Академический Документы

Профессиональный Документы

Культура Документы

SCIG (Phasor Type) - SimPowerSystems

Загружено:

Khaled SolimanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SCIG (Phasor Type) - SimPowerSystems

Загружено:

Khaled SolimanАвторское право:

Доступные форматы

Provide feedback about this page

Wind Turbine Induction Generator (Phasor Type)

Implement phasor model of squirrel-cage induction generator driven by variable pitch wind turbine

Library

Distributed Resources/Wind Generation

Description

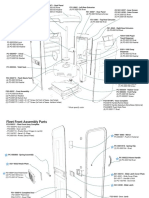

The wind turbine and the induction generator (WTIG) are shown below. The stator winding is connected directly to the grid and the rotor is driven by the wind turbine. The power captured by the wind turbine is converted into electrical power by the induction generator and is transmitted to the grid by the stator winding. The pitch angle is controlled in order to limit the generator output power to its nominal value for high wind speeds. In order to generate power the induction generator speed must be slightly above the synchronous speed. But the speed variation is typically so small that the WTIG is considered to be a fixed-speed wind generator. The reactive power absorbed by the induction generator is provided by the grid or by some devices like capacitor banks, SVC, STATCOM or synchronous condenser.

Pitch Angle Control System The wind turbine model uses the Wind Turbine block of the Distributed Resources/Wind Generation library. See documentation of this block for details. A Proportional-Integral (PI) controller is used to control the blade pitch angle in order to limit the electric output power to the nominal mechanical power. The pitch angle is kept constant at zero degree when the measured electric output power is under its nominal value. When it increases above its nominal value the PI controller increases the pitch angle to bring back the measured

power to its nominal value. The control system is illustrated in the figure below:

Dialog Box and Parameters

The WTIG parameters are grouped in two categories: Generator data and Turbine data. Use the Display listbox to select which group of parameters you want to visualize. Generator Data Parameters

Nominal power, line-to-line voltage and frequency The nominal power in VA, the nominal line-to-line voltage in Vrms and the nominal system frequency in hertz. Stator [Rs, Lls] The stator resistance Rs and leakage inductance Lls in pu based on the generator ratings. Rotor [Rr', Llr'] The rotor resistance Rr' and leakage inductance Llr', both referred to the stator, in pu based on the generator ratings. Magnetizing inductance Lm

Magnetizing inductance Lm The magnetizing inductance Lm in pu based on the generator ratings. Inertia constant, friction factor and pairs of poles Combined generator and turbine inertia constant H in seconds, combined viscous friction factor F in pu based on the generator ratings and number of pole pairs p. You may need to use your own turbine model, in order for example, to implement different power characteristics or to implement the shaft stiffness. Your model must then output the mechanical torque applied to the generator shaft. If the inertia and the friction factor of the turbine are implemented inside the turbine model you specify only the generator inertia constant H and the generator friction factor F. Initial conditions The initial slip s, electrical angle in degrees, stator current magnitude in pu and phase angle in degrees. Turbine Data Parameters

Refer to the Wind Turbine for a detailed documentation. External mechanical torque If this parameter is checked, a Simulink input named Tm appears on the block, allowing to use an external signal for the generator input mechanical torque. This external torque must be in pu based on the nominal electric power and synchronous speed of the generator. For example, the external torque may come from a user defined turbine model. By convention for the induction machine, the torque must be negative for power generation. Display wind turbine power characteristics If this parameter is checked, the turbine power characteristics at the specified pitch angle are displayed for different wind speeds. This parameter is not visible when the External mechanical torque parameter is checked. Nominal wind turbine mechanical output power External mechanical torque

