Академический Документы

Профессиональный Документы

Культура Документы

Styrene Production

Загружено:

Rio GelmourИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Styrene Production

Загружено:

Rio GelmourАвторское право:

Доступные форматы

Senior Design Final Report

Professor J.A. Sykes

May 12, 2006

By Team #7:

Larae Baker

Maxine Bent

Jonathan Bush

Mike Heslinga

Adam Jones

Abstract: A new process to produce styrene monomer is under development by Dow

Chemical and Snamprogetti. Team #7 has designed and simulated an industrial plant to

produce two billion pounds of styrene monomer per year. An advantage to the new

process is that it starts with a less expensive raw material, ethane, instead of ethylene.

The process has three key stages: 1.) A distillation reactor alkylates benzene and

ethylene to make ethylbenzene. 2.) A dehydrogenation reactor where ethylbenzene and

ethane are converted into styrene and ethylene respectively. 3.) A distillation train where

a purity of 99.93% styrene is achieved. Styrene can be produced at an estimated market

price of $0.99/lb with this process.

Table of Contents

1 INTRODUCTION..................................................................................................... 4

2 THE CHEMISTRY .................................................................................................. 4

2.1 ALKYLATION ....................................................................................................... 4

2.2 DEHYDROGENATION............................................................................................ 6

2.3 POLYMERIZATION................................................................................................ 7

3 OBJECTIVES........................................................................................................... 8

4 PROCESS DESCRIPTION..................................................................................... 9

4.1 DESIGN ALTERNATIVES ....................................................................................... 9

4.1.1 Styrene from Ethylene and Benzene.............................................................. 10

4.1.2 Co-Production of Styrene and Propylene Oxide .......................................... 10

4.2 AREA 100 ALKYLATION.................................................................................. 10

4.2.1 Equipment Design......................................................................................... 11

4.2.2 Catalyst Design............................................................................................. 13

4.3 AREA 200 DEHYDROGENATION ...................................................................... 13

4.3.1 Equipment Design......................................................................................... 14

4.3.2 Catalyst Design............................................................................................. 16

4.4 AREA 300 SEPARATIONS OF AROMATIC PRODUCTS ........................................ 17

4.4.1 Separations Train and Column Design......................................................... 17

4.4.2 Separations Inhibitors................................................................................... 20

4.5 AREA 400 LIGHT GAS SEPARATION ................................................................ 21

4.6 HEAT EXCHANGER DESIGN................................................................................ 22

4.7 PUMP, COMPRESSOR AND TURBINE DESIGN ...................................................... 23

4.8 MATERIALS OF CONSTRUCTION......................................................................... 24

5 ENVIRONMENTAL, HEALTH AND SAFETY ISSUES.................................. 25

5.1 ENVIRONMENTAL CONCERNS ............................................................................ 25

5.2 CHEMICAL HAZARDS ......................................................................................... 26

5.3 SAFETY HAZARDS.............................................................................................. 27

6 CONTROL DESIGN.............................................................................................. 28

6.1 CONTROL DESIGN ON AREA 100........................................................................ 28

6.2 CONTROL DESIGN ON AREA 200........................................................................ 29

6.3 CONTROL DESIGN ON AREA 300........................................................................ 30

6.4 CONTROL DESIGN ON AREA 400........................................................................ 32

7 ECONOMIC ANALYSIS ...................................................................................... 32

8 UNCERTAINTIES AND ASSUMPTIONS.......................................................... 34

9 FUTURE WORK.................................................................................................... 34

1 Introduction

Styrene is a precursor to many polymer products such as polystyrene, acrylonitile

butadiene styrene (ABS), styrene-acrylonitrile, and various styrene-butadiene

products. These materials are used around the world in a variety of ways including

food storage, packaging, and automobile parts.

1

The market for styrenics has seen

overall growth in the previous decade despite a recent down year. The market is

expected to recover and see large gains in the near future. Therefore, now is an

excellent time to join the market, particularly if current styrene production cannot

meet future demand.

2

The process of producing styrene is well established. It was first produced in the

1930s by I. G. Farben in Germay and Dow Chemical in the United States. Styrene

is a clear liquid at room temperature with an aromatic odor. It is currently sold with

a minimum purity of 99.8% but is more commonly produced at 99.93%. The price

of styrene remains largely dependant on the cost of its raw materials.

3

2 The Chemistry

Production of styrene requires two reactions, an alkylation and a dehydrogenation.

2.1 Alkylation

The alkylation is a basic Friedl-Crafts alkylation, where ethylene reacts with benzene

to form ethylbenzene by Reaction 1a:

3

(Rxn 1a)

This reaction is exothermic and takes place in a distillation reactor system that is

partially packed with catalyst. The benzene is in vapor-liquid equilibrium and it is

alkylated as it passes through the catalyst.

4

This alkylated product has a lower

boiling point than benzene and will therefore become the distillate product in the

column. The catalyst is a molecular sieve known as EBZ-500S available through

UOP, LLC. EBZ-500S minimizes the amount of byproduct, such as polyaklylated

and oligomerized products.

5

The polyalkylated products that are formed come off in

the bottoms of the distillation. They are sent to a transalkylation reactor to be

converted back to ethylbenzene by Reaction 1b:

(Rxn 1b)

The catalyst in this reaction is EBZ-100, also available through UOP, LLC.

Oligomerization products are caused by the partial polymerization of ethylene.

These may either come off the top of the column or aklylate with benzene to form

byproducts that include cumene, n-propylbenzene, butylbenzenes as well as other

heavy alkybenzenes. Other byproducts come from the raw materials; for example,

toluene and C

6

non-aromatics can be present in the benzene feedstock, up to

1000ppm and 2000ppm respectively. These can also be alkylated, and leave as a

bottoms product.

3

2.2 Dehydrogenation

The dehydrogenation occurs in a fluidized catalyst cracking reactor, or FCC.

6

An

FCC was chosen over other reactor systems because it has the advantage of

continuous catalyst regeneration. The catalyst is comprised of gallium oxide

(Ga

2

O

3

), platinum, iron oxide (Fe

2

O

3

), potassium oxide (K2O) and silica suspended

on alumina.

7

It is unique in that is used to simultaneously dehydrogenate ethane and

ethylbenzene via reactions 2a and 2b:

(Rxn 2a)

(Rxn 2b)

These reactions are highly endothermic. The energy for the reaction is provided by

the catalyst in the regeneration reactor, where it is heated to 660C upon decoking.

The catalyst needs to be decoked continuously because two side reactions occur that

form toluene, benzene and coke, as shown in Reactions 2c and 2d:

H

2

H

2

(Rxn 2c)

(Rxn 2d)

The coke deposits on the catalyst, reducing the number of active sites, and thus

lowering the conversion of the desired reactions, 2a and 2b.

8

Toluene can also lose

another carbon to become benzene. These reactions account for total of 3% loss in

conversion.

3

Reactions 2a and 2b are also highly selective with 90-94% and 90-93%

selectivities respectively.

9

Other byproducts in the dehydrogenation form from byproducts in the alkylation.

For example, dehydrogenated cumene becomes -methylstyrene and n-

propylbenzene becomes allylbenzene. Other byproducts include vinlytoluenes,

xylenes, ethyltoluenes, phenylacetylene, unconverted alkylation byproducts and

heavy aromatics. These byproducts are insignificant in terms of yield loss, but

greatly affect the cost of purification and quality of the product.

3

2.3 Polymerization

Under the right conditions styrene can polymerize violently. This is an exothermic

reaction; therefore, once polymerization begins it can escalate out of control.

