Академический Документы

Профессиональный Документы

Культура Документы

Acceleration of Re Activity

Загружено:

Justina RodriguezИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Acceleration of Re Activity

Загружено:

Justina RodriguezАвторское право:

Доступные форматы

Cement and Concrete Research, Vol. 25, No. 1. pp. 15-21.

1995

Pergamon

Copyright 0 1995 Elsevier Science Ltd Printedin the USA. All rights reSenteN 0008-f&346/95 $9.50+.0

0008-8846(94)00107-3

ACCELERATION OF THE REACTIVITY OF FLY ASH BY CHEMICAL ACTIVATION

Department

Caijun Shi and Robert L. Day of Civil Engineering, The University of Calgary Calgary, Alberta, Canada T2N 1 N4

(Communicatedby I. Odler) (Received Juiy 18.1993; in final form March 11. 1994)

ABSTRACT:

Experiments were performed to determine the effect of various chemical activators on strength of lime fly-ash pastes manufactured with two types of fly ash - a low calcium subbituminous ash (LFA) and a high calcium subbituminous ash (HFA). The strengths of blends of 80% fly ash and 20% hydrated lime were used to evaluate the pozzolanic reactivity of the ashes. Pastes were continuously moist-cured at 50C. The results indicate that the addition of small amounts of Na2S04 and CaC12 can increase the pozzolanic reactivity of both types of ash; this results in a significant improvement in strength. Na2S04 has its predominant influence at early ages; its effect at later ages varies with the nature of fly ash used. In general, early-age strength increases with the amount of Na2S04 dosage. Extent of strength improvement at later ages depends upon the dosage and type of fly ash used. The addition of CaC12 has a variable influence on strength at early and intermediate ages. However, strengths at 90 days and 180 days are significantly improved by addition of 34% CaC12 activator. The use of up to 5% NaCl rather than CaCl2 did not result in substantial improvements to strength. X-ray analysis suggests that the addition of Na2S04 results in the formation of substantial amounts of ettringite (AFt). Addition of CaCl2 results in the formation of solid solution C4AHtaC3A.CaC12.1OH20.

The quantities of fly ash used in concrete continue to increase due to observations that (a) ash can improve some aspects of the performance of concrete; (h) the use of ash can reduce the cost of concrete, and (c) a consistent quality of ash that produces predictable effects in concrete can be supplied to the producer (1). One clear disadavantage in the use of most fly ashes for cement-replacement purposes is that the replacement of cement, especially in high volumes, decreases rate of early strengb development of the concrete. Research has been performed to examine the effect of some chemical activators on strength of hardened cement pastes manufactured with various blends of fly ash, blast furnace slag, natural pozzolan, calcium

15

C. Shi andR.L. Day

Vol. 25, No. 1

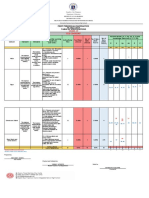

TABLE I

Chemical Composition (% of total mass) and Some Physical Properties of Fly Ashes (3)

hydroxide and Portland cement (2). This paper examines whether significant improvements in the reactivity of fly ash can be realized through the use of some types of chemical activator.

Raw Materials Two fly ashes were chosen for examination. One is a locally produced subbituminous ash from Alberta that is used extensively in concrete applications throughout Western Canada. The second is a subbituminous ash from Wyoming, U.S.A. Chemical compositions and physical properties are given in Ihble I, while a comparison of the X-ray diffraction traces for the two ashes is given in Figure 1. The notation used for these ashes is derived from their CaO content - the Alberta ash is denoted LFA as a low-calcium fly ash, while the Wyoming ash is denoted HFA for high-calcium fly ash. A commercial Alberta hydrated lime, commercial flaked CaC12.2H20, reagent grade Na2S04 and purified NaCl were the other chemicals used in the examination. and m The lime-fly ash cements consisted of 20% hydrated lime and 80% fly ash by mass. The addition of chemical activators are based on the mass of lime-ash cement. The range of addition of activator was 0 - 5%. The water to cement ratio was 0.35 for lime-LFA cement and 0.375 for lime-HFA cement; these values gave approximately constant flows for the two pastes. Mixing and specimen preparation were performed at room temperature. However, raw materials were heated to make the initial temperature of the fresh pastes approximately equal to the curing temperature of 50C. The fresh pastes were cast into (~25 glass vials and immediately placed into a saturated limewater bath at 5OC. When the paste cylinders had achieved sufficient strength (usually by one day) they were demoulded quickly and then returned to the bath. At strength-test ages of 1, 3, 7, 28, 90 and 180 days, four specimens were removed from the bath one hour before the testing time to cool. Ends of the specimens were cut and polished to make the two bearing surface flat and parallel; specimens that were tested for strength had nominal dimensions of (~25 x 50 mm. At each age three specimens were tested for compressive strength; results reported are averages of three tests. The maximum coefficient of variation of strength results was 8%. After the strength tests pieces of specimens were ground to a powder in 2-propanol then vacuum-dried at ambient temperature in a desiccator until constant weight. The powders were kept in sealed containers

