Академический Документы

Профессиональный Документы

Культура Документы

PQR 014 (Qualified Sa 106 GR B

Загружено:

ersenthilИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PQR 014 (Qualified Sa 106 GR B

Загружено:

ersenthilАвторское право:

Доступные форматы

Page 1 of 5

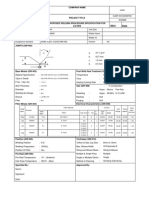

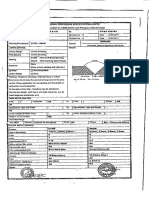

PROCEDURE QUALIFICATION RECORD Reference: ASME B31.3, ASME

Sec IX, GASCO Doc No. 5208-RP-300-6300-001

Client : Contractor: Sub Contractor: Subcontract No: 25113-000-HC3-P00Z-00004 Date: Date:

Project Name: OGD III (Subcontract: PME - Offsites & Utilities)

PQR No: WPS No.: Welding Process: SMAW Types (Manual, Automatic, Semi-Auto): Manual JOINTS DESIGN:(QW-402)

Rev: 0 Rev: 0

10.97 mm

PQR Test Coupon: 6" x SCH 80 (10.97mm)

BASE METAL(QW-403)

Material Spec.: ASTM A106 (Pipe) Type or Grade: Gr. B P.No. / Group No.: P.No: 1 , Group No: 1 Thickness of Test Coupon: 10.97mm Dia of Test Coupon: 6" (168.3mm) Heat No: Pipe - 59B5452 Material Certificate No: Pipe - 040000813205 (MITTAL)

POSTWELD HEAT TREATMENT(QW-407)

Heating Method: NA Heating Rate: NA Soaking Temp: NA Soaking Time: NA Cooling Rate: NA GAS: PERCENTAGE COMPOSITION (QW-408) Gas(es) % Comp. Shielding NA NA NA NA NA NA Flow Rate NA NA NA

FILLER METALS (QW-404)- See Table - Page 2 of 3 POSITION (QW -405) Position of Groove: 6G Position of Fillet: NA Weld Progression (Uphill, Downhill): Uphill PREHEAT (QW - 406) Preheat Temp. (Min): N/A Method of Heating: N/A Temp. Monitoring Method: Digital Thermometer Interpass Temp.(In Degree Centigrade): Minimum Recorded: 89 Maximum Recorded : 125

Trailing Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current & Polarity: DCEP Amps / Volts: See Page 2 of 3 Tungsten Electrode Class & Size: NA TECHNIQUE (QW-410) Travel Speed: See Page 2 of 3

String or Weave Bead: String on Root, Weave - Fill & Cap

Oscillation: N/A Multipass or Single Pass (Per Side): Multiple Pass Single or Multiple Electrodes: Single Electrode

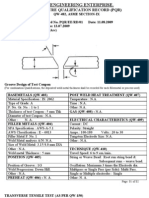

Page 2 of 5

PROCEDURE QUALIFICATION RECORD Reference: ASME B31.3, ASME

Sec IX, GASCO Doc No. 5208-RP-300-6300-001

Client : Contractor: Sub Contractor: Subcontract No: 25113-000-HC3-P00Z-00004 Date:

Project Name: OGD III (Subcontract: PME - Offsites & Utilities)

PQR No: FILLER METALS Weld AWS Class Dia (mm) Pass No. 1 2 3 4 5 6 7 8 E 6010 E 7018 E 7018 E 7018 E 7018 E 7018 E 7018 E 7018 3.2 3.2 3.2 4.0 4.0 3.2 3.2 3.2 SFA 5.1 5.1 5.1 5.1 5.1 5.1 5.1 5.1 F.No. A.No. 3 1 4 1 4 1 4 1 4 1 4 1 4 1 4 1

Rev: 0

Manufacture

Trade Name

PIPEWELD

Lot No.

VT532E66 88

Certificate No. 023530 EC20330164 EC20330164 EC20323739 EC20323739 EC20330164 EC20330164 EC20330164

ESAB ESAB ESAB ESAB ESAB ESAB ESAB ESAB

Ok 48.00 SF604303 Ok 48.00 SF604303 Ok 48.00 SF603207 Ok 48.00 SF603207 Ok 48.00 SF604303 Ok 48.00 SF604303 Ok 48.00 SF604303

SUMMARY OF WELDING PARAMETERS RECORDED WELD PASS PROCESS NO. Root-1 Hot-2 Fill-3 Fill-4 Fill-5 Cap-6 Cap-7 Cap-8 S.No. 1 2 3 4 SMAW SMAW SMAW SMAW SMAW SMAW SMAW SMAW FILLER METAL AWS CLASS DIA E 6010 3.2 E 7018 3.2 E 7018 3.2 E 7018 4.0 E 7018 4.0 E 7018 3.2 E 7018 3.2 E 7018 3.2 CURRENT TYPE AND POLARITY DCEP DCEP DCEP DCEP DCEP DCEP DCEP DCEP Report No.

