Академический Документы

Профессиональный Документы

Культура Документы

Pipeline Stability Calculation of 24 Oil Empty

Загружено:

baghelrohitИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pipeline Stability Calculation of 24 Oil Empty

Загружено:

baghelrohitАвторское право:

Доступные форматы

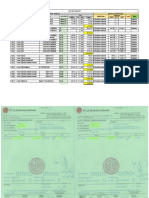

Cairn Energy India PTY Ltd

BSPL Project - Barmer to Salaya Pipeline

CALCULATION

PROJECT NO.

Stability Calculation 52893.03

24" Oil Pipeline (Empty) REF

03-P-2-003

No OF SHEETS

1 of 4

OFFICE CODE PROJECT No AREA DIS TYPE NUMBER

DOCUMENT No

05 5893 03 P 2 003

01 21.05.07 Issued For IDC PD JC PD BS CEIL

REV DATE DESCRIPTION BY CHK ENG PM Client

Cairn Energy India Limited

PIPELINE STABILITY CALCULATION

JP Kenny

CLIENT Cairn Energy India Limited JOB NO. 52893.03 .

SUBJECT 24" Crude Oil Pipeline

DOC NO. 05 - 2893 - 03 - P - 2 - 003 REV NO. 0 .

PRPD BY Paul Docherty CHKD BY Jateen Chohan APP'D BY P Docherty

DATE 5-May-07 DATE 21-May-07 DATE 21-May-07

1.0 INTRODUCTION

The aim of this calculation is to determine the stability of the pipeline through water course crossings.

2.0 METHOD

The method used to determine the stability of the pipeline through water courses is to calculate the

total weight of the pipeline and compare it with the weight of the external fluid (water) it would

displace. In order for the pipeline to be considered stable, the pipeline weight must be 10% greater

than the weight of the water displaced.

The above method is overly conservative as it considers a pipeline free floating in water. In reality the

pipeline lays in a trench covered by soil which will provide a hold down force to prevent floatation.

This force is calculated by determining the submerged weight of soil above the pipeline.

3.0 REFERENCE DATA

The reference data for this calculation has come from:

Reference 1: ASME B 31.4 Design and OISD - STD - 141 2001 API 5L

X65

Reference 2: Crude Pipeline Design Refer to Wall thickness Report 052893 - 03 - P - 3 - 020

and range of Calculations from 002 to 010

4.0 CALCULATIONS

4.1 Pipe Details

Nom. Pipe Outside Diameter OD = 0.610 m = 24 in

Specified Wall Thickness t = 0.018 m = 17.5 mm

Concrete Coating Thickness tc = 0.102 m = 102 mm

4.2 Coating and Insulation Details

Thickness of the outer coating tp = 0.008 m = 8.0 mm

3 3

Density of the outer coating Dp = 9771 N/m = 996 kg/m

Thickness of the Insulation ti = 0.100 m = 100.0 mm

3 3

Density of the insulation Di = 589 N/m = 60 kg/m

4.3 Density and Stability Factor

3 3

Density External Fluid (Water) De = 9810 N/m = 1000 kg/m

3 3

Density Pipe Contents (Empty) Di = 0 N/m = 0 kg/m

Density Pipe Steel Ds = 76420 N/m3 = 7790 kg/m3

3 3

Density Concrete Dc = 29921 N/m = 3050 kg/m

3 3

Density Soil Dg = 14862 N/m = 1515 kg/m

DL 3 3

Density of Liquified Soil = 12753 N/m = 1300 kg/m

Stability Requirement Sm = 1.1

Depth of Cover H = 1.0 m

03-P-2-003 Rev 01 - 24 inch Stability Empty with insulation.xls Self Check...........................

21/05/2007 Page 2 of 4 Date...........................