3

Polymerization is most likely to occur in the purification and storage phases of

production. Inhibitors are necessary to prevent this. For the storage tanks 4-tert-

Coke

Coke

Butylcatechol, or 4-TBC, is used in a concentration of 15 ppm. The tank is held

below 75F and oxygen is bubbled through the tank to increase the lifetime of the

styrene product. In the distillation columns 2,4-Dinitrophenol is fed continuously.

10

These steps allow the final product to be sold at a purity of 99.93% styrene

monomer, this is equal to the industry standard.

3 Objectives

The following objectives were satisfied in the design:

1.) To design a plant with the capacity to produce styrene monomer at a rate of 2.2

billion lbs/yr with a purity at or above the industrial standard of 99.93 wt%

2.) To analyze the design to determine whether it is economically competitive at the

average market price over the past three years

3.) To develop the design with the following design norms in mind:

a. Justice and caring Design decisions were made that consider the rights

and needs of all stakeholders, even those seemingly unaffected by the

plant. If styrene products can be made available to more people at a

lower cost, people of a wider economic range might be able to benefit

more from this product.

b. Trustworthy People living around this plant need to trust that they will

be safe, even in the case of an accident. Customers need to be able to

trust the operators of the plant to have the amount of styrene promised at

the specification needed. Customers rely on knowing that the process

will not only run continuously, but also at the required purity.

c. Stewardship Caring for the earth and all that is in it was a key motivator

in designing a chemical processing plant. Making sure that the plant is

optimized to not have more adverse affects on the environment than is

necessary and also being sure that none of our starting materials go to

waste, but are used to their fullest potential. Additionally, optimized

equipment allows the plant to operate using the less energy than non-

optimized.

4.) To simulate the design using HYSYS

5.) To choose a suitable location for the plant to be built

6.) To determine the design specifications on the following pieces of process

equipment: compressors, turbines, pumps, heat exchangers, distillation columns

and reactors.

4 Process Description

The process to synthesize styrene monomer from ethane and benzene can be

simplified to four stages: alkylation, dehydrogenation, light gas separations, and

separations of aromatic products. However, starting with different raw materials

would lead to different designs.

4.1 Design Alternatives

There are two major design alternatives prevalent in industry today. The first is the

production of styrene from ethylene and benzene via an ethylbenzene intermediate.

The second is the co-production of styrene and propylene oxide from ethylene,

benzene and propylene.

4.1.1 Styrene from Ethylene and Benzene

The production of styrene from ethylene and benzene is the most common industrial

process to produce styrene. A basic Friedl-Crafts Alkylation occurs between

ethylene and benzene forming ethylbenzene. The ethylbenzene is then

dehydrogenated to form styrene.

11

These are the same as reactions 1a and 2a,

respectively. Therefore, the impurities, catalysts, and separations of aromatic

products are the same as with the designed process.

4.1.2 Co-Production of Styrene and Propylene Oxide

Styrene is produced via the oxidation of ethylbenzene (formed from ethylene and

benzene) to ethylbenzene hydroperoxide. The ethylbenzene is epoxidized with

propylene, forming propylene oxide and -phenylethanol, the later of which is

dehydrated to form styrene. The amount of styrene produced is very dependant on

the market for propylene oxide because this process is a co-production. This process

also requires very complex and costly separations due to the aldehydes that form and

hinder the polymerization of styrene, a major concern for the customer.

3

4.2 Area 100 Alkylation

The distillation reactor system requires four distillation reactors (R-100) run in

parallel, one distillation column (T-100), and four packed bed reactors (R-101) run in

parallel. The process begins with benzene and ethylene reacting to form

ethylbenzene, the precursor to styrene.

4.2.1 Equipment Design

A Friedl-Crafts alkylation occurs in a distillation reactor system. Benzene and

ethylene (recycled from the ethylene and ethane separations process) enter a

distillation reactor. The distillation reactor contains twenty-five trays, but is packed

with catalyst in the upper 30 vol% of the reactor.

4

It is 6.5m tall and has a 1.9m

diameter. Two streams enter the reactor system; one is rich in benzene and the other

is rich in ethane with 9.01 mol% ethylene. The ethane exits as the distillate of R-

100, thus removing a distillation column from the Area-300 design. The inlet stream

with ethylene can operate at concentrations up to 95% ethane, with the remainder

ethylene. The boiling point of ethylbenzene is greater than ethane or benzene, so

once the ethylbenzene is formed it falls down the reactor as the bottoms product.

This reactor design has several advantages over the more industrially common

packed bed reactor:

4

1.) High conversion of ethylene is controlled by having a 10:1 ratio of benzene to

ethylene and sufficiently large height of packed catalyst. This minimization of

unreacted ethylene reduces separation and recovery problems.

2.) The benzene that comes off the reactor as the distillate is recycled back to the

reactor feed. A purge is added so that very light gasses do not accumulate. Only

the benzene that has reacted leaves the distillation reactor.

3.) The continued removal of the alkylated and polyakylated products forces the

chemistry in Reaction 1a to favor the products. This also minimizes both the

polysubstitution and decomposition of the product.

4.) Because the compounds in the distillation reactor are boiling, the temperature at

which the reaction takes place is controlled by the boiling point of the mixture.

This has the further advantage that as the exothermic alkylation takes place the

reaction enthalpy increases the boil-up.

5.) The rate of reaction and distribution can be well controlled by regulating the

system pressure. Thus, upon piloting this process, the distillation reactor

efficiency can be increased significantly.

6.) Two stages are condensed into one; the first stage would consist of the reaction

of benzene and ethylene to ethylbenzene. The second would be the separation of

benzene from ethylbenzene. These two processes occur in one distillation

reactor.

The bottom products from the distillation reactor are then sent to a distillation

column, where the polyalkylated benzenes (mostly di- and tri- ethylbenzene) are

separated from ethylbenzene. This design achieves a purity of 99.78 mol%

ethylbenzene in the distillate. The bottoms product is entirely byproducts. The

polyalkylated benzenes, along with the heavier impurities, are sent to a

transalkylation reactor where reaction 1b occurs. The transalkylation unit is a

packed bed reactor. In the presence of more benzene, the formation of ethylbenzene

from the polyalkylated benzenes is favored.

3

The unconverted polyalkylbenzenes

are then recycled to distillation column T-100. The 99.78 mol% pure ethylbenzene

is sent on to the dehydrogenation.

4.2.2 Catalyst Design

There are two catalysts used in Area-100. EBZ-500S is available from UOP and is

used in the distillation reactor. Its a zeolite catalyst in the solid -phase. It has a

spherical shape with a nominal diameter of 2.2mm and is absent of precious metals.

Unwanted side-reactions are minimized and it more resistant to poisons like water,

oxygenates, olefins, chlorides and sulfur. EBZ-500S has a life time of five years

without regeneration and can be regenerated up to three times, thus allowing the

catalyst to be used for 20 years before replacement.

5

It is available from UOP for

approximately $105 per pound.

12

When used in conjunction with EBZ-100 in the

transalkyation, a purity of 99.97% ethylbenzene can be achieved. EBZ-100 is

another catalyst also available through UOP. It is specifically designed to operate in

the transalkylation. It is also a solid zeolite catalyst with no precious metals and has

a nominal diameter of 1.6mm with an extrudated shape. Its life time is five years

without regeneration and it can be regenerated three times, and needs to be replaced

every 20 years.

13

Its cost is $40 per pound.

12

Together these solid catalysts will

provide the desired conversion for the distillation reaction system.