Visuals O.K. PLL/BECHTEL/GASCO/21 PLL/BECHTEL/GASCO/19

Amps 75.9 107.1 120.3 132.9 128.5 113.2 115.4 112.9

VOLTS 24.5 25.0 25.2 24.9 24.0 23.5 24.0 23.6

TRAVEL Heat Input SPEED KJ / mm mm / min 79.8 109.8 102.6 120.6 96.0 138.6 156.0 144.0 1.40 1.45 1.76 1.63 1.92 1.15 1.06 1.11 Result Accepted Accepted Accepted

Type of Inspection

Visual Inspection Magnetic Particle Inspection Radiographic Inspection Ultrasonic Inspection

Date 2-May-2006 5-May-2006 5-May-2006

N/A

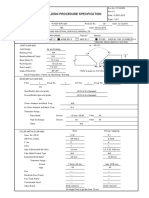

5. TENSILE TEST -(QW-150) Report No.: PHY-RPT-1644-01 dt 15th May 2006

Specimen No.

Size, (mm) 19.23 x 10.13

Area, (mm2) 194.80

Tensile Load (N) 103223

TT1

Tensile Strength Fracture Location (N/mm2) 530 PARENT METAL

Page 3 of 5

PROCEDURE QUALIFICATION RECORD Reference: ASME B31.3, ASME

Sec IX, GASCO Doc No. 5208-RP-300-6300-001

Client : Contractor: Sub Contractor: Subcontract No: 25113-000-HC3-P00Z-00004 Date: 508

Project Name: OGD III (Subcontract: PME - Offsites & Utilities)

PQR No: TT2

Rev: 0 19.08 x 10.28 196.14 99669

PARENT METAL

Page 4 of 5

PROCEDURE QUALIFICATION RECORD Reference: ASME B31.3, ASME

Sec IX, GASCO Doc No. 5208-RP-300-6300-001

Client : Contractor: Sub Contractor: Subcontract No: 25113-000-HC3-P00Z-00004 Date:

Project Name: OGD III (Subcontract: PME - Offsites & Utilities)

PQR No:

Rev: 0

6. GUIDED - BEND TESTS (QW-160) - Report No.:PHY-RPT-1644-01 dt 15th May 2006 Angel of Bend Specimen TYPE Mandrel Diameter No. (Degrees) SB1 SIDE BEND 4T 180 SB2 SIDE BEND 4T 180 SB3 SIDE BEND 4T 180 SB4 SIDE BEND 4T 180 7. TOUGHNESS TESTS (QW-170) - REPORT No.: Test Impact Values (Joules) Specimen Notch Specimen Temp.OC No. Location Size,(mm) A B C

Result PASS PASS PASS PASS

Average (Joules)

Remarks

8. OTHER TESTS: S.No. 1 2 3 Type of Inspection

Macro Examination Micro Examination Hardness Test

Report No. PHY-RPT-1660/1661-01 N/A PHY-RPT-1648/1649-01

_N /A _

Date Laboratory ### LONESTAR, ABU DHABI ### LONESTAR, ABU DHABI

Result Accepted Accepted

OTHER DETAILS: Weld Finishing: As Welded (Wire Brushed) Number of Welders: One Tack Welding Method: Temp. Bar / Bridge Tack Welds Tack Welding Parameters: As per fill pass Welder's Name(s): Sukumar Debnath Welder ID: PLU - 35 Test Coupon Welded on: 02-May-2006 We certify that the Statements in this record are correct and that test welds were prepared, welded and tested in accordance with the requirments of ASME Section IX & GASCO Spec: 5208-RP-300-6300-001 PLL QC Name, Signature & Date EBCL QC Name, Signature & Date GASCO Name, Signature & Date Test Conducted By:LONESTAR Test Witnessed By:PLL,VELOSI,BECHTEL,GASCO

Page 5 of 5

PROCEDURE QUALIFICATION RECORD Reference: ASME B31.3, ASME

Sec IX, GASCO Doc No. 5208-RP-300-6300-001

Client : Contractor: Sub Contractor: Subcontract No: 25113-000-HC3-P00Z-00004 Date:

Project Name: OGD III (Subcontract: PME - Offsites & Utilities)

PQR No:

Rev: 0

Вам также может понравиться

- Teleportation Via Wormhole-StargatesДокумент34 страницыTeleportation Via Wormhole-StargatesFranca GoiaОценок пока нет

- Winch DesignДокумент132 страницыWinch DesignShreyas Raut100% (2)