Cairn Energy India Limited

PIPELINE STABILITY CALCULATION

JP Kenny

4.4 Weight of Pipeline

Cross-sectional area Steel As = pi()*(OD^2-(OD-2*t)^2)

4

2

= 0.033 m

Weight of steel Ws = As*Ds

= 2488 N/m

Cross-sectional area - internal Ai = pi()*(OD-2*t)^2

4

2

= 0.259 m

Weight of pipe contents Wi = Ai*Di

= 0 N/m

4.5 Insulation and Protective Coating

CSA Insulation Ain = pi()*(((2*ti)+OD)^2-(OD)^2)

4

2

= 0.223 m

Weight of Insulation Win = Ain*Di

= 131 N/m

CSA Polyurathane Coating Ap = pi()*(((2*(tp+ti))+OD)^2-((2*ti)+OD)^2)

4

2

= 0.021 m

Weight of Coating Wp = Ap*Dp

= 201 N/m

4.6 Concrete Coating ( Note: no consideration has been made for reinforcement)

Total Pipeline Outside Diam. ODT = OD + 2*(tp+ti+tc)

= 1.0296 m

Cross-sectional area - coating Ac = pi()*(ODT^2 -(2*tp+2*ti+OD)^2)

4

2

= 0.297 m

Weight of concrete coating Wc = Ac*Dc

= 8894 N/m

Total Weight of Pipeline Wt = Wp+Win+Ws+Wi+Wc

= 11713 N/m

4.7 Pipeline Buoyancy in Water

CSA Pipe+ Ins + coatings At = pi()*ODT^2

4

2

= 0.833 m

Weight of displaced fluid We = At*De

= 8168 N/m

Required Buoyancy Br = Sm*We

= 8984 N/m

03-P-2-003 Rev 01 - 24 inch Stability Empty with insulation.xls Self Check...........................

21/05/2007 Page 3 of 4 Date...........................

Cairn Energy India Limited

PIPELINE STABILITY CALCULATION

JP Kenny

Pipeline Buoyancy, open trench Bp = Wt-Br

= 2729 N/m

Cross-sectional area of trench Ad = (OD+2*ti+2tp)*H

= 0.826 m2

Submerged weight of soil Wg = Ad*(Dg-De)

= 4171 N/m

Pipeline Buoyancy, buried Bs = (Wg+Wt)-Br

= 6900 N/m

4.8 Pipeline Buoyancy in Liquified Soils

Weight of displaced fluid Wm = At*DL

= 10618 N/m

Required Buoyancy Bm = Sm*Wm

= 11680 N/m

Pipeline Buoyancy, liquified soil BL = Wt-Bm

= 34 N/m

5.0 Summary of Results

The results of the stability calculations are detailed in the following table:

Variable Value Required

Pipeline Buoyancy, open (N/m) 2728.9 0.0 OK

Pipeline Buoyancy, buried (N/m) 6899.9 0.0 OK

Pipeline Buoyancy, liq soil (N/m) 33.6 0.0 OK

The pipeline in an open trench will be stable through flooded water courses.

The buried pipeline will be stable through flooded water courses.

The pipeline will be stable through flooded water courses where soil liquification has occurred.

03-P-2-003 Rev 01 - 24 inch Stability Empty with insulation.xls Self Check...........................

21/05/2007 Page 4 of 4 Date...........................

Вам также может понравиться

- Upheval Bukling CalculationДокумент2 страницыUpheval Bukling Calculationbaghelrohit100% (7)

- Mathcad - KpeterДокумент4 страницыMathcad - KpeterMahmoud Samir100% (1)

- 24in Pipeline Buoyancy CalculationДокумент1 страница24in Pipeline Buoyancy CalculationAdaghara67% (3)

- Pipeline Sesmic CalculationДокумент4 страницыPipeline Sesmic Calculationbaghelrohit100% (3)

- (Ihs) PEL - PL - CAL - 003 Pipeline Stability and Bouyancy Calculation Benoa - Pesanggaran (Rev 0)Документ11 страниц(Ihs) PEL - PL - CAL - 003 Pipeline Stability and Bouyancy Calculation Benoa - Pesanggaran (Rev 0)Indra HarapanОценок пока нет

- Upheaval Buckling CalculationДокумент6 страницUpheaval Buckling Calculationheldermanuel100100% (2)