4.3 Area 200 Dehydrogenation

The fresh ethane feed and the ethylbenzene formed in Area-100 enter the

dehydrogenation . Four reaction vessels designed to the specifications of R-200 and

R-201 are used in parallel, allowing for temporary shutdown of one reactor. Here

Reactions 2a and 2b form the main product, styrene, along with ethylene. Side

reactions occur to form toluene, benzene, and coke.

4.3.1 Equipment Design

The fluidized catalyst cracking reactor (FCC) has two reaction vessels, RV-200 and

R-201. Ethane and ethylbenzene enter R-200 and form the dehydrogenated products

ethylene and styrene respectively. At the inlet of R-200 the ethane to ethylbenzene

volumetric feed ratio is 4.08:1. At this feed ratio, the product of conversion and

selectivity for Reaction 2a is 48% and for Reaction 2b is 9.7%.

7

R-200 uses the

Optimix LSi FCC feed distribution system available through UOP LLC. The

ethane and ethylbenzene carry the solid catalyst to the top of the reactor, where it

exits through special disengaging arms which generate a centrifugal flow pattern.

14,15

This is designed to disperse the catalyst uniformly in the riser of the reaction vessel.

The catalyst remains fluidized by the reagent mixture in the gaseous phase. The

dynamics of the reaction vessel cause the catalyst to move downward (due to

gravity) and components in the gaseous phase to move counter-current to the

catalyst. This causes thorough mixing between the catalyst and reaction

components. Ethane, ethylene, ethylbenzene, styrene, toluene, and benzene are the

major compounds leaving the FCC chamber, along with the dehydrogenated form of

the Area-100 byproducts. A solid side product, coke, is produced via Reactions 2c

and 2d, and deposits onto the catalyst.

3

The gaseous products leave the reactor

through a solid filtering technique, known as cyclones. The cyclones extend towards

the bottom of the riser, but stop before the catalytic stripping part of R-200. This

design is common in VSS reactor systems available through UOP LLC. It contains

the hydrocarbons to the riser of the reactor and pre-strips the catalyst.

15

The catalyst

falls further to an AF spent catalyst stripper, also available through UOP LLC. In

the catalyst stripper, absorbed hydrocarbons leave the catalyst particles. The catalyst

falls to the bottom of the stripping trays and is sent to regenerator R-201.

16

In the regenerator the coke deposited on the catalyst is burned off via air at 560C,

producing carbon-dioxide. Hydrogen, recycled from Area-400, also enters R-201

and is combusted to produce water. By this process, the catalyst is heated to 680C

and transported back to R-200. The high temperature of the catalyst provides the

heat of reaction for Reaction 2a and 2b to occur. There are several reasons to use a

reactor-regenerator system:

7

1.) The catalyst is continually regenerated. By continually removing coke the

catalyst will not degrade over time. This means the operating parameters and

catalyst performance will be constant for the lifetime of the plant.

2.) The heat for Reactions 2a and 2b are provided by the catalyst, thus super-heating

ovens are not needed.

3.) The re-mixing of the fluidized bed prevents hot spots from forming, which would

lower selectivity.

4.) The hydrogen can be recycled to R-201, where it is burned.

5.) The process can be made continuous without changing the operating parameters

of the plant over its lifetime.

6.) R-200 and R-201 are physically separate. This disallows mixing between the

hydrocarbons and any oxygen, an inherent process danger.

7.) Less inert gas needs to be used in the feeding to the reactor, thus higher

concentrations of the reactants can be used, which lead to higher reaction

selectivites.

4.3.2 Catalyst Design

This process is very catalyst-specific. Therefore, the design and development of the

catalyst is crucial. The catalyst in Area-200 is comprised of less than 10 wt% Ga

2

O

3

,

20 wt% Fe

2

O

3

, 100 ppm platinum, and the remainder alumina. The catalyst is

synthesized in a four-step process. The promoters are added to the carrier via an

aliquot. The sample dried at 150C and calcinated at 900C. The iron oxide and

remaining promoters are added to the carrier. The catalyst is dried and calcinated

again, as described previously.

7

In order to determine the amount of catalyst needed

for a given feed composition, data from Figure 1 was taken from US patents

#6,031,143:

Weight of Catalyst vs. Ethane to EB Volumetric Ratio

y = 498.18x

-0.6678

R

2

= 0.9967

y = 17.28x

0.5396

R

2

= 0.9996

0

50

100

150

200

250

300

0 2 4 6 8 10 12

Ethane/EB vol

g

/

h

/

k

g

c

a

t

Styrene Ethane

Figure 1: Weight of Catalyst vs. Ethane and Ethylbenzene Volumetric Ratio

The catalyst for the selective combustion of hydrogen is available through UOP and

is OC-5. It is a solid sphere with a nominal diameter of 3.8mm and a density of

750 kg/m

3

.

17

OC-5 uses platinum as a promoter and is available at $115 per

pound.

12

4.4 Area 300 Separations of Aromatic Products

The separations system is set up to recover styrene at a purity of 99.93%, toluene at a

purity of 99.75%, benzene at a purity of 99.85%, and ethylbenzene at a purity of

98%. This system uses seven distillation columns of which three are for the

purification of styrene. The inhibitor 2,4-dinitrophenol is used in this system to

prevent the polymerization of styrene. The components that enter Area-300 can be

simplified into six categories: Light gases, C

6

non-aromatics (modeled as n-hexane),

benzene, toluene, ethylbenzene, styrene, and heavy aromatics.

4.4.1 Separations Train and Column Design

In column T-300, light gases such as ethane and ethylene are vented to the light

gases area. Toluene and benzene are separated from ethylbenzene and styrene. To

ensure minimal styrene polymerization product the temperatures should stay low. T-

300 is a packed column which uses Flexipac HC structured packing, available

through Koch-Glitsch. The advantage to using structured packing is that there is a

small pressure drop across each stage of approximately 0.05 psi. This minimizes the

temperature difference across the column and therefore the temperature necessary in

the reboiler, which is crucial in preventing polymerization of the styrene product.

The column operates at vacuum conditions with a pressure of 26.7 kPa. It contains

66 stages, with the feed entering in the 50

th

stage. The diameter is 2.04m and its

height is 40.23m. The reflux ratio is optimized at 12:1. The distillate product is rich

in toluene (49.6 mol%) and benzene (49.1 mol%), with some n-hexane (1.2 mol%)

and the remainder ethylbenzene (0.1 mol%). These products are sent to column T-

301.

In T-301, a column of 23 trays, toluene is purified and leaves as the bottoms product.

It has a purity of 99.8% toluene, which is then to spot sold as high-grade toluene. T-

301 is a sieve-tray column with a diameter of 2.04m (6.7ft) and a height of 14.02m

(46ft). Sieve trays are used because polymerization in not a concern, and is less

expensive. The operating pressure is 26.7 kPa. The reflux ratio is optimized at 3.4:1

and the optimum feed inlet is tray ten. The distillate is mainly benzene, with some

non-aromatic impurities. It is then sent to column T-302 for further separation.

Column T-302 separates benzene from non-aromatic C

6

hydrocarbons in 40 sieve

trays. This process is economically viable because the recovered benzene can be

recycled to Area-100. Like column T-302, sieve trays are used because costs can be

reduced without sacrificing product purity. The optimum feed inlet is in tray 28, and

optimum reflux ratio is 15:1. The diameter is 2.1m (6.9ft) with a height of 14.63m

(48ft). The operating pressure is 26.7 kPa. The benzene is purified to 99.85 mol%.

