Академический Документы

Профессиональный Документы

Культура Документы

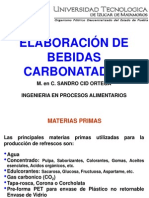

Sugar-Free Hibiscus Water Production-Amidiq 2010

Загружено:

SANDRO CID ORTEGAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sugar-Free Hibiscus Water Production-Amidiq 2010

Загружено:

SANDRO CID ORTEGAАвторское право:

Доступные форматы

Huatulco, Oaxaca, Mxico.

Del 04 al 07 de Mayo del 2010

LA INGENIERA QUMICA EN EL BICENTENARIO

Memorias del XXXI Encuentro Nacional de la AMIDIQ

Huatulco, Oaxaca, Mxico. Del 04 al 07 de Mayo del 2010

La presentacin y disposicin en conjunto de:

LA INGENIERA QUMICA EN EL BICENTENARIO

Son propiedad de los autores. Ninguna parte de esta obra puede ser reproducida o transmitida, mediante ningn sistema o mtodo, electrnico o mecnico (INCLUYENDO EL FOTOCOPIADO, la grabacin o cualquier sistema de recuperacin y almacenamiento de informacin), sin consentimiento por escrito de los autores. Derechos reservados conforme a la ley: Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica (AMIDIQ) ISBN: 978-970-764-976-7 Impreso en Mxico / Printed in Mxico

BIENVENIDA

La mesa directiva de la Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica (AMIDIQ) tiene el honor de darles la ms cordial bienvenida al XXXI Encuentro Nacional de la AMIDIQ que se celebra en esta ocasin en las hermosas Bahas de Huatulco, Oaxaca. Esperamos que su estancia sea placentera y que disfruten este magno evento que la mesa directiva prepar para Ustedes. Cada ao los miembros de la AMIDIQ y estudiantes en el rea de Ingeniera Qumica, nos reunimos para compartir el avance de nuestros proyectos de investigacin y saludarnos personalmente. El XXXI Encuentro Nacional de la AMIDIQ, se lleva a cabo en un ao especial para nuestro Pas; El Bicentenario de la Independencia de Mxico y el Centenario de la Revolucin Mexicana, estos dos acontecimientos de gran trascendencia nos permitirn reflexionar sobre el presente y futuro de la Ingeniera Qumica. Con este motivo, habr un foro de docencia donde se abordaran temas relacionados con nuestra rea de desarrollo. Adicionalmente se impartirn cuatro cursos sobre tpicos de inters para nuestros estudiantes. En este ao se recibieron ms de 800 contribuciones, donde se presentarn cerca de 200 trabajos orales y 600 en forma de cartel que se presentarn en tres bloques. Cada ao se logran nuevos records de asistencia, lo que demuestra que la AMIDIQ es un referente nacional de lo que sucede en docencia e investigacin en Ingeniera Qumica en el pas.

DR. AGUSTIN JAIME CASTRO PRESIDENTE AMIDIQ

DR. RUBEN GONZALEZ NUEZ VICEPRESIDENTE AMIDIQ

MESA DIRECTIVA 2009 2011 Dr. Agustn Jaime Castro Montoya Universidad Michoacana de San Nicols de Hidalgo Presidente presidente@amidiq.com Dr. Ruben Gonzlez Nez Universidad de Guadalajara Vicepresidente vicepresidente@amidiq.com Dr. Miguel ngel Morales Cabrera Universidad Veracruzana Secretario secretario@amidiq.com Dr. Juan Gabriel Segovia Hernndez Universidad de Guanajuato, Campus Guanajuato Tesorero tesorero@amidiq.com Dra. Mara del Rosario Enrquez Rosado Universidad del Mar Vocal de Docencia vocaldocencia@amidiq.com Dr. Mauricio Sales Cruz Universidad Autnoma Metropolitana-Cuajimalpa Vocal de Investigacin vocalinvestigacion@amidiq.com