K20 Loss on Ignition Glass Content Quartz Mullite

0.5 0.5 83.9

0.4

0.4

64.0

4.1

10.2 I 1.4 IO

9.0

7.5

IIHematite

Vol. 25. No. 1

CHEMICAL ACTIVATION, FLY ASH, Na2SO4, CaC12

17

, Quark + Mdllte

10

15

20

25

30 35 40 45 50 55 60

65 70 75

DIFFRACTION

ANGLE (2&l), Cobalt Radiation FIGURE 1

X-Ray

Diffraction

Patterns for the Fly Ashes

until X-ray diffraction tests were performed. A Philips X-ray diffractometer was used to identify the hydration products. At each age the 4th cylinder was cut into small fragments and placed in a bath of pentane at -125C. After 2-3 minutes in the bath, these fragments were freezedried for 24 hours to remove all free water and then stored in sealed containers; the procedure has been outlined previously by Orr (4). The fragments were were used for the observation of morphology of hydration products by scanning electron microsope.

Fig.2 is a summary of the strength results for both sodium sulphate and calcium chloride activation. For brevity of discussion below, the Iime-LFA pastes and the Iime-HFA pastes will simply be denoted LFA and HFA pastes respectively.

Effect of Na2S04 Dosage on Strength Development of Lime-fly Ash Cement Pastes

Figure 2(a) shows the effect of various additions of sodium sulphate on strength development.At 1 and 3 days, the increase in strength of the LFA pastes with NazS04 dosage is approximately linear. Beyond 3 days the addition of 1 or 2% Na2S04 does not appear to benefit strength development. Note that the reduction in strength at 180 days for 1% addition is not statistically significant (5% level). There is, however, a clearly significant improvement of strength at 90 days and 180 days for NazS04 activator dosage in the range 3 to 5 % . The effect of NazS04 dosage on the strength of HFA pastes is somewhat different than that of the LFA pastes - right side of Fig.2(a). Up to 90 days there is a clear increase in strength over all dosage levels, when compared to the control (0%) paste. The large increase in l-day strengths is particularly signiticant. In largelrolume concrete applications it can be expected that internal temperatures will rise well

C. Shi and R.L. Day

Vol. 25, No

(a)

LIME-LFA PASTES

LIME- HFA PASTES

a9Od -28d 7d m3d -Id -180d

-!

012345

SODIUM SULPHATE

012345

DOSAGE (X)

LIME-LFA PASTES

LIME- HFA PASTES

a9Od -28d 7d D3d -Id -180d

012345

CALCIUM CHLORIDE

012345

DOSAGE (%)

FIGURE

2 on Strength

Effect of Sodium Sulphate and Calcium Chloride Activators

Vol. 25, No. 1

CHEMICAL ACITVATION. FLY ASH, Na#O,+ CaCl2

19

above ambient for the first few days; the presence of sodium sulpbate activator in such an environment is likely to have an appreciable effect on the rate of activation of fly ash, and thus on the rate of strength development of the concrete at early ages. One must keep in mind, however, that there are other factors besides strength which may be influenced by the presence of significant amounts of sodium sulphate possibly to the detriment of the quality of the concrete. The addition of Na2S04 has a larger influence on HFA pastes than on LFA pastes. This may be attributed to the higher propotion of reactive ahtminates in HFA than that in LFA. This is discussed in more detail below. Although the apparent regression in strength between 90 days and 180 days for some of the HFA pastes is not, on average, statistically significant, more tests need to be performed to examine whether sodium sulphate may have a detrimental effect on long term properties.