- Appendix 2F Pipeline Hydro Test PlanДокумент23 страницыAppendix 2F Pipeline Hydro Test PlanSanjay KumarОценок пока нет

- Pipeline Anchor Length CalculationsДокумент3 страницыPipeline Anchor Length Calculationslsatchithananthan100% (3)

- Pipe Lowering CalculationДокумент8 страницPipe Lowering CalculationMochamad Safarudin50% (4)

- Cairn Energy India PTY Ltd BSPL Project - Barmer to Salaya Pipeline CALCULATIONДокумент4 страницыCairn Energy India PTY Ltd BSPL Project - Barmer to Salaya Pipeline CALCULATIONschaali100% (5)

- MJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)Документ11 страницMJPN-PGAS-3514-PL-CA-001 (Calculation For Pipeline Free Span) Rev. B (REVIEW)frusdt100% (3)

- On-Bottom Stability AnalysisДокумент42 страницыOn-Bottom Stability AnalysisYoungtae Kim67% (3)

- Pipeline Design Calculations PDFДокумент21 страницаPipeline Design Calculations PDFjimallen21281% (21)

- FatFREE 10.1Документ1 страницаFatFREE 10.1jesusgameboyОценок пока нет

- Elastic Bending Radius Calculation of PIPELINESДокумент1 страницаElastic Bending Radius Calculation of PIPELINESmailmaverick816777% (13)

- 6.57 Onshore Pipeline Mechanical Design ReportДокумент17 страниц6.57 Onshore Pipeline Mechanical Design ReportSanjay Kumar100% (2)

- Crossing Calculation API RP1102 (TEMPLATE)Документ1 страницаCrossing Calculation API RP1102 (TEMPLATE)bebas_amarah100% (5)

- GF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Документ60 страницGF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Rami KsidaОценок пока нет

- 1990 Palmer Upheaval BucklingДокумент10 страниц1990 Palmer Upheaval Bucklingppyim2012100% (1)

- PIPE WALL THICKNESS CALCULATIONSДокумент59 страницPIPE WALL THICKNESS CALCULATIONSKarthik Channamsetty67% (3)

- QCS 2010 Section 8 Part 4 Pipeline InstallationДокумент29 страницQCS 2010 Section 8 Part 4 Pipeline Installationahmed abdohОценок пока нет

- Pipeline Stability and Weight Coating CalculationДокумент4 страницыPipeline Stability and Weight Coating CalculationAdaghara67% (3)

- OPT98 Fatigue Design-DNV-Guideline-Free Spanning PipelinesДокумент24 страницыOPT98 Fatigue Design-DNV-Guideline-Free Spanning PipelinesYemi LawalОценок пока нет

- Bottom Roughness AnalysisДокумент46 страницBottom Roughness AnalysisIsaac Mohanadasan100% (2)

- Static Analysis Report Rev-A PDFДокумент16 страницStatic Analysis Report Rev-A PDFbee4manuОценок пока нет

- API RP 1102 SpreadsheetДокумент5 страницAPI RP 1102 Spreadsheetdrramsay100% (4)

- Pipeline Design ReportДокумент37 страницPipeline Design Reporthalim_ka100% (2)

- DNV RP E305 ON-BOTTOM STABILITY CALCULATIONДокумент21 страницаDNV RP E305 ON-BOTTOM STABILITY CALCULATIONAdam Putra Chandra75% (4)

- Class 10 - Free Span AnalysisДокумент37 страницClass 10 - Free Span AnalysisM R Patraputra100% (1)

- Onshore Pipeline EngineeringДокумент52 страницыOnshore Pipeline EngineeringShaka Shalahuddin Shantika Putra100% (4)

- Virtual Anchor Length - KBRДокумент22 страницыVirtual Anchor Length - KBRSammar Adhikari100% (2)

- Introduction FreeSpanningPipelinesDNV RP F105Документ13 страницIntroduction FreeSpanningPipelinesDNV RP F105Nabil37Оценок пока нет

- 14 - NRG - Pipe Installation - Davit LiftДокумент16 страниц14 - NRG - Pipe Installation - Davit LiftBalanОценок пока нет

