger Install ManualДокумент43 страницыS2000 SOS Supercharger Install ManualMatthew Chtchavlinski100% (4)

- SL162B Helicoil PDFДокумент2 страницыSL162B Helicoil PDFjeffrey_fay100% (2)

- Peco Filter CaseДокумент11 страницPeco Filter CaseLuis MaureraОценок пока нет

- 4L80E Modifications Guide v2Документ36 страниц4L80E Modifications Guide v2sonyaОценок пока нет

- Sno 20010Документ13 страницSno 20010Alexander SharamiginОценок пока нет

- TCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UpДокумент8 страницTCI 220500 TRANS-SCAT: Installation Instructions For A500 (42RH/42RE) - 1989 and Up A518 (46RH/47RH) - 1989 and UphidraulicОценок пока нет

- Condensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsДокумент4 страницыCondensate Collection (CCA/CCAF/CCM) and Steam Distribution (MSD/SMSD) Manifolds Installation, Operation and Maintenance InstructionsMarcial NuñezОценок пока нет

- Main Engine (S) Unit 6 OverhaulДокумент4 страницыMain Engine (S) Unit 6 OverhaulMocanu MarianОценок пока нет

- 4L80E Build Tips and TricksДокумент5 страниц4L80E Build Tips and TricksSjoling8211Оценок пока нет

- Lycoming Flyer Key ReprintsДокумент114 страницLycoming Flyer Key Reprintsroux100% (2)

- Design & Detail Col Base PlateДокумент19 страницDesign & Detail Col Base PlateJoel MooreОценок пока нет

- Martini L1 IntroductionДокумент12 страницMartini L1 IntroductionphdcaoОценок пока нет

- Industrial AutomationДокумент2 страницыIndustrial Automationsarath kcОценок пока нет

- SWOP BrochureДокумент16 страницSWOP BrochurePurwanto ritzaОценок пока нет

- D475a-5gen00051 Fa-03Документ240 страницD475a-5gen00051 Fa-03Gabo GaboОценок пока нет

- Servicing Differential & Front AxleДокумент39 страницServicing Differential & Front AxleTesda Ptc Malilipot86% (7)

- Installation of Rotating Equipment Rev.01Документ17 страницInstallation of Rotating Equipment Rev.01SefaОценок пока нет

- Tekcast Industries, Inc.: Complete Tek 18X4" Equipment SystemДокумент1 страницаTekcast Industries, Inc.: Complete Tek 18X4" Equipment SystemНика ЛаськоОценок пока нет

- PDAM Detail JunctionДокумент4 страницыPDAM Detail JunctionC. A. ArdhaniОценок пока нет

- M7R Install InstructionsДокумент8 страницM7R Install InstructionstaylorОценок пока нет

- Electromagnetic Braking SystemДокумент16 страницElectromagnetic Braking SystemGallant Info100% (1)

- Tolerances For Frame Side Members (RLT) : Accuracy of ShapeДокумент8 страницTolerances For Frame Side Members (RLT) : Accuracy of ShapeAkmal NizametdinovОценок пока нет

- 2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyДокумент9 страниц2011 - Papanikolaou E. - Markatos N. - Int J Hydrogen EnergyNMarkatosОценок пока нет

- Ford Fiesta Common Problems Solutions Hints and TipsДокумент6 страницFord Fiesta Common Problems Solutions Hints and TipsEndro PrayitnoОценок пока нет

- Pros & Cons of Centralized Vacuum SystemsДокумент66 страницPros & Cons of Centralized Vacuum SystemsDjapaОценок пока нет

- Case Study On Design and Development of A Metal Matrix Composite For Aeronautical ApplicationsДокумент13 страницCase Study On Design and Development of A Metal Matrix Composite For Aeronautical ApplicationsAruna MОценок пока нет

- Ivanov - Smolensky-Electrical Machines, Vol. 2Документ466 страницIvanov - Smolensky-Electrical Machines, Vol. 2elmer100% (3)

- ComparatorsДокумент25 страницComparatorsMayank KhinchiОценок пока нет

- PurifierДокумент5 страницPurifierPanagiotis MouzenidisОценок пока нет

- SNEFERU - Architectural ReviewerДокумент58 страницSNEFERU - Architectural ReviewerPia Eleanor Santos100% (11)

- Conval Clampseal Catalog 2019Документ44 страницыConval Clampseal Catalog 2019Roger SeaverОценок пока нет

- Steel To Concrete Joints Design-Manual II enДокумент292 страницыSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- Perkins Diesel EngineДокумент12 страницPerkins Diesel EngineDilhan RajasekaraОценок пока нет

- Continuum Mech Problem Set #3Документ1 страницаContinuum Mech Problem Set #3behzadОценок пока нет

- Sec02 1Документ19 страницSec02 1Mahmoud NaDaaОценок пока нет

- CNC EbookДокумент1 066 страницCNC Ebooklibrojames93% (14)

- 8-Baf - DP 3045 MT 234 Motor 1,2kw AtexДокумент5 страниц8-Baf - DP 3045 MT 234 Motor 1,2kw AtexSantiago RodaОценок пока нет

- 1-Load ParametersДокумент97 страниц1-Load ParametersJuNe RaMos JavierОценок пока нет

- 001-Sample Method Statement Piping Pre-ShutdownДокумент4 страницы001-Sample Method Statement Piping Pre-ShutdownS.C.Satish ChanderОценок пока нет