C O M I T T C N I C O AMIDIQ 2010

Dra. Alma Hortensia Serafn Muoz Dra. Guadalupe Mara Guatemala Morales Dra. Irene Cano Rodrguez Dr. Agustn Uribe Ramrez Dr. Alberto Florentino Aguilera Alvarado Dr. Alberto Ochoa Tapia Dr. Arturo Jimnez Gutirrez Dr. Enrique Arriola Guevara Dr. Hctor Hernndez Escoto Dr. Ignacio Ren Galindo Esquivel Dr. Jorge Ramn Robledo Ortz Dr. Jos Antonio de los Reyes Dr. Jos Mara Ponce Ortega Dr. Luis Ignacio Salcedo Estrada Dr. Medardo Serna Gonzlez Dr. Pedro Quintana Hernndez Dr. Rafael Maya Yescas

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca

SUGAR-FREE HIBISCUS WATER PRODUCTION: DESIGN AND ECONOMIC EVALUATION

PROCESS

S. Cid Ortegaa, A. E. Navarro Frmetaa, M. A. Rostagnob, E. M. Lpez Mndeza, A. Monterrosas Fuentesa

a

Universidad Tecnolgica de Izcar de Matamoros. Ingeniera en Procesos Alimentarios. Prolongacin Reforma No. 168, Barrio de Santiago Mihuacn. Izcar de Matamoros, Puebla, Mxico. E-mail: scidortega@hotmail.com Instituto Nacional de Investigacin y Tecnologa Agraria y Alimentaria (INIA). Centro para la Calidad de los Alimentos. Soria, Espaa.

Abstract In order to produce a beverage with improved nutraceutical characteristics compared with those existing in the market and diversify the products offered by the company Integradora Agroindustrial de Chiautla de Tapia S. A. de C. V., a technology to manufacture sugar-free water flavored with hibiscus was developed and its economic evaluation was performed. The best artificial sweetener was canderel (aspartame + acesulfame potassium). The designed process allows yields of 62 bottles of water per kilogram of dried flower with a production cost of $5.12 each. With a commercial price of $8.00 according to a market study, company earnings will be about 55 %. These figures permit to conclude that the designed process allows the obtention of a product with good quality and economically viable for the company. This work was financially supported by FUPPUE. Keywords: Aqueous extract, Hibiscus Sabdariffa, economic study. 1. Introduction The beneficial properties of hibiscus and its aqueous extract as well as the presence of important essential trace elements, which have been already studied (Galicia-Flores et al, 2008; Herrera-Arellano et al, 2007; Lee et al, 2009; Mrquez et al, 2007; CarvajalZarrabal et al, 2005), make the manufacture of derived products, mainly those low in calories, a good alternative for the food industry. They show a sharp increment in the international market, specifically flavored drinks. Moreover, the presence of minerals in processed foods is of great importance, because these trace elements are involved in the respiratory, gastrointestinal, autonomic and muscular, as regulators and balancing agents.

Figure 1 Experiments for process design.

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4947

AMIDIQ

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca 2. Methodology Process design for the obtainment of the sugar-free hibiscus water was made through the experiments depicted in figure 1, evaluating sugar cane and three artificial sweeteners: Canderel (aspartame + acesulfame potassium), Splenda (sucralose) and Sweet Low (saccharin). Concentrations of the artificial sweeteners were selected according to the maximum acceptable daily intake (ADI), established by FAO and WHO (IFIC, 2009). Physical, chemical and microbiological characteristics of the beverages were determined accordingly Mexican standards. The extraction process was evaluated by quantifying the concentration of trace elements in an AAE Avanta 932 (GBC Analytical) by routine procedures and determination of anthocyanins content according to the pH differential method of AOAC (AOAC, 2005). The sensorial evaluations were performed using a structured hedonic scale of acceptance (Ramrez and Olgun, 1998; Pedrero and Pangborn, 1997). The economic evaluation was conducted through the determination of production costs as well as the estimation of economic and financial indicators (Gallardo, 1998): Break Point (BP), cost/benefit ratio (RC/B), Net Present Value (NPV) and Internal Rate of Return (IRR). 3. Results and Discussion The results (Table 1) showed a high efficiency in the extraction process (95 3%) for K, Ca, Mg, Fe, Co, Mn and Zn concentrations, but not (64 2%) for Na and Cu. The concentration of monomeric anthocyanins for the aqueous extract was 10 mg/L. The sensorial evaluation survey was applied to fifty people for each one of the samples; the results (Figure 2) showed a greater acceptance (86%) for the water with CANDEREL. Microbiological analysis of the samples gave negative results. Physical and chemical characteristics of the water flavored with hibiscus were: pH 2.540.04; Bx 2.00.02; acidity (as citric acid) 0.380.01% and approximately 5 mg of anthocyanins by bottle (500 ml).