The bottoms product from column T-300 contains ethylbenzene (49.4 mol%),

styrene (50.4 mol%), the toluene (0.17 mol%) and the remainder heavy aromatic

byproducts. These are sent to column T-303, where the ethylbenzene is separated off

the top to be recycled to Area-200. Like T-300, this column uses Flexipac HC to

reduce pressure drop across the column. T-303 is 72 stages, with an optimum feed

inlet at stage 48 and optimum reflux ratio of 10:1. To further reduce operating

temperatures, and thus the possibility of polymerization, the pressure is decreased to

7.99 kPa. The diameter of T-303 is 5.33m and the height is 43.89m.

The remainder of the styrene product is then sent to T-304, where it is then purified.

Column T-304 incorporates the same packing as previously mentioned above the

feed inlet, and trays in the stages below the feed inlet. The advantage to designing a

hybrid column like this is due to some of the styrene monomer beginning to

polymerize. If any styrene polymerizes enough to form a solid within the column

then it will deposit onto the tray. Occasionally the column will need to be opened

and the trays cleaned to remove any solid polymer residue. This is easy to do with a

sieve tray and very difficult with packing. Since the highest temperatures are in the

reboiler, the polymers are most likely to form at the bottom of the column, on the

sieve trays. T-304 operates at a lower pressure (5.33 kPa) than column T-303. It has

a height of 27.4m and a diameter of 5.2m. The optimum reflux ratio is 0.75:1. The

total number of trays is 45 and the feed enters on the 24

th

tray. The bottoms product

is then further purified in T-305. The distillate is purified styrene and is sent to

storage or to the customer.

Column T-305 has a similar design to T-304. It is another hybrid column with

structured packing from stages one to fifteen and sieve trays from sixteen to the last

tray, thirty. It operates at 5.33 kPa, with a height of 18.3m and a diameter of 3.3m

(10.9ft). The optimum reflux ratio is 1.29:1. The bottoms product is sent to column

T-306. The distillate joins with the distillate from T-304 and goes to storage and for

sale.

The final column in Area-300 is T-306. It has the same dimensions as T-305 and

same tray design. The only difference is that it operates with a reflux ratio of 15:1.

The distillate product in columns T-304, T-305 and T-306 are mixed to produce the

final styrene product available at a purity of 99.93 wt% styrene. The bottom

products of T-306 are the heavy side-products. They are mixed with the heavy

byproducts from the alkylation and sent to be incinerated.

4.4.2 Separations Inhibitors

Without inhibitors the distillation design in Area-300 would not work.

Polymerization would occur often, causing the columns to need to be shut down

frequently for cleaning. Therefore, the inhibitors that are used, and where they enter

the process, are important. There are two different types of inhibitors: retarders

(which slow polymerization) and true inhibitors (which stop polymerization in the

free radical stage).

The inhibitor which retards the polymerization process is 2,4-dinitrophenol. It is

added in the liquid stream coming from the condenser on column T-303, the first

column where the styrene product is purified. It will then fall through column T-

303, where the concentration of styrene increases as the inhibitor moves down the

column. It is carried through T-306 and removed before the styrene is sent to storage

tanks.

After removal of the 2,4-dinitrophenol, but before storage, the inhibitor 4-TBC is

mixed into the styrene product stream. It stops polymerization by interacting with

the free radicals formed in the initiation step of the polymerization mechanism. In

the storage tanks, oxygen is bubbled through the tank to activate the 4-TBC. The

styrene product is sent to customers with the 4-TBC present. Customers remove it

by adsorption when polymerization is desired.

4.5 Area 400 Light Gas Separation

The products from Area-200 are cooled to -50C and then separated in V-202 so that

the vapor products are rich in ethane, ethylene, nitrogen, and hydrogen and the liquid

products contain the aromatic products from the dehydrogenation. The vapor

products are then sent to Area-400, the light gas separations. Here the ethane and

ethylene are separated from the hydrogen and nitrogen via a series of compression,

cooling, expanding and two-phase separations. The necessary equipment includes

33 compressors in eleven compression stages, 30 heat exchangers, ten turbines, and

ten two-phase separators. Under ideal circumstances, ten throttling valves would be

used instead of turbines that operate at 85% efficiency. However, HYSYS could not

correctly model an isoentropic expansion for this case. If throttling valves were used

a cost reduction could be seen in both the equipment savings and in the compressor

duty. Because the turbine is not 100% efficient, some of the enthalpy of expanding

the gas goes to entropy, which must be made up by the compressors. The two-phase

separators operate at a range of temperatures from -68.5C in the first stage to

-168.2C in the last stage. The temperatures after compression get as high as 42C.

Three streams leave Area-400. The first is the bottoms product of the first two phase

separator and consists of mostly styrene, ethylbenzene, and other aromatics. The

second is the distillate recovered after ten two-phase separators. At -159.4C, it is

comprised of 64.9 mol% nitrogen, 34.9% hydrogen, and the remainder ethane and

ethylene. This stream is sent to Area-200 and is burned in R-201 to provide heat for

the reaction. The third stream is the mixture of the bottoms of each two-phase

separator, and is rich in ethane and ethylene at 90.0 mol% and 9.98 mol%

respectively. This stream is fed to Area-100 and supplies the ethylene feed for

Reaction 1a. Area-400 is the most expensive area in the process.

4.6 Heat Exchanger Design

Sixty-six heat exchangers have been designed in the process. The fundamental

design equation is:

17

lm

T UA q = Equation 1

where q is the total heat transferred, U the overall heat transfer coefficient, T

lm

is

the log-mean temperature difference, and A is the area used for exchanger design.

The overall heat transfer coefficient is estimated from design tables provided by

Peters, Timmerhaus and West.

18

Water is the coolant for streams needing to be

cooled down to 15C. It is used in the condensers in Area-300 and on exchanger E-

202.1. The coolant, R-22, is available to -60C and is primarily used in Area-400.

19

The reboilers in Area-300 use exhaust steam available at 150 kPa and 109.95C for

heating the product streams. However, one exchanger uses saturated steam at 3550

kPa and 243.38C. Area-300 accounts for a total of sixteen exchangers. Area-400

uses thirty exchangers for interstage cooling after compression. Eleven exchangers

are used in Area-100 and ten exchangers are used in Area-200. The pressure drop

across the tube and shell side of each exchanger can be calculated. An example

calculation can be seen in Appendix E.1. The pressure drops were also increased to

account for losses due to piping and to ensure that estimates are on the conservative

side. The specifications on each exchanger can be seen in Appendix A.2. The cost

is a function of exchanger area and duty of the coolant or steam.

4.7 Pump, Compressor and Turbine Design

There are fifteen places in the plant design where vapor compression is necessary.

At each point the compressor arrangement is optimized. Forty-one compressors

operating at 75% efficiency are used in the process. The optimum arrangement

requires anywhere from one to six compressors with interstage cooling. Area-400

requires thirty-two of these compressors in order to separate ethane and ethylene

from nitrogen and hydrogen. The optimum arrangement was determined by

specifying that the duty on each compressor in one chain is equal, and a cost analysis

done for each case. This required over eighty various arrangements to be evaluated

and the optimum fifteen to be taken from this. The cost of each compressor was

determined from the material of construction, size and duty required. The cost of

each compression chain was the sum of the compressor and heat exchanger costs

annualized over twenty years.

There are ten turbines in the process; all of which are used in Area-400. Each

turbine is 85% efficient and used to cool the vapor into the two phase region. The

cost on each turbine is determined from the material of construction, size and duty.