- Pipeline Anchor Length Calculation PDFДокумент3 страницыPipeline Anchor Length Calculation PDFAlvin SmithОценок пока нет

- PTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-PusriДокумент16 страницPTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-Pusrihamid sobirin100% (3)

- On A New Methodology For The Design and Operations Planning of Natural Gas Pipeline NetworksДокумент41 страницаOn A New Methodology For The Design and Operations Planning of Natural Gas Pipeline NetworksDilip Banerjee100% (1)

- On-Bottom Analysis ABAQUSДокумент206 страницOn-Bottom Analysis ABAQUSlsatchithananthan100% (1)

- Design of Long Distance Oil PipelineДокумент21 страницаDesign of Long Distance Oil PipelineHaseeb Khawaja100% (1)

- 48'' Pipeline Shore Approach Reportpdf PDFДокумент22 страницы48'' Pipeline Shore Approach Reportpdf PDFvpandya1981100% (2)

- Flowline Road Crossing CalculationДокумент7 страницFlowline Road Crossing CalculationZeeshan Ahuja100% (2)

- AWWA M45 Pipe Design CalculationsДокумент37 страницAWWA M45 Pipe Design CalculationsSana Ullah100% (1)

- Mechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestОт EverandMechanics of Offshore Pipelines, Volume 2: Buckle Propagation and ArrestОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОценок пока нет

- Offshore Pipelines: Design, Installation, and MaintenanceОт EverandOffshore Pipelines: Design, Installation, and MaintenanceРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Calculo Estabilidad de OleoductoДокумент4 страницыCalculo Estabilidad de Oleoductosok_splОценок пока нет

- Stability-Calculation For PipelineДокумент2 страницыStability-Calculation For PipelineGeorge100% (1)

- Upbk ValДокумент26 страницUpbk ValRYZKI EFENDI SIMANULANGОценок пока нет

- On Bottom Stability For Swampy Area: 1.0 INPUTДокумент3 страницыOn Bottom Stability For Swampy Area: 1.0 INPUTKePomPhong UlatОценок пока нет

- 1 Design Philosophy and Design BasisДокумент9 страниц1 Design Philosophy and Design BasisFazilat Mohammad ZaidiОценок пока нет

- PIPE THICKNESS CALCULATIONДокумент23 страницыPIPE THICKNESS CALCULATIONdsdeshpandeОценок пока нет

- Upheaval Buckling PipelineДокумент11 страницUpheaval Buckling PipelineRYZKI EFENDI SIMANULANGОценок пока нет

- Cal Temp Latest 2Документ79 страницCal Temp Latest 2Benedict OgbaghaОценок пока нет

- S-1 Stilt Floor: Edge ConditionДокумент7 страницS-1 Stilt Floor: Edge ConditionMohdDanishОценок пока нет

- Design of 3000mm MS Pipe for Sewerage NetworkДокумент9 страницDesign of 3000mm MS Pipe for Sewerage Networknavneet3bawaОценок пока нет

- Double Pipe HE - Revs1Документ9 страницDouble Pipe HE - Revs1Rizki FadillahОценок пока нет

- Structural Design and Analysis: Proposed 3-m Concrete Hollow Block WallДокумент6 страницStructural Design and Analysis: Proposed 3-m Concrete Hollow Block WallJay CuaОценок пока нет

- 1mht. 800-T-029 TANK R3Документ6 страниц1mht. 800-T-029 TANK R3g4goharОценок пока нет

- MONTHLY Graduate Trainee Report Summary for Road ConstructionДокумент2 страницыMONTHLY Graduate Trainee Report Summary for Road ConstructionmichaelОценок пока нет

- 03 Composite BeamДокумент24 страницы03 Composite BeamsaztaОценок пока нет

- 4-Efflorescence of Clay BricksДокумент3 страницы4-Efflorescence of Clay BricksZhiwar oramariОценок пока нет