Effect of CaCl2 Dosage on Strength Development of Lime-Fly Ash Cement Pastes

The effect of CaCl2 dosage on strength development of LFA and HFA pastes is shown in Fig.2(b). For

both types of paste the addition of calcium chloride has no significant effect on l-day strength [this effect is similar to that observed for lime-natural pozzolan pastes (5)]. After 1 day, however, the strength of LFA pastes is improved substantially by dosages of calcium chloride from 1 to 5%. For HFA pastes this improvement is only significant for dosages in the range 3 to 5%. Note the interesting contrast between the effect of sodium sulphate and the effect of calcium chloride on the two types of paste. Sodium sulphate has the more pronounced improvement on HFA pastes, while calcium chloride benefits LFA pastes more than HFA pastes. For maximum benefits one clearly must match the type of activator with the type of material being activated. It was found during the casting of specimens that the addition of Na2S04 retards setting while CaCl2 accelerates tbe setting of HFA pastes. The higher the dosage, the more conspicuous was the acceleration or retardation effect.

Effect of NaCl on Strength Development of Lime-HFA Pastes

Figure 3 shows the strength development of HFA pastes with NaCl dosages from 0 to 5%. No significant effect of NaCl is observed. This same observation was made when pastes made from natural pozzoIan and lime were tested (2). Although no tests were performed with NaCl on LFA pastes, it can be deduced that the same lack of activation of NaCl would be observed, since the chemical composition of the low calcium fly ash is very similar to the composition of the natural pozzolans that were tested.

Effect of Activators on Hydration Products

The sensitivity of the two fly ashes to the type of activator arises because of differences in the chemistry

and mineralogy of the ashes. X-ray diffractometry (XRD) and scannning electron microscopy (SEM) were used to examine pastes with and without activators. Although no quantitative X-ray diffraction was performed it is believed that observations of consistent trends in changes of peak intensities, combined with SEM observations, can lead to reliable hypotheses concerning mechanisms of activation. es W~mouU&&z Table II summarizes conclusions concerning the hydration compounds present in the two lime-fly ash pastes without activators. One principal hydration product of both pastes is C-S-H. other products of hydration depend specifically upon the chemistry and mineralogy of the ash. The second major product in LFA pastes is C4AH13. For HFA pastes C4AH13 is present at early ages, but at all ages CsAH6 appears to be a major hydration compound. The minor products in tbe two pastes are also different: ettringite (AR) peaks appear at early ages and C2ASHs forms

20

C. Shi and R.L. Day

Vol. 25. No. 1

09Od -28d 7d 18Od

For LFA pastes at 7 days and thereafter, AFm rather than AFt was detected at 1 or 2% NazS04 dosages, while above 2% dosFIGURE 3 age. Only AR was detected. Detection of Influence of Sodium Chloride Activator on AFm by X-ray analysis was accompanied Strength Development by SEM observations of hexagonal plates dispersed throughout the microstructure. It was observed that at 1 day the peak intensities of AFt in LFA pastes increase with the dosage of NazS04. At the same time strength increases almost linearly with dosage. Although no causal relationship can be confirmed, it is postulated that a significant increase in ettringite content at 1 day due to activator dosage has a key influence on the observed compressive strength.

SODIUM CHLORIDE DOSAGE (K)

h

1

C3AH6 AR El AFm

@I a 0 0 @.I 0

at later ages in the LFA pastes. For the HFA pastes, monosulphoahrminate (AFm) was identified up to an age of 7 days, while no other minor products were detected at 28 and 90 days. Effect: At 1 day in the NazS04-LFA pastes, the diffraction intensity of the AFt major peak increases with activator dosage. Conversely, at one day the diffraction intensity of &AH13 decreases with dosage up to 3% and C4AH13 peaks were not observed in pastes with activator dosage in the range 35%.