There are four pumps needed in the process. They are on the benzene feed to Area-

100, benzene recycle from Area-400 to Area-100, and the toluene and styrene

products from Area 300. The cost of each pump is determined from its material of

construction, capacity, duty and pressure. Calculations and specifications for each

compressor, turbine and pump can be seen in Appendices A.1, A.6 and A.3,

respectively.

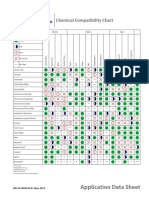

4.8 Materials of Construction

Carbon or stainless steel is used in all areas of the plant. Carbon steel is generally

less expensive than stainless steel, but has two problems. First, it degrades at

temperatures above 455C. Carbon will segregate from the piping, putting graphite-

like deposits into the process.

19

Therefore, in all areas operating above 455C

stainless steel is used. This is most prominent in Area 200. Reactors T-200 and T-

201 reach temperatures above 600C. The product stream is cooled below 400C

after exchanger E-200. However, the product stream contains hydrogen gas. The

second problem with carbon steel is that hydrogen gas can imbed itself within the

material, degrading the steel over time.

18

Therefore, carbon steel cannot be used

again until Area-300 and cannot be used at all in Area-400. The materials of

construction greatly effect equipment cost. Therefore, whenever possible carbon

steel is used instead of stainless steel.

5 Environmental, Health and Safety Issues

Christian engineers are called not only to design for profit, but to design in a manner

that glorifies Gods creation and respects His people. Therefore, the design of this

plant includes taking consideration of environmental issues, as well as concerns for

the well-being of all people that might be impacted by the plant or its products. This

concern for the stakeholders in the plant guides this design.

5.1 Environmental Concerns

One of the design objectives is to show stewardship and therefore minimize the

impact on the environment. The importance of this objective cannot be overstated.

The environment consists of the land, water, air, animals and people near the plant.

One major byproduct is carbon dioxide. This is created from the incineration of

gaseous hydrocarbon side products and the burning of coke on the catalyst. Streams

306 and 311 are to be combusted to carbon dioxide and water. Purge stream 227

also contains carbon dioxide. All products are to be sent though scrubbers to reduce

the carbon monoxide content from side combustion reactions and bring the limits

within the National Ambient Air Quality standards of 9ppm per 8 hour non-

overlapping average.

20

Unfortunately, the modeling of the incineration process and

estimations of the side combustion reactions are beyond the scope of the design. As

of 2004, the average American produced 5.76 metric tons of carbon dioxide per

year.

21

The designed process produces the equivalent amount of 5750 Americans in

one production year. This is a weakness of the design, and would need to be reduced

before implementation.

The other byproducts consist of heavy hydrocarbons. These are incinerated when

possible and treated when they cannot be incinerated. The modeling of this process,

and the reactions that govern it, is also beyond the scope of the design. Water

generated from the combustion of hydrogen in T-202 is sent for treatment as well.

The significant benefit to the process is that the dehydrogenation reactions (2a and

2b) occur simultaneously. Thus the designs for ethane to ethylene and ethylbenzene

to styrene plants are incorporated into one design. This is evidenced by the need for

two separations process, Area-300 and Area-400. A possible pollution reduction can

be accomplished by incorporating two plants into one. An in depth analysis of this

hypothesis is beyond the scope of the design.

5.2 Chemical Hazards

Caution should be taken when dealing with several compounds in the process.

Styrene monomer should not have contact with skin. If it does, the skin should be

washed with water for at least fifteen minutes. Styrene is extremely flammable and

can travel a considerable distance to an ignition source and should be put out using a

dry chemical, alcohol foam or carbon dioxide. Pure styrene has a penetrating odor.

The flammability limits lie from 1.1 wt% to 6.1 wt%. Styrene waste should be

mixed with a more flammable solvent and then be atomized into an incinerator.

22

The precursor to styrene, ethylbenzene, is also dangerous. It should never be inhaled

and CPR may be needed after doing so. It is labeled as a severe fire hazard and the

same method of fire fighting used for styrene should be applied to ethylbenzene.

23

Benzene is an eye irritant and causes nausea, unconsciousness, and a change in blood

composition when breathed in. It is also a fire hazard, and should be put out with the

same method as styrene and ethylbenzene. The flammability limits are from 1.3

vol% to 7.9 vol%. A self contained breathing apparatus should always be used when

around benzene that could enter the surrounding air.

24

Ethane is non-toxic but can

cause asphyxiation. It is also a fire hazard. If a cylinder is exposed to fire it may

rupture. The flammability limits are from 3.0 vol% to 12.5 vol%.

25

Ethylene can

cause dizziness, asphyxiation, drowsiness, unconsciousness and muscular weakness

from overexposure. It is flammable, with limits from 3.1 vol% to 32.0 vol%. Fires

for both ethane and ethylene are best treated by removing or shutting off the

source.

26

5.3 Safety Hazards

Safety is a primary concern in all areas of the process. There are three major

variables that affect equipment safety. They are the operating pressures,

temperatures, and the chemicals present. Choosing the appropriate materials of

construction (see sect 4.8) reduces the dangers associated with temperature and

certain chemicals. For example, carbon steel cannot be used above 455C or with

hydrogen gas, thus stainless steel is the appropriate material in streams which carbon

steel cannot be used. For equipment operating at high pressures, the thickness of

equipment must be increased. This is taken into account as a pressure factor used

when costing equipment. The flammability of each stream is also taken into

consideration. The only streams with oxygen present enter regenerator R-201. The

oxygen is consumed in the reaction. All other streams operate well above the upper

flammability limits. Using pressure, temperature, level, and flow controllers the

streams can be kept within the designated safety ranges.

6 Control Design

Whatever can be controlled in the process should be controlled.

27

Controls are vital

to the safety of a process and are, therefore, incorporated in the design to converge

the real-world variables to the design variables. They are designed to check for

unsteady states, minimize the occurrence of unsteady states, and then correct the

problem. As such, the time lag between the occurrence of a problem and the

correction needs to be minimized. This is done by placing controls where they can

have the fastest impact.

6.1 Control Design on Area 100

The fresh benzene feed is to be controlled via a flow controller, which measures the

flow rate of incoming benzene. This controller disallows backflow to benzene

storage tanks and adjust the feed so that the benzene to ethylene ratio is 10:1 in R-

100. A temperature controller is used to verify this specification and is on the

reboiler, so that it will have a direct impact on space time and reaction temperature

inside R-100. Since there are actually four R-100 reactors in parallel, the feed

controller needs to be on each incoming stream. This would allow for temporary

shutdown or production rate decrease. However, the process is designed to operate

under constant production conditions and not vary with market demand or equipment

failure. R-100 has a flow controller on the condenser, which affects the ethane going

to Area-200. Column T-100 has two level controls; one on the reboiler and

condenser each. The bottoms of T-100 are sent to R-101, but with a flow control on

the purge stream. Like the benzene inlet control on R-100, this control varies the

polyalkylated benzene feed to keep its ratio with benzene constant.

6.2 Control Design on Area 200

The ethylbenzene and ethane from Area-100 is mixed with ethylbenzene from Area-

300 and fresh ethane feed. There is a feed controller on the ethane feed, controlled

based on the product from Area-100. The mixed stream is sent though exchanger E-

200, where a temperature control is used to stabilize temperature fluctuations. The

ethylbenzene is sent though a series of compressions and then mixed with inert gas.