40

Sugar cane

35 30

25

Canderel

Splenda Sweet Low

PEOPLE (%)

20 15

10

5 0 0 1 2 3 4 5 6 7 8 9 10

ACCEPTANCE SCALE

Figure 2 Sensory evaluation results.

Table 2 Results of the microbiological tests carried out on the aqueous extract and hibiscus water. Sample

Hibiscus extract (Monitoring for 3 weeks) Sugar free hibiscus water Samples with Sugar cane Samples with Canderel (Monitoring for 3 months) Samples with Splenda Samples with Sweet Low

a

Analysis

Aerobic mesophilic bacteriab. Molds and yeastsa. Total coliforms and faecalc. Aerobic mesophilic bacteriab. Molds and yeastsa. Total coliforms and faecalc.

Results

<10 UFC/ml

<10 UFC/ml

NOM-111-SSA1-1994, bNOM-092-SSA1-1994, cNOM-181-SSA1-1998 informative appendix B. d NOM-113-SSA1-1994.UFC = Colony Forming Units.

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4948

AMIDIQ

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca Table 1 Mineral content in Hibiscus flower, Aqueous extract, and flower after the extraction (residue).

With these results the process flow chart for sugar-free hibiscus water production in the company was established as shown in figure 3. Yields obtained with this technology were around 62 bottles (500 ml) of water per kilogram of dried flower. Production costs for water were $5.12 considering that the company processes 200 kilogram per month of dried flower (Table 3). According to the market research conducted (figure 4), the commercial price of the product was established as $8.00. With this price the calculated earnings will be 55%. A comparison was made between the hibiscus water that we development (Roja Mixteca) with other of recognized trademark. It uses a scale of acceptance, which was applied to 52 people. The results are shown in the graph of figure 5, as can Figure 3 Process flow chart. be seen these are conclusive, 85% of people (44) preferred Roja Mixteca and only 8 people do not like it. According to the income and outcome projection the winnings would be taken in the first year of operation (Table 4 and figure 6). The profitability indicators were: BP = $ 445,004.52 (55,626 bottles), RC/B = 1.56 (Table 5), NPV = $ 30, 836.21 and an IRR = 81% (Table 6). According to the results, we conclude that the product is economically viable for the company.

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4949

AMIDIQ

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca

70 60

30

90

85

80 70

44

PEOPLE (%)

50

PEOPLE (%)

7 2 2 2

60 50 40 30 20 10 15 8

40 30

9

20 10

0

$10.00

$8.00

$7.50

$7.00

$6.50

$6.00

Roja Mixteca

Commercial Water

PRICE (Mexican pesos)

Sugar-Free Hibiscus water

Figure 4 Market research results.

Figure 5 Results compared with commercial hibiscus water.

Table 3 Budget the cost of production for sugar free hibiscus water.

CONCEPT 1 Raw Material

Hibiscus Flower (kg) Purified water (L) Sweetener (kg) Sodium benzoate (kg)