- PQR-WPS-WPQR XXX Rev 0Документ6 страницPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- WQT RecordДокумент6 страницWQT RecordGururaj P KundapurОценок пока нет

- Everything You Need to Know About Stainless Steel Welding Procedure SpecificationДокумент6 страницEverything You Need to Know About Stainless Steel Welding Procedure SpecificationDanem HalasОценок пока нет

- Weldspec ASME PQRДокумент2 страницыWeldspec ASME PQRSunil KumarОценок пока нет

- WPS FormatДокумент1 страницаWPS FormatAbdullah AnsariОценок пока нет

- Weld Joint 1Документ81 страницаWeld Joint 1rajibali27100% (1)

- PQR Is7307Документ1 страницаPQR Is7307Tridib Dey100% (1)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Документ20 страницWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingДокумент3 страницыDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyОценок пока нет

- Specialty Chemicals for Corrosion Inhibition and Water TreatmentДокумент27 страницSpecialty Chemicals for Corrosion Inhibition and Water TreatmentMehman NasibovОценок пока нет

- AfnanQM PDFДокумент356 страницAfnanQM PDFAyorinde T TundeОценок пока нет

- WPS (AsmeДокумент8 страницWPS (AsmeMohammad Elhedaby100% (6)

- WPS Format For ASME IX - PQR-AllДокумент3 страницыWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- For Fillet Weld Joint Project:Production ManifoldДокумент1 страницаFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- PQRДокумент2 страницыPQRafqzfieОценок пока нет

- WPS FormatДокумент2 страницыWPS FormatAmit SarkarОценок пока нет

- WPS MS 01C Rev. 0Документ1 страницаWPS MS 01C Rev. 0alinor_tnОценок пока нет

- A Dictionary of ColoursДокумент528 страницA Dictionary of ColoursMohammed Mahfouz78% (9)

- API CatalogueДокумент20 страницAPI CatalogueMadirley Pimenta100% (1)

- Wps - Asme Ix - Gtaw - Plat SteДокумент6 страницWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Документ6 страницMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajОценок пока нет

- GHS - SDS Checklist (8-13, See 11)Документ2 страницыGHS - SDS Checklist (8-13, See 11)Thupten Gedun Kelvin OngОценок пока нет

- All Position Stainless Steel Welding ProcedureДокумент6 страницAll Position Stainless Steel Welding ProcedureJaime PatrónОценок пока нет

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Cylinder Design Standards WSNZДокумент5 страницCylinder Design Standards WSNZjamilОценок пока нет

- WPS Resrvoire Sous Pression Smaw SawДокумент6 страницWPS Resrvoire Sous Pression Smaw SawDanem HalasОценок пока нет

- Wps 1010 IfrДокумент28 страницWps 1010 IfrSyed Mahmud Habibur RahmanОценок пока нет

- WPSДокумент3 страницыWPSKhurram Burjees100% (1)

- Project quality control form QCF307Документ1 страницаProject quality control form QCF307minhnnОценок пока нет

- IIT JEE Laws of Motion PhysicsДокумент32 страницыIIT JEE Laws of Motion PhysicsShakil Khan100% (1)

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Plate Inspection ReportДокумент1 страницаPlate Inspection ReportlalitaliОценок пока нет

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmДокумент1 страницаWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- WPQ Template (Asme Ix) No LogoДокумент4 страницыWPQ Template (Asme Ix) No LogorcpretoriusОценок пока нет

- Sample Wps-Carbon Steel GTAW+SMAWДокумент2 страницыSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- WPS PQR PDFДокумент23 страницыWPS PQR PDFtomj9104Оценок пока нет

- WPSДокумент6 страницWPSNur Wijianto100% (1)

- WPSДокумент2 страницыWPSAlam MD Sazid100% (1)

- WPS Sitelca S002Документ2 страницыWPS Sitelca S002Jose Antonio GomezОценок пока нет

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpДокумент1 страницаPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarОценок пока нет

- Welder Visual Inspection ReportsДокумент24 страницыWelder Visual Inspection ReportsKyОценок пока нет

- WPS - PQR (Sa516 GR.70)Документ4 страницыWPS - PQR (Sa516 GR.70)miltonangulomorrisОценок пока нет

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- WPS - Smaw - 2Документ6 страницWPS - Smaw - 2Harkesh RajputОценок пока нет

- Utoc Preliminary Wps Shell Project 270807 PDFДокумент55 страницUtoc Preliminary Wps Shell Project 270807 PDFErick HoganОценок пока нет

- Gtaw 106Документ2 страницыGtaw 106ganeshkumarg_1Оценок пока нет

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- Aws d1.1 WPS, PQR & WQTДокумент4 страницыAws d1.1 WPS, PQR & WQTWeld Bro SandeepОценок пока нет

- Wps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxДокумент5 страницWps PQR WPQ Format - Sa 516 GR 70 2 Zbo7uxjobert100% (1)