This stream is sent though E-201, where the temperature entering the reaction needs

to be consistent and is controlled by a temperature controller. The product from T-

200 is sent through a flow control, which is modified based on the temperature after

E-202. After filtration, another temperature is used for exchanger E-204, so that the

temperature into the two-phase separator, V-200, is consistent and will cause the

aromatic products to be sent to Area-300 and the light gases to Area-400. Because

this controller determines the split in V-200 it will affect the entire process.

The air feed to Area-200 has a flow controller across a gate valve and then a pressure

controller on compressor K-201. This stream is heated by the product from T-201,

thus a flow controlled bypass is used to control the temperature of this stream. Its

temperature is vital because it causes the combustion in T-201 to occur, which

provides the energy for the reactions in T-200. The product stream from T-201 is

also heat exchanged with the hydrogen and nitrogen inlet from Area-400. A flow

controlled bypass is again used to control the temperature of both streams. The

product stream is filtered and another temperature controller used across the heat

exchanger before V-201. After a series of compression, where a pressure controller

is used, E-202 has a temperature control. When separated in V-200, the gaseous

nitrogen and carbon dioxide are sent across a flow control. This control varies how

much is purged and how much is sent to R-200 to fluidize the reactor bed.

6.3 Control Design on Area 300

There are three parameters that need to be controlled in Area-300. They are: the exit

composition of each column, the column pressure, and the reflux ratio on each

condenser. The first controller is a flow controller used directly before T-300. The

column then has six controllers. Because this column operates under vacuum

pressure, the pressure control is crucial. Depending on the column pressure, the

temperature, reflux and flows will all change. Therefore, it is essential that the

pressure meets the specs by which the column was designed. The pressure control

can open a gate valve used to vent off gases in case the pressure is too high. The

temperature control is on the column. The equilibrium within the column dictates

that a specific composition resides at a specific temperature. Thus a flow control is

connected to the reboiler exhaust steam. A level control varies what leaves T-300

through the bottoms and another level control is used on the condenser. On the

condenser, the level control operates a gate valve on the product stream. Its function

is to set the reflux ratio, which should be converged to the designed optimum reflux

ratio. Lastly, a flow controller controls how much reflux is sent back to T-300.

Since this is the first column in the distillation chain, it may be tempting to put two

temperature controllers on the column, each one to specify the composition on either

end. However, studies have shown that this creates many problems because the two

controllers are not mutually exclusive. One controller can interfere with the other

based on how much it tries to control the exchanger duty. Using only one

temperature controller is easier and still does a good job.

Columns T-301, T-302, and T-303 are designed in a similar manner, with six

controllers per column used to control the composition, pressure and reflux ratio.

For each of these columns, the reflux ratio is greater than one, and so the gate valve

for the level control on the condenser is positioned on the product stream. When the

reflux ratio is less than one, then the level control is on the condenser coolant, as

with T-304 and T-305. The flow control is on the product stream, and another flow

control manages the reboiler steam. A level control operates a gate valve on the

bottoms product. T-306 has a reflux ratio above 1, so there is a level control on the

distillate, and flow control on the reflux. However, the bottoms are designed with

the level control on the product stream, and the flow control on the reboiler steam.

The mixed styrene product stream is then sent to storage. There is a flow control on

this final stream.

6.4 Control Design on Area 400

Even though Area-400 has eighty two pieces of equipment, the control design is

simple. Every compressor has a pressure control. Every heat exchanger has a

temperature control and a flow control on the coolant. Every turbine has a pressure

control as well. Therefore, there are 102 controls used in Area-400 total.

7 Economic Analysis

Capital, utility and raw material costs along with revenue from the products

determine the profitability of the design. The purchase and installation of

equipment, land and piping affect the capital cost. Of these, the largest contributor to

the capital cost is from the equipment. This is priced according the cost spreadsheets

available from Peters, Timmerhaus and West. Direct costs, indirect costs, and

working capital affect the total capital investment. A few direct costs are the

purchased equipment, delivery, installation, piping and instrumentation costs.

Indirect costs are things like construction and legal expenses, engineering and

supervision, contractor fees, and contingency costs. Working capital is the cash on

hand needed to start the plant. The total capital investment is 2,508.7 million dollars.

Raw material costs are from ethane, benzene, air, OC-5, EBZ-100, EBZ-500S, TBC,

and DNP. The annual cost of all raw materials is 731.5 million dollars. Electricity,

refrigeration, steam, water treatment, and cooling water usage determine utility costs.

The total is 197.8 million dollars per year. The revenue generated from the products

styrene and toluene is 1,976.2 million dollars per year. The selling price for styrene

is $0.99 per pound. The variable costs consist of raw material costs, utilities and

general expenses; projected at 1,084 million dollars per year. The fixed costs include

fixed charges, plant overhead and general expenses; and are 297.7 million dollars per

year.

18

The price for the styrene is chosen by varying the Investors Rate of Return (IRR). If

the IRR is set to 15.0%, the price of styrene is $0.99 per pound as shown in Figure 1:

IRR Analysis - Product Price Fluctuation

-5.0%

0.0%

5.0%

10.0%

15.0%

20.0%

25.0%

30.0%

35.0%

$0.70 $0.80 $0.90 $1.00 $1.10 $1.20 $1.30 $1.40

Styrene Monomer Product Price ($/lb)

I

R

R

Figure 2: IRR Analysis Product Price Fluctuation

15.0% IRR is a common value and a good starting point.

28

The Net Present Value

for this IRR is 1.99 million dollars, which is basically zero when compared to the

high capital costs. Equation 2 can be used to solve for the IRR:

=

+

=

n

i

i

i

IRR

CF

0

) 1 (

0 (Equation 2)

The return on investment (ROI) stabilizes after the sixth production year, where it is

15.4% for the lifetime of the plant.

8 Uncertainties and Assumptions

Most of the process specifications used in the HYSYS simulation came directly from

the patents. Generally, having some data is better than no data. This is true of the

data provided in the patents as well. However, the patents often provide one value

for one experiment. Without having multiple experiments run for each point, one

must trust the validity of that data point. In designing a pilot plant, this may not be a

big deal. When designing a plant to accumulate 14% of an already competitive

market more data would be better.

In HYSYS, the design was simulated using the General NRTL fluid package. The

NRTL is a local-composition thermodynamic model, and therefore, analyzes the

system according to its molecular interactions.

9 Future Work

Broadening the scope of the design would lead to the possibility to do a lot of further

work. Some of the most important work could be done to minimize pollutants. The

current design produces 33,098,000 kg/hr of carbon dioxide. This amount needs to

be reduced. Public opinion of processes that produce greenhouse gases is

continually becoming more negative. In order to be good stewards, the amount of

pollutants placed in the atmosphere must be reduced. To do this analysis, a

simulation of the combustion and side reactions should be done in HYSYS. A way

to model the formation of carbon monoxide would make the simulation more

realistic. This leads to stack scrubbing costs having an impact on the economic

analysis because the costs associated with the treatment of this gas can rise quickly.

Too much carbon monoxide production (or inadequate smokestack design) would

lead to fines from the EPA.

The fluidized catalyst cracking reactor could be designed with greater detail. If a

kinetic model could be developed and then used to design the various parameters of

the reactor, then the estimates on the reactor size could be improved. This would

help in pricing the reactor system. The reactor price is currently an educated

estimate. A more accurate price would improve the economic analysis as a whole.

FCC simulation software is also available. This would help because interpolated

values in the patents do not account for catalyst degradation. In fact, the values in

the patents are for a very specific system, using a specific catalyst and reactor set-up.