1

YEAR PERIOD 2 $349,233.60

3,000.0 75,330.00 941.16 40.92

3 $419,080.32

3,600.0 90,396.00 1,129.39 49.10

4 $488,927.04

4,200.0 105,462.00 1,317.62 57.29

5 $558,773.76

4,800.0 120,528.00 1,505.86 65.47

$279,386.88

2,400.00 60,264.00 752.93 32.74

Direct labor

$20,832.00 $14,880.00 $218,140.80

148,800.00 62,496.00 6,844.80

$27,081.60 $19,344.00 $272,676.00

186,000.00 78,120.00 8,556.00

$35,206.08 $25,147.20 $327,311.20

223,300.00 93,744.00 10,267.20

$45,767.90 $32,691.36 $381,746.40

260,400.00 109,368.00 11,978.40

$59,498.28 $42,498.77 $436,281.60

297,600.00 124,992.00 13,689.60

Indirect labor1 Indirect Materials

Primary packaging (bottle + cover) Tags Secondary packaging

Cost of Inputs

Electric Power

7,440.00 $166,656.00

1 1,2

9,300.00 $233,318.40 $6,190.08 $63,835.20

186,000.00

11,160.00 $308,105.28 $8,047.10 $82,985.76

223,200.00

13,020.00 $390,079.20 $10,461.24 $107,881.49

260,400.00

14,880.00 $479,136.00 $13,599.61 $140,245.93

297,600.00

Others

Maintenance costs

$4,761.60 $49,104.00 $761,201.28

148,800.00

Depreciation and amortization Production Costs Unit Cost

1 2 3

$980,978.88 $1,217,042.94 $1,470,574.63 $1,744,913.94 $5.27 $5.45 $5.65 $5.86

Production volume (bottles 500 ml)

It is considered an annual inflation of 30%. Depreciation of equipment 10%. Income Tax (ISR), 28%.

$5.12

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4950

AMIDIQ

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca Table 4 Projection of revenues and expenditures to 5 years.

YEAR CONCEPT Production Capacity Annual Income Fixed Costs Variable Costs Total costs Operating Income Credit payment Net income

3 2 1

1 148800 $1,190,400.00 $256,233.60 $504,967.68 $761,201.28 $429,198.72 $429,198.72 37.4 $445,004.52 55626

2 186000 $1,581,000.00 $349,769.28 $631,209.60 $980,978.88 $600,021.12 $600,021.12 36.8 $582,218.17 68496

3 223200 $2,008,800.00 $459,491.42 $757,451.52 $1,216,942.94 $791,857.06 $791,857.06 36.7 $737,625.36 81958

4 260400 $2,473,800.00 $586,881.19 $883,693.44 $1,470,574.63 $1,003,225.37 $1,003,225.37 36.9 $913,037.35 96109

5 297600 $2,976,000.00 $734,978.58 $1,009,935.36 $1,744,913.94 $1,231,086.06 $1,231,086.06 37.4 $1,112,525.10 111253

Break Point (%) Economic Break Point Productive Break Point

1 2 3

Number of bottles (PET 500 ml). Considering an annual increase in the selling price other than second year of 6.25%. Considering an annual rate of 28%.

Table 5 Cost/benefit ratio for hibiscus water.

CONCEPT 1 Raw Material Direct labor

1 1

YEAR PERIOD 2 $349,233.60 $27,081.60 $19,344.00 $272,676.00 $9,300.00 $233,318.40 $6,190.08 $63,835.20 $980,978.88 186,000.00 $5.27 $8.50 $1,581,000.00 1.61 3 $419,080.32 $35,206.08 $25,147.20 $327,311.20 $11,160.00 $308,105.28 $8,047.10 $82,985.76 $1,217,042.94 223,200.00 $5.45 $9.00 $2,008,800.00 1.65 4 $488,927.04 $45,767.90 $32,691.36 $381,746.40 $13,020.00 $390,079.20 $10,461.24 $107,881.49 $1,470,574.63 260,400.00 $5.65 $9.50 $2,473,800.00 1.68 5 $558,773.76 $59,498.28 $42,498.77 $436,281.60 $14,880.00 $479,136.00 $13,599.61 $140,245.93 $1,744,913.94 297,600.00 $5.86 $10.00 $2,976,000.00 1.71 $279,386.88 $20,832.00 $14,880.00 $218,140.80 $7,440.00 $166,656.00 $4,761.60 $49,104.00 $761,201.28 148,800.00 $5.12 $8.00 $1,190,400.00 1.56

Indirect labor Indirect Materials Cost of Inputs Others

3

Maintenance costs1 Depreciation and amortization1,2 Production Costs Production volume (bottles 500 ml) Unit production cost Unit Cost of sales Ingresos Anuales COST/BENEFIT RATIO

1 2 3

It is considered an annual inflation of 30%. Depreciation of equipment 10%. Income Tax (ISR), 28%.

Table 6 Net Present Value and Internal Rate of Return.