This parameter is not visible when the External mechanical torque parameter is checked. The nominal turbine mechanical output power in watts. Base wind speed This parameter is not visible when the External mechanical torque parameter is checked. The base value of the wind speed, in m/s, used in the per unit system. The base wind speed is the mean value of the expected wind speed. This base wind speed produces a mechanical power which is usually lower than the turbine nominal power. Maximum power at base wind speed This parameter is not visible when the External mechanical torque parameter is checked. The maximum power at base wind speed in pu of the nominal mechanical power. Base rotational speed This parameter is not visible when the External mechanical torque parameter is checked. The rotational speed at maximum power for the base wind speed. The base rotational speed is in pu of the base generator speed. Pitch angle controller gain [Kp Ki] This parameter is not visible when the External mechanical torque parameter is checked. Proportional and Integral gains Kp and Ki of the pitch controller. Specify Kp in degrees/(power deviation pu) and Ki in degrees/(power deviation pu)/s. The power deviation is the difference between actual electrical output power and the nominal mechanical power in pu of the generator nominal power. Maximum pitch angle (deg) This parameter is not visible when the External mechanical torque parameter is checked. The maximum pitch angle in degrees. Maximum rate of change of pitch angle This parameter is not visible when the External mechanical torque parameter is checked. The maximum rate of change of the pitch angle in degrees/s.

Inputs and Outputs

A B C The three terminals of the WTIG. Trip Apply a simulink logical signal (0 or 1) to this input. When this input is high the WTIG is disconnected. Use this input to implement a simplified version of the protection system. Wind (m/s) This input is not visible when the External mechanical torque parameter is checked. Simulink input of the wind speed in m/s. Tm This input is visible only when the External mechanical torque parameter is checked. Simulink input of the mechanical torque. Tm must be negative for power generation. Use this input when using an external turbine model.

m Simulink output vector containing 8 WTIG internal signals. These signals can be individually accessed by using the Bus Selector block. They are, in order: Signal 1 Signal Names Vabc (cmplx) (pu) Definition Phasor voltages (phase to ground) Va, Vb, Vc at the WTIG terminals in pu based on the generator ratings. Phasor currents Ia, Ib, Ic flowing into the WTIG terminals in pu based on the generator ratings. WTIG output power in pu based on the generator ratings. A positive value indicates power generation. WTIG output reactive power in pu based on the generator ratings. A positive value indicates reactive power generation. Generator rotor speed (pu) Mechanical torque applied to the generator in pu based on the generator ratings. Electromagnetic torque in pu based on the generator ratings. Blade pitch angle in degrees.

2 3

Iabc (cmplx) (pu) P (pu)

Q (pu)

5 6 7 8

wr (pu) Tm (pu) Te (pu) Pitch_angle (deg)

Example

See the power_wind_ig demo which illustrates the steady-state and dynamic performance of the WTIG. Three WTIG blocks are used to simulate a 9 MW wind farm connected in a 25 kV, 60 Hz, system. Voltage regulation is performing by a 3 Mvar STATCOM.

References

[1] Siegfried Heier, "Grid Integration of Wind Energy Conversion Systems," John Wiley & Sons Ltd, 1998, ISBN 0-471-97143-X

See Also

Wind Turbine, Wind Turbine Doubly-Fed Induction Generator (Phasor Type)

Provide feedback about this page

Wind Turbine Doubly-Fed Induction Generator (Phasor Type) 1984-2008 The MathWorks, Inc. Terms of Use Patents

Zigzag Phase-Shifting Transformer Trademarks Acknowledgments

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A - Case Method Introduction - OK35Документ48 страницA - Case Method Introduction - OK35Adeel AhmadОценок пока нет

- Sy 129 201920Документ9 страницSy 129 201920anirudh patelОценок пока нет

- TOTAL TOWER ANALYSIS REPORT SST 150 M PDFДокумент74 страницыTOTAL TOWER ANALYSIS REPORT SST 150 M PDFErpanBeanTarpoОценок пока нет

- 2.1.6 NG1005 Welding and TestingДокумент154 страницы2.1.6 NG1005 Welding and TestingjovicatrpcevicОценок пока нет

- Battery Ignition System - PPTДокумент14 страницBattery Ignition System - PPTchetan0% (1)

