Академический Документы

Профессиональный Документы

Культура Документы

53228-mt - Computer Aided Process Planning

Загружено:

SRINIVASA RAO GANTA0 оценок0% нашли этот документ полезным (0 голосов)

308 просмотров1 страницаComputer AIDED PROCESS PLANNING (CAD / CAM) Time: 3hours Answer any FIVE questions. Explain the conventional (or) traditional process planning. Explain generative CAPP with a block diagram. Enumerate its advantages. Explain retrieval CAAP system. List out applications.

Исходное описание:

Оригинальное название

53228-mt----computer aided process planning

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документComputer AIDED PROCESS PLANNING (CAD / CAM) Time: 3hours Answer any FIVE questions. Explain the conventional (or) traditional process planning. Explain generative CAPP with a block diagram. Enumerate its advantages. Explain retrieval CAAP system. List out applications.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

308 просмотров1 страница53228-mt - Computer Aided Process Planning

Загружено:

SRINIVASA RAO GANTAComputer AIDED PROCESS PLANNING (CAD / CAM) Time: 3hours Answer any FIVE questions. Explain the conventional (or) traditional process planning. Explain generative CAPP with a block diagram. Enumerate its advantages. Explain retrieval CAAP system. List out applications.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

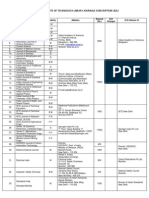

Code No: 53228/MT

NR

M.Tech. – II Semester Regular Examinations, September, 2008

COMPUTER AIDED PROCESS PLANNING

(CAD/CAM)

Time: 3hours Max. Marks:60

Answer any FIVE questions

All questions carry equal marks

---

1.a) Explain the conventional (or) traditional process planning.

b) What are the limitations of conventional process planning?

2.a) Explain generative CAPP with a block diagram. Enumerate its

advantages.

b) Explain the role of inference engine in generative CAPP.

3.a) Explain retrieval CAAP system. List out its merits and

applications.

b) Describe the structure of retrieval CAAP system.

4.a) What are the reasons for optimal selection of machining

parameters?

b) Explain the effect of machining parameters on production rate,

cost and surface quality.

5. Describe any two quantitative methods for optimal selection of

manufacturing sequence.

6.a) What is the importance of manufacturing tolerances and design

tolerances?

b) Explain the sequential approach of design and manufacturing

tolerances.

7. Explain the quantitative methods for the generation of tool path.

8.a) Explain the selection criteria of CAAP system.

b) Explain the capacity planning system.

******

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- IP Addresses and SubnettingДокумент16 страницIP Addresses and SubnettingHusnainОценок пока нет

- Guidelines For Open Educational Resources (OER) in Higher EducationДокумент27 страницGuidelines For Open Educational Resources (OER) in Higher EducationSRINIVASA RAO GANTAОценок пока нет

- JNTUH M.TECH PEDS 2013 SyllabusДокумент24 страницыJNTUH M.TECH PEDS 2013 SyllabusSRINIVASA RAO GANTA100% (1)

- JNTUH MBA Course Structure and Syllabus 2013Документ80 страницJNTUH MBA Course Structure and Syllabus 2013SRINIVASA RAO GANTAОценок пока нет

- JNTUH Syllabus 2013 M.Tech EPSДокумент23 страницыJNTUH Syllabus 2013 M.Tech EPSSRINIVASA RAO GANTAОценок пока нет

- JNTUH MCA Syllabus 2013Документ107 страницJNTUH MCA Syllabus 2013SRINIVASA RAO GANTAОценок пока нет

- JNTUH Syllabus 2013 M.Tech CSEДокумент33 страницыJNTUH Syllabus 2013 M.Tech CSESRINIVASA RAO GANTAОценок пока нет

- NET - 59-12 (Library & Inf Sci)Документ16 страницNET - 59-12 (Library & Inf Sci)SRINIVASA RAO GANTAОценок пока нет

- JNTYH Syllabus 2013 M.Tech CAD CAMДокумент23 страницыJNTYH Syllabus 2013 M.Tech CAD CAMSRINIVASA RAO GANTAОценок пока нет

- JNTUH Syllabus 2013 M.tech Communication SysДокумент26 страницJNTUH Syllabus 2013 M.tech Communication SysSRINIVASA RAO GANTAОценок пока нет

- Paper-I Set-WДокумент16 страницPaper-I Set-WKaran AggarwalОценок пока нет

- JNTUH Syllabus 2013 M.tech Embedded SystemsДокумент24 страницыJNTUH Syllabus 2013 M.tech Embedded SystemsSRINIVASA RAO GANTAОценок пока нет

- J-59-12 (Library of Inf Sci)Документ20 страницJ-59-12 (Library of Inf Sci)SRINIVASA RAO GANTAОценок пока нет

- JNTUH Syllabus 2013 Civil Engg Course StructureДокумент2 страницыJNTUH Syllabus 2013 Civil Engg Course StructureSRINIVASA RAO GANTAОценок пока нет

- The Ideal Library - The InformatoriumДокумент1 страницаThe Ideal Library - The InformatoriumSRINIVASA RAO GANTAОценок пока нет

- ISBN Manual 2012Документ31 страницаISBN Manual 2012SRINIVASA RAO GANTAОценок пока нет

- Dspace On WindowsДокумент15 страницDspace On WindowsSRINIVASA RAO GANTAОценок пока нет

- Kvs Librarypolicy2012Документ59 страницKvs Librarypolicy2012SRINIVASA RAO GANTAОценок пока нет

- AICTE Hand Book 2011-12Документ188 страницAICTE Hand Book 2011-12SRINIVASA RAO GANTAОценок пока нет

- Academic Conference and Case Chase Competition 12Документ8 страницAcademic Conference and Case Chase Competition 12SRINIVASA RAO GANTAОценок пока нет

- Library Quality Criteria For NBA AccreditationДокумент3 страницыLibrary Quality Criteria For NBA AccreditationSRINIVASA RAO GANTA100% (6)

- NET EXAM Paper 1Документ27 страницNET EXAM Paper 1shahid ahmed laskar100% (4)

- Teqip IiДокумент244 страницыTeqip IiSRINIVASA RAO GANTAОценок пока нет

- Vbit Journals 2011-12Документ6 страницVbit Journals 2011-12SRINIVASA RAO GANTAОценок пока нет

- Librarian Is Teaching or Non TeachingДокумент1 страницаLibrarian Is Teaching or Non TeachingSRINIVASA RAO GANTAОценок пока нет

- Use Full Library TermsДокумент20 страницUse Full Library TermsSRINIVASA RAO GANTAОценок пока нет

- Good Handling PrinciplesДокумент11 страницGood Handling PrinciplesSRINIVASA RAO GANTAОценок пока нет

- Ready Reckoner Radar EwДокумент27 страницReady Reckoner Radar EwSRINIVASA RAO GANTAОценок пока нет

- Reg Pay Degree 020110Документ16 страницReg Pay Degree 020110SRINIVASA RAO GANTAОценок пока нет

- PSoC Express First Touch DocumentationДокумент12 страницPSoC Express First Touch DocumentationSRINIVASA RAO GANTAОценок пока нет