Year period Initial fixed investment Salvage value Annual income Expenditures Net Flows NPV1 (Net Present Value) IRR (Internal Rate of Return)

1

0 $487,230.00

$1,190,400.00 $1,581,000.00 $2,008,800.00 $2,473,800.00 $2,976,000.00 $761,201.28 $980,978.88 $1,217,042.94 $1,470,574.63 $1,744,913.94 -$487,230.00 $296,766.72 $411,193.92 $541,490.34 $688,336.30 $849,697.22 $30,836.21 81%

Discount rate = 10%

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4951

AMIDIQ

Proceedings of XXXI Encuentro Nacional of AMIDIQ

4 al 7 de Mayo de 2010, Huatulco Oaxaca 4. Conclusions It may be concluded that a beverage with important nutritional and good sensory characteristics was obtained. The process developed at the company had the following yields: 62 bottles of water per kilogram of dried flower. The production cost for water was $ 5.12 as the company processed 200 kg / month of hibiscus. According to market research, the commercial price of the product was established as $8.00. With this price the calculated earnings will be 55% and according to the projection of revenues and expenses, earnings will be obtained in the first year of operation. According to the results of the profitability indicators, we conclude that the product is viable. References AOAC, 2005. Total Monomeric Anthocyanin Pigment Content of Fruit Juices, Beverages, Natural Colorants, and Wines. pH Differential Method. Carvajal-Zarrabal O., S. M. Waliszewski, D. M. Barradas-Dermitz, Z. Orta-Flores, P. M. HaywardJones, C. Nolasco-Hiplito, O. Angulo-Guerrero, R. Snchez-Ricao, R. M. Infanzn, y P. R. L. Trujillo. 2005. The Consumption of Hibiscus Sabdariffa Dried Calyx Ethanoloic Extract Reduced Lipid Profile in Rats. Plant Foods For Human Nutrition 60: 153-159. Galicia-Flores, L. A., Y. Salinas-Moreno, B. M. Espinoza-Garca y C. Snchez-Feria. 2008. Revista Chapingo Serie Horticultura 14 (2): 121-129. Gallardo, C. J. 1998. Formulacin y Evaluacin de Proyectos de Inversin. Un enfoque de Sistemas. McGraw-Hill Interamericana S. A. de C. V. Mxico. pp. 54-55, 58-60. Herrera-Arellano A., J. Miranda-Snchez, y P. vila-Castro. 2007. Planta Med. 73: 6-12. IFIC, 2009. IFIC Review: Low-Calorie Sweeteners and Health. International Food Information Council Foundation. Washington, DC 20036. 12 p. http://www.foodinsight.org Lee W., Wang C., Chen Y., Hsu J., Cheng S., Chen H., Lee H., 2009. Journal of Agricultural and Food Chemistry 57 (6): 2206-2210. Mrquez, V. R. L., C. de la Rosa T., C. A. Rivero, M. Medina M. 2007. Actividad diurtica del extracto total acuoso de los clices de Hibiscus sabdariffa L. administrado en ratas albinas variedad Wistar. Scientia et Technica Ao XIII, No. 33, 377-381. UTP. ISSN 0122-1701 Pedrero, F. D. y Pangborn, R. M. 1997. Evaluacin sensorial de los alimentos. Mtodos analticos. Alambra Mexicana S. A. Mxico. pp. 63-105. Ramrez, S. A. y Olgun, M. L. 1998. Introduccin a la Tecnologa de Alimentos. Limusa S. A. Mxico. pp. 127-137.

$3,500,000.00

Total cost

$3,000,000.00

$2,500,000.00

Sales income

Costs

$2,000,000.00 $1,500,000.00 $1,000,000.00

Loses

Earnings

Variable costs

$500,000.00

Fixed costs

$0.00

0 50,000 100,000 150,000 200,000 250,000 300,000 350,000

Units (Bottles 500 ml)

Figure 6 Break Point for hibiscus water.

2010 Academia Mexicana de Investigacin y Docencia en Ingeniera Qumica AMIDIQ

4952

AMIDIQ

Вам также может понравиться

- Elaboración de Cajeta A Partir de Leche de Vaca y Reducida en AzúcarДокумент8 страницElaboración de Cajeta A Partir de Leche de Vaca y Reducida en AzúcarSANDRO CID ORTEGAОценок пока нет

- Tecnología de AlimentosДокумент32 страницыTecnología de AlimentosSANDRO CID ORTEGA100% (1)

- Evaluación Proceso Extracción para Producción de Extracto Jamaica LiofilizadoДокумент9 страницEvaluación Proceso Extracción para Producción de Extracto Jamaica LiofilizadoSANDRO CID ORTEGAОценок пока нет