- Megamin Activ, Buy Now This Super Potent AntioxidantДокумент3 страницыMegamin Activ, Buy Now This Super Potent AntioxidantMartin LewisОценок пока нет

- Upgrade Your Motors From Non-IE To IE3Документ28 страницUpgrade Your Motors From Non-IE To IE3Mohamed AskarОценок пока нет

- Structure and Advantages: Miniature SEB TypeДокумент10 страницStructure and Advantages: Miniature SEB TypesunhuynhОценок пока нет

- A4vg125hwdl232r-Nzf02f021s-S R902189541 StaraДокумент34 страницыA4vg125hwdl232r-Nzf02f021s-S R902189541 StaraRodrigues de OliveiraОценок пока нет

- Brittle Fracture and Reporting OverviewДокумент38 страницBrittle Fracture and Reporting OverviewRaja HoneОценок пока нет

- 4.11.4 Steam Pipe Sizing and DesignДокумент3 страницы4.11.4 Steam Pipe Sizing and DesignSaurabh VijОценок пока нет

- SECTION 15075: Not For ConstructionДокумент4 страницыSECTION 15075: Not For ConstructionahmadОценок пока нет

- Itp For Plumbing Amp Drainage SystemДокумент98 страницItp For Plumbing Amp Drainage Systemtristan guarinoОценок пока нет

- List of Forces To Be Considered While Designing A Well Foundation Are As Follow1Документ2 страницыList of Forces To Be Considered While Designing A Well Foundation Are As Follow1jagadeshОценок пока нет

- A Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationДокумент31 страницаA Comprehensive Review On Process and Engineering Aspects of Pharmaceutical Wet GranulationManuel AlemanОценок пока нет

- Magnatech Tubemaster 427aДокумент113 страницMagnatech Tubemaster 427aEduardo Ricardo Puga RomeroОценок пока нет

- Formula Table Solid MechanicsДокумент26 страницFormula Table Solid MechanicsmechfunОценок пока нет

- AQA AS Physics A Chapter 11 Textbook AnswersДокумент3 страницыAQA AS Physics A Chapter 11 Textbook AnswerscathylisterОценок пока нет

- Dynamics - Chapter 13Документ54 страницыDynamics - Chapter 13Hamza Paga100% (1)

- Pipe & Pipe Fitting Guide For Oil & Gas CareerДокумент208 страницPipe & Pipe Fitting Guide For Oil & Gas Careervarun156750% (4)

- COMSOL Model of Halothane Vaporizer For The Developing WorldДокумент19 страницCOMSOL Model of Halothane Vaporizer For The Developing Worldapi-318956624Оценок пока нет

- Aerofoil SelectionДокумент3 страницыAerofoil SelectionAlaa AhmedОценок пока нет

- Martin Yale 959 ManualДокумент16 страницMartin Yale 959 ManualnapoleanpintoОценок пока нет

- OUR CAT SPARE PARTS STOCKLIST FOR IMMEDIATE DELIVERY 2017 1.odtДокумент9 страницOUR CAT SPARE PARTS STOCKLIST FOR IMMEDIATE DELIVERY 2017 1.odtbill neapolitan100% (1)

- D7918-En (LHT)Документ15 страницD7918-En (LHT)Asa ReidОценок пока нет

- Guideline For Energy Audit ReportДокумент16 страницGuideline For Energy Audit Reportashwini_kumar1984Оценок пока нет

- API Sand and API Clay InformationДокумент27 страницAPI Sand and API Clay InformationIqbal AamerОценок пока нет

- Do's and Don'Ts For Eq Resistant Design of BuildingsДокумент44 страницыDo's and Don'Ts For Eq Resistant Design of BuildingsPraveen Gavad100% (1)

- Parts FS3-30001 PDFДокумент4 страницыParts FS3-30001 PDFJosé RezendeОценок пока нет

- Week 4Документ4 страницыWeek 4Waqar AhmadОценок пока нет