- PQRДокумент2 страницыPQRSreenivas Kamachi Chettiar100% (1)

- WPS PQR-08Документ8 страницWPS PQR-08Ranjan KumarОценок пока нет

- Stirling EngineДокумент14 страницStirling EngineShivakumar Ainapur100% (1)

- Welding Procedure Specification "WPS": O O O OДокумент1 страницаWelding Procedure Specification "WPS": O O O OAli MoosaviОценок пока нет

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELДокумент4 страницыWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidОценок пока нет

- WPS Asme IxДокумент4 страницыWPS Asme Ixjcarlosherrerac7100% (1)

- Qualified Welder List Valid Until - 03-12-2019Документ2 страницыQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- Asme PQR DemoДокумент3 страницыAsme PQR DemoMuthusamy AyyanapillaiОценок пока нет

- PQR TipsДокумент4 страницыPQR TipsWaqas WaqasОценок пока нет

- WPQ WeldCanada PDFДокумент1 страницаWPQ WeldCanada PDFAhmad DanielОценок пока нет

- Qw-482 Welding Procedure Specification (WPS)Документ4 страницыQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- SS WPSДокумент1 страницаSS WPSMOHAMEDABBASОценок пока нет

- Gtaw Smaw 6 Inch 6G CSДокумент1 страницаGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- PT Kuwera Karya Me: PanduДокумент2 страницыPT Kuwera Karya Me: PanduGalang Pratama PutraОценок пока нет

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterДокумент3 страницыSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013Оценок пока нет

- Stoich AnsДокумент23 страницыStoich AnsNaze TamarayОценок пока нет

- Optical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorДокумент4 страницыOptical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorAhmad IbrahemОценок пока нет

- International Atomic Energy Agency - Production of Yellow Cake and Uranium Fluorides (Panel Proceedings) (1981, IAEA) PDFДокумент368 страницInternational Atomic Energy Agency - Production of Yellow Cake and Uranium Fluorides (Panel Proceedings) (1981, IAEA) PDFZia KhanОценок пока нет

- PVH - Restricted Substance ListДокумент31 страницаPVH - Restricted Substance ListDebashishDolonОценок пока нет

- Raptor Defender® Fixed Plant LWP PDFДокумент20 страницRaptor Defender® Fixed Plant LWP PDFBorisRakelaGonzalezОценок пока нет

- CaseStudy2 WindmillДокумент8 страницCaseStudy2 WindmillAnthony BergemannОценок пока нет

- LirioДокумент220 страницLirioAntonio MeseguerОценок пока нет

- Army Public School Bhopal: TOPIC:-" "Документ20 страницArmy Public School Bhopal: TOPIC:-" "Gourav Pathariya100% (1)

- Junctions ExplainedДокумент4 страницыJunctions ExplainedJulio SaldanhaОценок пока нет

- Atomic Structure and Chemical Bonding Chapter 2 QuestionsДокумент19 страницAtomic Structure and Chemical Bonding Chapter 2 QuestionsAhmed ZiadОценок пока нет

- ADHD Medication For Adults and Children: Vyvanse, Ritalin, Concerta, Adderall, Strattera...Документ4 страницыADHD Medication For Adults and Children: Vyvanse, Ritalin, Concerta, Adderall, Strattera...rico ruben100% (1)

- Southern Company/MHI Ltd. Plant Barry CCS DemonstrationДокумент23 страницыSouthern Company/MHI Ltd. Plant Barry CCS Demonstrationrecsco2100% (1)

- ALS Minerals Service Schedule USDДокумент44 страницыALS Minerals Service Schedule USDGAUCHEX697355Оценок пока нет

- Purificazione e Studio Cinetico - Lattato Deidrogenasi (LDH) Da Fegato Di ConiglioДокумент10 страницPurificazione e Studio Cinetico - Lattato Deidrogenasi (LDH) Da Fegato Di ConiglioS_CucinottaОценок пока нет

- Bob Kimmel CV Expert Witness Plastic PackagingДокумент11 страницBob Kimmel CV Expert Witness Plastic PackagingBob KimmelОценок пока нет

- A Practical Handbook of Seawater AnalysisДокумент328 страницA Practical Handbook of Seawater Analysisfdlab100% (2)

- Austenitic Stainless SteelДокумент3 страницыAustenitic Stainless SteelGeorge MarkasОценок пока нет

- Production of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityДокумент10 страницProduction of Dishwashing Liquid Detergent (Base) : Cebu Institute of Technology - UniversityNicely EleccionОценок пока нет

- App1Документ12 страницApp1Diastari KusumawatiОценок пока нет

- Ginger CandyДокумент8 страницGinger CandyRizka Arifani Kromodimedjo100% (2)