- Bebidas CarbonatadasДокумент40 страницBebidas CarbonatadasSANDRO CID ORTEGA80% (5)

- Medios de Cultivos PurosДокумент3 страницыMedios de Cultivos PurosAlejandra Torres GarciaОценок пока нет

- Solicitud Única Banco de GuayaquilДокумент7 страницSolicitud Única Banco de GuayaquilViktorValentin80% (5)

- Práctica #01 Procesamiento de Pescado Salado en Pila Húmeda OFICIALДокумент12 страницPráctica #01 Procesamiento de Pescado Salado en Pila Húmeda OFICIALAngie PortugalОценок пока нет

- Unidad de Aprendizaje # 1Документ21 страницаUnidad de Aprendizaje # 1Hilde Idrogo Torres100% (1)

- Cerveza Como Bebida HidratanteДокумент202 страницыCerveza Como Bebida HidratanteErik PabonОценок пока нет

- Proyeccion Cerdo para Ejercicio VersionДокумент40 страницProyeccion Cerdo para Ejercicio VersionPedro RománОценок пока нет

- Anexo II Del Reglamento (CE) No 1333-2008Документ11 страницAnexo II Del Reglamento (CE) No 1333-2008FanyGonzalezОценок пока нет

- La LlamadaДокумент1 страницаLa LlamadaFermina CubaОценок пока нет

- Historia y Generalidades de Los PorcinosДокумент4 страницыHistoria y Generalidades de Los PorcinosJessicaRamirezZandateОценок пока нет

- 159 Traducciones para Las Escuelas de Idiomas Nivel 1 (Spanish Edition) by Edward RossetДокумент114 страниц159 Traducciones para Las Escuelas de Idiomas Nivel 1 (Spanish Edition) by Edward RossetKevinОценок пока нет

- Granja HipoteticaДокумент8 страницGranja HipoteticaYurani RojasОценок пока нет

- Practica PastizalesДокумент13 страницPractica PastizalesBrandon Cruz DominguezОценок пока нет

- Las Cosas SimplesДокумент33 страницыLas Cosas SimplesAnonymous pPkLs9Оценок пока нет

- Plan NutricionalДокумент15 страницPlan NutricionalJessica JaimesОценок пока нет

- Codigos AFIPДокумент4 страницыCodigos AFIPMarcelo LeguizaОценок пока нет

- Hasta La Vista BarrancoДокумент54 страницыHasta La Vista BarrancoLuisBenjamínTeránEustaquioОценок пока нет

- Estudio Fenotípico de La Cachama Blanca (Piaractus Brachypomus)Документ6 страницEstudio Fenotípico de La Cachama Blanca (Piaractus Brachypomus)Brando CeliОценок пока нет

- Historia de AscopeДокумент4 страницыHistoria de AscopeJonatan Saona ReyesОценок пока нет

- InduvecaДокумент10 страницInduvecaRobert Joel FelizОценок пока нет

- La RuedaДокумент4 страницыLa RuedaJoseph Antoine LeblancОценок пока нет

- Los Yanomamis 2Документ8 страницLos Yanomamis 2daniloОценок пока нет

- Recetario para La FelicidadДокумент31 страницаRecetario para La FelicidadKaren QuevedoОценок пока нет

- Trabajo Final Produccion y Tecnificacion de SemillasДокумент31 страницаTrabajo Final Produccion y Tecnificacion de SemillasduveltОценок пока нет

- Preparamos Postres Peruanos Usando Fracciones y Números MixtosДокумент10 страницPreparamos Postres Peruanos Usando Fracciones y Números MixtoslilianaОценок пока нет

- Conclusiones LA YUCAДокумент2 страницыConclusiones LA YUCAana luis40% (5)

- Practica 2Документ3 страницыPractica 2Monrroy Choque KevinОценок пока нет

- Decreto 2395 de 1999Документ4 страницыDecreto 2395 de 1999pauli4612Оценок пока нет

- Protocolo de MuestreoДокумент8 страницProtocolo de MuestreoYeni PérezОценок пока нет

- Tablas de AlimentaciónДокумент9 страницTablas de AlimentacióneliarОценок пока нет

- Produccion de Pollo de EngordeДокумент17 страницProduccion de Pollo de EngordePilar HernandezОценок пока нет