Hydration

TABLE II Products of LFA and HFA Pastes without Activator. Cure at 50C. Check mark indicates identification of compound CSH 0

@I

Age (d) 1

7 LFA

&AH13 @I

@I

GASHa

@I

28 90

1

El El

@I J

EI @I

El 0

q

@.I @I 0

7 HFA 28 90

Vol. 25, No. 1

CHEMICAL ACTIVATION, FLY ASH, Na2S04, CaC12

21

In HFA pastes, the addition of Na2SO4 appears to accelerate the formation of one of the main hydration products of this type of ash - CsAHe. Although the addition of different amounts of Na2S04 results in the formation and transformation of AR (similar to the LFA pastes), it seems that the influence of &AI-I6 dominates the strength development of the pastes. Thus, the strength of lime-HFA pastes continues to increase with Na2S04 dosage at later ages. Effect: In LFA-CaClz pastes, the intensity of diffraction peaks for C4AHls was seen to increase signiticandy with CaC12 dosage. Also, as calcium chloride dosage increased, the main diffraction peak for C&AH13 shifted from 7.89 to 7.74 A. This shift is believed to be associated with the formation of a solid solution of C4AHlaC3A.CaC12.10H20. It is postulated that the formation of this compound reinforces and strengthens the paste; thus, the strengths of LFA pastes increase as CaC12 dosage increases. The addition of CaC12 to HFA pastes results in a reduction in the amount of C3AHe formed - as evidenced by a pronounced reduction in the intensity of the corresponding X-ray diffraction peaks. However, as CaCl2 dosage increases, the amount of solid solution of C4AH13-CsA.CaC12.1OH7_0 also increases. The interaction of these two mechanisms may be responsible for the small reduction in strength followed by an increased strength at CaC12 dosage increases [Fig 2.b]. Conclusions The conclusions noted below are based upon the research performed on lime-pozzolan from two subbituminous fly ashes and cured in water at 50C. pastes made

Lime-ash pastes made from two types of fly ash show different types of hydration product and show different degrees of sensitivity to chemical activator. Differences in performance are due to differences in the chemistry and mineralogy of the two subbituminous ashes examined. Chemical activators can significantly improve the rate of strength gain, and especially early rate of strength gain, associated with the reactivity of fly ash. For the two fly ashes and three activators examined, the use of CaC12 activator produced the highest strengths in the pastes with low calcium ash (LFA). For pastes made with high calcium ash, Na2S04 was the more efficient activator. The influence of a particular activator on the strength of lime-ash pastes appears to be primarily due to specific influences that the activator has on the quantity and types of hydration products. nowledFinancial support from the International Development Research Centre of Canada and the Natural Sciences and Engineering Research Council of Canada is gratefully acknowledged. References 1. 2. 3. R. Helmuth, FlyAsh in Cv 3 Portland Cement Association, Skokie, Ill., (1987). C. Shi, Activation of NW Fly p, Ph.D. Thesis, The University of Calgary, (1992). R. L. Day and J. Konecny, Fly Ash and Coal Conversion By-products:Characteristics, Utilization and Disposal, ed by R. L. Day and F. P. Glasser, Proceedings of Materials Resear& Society, Vol. 178, pp 217-233, (1990). D.M.F. Orr, Cem. Concr. Res., V 13, No. 1, 146-148, (1983). C. Shi and R.L. Day, Chemical Activation of Blended Cements Made with Lime and Natural Pozzolans, Cem. Concr. Res. Z(6), 1389-1396 (1993).

4. 5.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Audi R8 Advert Analysis by Masum Ahmed 10PДокумент2 страницыAudi R8 Advert Analysis by Masum Ahmed 10PMasum95Оценок пока нет

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaДокумент8 страницUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaОценок пока нет

- HU - Century Station - PAL517PДокумент232 страницыHU - Century Station - PAL517PTony Monaghan100% (3)

- NaOH and Column CleaningДокумент6 страницNaOH and Column CleaningJustina RodriguezОценок пока нет

- Arbitration Book 2004Документ650 страницArbitration Book 2004Justina RodriguezОценок пока нет

- Strenghening of OpeningsДокумент170 страницStrenghening of OpeningsJustina RodriguezОценок пока нет

- Resapol BrochureДокумент95 страницResapol BrochureJustina RodriguezОценок пока нет