- Microstructural and Mechanical Properties of Novel Co-Free Maraging Steel M789 Prepared by Additive ManufacturingДокумент16 страницMicrostructural and Mechanical Properties of Novel Co-Free Maraging Steel M789 Prepared by Additive Manufacturingzbigniew3brytanОценок пока нет

- Aisi 1045Документ1 страницаAisi 1045edraelmx100% (1)

- Rii HL LB 01 02 03 (4822)Документ3 страницыRii HL LB 01 02 03 (4822)hendri heryanaОценок пока нет

- Unit 6 P1 ExampleДокумент13 страницUnit 6 P1 ExampleYI HEN ONGОценок пока нет

- Why Is Casting An Important Manufacturing ProcessДокумент2 страницыWhy Is Casting An Important Manufacturing ProcessSa'ad Sabar33% (3)

- Scott Badercompositescatalogue PDFДокумент20 страницScott Badercompositescatalogue PDFbuddy1971Оценок пока нет

- Advanced Earthquake Resisting TechniquesДокумент26 страницAdvanced Earthquake Resisting TechniquesKr JadejaОценок пока нет

- Ds Rebar Splicing HBДокумент76 страницDs Rebar Splicing HBaapennsylvaniaОценок пока нет

- Section Aa' 1:50: C - Shaped Staircase Floor Plan 1:50Документ1 страницаSection Aa' 1:50: C - Shaped Staircase Floor Plan 1:50Raji ChokshiОценок пока нет

- Mbrace: Composite Strengthening SystemДокумент12 страницMbrace: Composite Strengthening SystembudiОценок пока нет

- (F.N. Cogswell) Polymer Melt Rheology A Guide For PDFДокумент197 страниц(F.N. Cogswell) Polymer Melt Rheology A Guide For PDFSherafghan Iftikhar100% (1)

- Measuring Inclusions in Al-Si Alloys with UltrasoundДокумент116 страницMeasuring Inclusions in Al-Si Alloys with UltrasoundСтанислав ПодольскийОценок пока нет

- KS3 Physics: 8I Heating and CoolingДокумент44 страницыKS3 Physics: 8I Heating and CoolingPichakorn PОценок пока нет

- Complete Lines For Technical and Window ProfilesДокумент5 страницComplete Lines For Technical and Window ProfilesHamza Mh-DiaОценок пока нет

- Pump Hose Machine Foundation DesignДокумент11 страницPump Hose Machine Foundation DesignARSEОценок пока нет

- Timber CladdingДокумент24 страницыTimber CladdinglidwinachristianОценок пока нет

- Witzenmann GmbH Expansion Joints DataДокумент290 страницWitzenmann GmbH Expansion Joints DatanagarajhebbarОценок пока нет

- Wha 1250XLДокумент2 страницыWha 1250XLfireoniceОценок пока нет

- Monarch-Nice 1000 Electric Drawing PDFДокумент9 страницMonarch-Nice 1000 Electric Drawing PDFGalang AntoОценок пока нет

- Glass Fibers ASM PDFДокумент9 страницGlass Fibers ASM PDFMayra ZezattiОценок пока нет

- The Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteДокумент6 страницThe Effect of Using Fan Palm Natural Fibers On The Mechanical Properties and Durability of ConcreteGladys Eras ValladolidОценок пока нет

- Experimental Study On Partial Replacement of Fine Aggregate With Waste Foundry Sand in ConcreteДокумент6 страницExperimental Study On Partial Replacement of Fine Aggregate With Waste Foundry Sand in ConcreteNaReN KumarОценок пока нет

- Shree Mega Power FinalДокумент114 страницShree Mega Power FinalRaja RamachandranОценок пока нет

- Status LGДокумент2 страницыStatus LGWillyОценок пока нет

- Astm A325M-Bolts: Maximum Bolt Capacity in TensionДокумент10 страницAstm A325M-Bolts: Maximum Bolt Capacity in TensionPappu Kishore KumarОценок пока нет

- Application of Pre-Stressed ConcreteДокумент11 страницApplication of Pre-Stressed Concretemoney coxОценок пока нет

- Esab Storage HandlingДокумент4 страницыEsab Storage HandlingTasmanijskaNema100% (1)