Any method for further modeling the FCC system that allows these parameters to

change would only improve the simulation.

The computer simulation software, HYSYS, can simulate processes which involve

solids. However, the HYSYS software used for this design does not have this

license available. A solid modeling license would allow the catalyst regeneration

step to be simulated, thus making the simulation more realistic. Filters that remove

solid catalyst particles from the regeneration product stream could also be simulated.

A better estimate of the pressure drop across a filter could be determined. Currently,

a valve simulates the pressure drop across a filter in HYSYS.

The HYSYS simulation also has another problem: it cannot model throttling valves.

Therefore, the designed process used expanders that were 85% efficient. Since this

caused a loss of energy and increased equipment costs, the turbines are far less

favorable than throttling valves.

There are sixty-six heat exchangers used in the process. The overall heat transfer

coefficients for each exchanger could be improved. Currently, all heat transfer

values are estimated using Peters, Timmerhaus and West, which gives a range of 250

to 600 W/m

2

K for medium organics cooled with water, and a range of 250 to 500

W/m

2

K for medium organics heated with steam.

18

These temperature ranges can

vary the exchanger area significantly. Because the components are generalized and

the heat transfer coefficient given a broad range of possible values, it is likely that

the estimated heat transfer coefficients used for doing heat transfer area design are

wrong. A detailed analysis of all sixty-six exchangers would be ideal.

WORKS CITED

(1) SIRC: International Styrene Industry Forum. 9 Dec. 2005

http://www.styrene.org/international.html.

(2) Tullo, Alexander H. "Spotlight on Polymers." Chemical and Engineering News, 12

September 2005, 19-24.

(3) Kroschwitz, Jacqueline I., Raymond E. Kirk, Donald F. Othmer, and Mary Howe-

Grant. "Styrene." Encyclopedia of Chemical Technology. 4th ed. New York City:

Wiley, 1998.

(4) Smith, Jr., Lawrence A.; Arganbright, Robert P.; Hearn, Dennis. Process for the

preparation of ethyl benzene listed in US Patent #5,476,978; Nov 29, 1991.

(5) "EBZ 500S Catalyst." Ethylbenzene and Styrene. 2006. UOP. 20 Apr. 2006

<http://www.uop.com/objects/EBZ%20500S%20Catalyst.pdf>.

(6) Jones, Mark. "Ethane Plus Benzene." E-mail to the author. 18 Oct. 2005.

(7) Iezzi, Rodolfo; Buonomo, Franco, Sanfilippo, Domenico. Catalytic Composition

for the Dehydrogenation of C2-C5 Paraffins listed in US Patent # 5,143,886;

Sept 1, 1992.

(8) Buonomo, Franco; Sanfilippo, Domenico; Iezzi, Rodolfo; Micheli, Emilio. Catalytic

System and Proces for Dehydrogenating Ethylbenzene to Stryene listed in US

Patent # 6,242,660; June 5, 2001.

(9) Buonomo, Franco; Donati, Dianni; Micheli, Emilio; Tagliabue, Lorenzo. Process

for the Production of Styrene listed in US Patent #6,031,143; Feb 29, 2000.

(10) http://www.novachem.com/productservices/docs/StyMon_Safety_Guide.pdf

(11) Watson, Keith. Calvin College, Grand Rapids, MI. 5 Oct. 2005.

(12) Cooper, Geoff. "Catalyst Costs for a School Project." E-mail to the author. 1 May

2006

(13) "EBZ 100 Catalyst." Ethylbenzene and Styrene. 2006. UOP. 20 Apr. 2006

http://www.uop.com/objects/EBZ%20100%20Catalyst.pdf>.

(14) Optimix FCC Feed Distribuition Systsem

http://www.uop.com/objects/FCC%20Optimix.pdf

(15) FCC Vortex Separation Technology: The VDS Design and VSS Design

http://www.uop.com/objects/FCC%20Vortex.pdf

(16) AF FCC Spent Catalyst Stripper Technology http://www.uop.com/objects/

20%20AF%20Stripper%20Tech%20Sheet.pdf

(17) "OC 5 Catalyst." Ethylbenzene and Styrene. 2006. UOP. 20 Apr. 2006

<http://www.uop.com/objects/OC%205%20Catalyst.pdf>.

(18) Peters, Max S.; Timmerhaus, Klaus D.; West, Ronald E.; Plant Design and

Economics for Chemical Engineers. 5

th

Ed. University of Colorado. 2003.

(19) Perry, Robert H.; Green, Don W.; Perrys Chemical Engineers Handbook. 7

th

Ed.

McGraw-Hill. New York. 1997.

(20) http://www.epa.gov/oar/oaqps/greenbk/o3co.html

(21) http://pages.ca.inter.net/~jhwalsh/wfsesr.html

(22) http://msds.ehs.cornell.edu/msds/msdsdod/a98/m48796.htm#Section5

(23) http://msds.ehs.cornell.edu/msds/msdsdod/a401/m200166.htm#Section5

(24) http://msds.ehs.cornell.edu/msds/msdsdod/a49/m24066.htm#Section11

(25) http://msds.ehs.cornell.edu/msds/msdsdod/a328/m163906.htm

(26) http://msds.ehs.cornell.edu/msds/msdsdod/a194/m96822.htm

(27) VanAntwerp, Jeremy. In Class Lecture. Engr. 342. May 8, 2006.

(28) Medema, Robert. Interview. Feb. 22, 2006.

Chen, Kaidong, Alexis T. Bell, and Enrique Iglesia. "Kinetics and Mechanism of

Oxidative Dehydrogenation of Propane on Vandium, Molybdenum, and Tungsten

Oxides." J. Phys. Chem 104 (2000): 1292-99.

Chemical Industry Intelligence - Chemical Pricing Reports. www.icislor.com.

Dessau, Ralph M. Dehydrogenation and Dehydrocyclization Using a Non-Acidic NU-87

Catalyst listed in US Patent # 5,254,787.

Diephouse, Dan, Scott Dykstra, and Derek Ferwerda. Hot for Hydrogen. Grand Rapids,

MI: Calvin College, 2004.

Dreise, Manuel, Randall Elenbaas, and Eric Smith. Bond...H-Bond. Grand Rapids, MI:

Calvin College, 2004.

Egloff, Gustav. Production of Styrene listed in US Patent # 2,376,532; May 22, 1945.

Frash, M V., and R A. Santen. "Activation of Small Alkanes in Ga-Exchanged Zeolites:

A Quantum Chemical Study of Ethane Dehydrogenation." J. Phys. Chem 104

(2000): 2468-75.

Iezzi, Rodolfo; Barolini, Andrea; Buonomo, Franco. Process for Activating Catalyst

Precursors for the Dehydrogenation of C2-C5 Paraffins, and a Catalytic

Composition Activated by the Process listed in US Patent # 5,308,822; May 3,

1994.

Iezzi, Rodolfo; Sanfilippo, Domenico. Process for the Dehydrogenation of

Ethylbenzene to Styrene listed in US Patent # 6,841,712; Jan 11, 2005.

Iezzi, Rodolfo; Bartolini, Andrea; Buonomo, Franco. Process for Activating Catalyst

Percursors for the Dehydrogenation of C2-C5 Paraffins, and a Catalytic

Composition Activated by the Process listed in US Patent # 5,414,182; May 9,

1995.

Polystyrene Packaging Council Homepage. http://www.polystyrene.org/.

Ogunnaike, Babatunde A., and Harmon W. Ray. Process Dynamics, Modeling, and

Control. New York: Oxford University Press, 1994.