- Booklet On Epoxy Resin - Its Application in Structural RepairsДокумент36 страницBooklet On Epoxy Resin - Its Application in Structural RepairsJustina RodriguezОценок пока нет

- Concrete Filled Tubular Arch BridgeДокумент8 страницConcrete Filled Tubular Arch BridgeJustina Rodriguez100% (1)

- Construction Safety GuideДокумент38 страницConstruction Safety GuideJustina RodriguezОценок пока нет

- Bolted Joint Failure Modes: F. Matthews, in Handbook of Polymer Composites For EngineersДокумент27 страницBolted Joint Failure Modes: F. Matthews, in Handbook of Polymer Composites For EngineersJustina Rodriguez100% (2)

- Zygosaccharomyces James2011Документ11 страницZygosaccharomyces James2011edson escamillaОценок пока нет

- Agile ModelingДокумент15 страницAgile Modelingprasad19845Оценок пока нет

- Settlement Report - 14feb17Документ10 страницSettlement Report - 14feb17Abdul SalamОценок пока нет

- A Review of Mechanism Used in Laparoscopic Surgical InstrumentsДокумент15 страницA Review of Mechanism Used in Laparoscopic Surgical InstrumentswafasahilahОценок пока нет

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Документ6 страницRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoОценок пока нет

- JP Selecta IncubatorДокумент5 страницJP Selecta IncubatorAhmed AlkabodyОценок пока нет

- Teks Drama Malin KundangДокумент8 страницTeks Drama Malin KundangUhuy ManiaОценок пока нет

- Neelima A Kulkarni ResumeДокумент3 страницыNeelima A Kulkarni ResumeAcademics LecturenotesОценок пока нет

- Historical Exchange Rates - OANDA AUD-MYRДокумент1 страницаHistorical Exchange Rates - OANDA AUD-MYRML MLОценок пока нет

- Feds Subpoena W-B Area Info: He Imes EaderДокумент42 страницыFeds Subpoena W-B Area Info: He Imes EaderThe Times LeaderОценок пока нет

- Code ExplanantionДокумент4 страницыCode ExplanantionVivek JadiyaОценок пока нет

- PDF of Tally ShortcutsДокумент6 страницPDF of Tally ShortcutsSuraj Mehta100% (2)

- Docsity Detailed Lesson Plan 5Документ4 страницыDocsity Detailed Lesson Plan 5Sydie MoredoОценок пока нет

- Adverbs of Manner and DegreeДокумент1 страницаAdverbs of Manner and Degreeslavica_volkan100% (1)

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Документ13 страницNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllОценок пока нет

- MCQs - Chapters 31 - 32Документ9 страницMCQs - Chapters 31 - 32Lâm Tú HânОценок пока нет

- TMPRO CASABE 1318 Ecopetrol Full ReportДокумент55 страницTMPRO CASABE 1318 Ecopetrol Full ReportDiego CastilloОценок пока нет

- Biblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFДокумент400 страницBiblical Foundations For Baptist Churches A Contemporary Ecclesiology by John S. Hammett PDFSourav SircarОценок пока нет

- Cad Data Exchange StandardsДокумент16 страницCad Data Exchange StandardskannanvikneshОценок пока нет

- s15 Miller Chap 8b LectureДокумент19 страницs15 Miller Chap 8b LectureKartika FitriОценок пока нет

- Fmicb 10 02876Документ11 страницFmicb 10 02876Angeles SuarezОценок пока нет

- Internship ReportДокумент36 страницInternship ReportM.IMRAN0% (1)

- Baxter - Heraeus Megafuge 1,2 - User ManualДокумент13 страницBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliОценок пока нет

- 2 AcknowledgementДокумент8 страниц2 AcknowledgementPadil KonamiОценок пока нет

- Clash of Clans Hack Activation CodeДокумент2 страницыClash of Clans Hack Activation Codegrumpysadness7626Оценок пока нет

- CDR Writing: Components of The CDRДокумент5 страницCDR Writing: Components of The CDRindikuma100% (3)

- Rare Malignant Glomus Tumor of The Esophagus With PulmonaryДокумент6 страницRare Malignant Glomus Tumor of The Esophagus With PulmonaryRobrigo RexОценок пока нет