Seider, Warren D., J D. Seader, and Daniel R. Lewin. Product & Process Design

Principles. 2nd ed. New York City: Wiley, 2004

Stichlmair, Johann G., and James R. Fair. Distillation Principles and Practices. New

York: Wiley-VCH, 1998.

Styrene Producers Price Capacity. http://www.the-innovation-

group.com/ChemProfiles/Styrene.htm.

Wankat, Phillip C. Equilibrium Stated Separations. Upper Saddle River, NJ: Prentice

Hall, 1988.

Wood, Andrew. "Dow Joins Snamprogetti to Develope Ethane-Based Styrene Process."

Chemical Week, 20 April 2005, 17.

Wood, Andrew. "Celanese, Dow Revisit Catalytic Route from Ethane to Ethylene."

Chemical Week, 15 June 2005, 25.

Zhou, Ying; Cavis, Stephen M. Dehydrogenation Catalysts and Process for Preparing

the Catalysts listed in US Patent # 5,219,816; June 15, 1993.

Appendix Table of Contents

Appendix A: Equipment Spec. Sheets

A.1 Compressor Specifications

A.2 Heat Exchanger Specifications

A.3 Pump Specifications

A.4 Tank Specifications

A.5 Two Phase Separator Specifications

A.6 Turbine Specifications

A.7 Distillation Specifications

Appendix B: PFD / PID / Layout

B.1 PFD: Alkylation Unit Area 100

B.2 PFD: Dehydrogenation Unit Area 200

B.3 PFD: Separations Unit Area 300a

B.4 PFD: Separations Unit Area 300b

B.5 PFD: Light Gas Separations Area 400

B.6 PFD: Compressor Chains

B.7 P&ID: Alkylation Unit Area 100

B.8 P&ID: Dehydrogenation Unit Area 200

B.9 P&ID: Separations Unit Area 300a

B.10 P&ID: Separations Unit Area 300b

B.11 P&ID: Light Gas Separations Area 400

B.12 P&ID: Compressor Chains

B.13 Plant Layout

B.14 Plant Layout, Front View

Appendix C: Separations

C.1 Separations Hand Calculations

C.2 Estimates of Column Height

C.3 Fenske Equation

C.4 Dimensioning of Packed Columns

C.5 MathCad Packed Column

C.6 Summary of All Columns

C.7 Optimization Reflux Ratio

Appendix D: Compressor Optimization

D.1 Compressor Optimization Analysis

D.2 K-404 Optimization Analysis Example

D.3 Compressor Hand Calculation Example

Appendix E: Heat Exchanger Design

E.1 Example Pressure Drop Calculation

E.2 Styrene Tank Heat Exchanger Size

Appendix F: Reactor Sizing

F.1 Dehydrogenation Reactor Size

Appendix G: Economic Optimization

G.1 Investment Summary

G.2 Economic Summary

G.3 Profitability Measures

G.4 IRR Analysis Product Price Fluctuation

Appendix A: Equipment Spec. Sheets

ID Number: K-200.1 Date: 5/8/2006

Description: Dehydrogenation Feed Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

0.0000

0.0000

0.0001

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

Carbon Dioxide

0.8452

0.0001

0.0000

0.0003

0.0000

0.1542

0.0000

0.0000

0.0000

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 418300

142.4

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

461590

4000

480

75%

5872

5321

A.1: Compressor Specifications (1 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

78.7

96.2

102.4

ID Number: K-200.2 Date: 5/8/2006

Description: Dehydrogenation Feed Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

A.1: Compressor Specifications (2 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

96.2

113.0

142.4

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

348500

4000

480

75%

5872

5321

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

194.9

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 315800

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Carbon Dioxide

0.8452

0.0001

0.0000

0.0003

0.0000

0.1542

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0001

0.0000

0.0000

ID Number: K-200.3 Date: 5/8/2006

Description: Dehydrogenation Feed Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

0.0000

0.0000

0.0001

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

Carbon Dioxide

0.8452

0.0001

0.0000

0.0003

0.0000

0.1542

0.0000

0.0000

0.0000

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 241200

263.3

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

266100

4000

480

75%

5872

5321

A.1: Compressor Specifications (3 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

113.0

129.2

194.9

ID Number: K-201 Date: 5/8/2006

Description: Air Feed Compressor Prepared By: ACJ

No. Required 1 Checked By: MJH

A.1: Compressor Specifications (4 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

25.0

59.5

101.3

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

141760

4000

480

75%

1624

1471

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

135.8

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 128680

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Carbon Dioxide

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.2100

0.7900

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

ID Number: K-202.1 Date: 5/8/2006

Description: Recycle Stream Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

0.0057

0.0000

0.0000

0.0000

0.0000

0.0246

0.0000

0.0000

0.0000

Carbon Dioxide

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.9697

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 163200

186.8

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

180720

4000

480

75%

3388

3059

A.1: Compressor Specifications (5 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

25.0

69.2

128.8

ID Number: K-202.2 Date: 5/8/2006

Description: Recycle Stream Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

A.1: Compressor Specifications (6 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

31.1

75.2

183.8

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

129160

4000

480

75%

3388

3059

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

264.9

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 116640

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Carbon Dioxide

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.9697

0.0246

0.0000

0.0000

0.0000

0.0057

0.0000

0.0000

0.0000

0.0000

ID Number: K-300 Date: 5/8/2006

Description: Ethyl Benzene Recycle Stream Compressor Prepared By: ACJ

No. Required 1 Checked By: MJH

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0002

0.0000

Carbon Dioxide

0.0000

0.0000

0.0000

0.0041

0.0000

0.9957

0.0000

0.0000

0.0000

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 380800

105.0

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

Theoretical Power (Kw)

Centrifugal

Horizontal

Carbon Steel

425190

4000

480

75%

3404

3049

A.1: Compressor Specifications (7 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

61.7

137.4

8.0

ID Number: K-400 Date: 5/8/2006

Description: Light Gases Stream Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

A.1: Compressor Specifications (8 of 41)

Design Capacity (m

3

/hr)

Material of Construction

Orientation

Design Specifications

Compressor Type

Outlet Pressure (kPa)

-50.0

-28.1

124.0

Theoretical Power (Kw)

Centrifugal

Horizontal

Stainless Steel

315360

4000

900

75%

5050

4574

Max Design Pressure (kPa)

Max Design Temperature (C)

Adiabatic Efficiency

Design Power (Kw)

173.5

Vapor Composition (mol%)

Inlet Temperature (C)

Outlet Temperature (C)

Inlet Pressure (kPa)

Nitrogen

Water

Ethylene

Styrene

n-Butyl Benzene

Compressor Specifications

Fluid Properties

Process Feed Flow Rate (m

3

/hr) 285600

Ethane

n-Hexane

1 Meta 3 Ethyl Benzene

Toluene

Benzene

Ethyl Benzene

Hydrogen

Oxygen

Cumene

n-Propyl Benzene

Alpha Metal Styrene

Meta Diethyl Benzene

Carbon Dioxide

0.5804

0.0000

0.0000

0.0000

0.0000

0.0000

0.1199

0.0000

0.2367

0.0000

0.0630

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

ID Number: K-401.1 Date: 5/8/2006

Description: Light Gases Stream Compressor Train Prepared By: ACJ

No. Required 1 Checked By: MJH

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0630

0.0000

0.0000

Carbon Dioxide

0.5804

0.0000

0.0000

0.0000

0.0000

0.0000

0.1199

0.0000

0.2367

Cumene

n-Propyl Benzene

Alpha Metal Styrene